- Submissions

Full Text

Polymer Science: Peer Review Journal

The Overview of Composite Application Research of Bio-Based PA56/PET

Zhejiang Caiyue1 and Zhang Shouyun1,2*

1Intelligent Technology Co Ltd, China

2Donghua University, China

*Corresponding author: Zhang Shouyun, Donghua University, China

Submission: November 22, 2021;Published: December 08, 2021

ISSN: 2770-6613 Volume2 Issue4

Abstract

In this paper, the compatibility of bio-based PA56/PET and the composite application of different methods such as blending fiber and two-component parallel composite fiber are summarized. Studies show that when biobased PA56/PET is blended in a large proportion, its compatibility is very poor. The blending fibers is liable to appear uneven dispersion, difficult to form fibers, serious breakage in production and operation, and dark blotches are liable to appear in the stain of finished fabric. Using ‘sheath-coreskin’, ‘side-by-side’ type and ‘split’ structure to spin two-component parallel composite spinning fiber has good spinnability and the fabric has good moisture absorption, dyeing performance and antistatic properties. It is comfortable to wear properties.

Keywords: Bio-based PA56; PET; Composite application; Compatibility; Composite fiber

Introduction

The glass transition temperature (Tg) of bio-based PA56 is low, and its macromolecular structure is non-central symmetry, which reduces the probability of forming hydrogen bonds between C=O and N-H polar groups, and there are more polar groups in free state, which has good hypersonic absorption, coloring performance and soft feel [1-3]. However, the macromolecule of PET is rigidity, The shape preservation of fiber and fabric shape is better, and it is easy to be washed and easy to dry [4,5]. They have strong performance complementarity in the application field of textile and chemical fiber fields. The exploration of composite application of its performance has become a hot spot in the industry.

Discussion

The overview of biobased PA56/PET compatibility research

Firstly, the compatibility of biobased PA56/PET was studied. Through infrared spectroscopic analysis, we can see that the N-H group of bio-based PA56 can produce hydrogen bond with the C=O group of PET macromolecule, which helps to reduce its mixing free energy and may be improve its compatibility [5-7]. But the Δδ of the solubility parameters of PA56 and PET is 26.92cal0.5cm1.5mol-1. According to the solubility parameter theory of polymers, the smaller the Δδ is smaller the compatibility of the two polymers is better. when the Δδ is between 0.5 and 1.0. The compatibility of the two polymers is good, but in order to be able to mix evenly in any proportion, the Δδ must be ≤0.5. Therefore, the solubility parameter Δδ value of PA56 and PET is far from the compatibility range. The calculation formula is as follows:

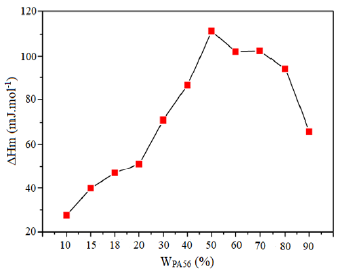

According to the calculation, only when the amount of PA56 in the blend is less than 15% the ΔHm of the blend can be in the range of the compatible system. When the proportion of bio-based PA56 is 18%, the ΔδHm value reaches 47.76×10-3J/mol. It is beyond the range of compatible system. The calculation formula is shown in (1-2). Table 1 describes the related parameters. Figure 1 is the Calculation result [8,9].

Figure 1: The calculated value of ΔHm for biobased PA56/PET blends.

Table 1: Related parameters of biobased PA56 and PET.

In the formula, δi is the solubility parameter of each component, Wi is the mass fraction of each component, Mi is the molecular weight of the repeating unit of each component, ρi is the density of each component, a and b represent different components of the blend.

