- Submissions

Full Text

Polymer Science: Peer Review Journal

Correlation of Sorption Properties and Growth of Helical Dislocations on the Surface of Polytetrafluoroethylene Nano-/ Microparticles Under γ-Irradiation

Smolyanskii AS1, Arsentyev МА1, Rashkovskii АY2, Magomedbekov EP1, Koshkina ОА3, Politova ЕD3 and Trakhtenberg LI3,4*

1D Mendeleev University of Chemical Technology of Russia, Russia

2PJSC, Novolipetsk Metallurgical Plant, Russia

3NN Semenov Federal Research Center for Chemical Physics, Russia

4Lomonosov Moscow State University, Russia

*Corresponding author: Leonid Trakhtenberg, NN Semenov Federal Research Center for Chemical Physics, Lomonosov Moscow State University, Russia

Submission: December 11, 2021;Published: January 06, 2022

ISSN: 2770-6613 Volume2 Issue5

Abstract

Transmission electron microscopy and low-temperature nitrogen sorption, X-ray phase analysis and differential scanning calorimetry have been used to study the effect of γ-radiation of the 60Co isotope on the sorption properties, degree of crystallinity and surface morphology of powdered polytetrafluoroethylene depending on the absorbed dose (10-1000kGy). It was found that the degree of crystallinity of polytetrafluoroethylene increases from 35 to 80% upon irradiation with doses up to 50kGy, and then practically does not change. Specific surface area of the polymer powder decreases upon irradiation up to dose of 10kGy, and then increases by 21% upon further γ-irradiation up to 50kGy. There is a tendency towards a gradual decrease in the specific surface area in the region of absorbed doses of 100-1000kGy. Also, in the range of 10-50kGy, an intensive formation and growth of screw dislocations was found. A conclusion is made about the dislocation mechanism of the radiation crystallization process, as well as about the correlation between the change in sorption properties, the degree of crystallinity and the surface morphology of polytetrafluoroethylene particles.

Keywords: Polytetrafluoroethylene; Radiolysis; Ionizing radiation; Crystallization; Specific surface area; Screw dislocation

Introduction

The use of radiation-modified Polytetrafluoroethylene (PTFE) powders as a filler is considered a promising approach for creating a new generation of composite materials with improved characteristics [1]. However, the laws governing the radiolysis of powdered PTFE have not been adequately studied [2]. Recently it was shown that in the process of γ-irradiation of powdered PTFE, reactions of formation and growth, mutual transformation of two types of crystals (needle crystals and lamellar spherulites) are possible [3]. The aim of this study is to establish the nature of the change in the sorption properties of polymer composite materials filled with irradiated PTFE, which is accompanied by a correlation with the growth of screw dislocations. The characteristics of powdered PTFE, the method of radiation treatment is given in [3]. Radiation treatment in the range of absorbed doses from 10 to 1000kGy was carried out in air, at room temperature, by exposure to gamma radiation of the 60Co isotope, at a dose rate of ~3Gy/s. The size and shape, morphology, and mutual transformations of nanocrystals of the initial and irradiated PTFE were studied using an FEI Tecnai G2 F20 S-Twin TMP Transmission Electron Microscope (TEM) at an accelerating voltage of 200kV in a bright field. Device resolution was 0.14nm (line resolution).

