- Submissions

Full Text

Polymer Science: Peer Review Journal

Aerogel Fibers - The World’s Lightest Insulating Fabrics

Maximilian Mohr*, Daniel Wolters and Thomas Gries

Institut für Textiltechnik, RWTH Aachen University, Germany

*Corresponding author: Maximilian Mohr, Institut für Textiltechnik der RWTH Aachen University, Otto-Blumenthal- Straße 1, 52074 Aachen, Germany

Submission: November 24, 2021;Published: December 06, 2021

ISSN: 2770-6613 Volume2 Issue4

Abstract

Aerogels are organic or inorganic materials that are unique in many ways. As the name suggests aerogels have a porous structure and contain a high percentage of air (>95%). This results in useful properties like low density, a high specific surface area and low thermal conductivity (~0.013W/m∙K). The resulting superior thermal insulation properties are not achieved with common insulation materials like expanded polystyrene 0.035W/m∙K at 10 °C. The problem with Aerogels as a bulk material is their stiffness which results in damage to the porous system under mechanical stress. This brittleness should be overcome using aerogel fibers instead. In fiber morphology, silica aerogels become more flexible and could be used as an ultralight thermal insulator for example. In the project “EvA”, aerogel filament nonwovens made of Polyacrylonitrile (PAN) were developed at ITA. In addition, fibers and textile structures of silica aerogels could be realized and tested for the first time in the VIP+ project “Silica Aero”. PAN aerogel textiles can preferably be used in price-sensitive standard insulation applications with a large market volume. The silica aerogel textiles are meant for application areas with special requirements regarding chemical and thermal resistance. In these fields more expensive products are used. The low weight of the nonwovens and the developed process are linked with cost savings and advantages in materials handling for both aerogel types in comparison to the established competitor products.

Keywords: Aerogel; Polyacrylonitrile; Silica; Fiber; Nonwoven; Insulation; Lightweight; Wetlaid; Solution spinning

Abbreviations: EPS: Expanded Polystyrene; PAN: Polyacrylonitrile; ITA: Institut für Textiltechnik der RWTH Aachen University; BMWI: Federal Ministry for Economic Affairs and Energy (Germany) FKZ: Funding Code

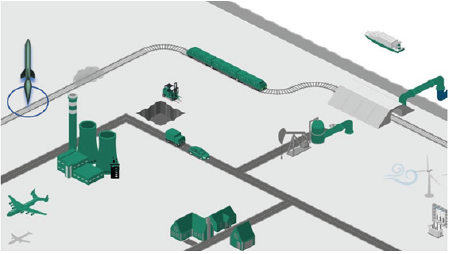

Necessity of Super Insulators

The 2030 climate targets call for a 55% reduction in greenhouse gases compared to 1990 [1]. In order to achieve these climate targets, new solutions for reducing greenhouse gases must be developed and implemented. Due to their good insulating properties, in combination with a low density, aerogels are particularly suitable for aeronautics and space, automotive, chemical and electric industry, the transport and building sectors [2]. Figure 1 shows this the drapability of textile structures can lead to diverse applications in this fields. In particular, the drapability of textile aerogel structures can be used for a variety of applications in these fields and generate additional economic benefits for the reduction of fuels and carbon dioxide.

Figure 1: Insulation and applicate fields of aerogels technologies [3].