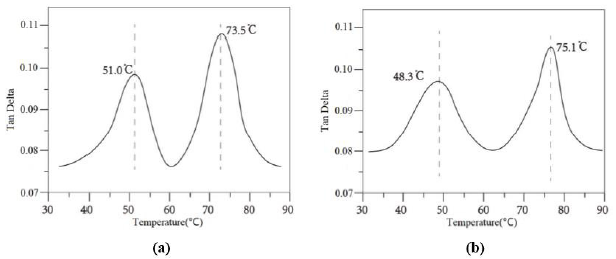

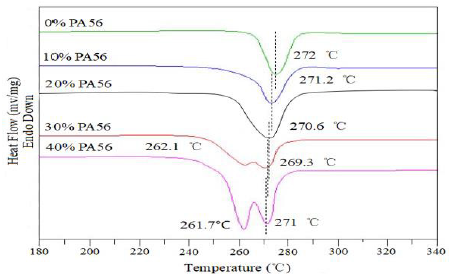

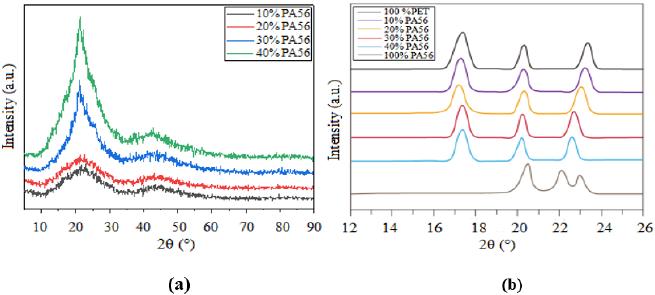

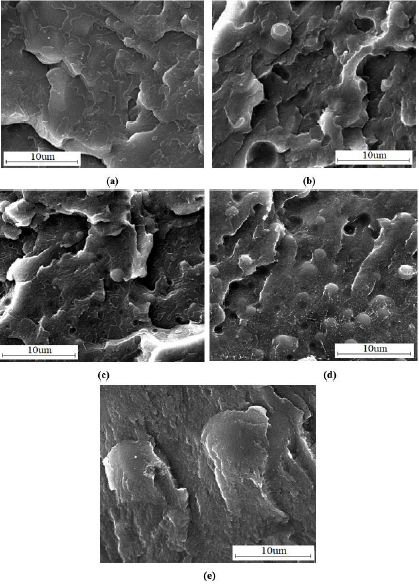

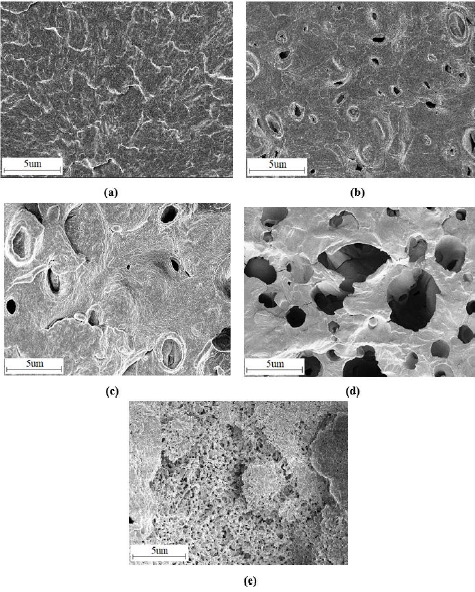

According to the above calculation and analysis, the compatibility of biobased PA56/PET is not good. The compatibility of the blend was further analyzed by test the Tg and melting point of biobased PA56/PET blends, XRD test and scanning electron microscopy. The results showed that when the amount of bio-based PA56 in PET reached 30%-40%, two glass transition temperatures and melting points appeared (Figures 2 & 3) and the higher the amount of bio-based PA56 was higher the two Tg were closer to their homopoly values. It shows they were incompatible [10-12]. The XRD test showed that the blends did not form eutectic (Figure 4). It can be seen from SEM photos (Figure 5) the Bio-based PA56 dispersed in PET matrix as spherical particles with a size of micron, and the interface between the two phases is clear. They formed into “sea-island” dispersed structure. After etching, we can see the biobased PA56 globular particles disintegrate and fall off from the blends and leaving uneven voids. As the amount of PA56 increased, the size of the dispersed phase increased significantly, and the size difference increased (Figure 6).

Figure 2: The glass-transition temperature (Tg) of bio-based PA56/PET blends measured by DMA method: (a) 30% PA56 and (b) 40 % PA56.

Figure 3: DSC heating curves of melting point of biobased PA56/PET blends.