Results and Discussion

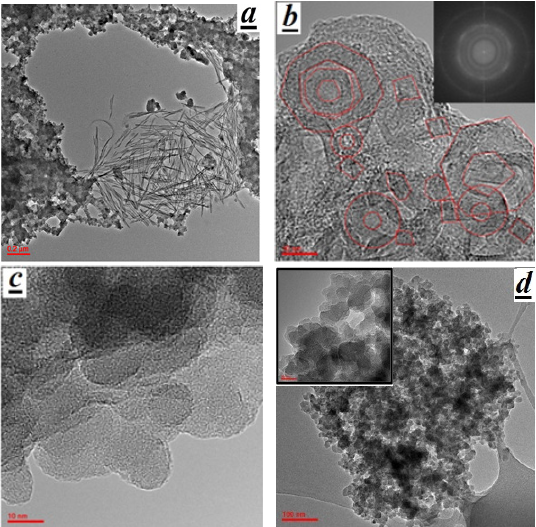

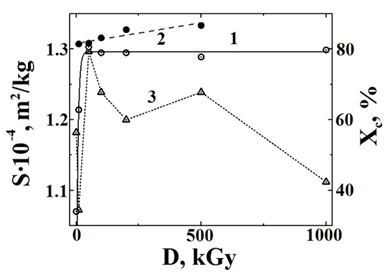

It was found that radiation treatment of PTFE powders leads to significant changes in the shape and structure of particles. In the powder of the initial polymer and irradiated up to 10kGy, nano-/microparticles of spherical or flaky shape with a size of ~20nm were observed, which were combined into micron-sized clusters consisting of several layers of PTFE particles (Figure 1a). Numerous whiskers of PTFE with a length of 0.1-0.2μm and a thickness of up to 10nm were also found. With an increase in the absorbed dose to 50kGy, the composition of PTFE particles changes - whiskers disappear (Figure 1b). In addition, a significant increase in the crystallinity of the polymer was found. The formation of screw dislocations with layers from 3 to 8nm thick is observed. At the same time, nanocrystals with a size of about 5nm are observed in the regions of junction of these structural elements (highlighted in red lines in Figure 1b). Fourier analysis of the resulting image (inset in Figure 1b) allows one to clearly observe rings and frequency maxima, the origin of which is associated with the presence of long-range order in the atomic-crystal structure of PTFE. A further increase in the absorbed dose to 100-500kGy leads to the disappearance of screw dislocations (Figure 1c). In this case, clusters of nano-/microparticles of PTFE become less branched, nanopores with a size of 10 to 15nm appear in them, and the size of the PTFE particles themselves is about 130nm (Figure 1d). As follows from the results of the analysis of X-ray spectra and thermograms obtained by the method of Differential Scanning Calorimetry (DSC) [3], in the region of absorbed doses from 10 to 50kGy, there is a sharp increase in the degree of crystallinity of PTFE from ~35 to 80% (Figure 2). In the range from 100 to 1000kGy, the degree of crystallinity of PTFE does not change practically.

Figure 1: Electron microscopic images of nano-/microparticles of polytetrafluoroethylene powder γ-irradiated at room temperature, in air up to (a)10, (b)50, (c)100 and (d)500kGy.

The dose dependence of the degree of crystallinity determined by the DSC method (Figure 2, curve 2) can be satisfactorily described by the following expression:

-where Xc max=79.25±6.82%, is the maximum (equilibrium) value of the degree of crystallinity; k=0.16±0.1kGy-1 is the rate constant of radiation destruction of PTFE crystals. The decrystallization rate constant k is inversely proportional to the absorbed dose corresponding to a decrease in the crystal concentration in the course of PTFE irradiation by 1% (~6.25kGy). The exponential form of the dose dependence (1) can be associated with the presence of the PTFE crystal size distribution. The specific surface area of the initial and irradiated PTFE powders was determined within the framework of the Brunauer–Emmett–Teller (BET) theory by analyzing the low-temperature nitrogen sorption isotherms obtained using a QuadraSorb Kr/SI sorption unit. The established specific surface area (Sspec) of unirradiated PTFE powder synthesized by emulsion polymerization (Figure 2), - about 1.2·104m2/kg, - differs from the previously obtained data (~0.2·104 and ~14·104m2/kg for PTFE powder synthesized by suspension and emulsion polymerization methods, respectively [4]), which may be due to the peculiarities of the manufacturing technology of the polymer powder under study (trade mark F-4 PN-90, Soviet State Standard 10007-80, manufactured at the JSC “Kirovo-Chepetsk Chemical Plant named after B.P. Konstantinov”). It can be concluded from the analysis of Figure 2, that at doses of 10 and 1000kGy, the value of (Sspec) of the irradiated polymer is lower than that of the original PTFE powder. Observed values of the specific surface area exceed the (Sspec), characteristic for unirradiated polymer powder in the area of absorbed doses from 50 to 500kGy. Of particular note is the abnormal behavior of (Sspec) at the initial stages of irradiation, in the range from 0 to 50kGy. A decrease in the specific surface area of PTFE powder γ-irradiated to 10kGy can be associated with an increase in radiation-induced compression stresses [3]. Irradiation with PTFE up to 50kGy is accompanied by an increase in (Sspec) by ~21% compared to the specific surface area of PTFE irradiated to 10kGy. It is in this range that the formation and growth of screw dislocations occurs.