Discussion

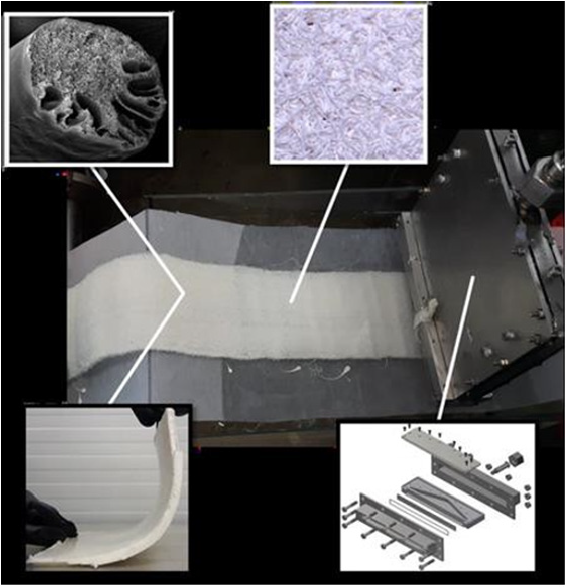

At ITA, a process has been developed to produce aerogel nonwovens, directly. The so-called wets unlaid process is an adaptation of the solvent spinning process. In this process a dissolved polymer is extruded into a spinning bath, where it solidifies in fiber form. The fibers are laid down on a conveyor belt inside the bath, which transports the nonwoven textile to the washing and drying step. To optimize the drying step a semibatch supercritical process is used. During the supercritical drying process, the gel -structure is converted with CO2 into a solid form without shrinking. After that process all solvents are removed and can be reused. The PAN aerogel nonwoven developed are shown in Figure 2. The PAN aerogel nonwoven has an internal surface area of 202m²/g and a thermal conductivity of 0.06W/(m∙K). Due to their low density, aerogel nonwovens made of Polyacrylonitrile (PAN) are flexible and at the same time have excellent insulating properties in relation to their weight. The project Chrysomallos (BMWI/FKZ: 20E1906), named after the golden fleece in Greek mythology, aims to develop a new and lighter insulation material for aviation [3]. According to [4], the potential that can be achieved with a saving of 35kg on a typical cargo aircraft amount to 80t of kerosene and 250t of carbon dioxide per year. The example described shows what a large impact on fuel consumption and carbon dioxide emissions even a small saving in weight can have.

Figure 2: Developed wet-spun-laid unit at ITA [4].

Conclusion

For an Airbus A320 aircraft, this would mathematically mean a reductio n in total weight of around 600kg and an additional gain in space to counteract the constricting atmosphere in a narrowbody aircraft. The production process can be economically scaled up to produce aerogel fleece at a price of less than 3€/m², which makes the aerogel nonwoven a cost- effective alternative to the glass fiber mats used up to now [5]. Other possible applications for the PAN aerogel nonwovens currently under development include filter applications, pollutant-free and antifungal interior insulation in buildings, and clothing applications. With internal surfaces > 600m2/g, the silica aerogels developed have even higher porosities than PAN aerogel nonwovens. They are also temperature stable and have a melting point >1000 °C. This makes them particularly interesting for high - temperature applications, such as the insulation of engines and motors. Due to their low weight, they can contribute to significant emission reductions in mobile applications. They are also interesting for the chemical industry due to their very large inner surface and chemical resistance. However, the price per square meter is seven times higher than PAN aerogels. This means that PAN aerogel textiles can preferably be used in price- sensitive standard insulation applications with a large market volume [6,7]. The silica aerogel textiles are targeted at applications with special requirements for chemical and thermal resistance in which significantly more expensive products are used. The low weight of the nonwovens and the developed process control promise cost savings and advantages in handling and processing for both aerogel variants compared to the established competitor products.

References

- (2030) The Federal Government (Germany), Climate Action Programme.

- Hüsing N, Schubert U (2007) Aerogels-airy materials: Chemistry, structure, and properties. Angewandte Chemie International Edition 37(1-2): 22-45.

- Wolters D (2021) Chrysomallos: Development of high-performance insulators for aircraft cabins based on aerogel nonwovens. Institut für Textiltechnik, RWTH Aachen University, Aachen, Germany.

- https://www.klimaschutz-portal.aero/verbrauch- senken/am-flugzeug/ gewicht- einsparen/

- Mroszczok J (2019) Production of aerogel nonwoven. Institut für Textiltechnik, RWTH Aachen University, Aachen, Germany.

- Peterek S (2020) Neuartige Aerogelfasern für die Hochtemperaturisolation. Institut für Textiltechnik der RWTH Aachen University, Aachen, Germany.

- Wolters D (2020) Technical-scale production of aerogel nonwovens. International Fiber Journal 34: 30-31.

© 2021 Maximilian Mohr. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)