Figure 4: The XRD test results of biobased PA56, PET and their blends: (a) XRD test curves and (b) XRD peak decomposing.

Figure 5: SEM images of biobased PA56/PET blends before etching treatment: (a) PET (b) 10 % PA56, (c) 20 % PA56, (d) 30 %PA56, and (e) 40 % PA56.

Figure 6: SEM images of bio-based PA56/PET blends after etching treatment: (a) 100 % PET, (b) 10 % bio-based PA56, (c) 20 % bio-based PA56, (d) 30 % bio-based PA56, (e) 40 %bio-based PA56.

The overview of research on biobased PA56/PET blending

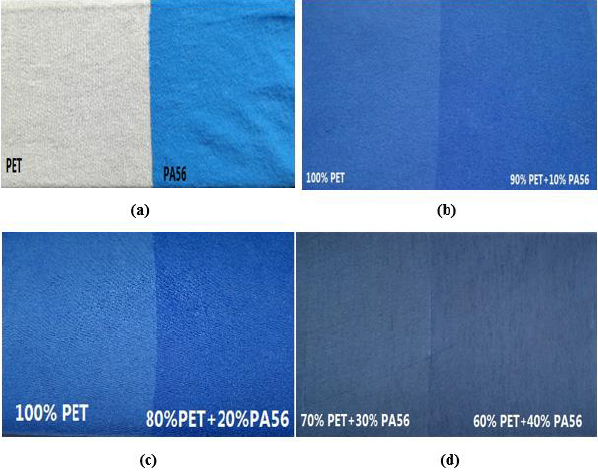

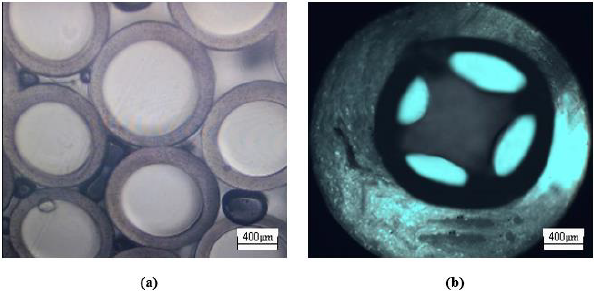

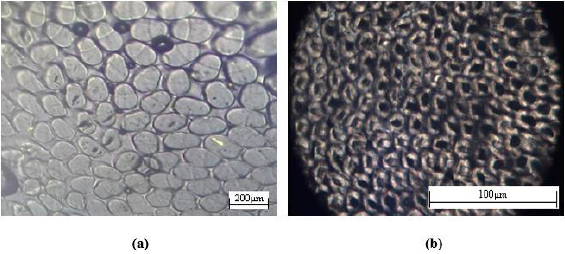

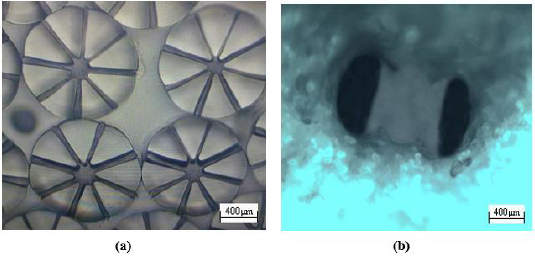

The above analysis indicated that the compatibility of bio-based PA56/PET was poor at large proportion [13-15]. The blended fiber preparation and the two-component parallel composite fiber preparation were studied, and the experiment showed that when the additive amount of PA56 in PET was more than 30%, the PA56 components distribution is not uniform and appears dark spots (Figure 7), the spinnability became worse [16,17]. When the additive proportion was reduced, the modification effect became worse. However, though the two-component parallel composite methods such as ‘sheath-core composite (Figure 8), ‘side-by-side composite’ (Figure 9) and ‘slice composite’ (Figure 10), we can be produced out high-quality composite fibers with good hygroscopicity, air permeability, moisture permeability and antistatic properties, soft feel and high wearing comfort.