Figure 2: Change in the degree of crystallinity (Xc), determined by differential scanning calorimetry (1) and X-ray phase analysis (2), as well as the dependence of the specific surface area of polytetrafluoroethylene powder (3) on the absorbed dose.

Based on the analysis of the recorded X-ray spectra, it was found that the surface density of dislocations in the studied γ-irradiated PTFE powders is ~1.55·1015m-2, or ~1.55·10-3nm-2. On the other hand, analyzing the electron microscopic image of a fragment of the surface of PTFE lamellar spherulites irradiated to 50kGy, one can detect the presence of four screw dislocations in the form of a polygonal spiral and an Archimedes spiral (in Figure 1b, the boundaries of the terraces of screw dislocations are highlighted in red). Considering the scale of the image shown in Figure 1b, it is easy to estimate the surface density of screw dislocations ~1.21·10- 3nm-2, which is in good agreement with the data obtained by the X-ray phase analysis method. Consequently, the discovered effect of increasing the specific surface area under γ-irradiation of the powdered PTFE can be associated with the processes of radiation formation of screw dislocations. A further increase in the absorbed dose is accompanied by the disappearance of these defects in the crystal structure, which leads to a decrease in (Sspec) (Figure 2, curve 3). It is known, growth of the specific surface area is a sign of increased catalytic activity of the material [5]. Therefore, it can be assumed that PTFE powder irradiated in the range of absorbed doses from 50 to 500kGy may turn out to be more effective filler for composite materials as compared to non-irradiated polymer powder.

Conclusion

a. It has been established that radiation-induced crystal growth in powdered polytetrafluoroethylene proceeds according to the dislocation mechanism.

b. A correlation was found between the processes of growth, mutual annihilation and dissolution of screw dislocations, and a change in the specific surface area of powdered polytetrafluoroethylene, depending on the value of the absorbed dose.

It is concluded that the reason for the high efficiency of the use of particles of gamma-irradiated powdered polytetrafluoroethylene as a filler may be associated with an increase in catalytic activity as a result of an augmentation in the specific surface area of the polymer by 10-20% in the range of absorbed doses of 50-500kGy.

Acknowledgement

This research is funded by the Ministry of Higher Education and Science of the Russian Federation in the framework of State assignments “Nanostructured systems of a new generation with unique functional properties” (FFZE-2022-0004) and No FSSM-2020-0004 with the use of equipment of LLC “Systems for microscopy and analysis”. The authors are grateful to A O Merkushkin for help in carrying out measurements by the method of low-temperature nitrogen sorption.

References

- Khan MS, Lehmann D, Heinrich G, Franke R (2009) Tribological study of peroxide-cured EPDM rubber filled with electron beam irradiated PTFE powder. Wear 266(1-2): 200-207.

- Allayarov SR, Olkhov YA, Dixon DA, Nikles DE (2014) Features of the phase behavior of gamma-irradiated polytetrafluoroethylene powder. High Energy Chemistry 48: 104-111.

- Smolyanskii AS, Arsentyev MA, Rashkovskii AY, Politova ED (2019) Radiation-induced changes in the degree of crystallinity of powdered polytetrafluoroethylene. Crystallogr Rep 64: 553-558.

- Lunkwitz K, Bürger W, Lappan U, Brink HJ, Ferse A (1995) Surface modification of fluoropolymers. J Adhesion Science and Technology 9(3): 297-310.

- Bernard P, Stelmachowski P, Broś P, Makowski W, Kotarba A (2021) Demonstration of the influence of specific surface area on reaction rate in heterogeneous catalysis. J Chem Educ 98(3): 935-940.

© 2021 Leonid Trakhtenberg. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)