Figure 7: Comparison of the dyeing effect in different mixed composite yarns: (a) Comparison of the dyeing performance of non-mixed PET fabrics (acid dye); (b) the mixing ratio of the bio-based PA56 was 10%, disperse dye; (c) the mixing ratio of the bio-based PA56 was 20%, disperse dye); (d) the mixing ratio of the bio-based PA56 was 30% and 40%, disperse dye.

Figure 8: The cross section of sheath-core composite fibre of: (a) concentric circles compound fibre and (b) multi-cavity composite fibers.

Figure 9: The cross section of side-by-side composite fiber of (a) “8” type composite fiber and (b) “2C” type composite fiber.

Figure 10: The cross section of splinter composite fiber of: (a) ‘米’ type composite fiber and (b) ‘米’ type composite fiber.

Conclusion

In conclusion, the compatibility of biobased AP56/PET is poor, especially in the case of large proportion blending. Therefore, the use of two-component parallel composite fiber preparation is more conducive to comprehensively the advantages of them and reflect their complementary performance. It has more advantages and application space than the two-blending application.

References

- Ning N, Gan JJ, Feng P, Chen G (2016) Numerical simulation of side-by-side PA 6/pet composite flat fiber extrusion molding process. Synthetic Fiber Ind 6: 60-64.

- Qian S, Zhu R, Zhang H, Shi L, Wang X, et al. (2020) Study on the thermal and rheological properties of PA56/PA6 blends. Synthetic Fiber China 49: 12-19.

- Yu L, Jin L, Zhang T, Tang Y, Liu Y, et al. (2016) The effect of compatibilizer on the properties of PA56/PET alloy. China Plastic Ind 449(7): 110-113.

- Ma X, Xu X, Chen Y (2019) The performance and application of bio-based chemical fiber PA56. China Text Lead 8: 43-46.

- Zhang S, Song B, Zhang B, Zhang M (2018) Study on compatibility of PET-PA66 and preparation of their composite fibrids. China Pulp Paper 37(7): 23-29.

- Yan Y, Wang Y, Huang Y, Zhou Y, Yang M (2019) Design and preparation of PA6/PET blend system with coating structure. J China Plast 5: 1-6.

- Liu Y, Wang J, Wang B, Li C (2018) Preparation and mechanical property of electrospun polyamide 56 nanofiber membranes. New Chem Mater 46: 149-152.

- Zhang J, Ding Y, Yu Q, Tang L, Zhang Y (2011) Effect of ionomer surlyn on properties of PET/PA66 blends. China Plastic 25: 22-26.

- Clerc C, Monasse B, Bunsell A (2007) Influence of temperature on fracture initiation in PE-T and PA66 fibres under cyclic loading. J Mater Sci 42(22): 9276-9283.

- Liang X, Qian X, Wang J, Zhang H, Zhen Q, et al. (2016) Production process of hollow segmented-pie PET/PA6 bicomponent spun bond fiber. China Synthetic Fiber Ind 38: 27-30.

- Zhou Y, Wang S, Liu L, Gan S, Hao X, et al. (2015) The research of PET-PA6 copolymerization process. Poly Ind 28:15-18.

- Min W, Yu B, Han J, Song W, Zhu F (2017) The influence of drawing pressure on the properties of PET/PA6 bicomponent spunbonded fibers. J Ind Text 46(5): 1281-1293.

- Huang J, Lin H, Wang Z, Li X (2017) Discussion on the production process of sheath-core polyesternylon composite fiber FDY. Chem Fiber Text Techno 46(2): 1-4.

- Li X, Lin H, Huang J, Wang Z, Zhen J (2017) Study of PET/PA6 splitable composite fiber. Chem Fiber Text Techno 46: 1-4.

- Yang N, Qian X (2015) Needle-punched process of PET-PA6 segmented pie bio-component spunbonded microfiber synthesis leather. China Leather 44: 60-63.

- Yang C, Pan J, Ye H, Zhang R, Feng P (2018) Research on the preparation and spinning process of PA6/PET sheath-core composite hollow fiber. J Synthetic Fiber Ind 3: 7-10.

- Tan P (2016) Production practice of pa6/pet sheath-core high-strength yarn. Text J (5): 58-59.

© 2021 Zhang Shouyun. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)