- Submissions

Full Text

Progress in Petrochemical Science

Status Quo and Prospect of Oil-Water Two-phase Flow Detection Technology in Petrochemical Pipeline Network

Wang Weikang1,2, Hu Shaolin2* and Ke Ye2

1School of Information and Control Engineering, Jilin Institute of Chemical Technology, China

2School of Automation, Guangdong University of Petrochemical Technology, China

*Corresponding author:Hu Shaolin, School of Automation, Guangdong University of Petrochemical Technology, China

Submission: July 17, 2023;Published: August 04, 2023

ISSN 2637-8035Volume5 Issue4

Abstract

In petrochemical production, the flow of oil-water mixture in pipelines is a common phenomenon referred to as oil-water two-phase flow. The main purpose of oil-water two-phase flow detection is to detect the proportion of oil or water in the liquid to be tested, which is significant for crude oil extraction, storage and transportation and even sales. This article analyzes the impact of complex environments on the detection results of oil-water two-phase flow and introduces the basic principle of oil or water content detection methods in oil-water two-phase flow detection as well as the applicability, advantages and disadvantages of various detection methods. Then the domestic and foreign scholars’ efforts toward the fundamentals are briefly introduced. Finally, existing methods are summarized, together with research trends for oil-water two-phase flow.

Keywords:Oil-water two-phase flow; Detection technology

Introduction

The main purpose of oil-water two-phase flow detection is to measure the water-to-oil weight ratio of the liquid to be tested (usually in percentage). The analysis of the water-to-oil weight ratio of liquids is a common analytical technique in petroleum and chemical engineering which is used to determine the water and oil content of liquids and evaluate their quality, properties and practicability. The oil-water two-phase flow content measurement has important practical significance for process optimization, process control and flow measurement. With the deepening research on oil-water two-phase flow detection technology by global scholars, more and more methods are utilized in oil-water detection. However, in practical applications, these methods have certain environmental and inherent limitations. This article analyzes the factors that affect the detection results of oil-water two-phase flow content, summarizes several typical detection methods for oil-water two-phase flow and introduces in detail their advantages, disadvantages and applicable environments. Finally, the developing trend of oil-water two-phase flow detection technology is presented in this prospect.

Factors Affecting Accuracy of Oil-Water Two-Phase Flow Content Detection

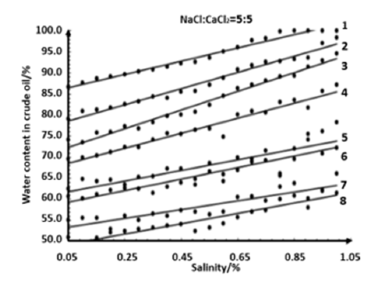

The complex environment of industrial production can affect the content measurement of oil-water two-phase flow, especially the salinity and temperature. In the process of crude oil exploitation, the water molecules in the oil-water mixture will be mineralized to a certain extent, which depends on the local geological conditions, changing the conductivity and density of the mixture and affecting the measurement results of crude oil. Especially when using capacitance, conductivity or microwave technology for measurement, large deviations may occur in the measurement results. Xiuxin [1] analyzed the influence of the degree of mineralization annular and sampling capacitance method for measuring oil-water two-phase flow. The results show that the annular sensor is slightly affected by the degree of mineralization and low water content, while the sampling sensor is not affected by meaningless results. Yaping et al. [2] analyzed the effect of mineralization degree on the capacitance method for measuring water content and the results show that the capacitance method has an apparent error in measuring high water content liquids. Yanpeng [3] analyzed the effects of different mineralization degrees of single and double components on the water content of oil-water mixtures detected by microwaves (Figure 1).

Figure 1:The influence of dual mineralization on samples with different initial water content [3].

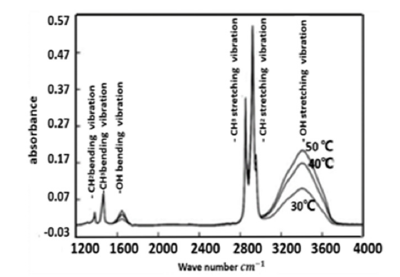

Figure 2:Infrared absorbance of 27.3% water content liquid at different temperatures [6].

Because the dielectric constant of aqueous crude oil changes with temperature, the influence of temperature should be considered when measuring the water content of crude oil through capacitance, inductance and microwave. As verified by Erji et al. [4], the relative dielectric constant of water with increasing temperature. Pengmin et al. [5] explored the effect of temperature on the measurement results of crude oil moisture using microwave sensors and the results show that the moisture has a decreasing trend with increasing temperature; Yufei et al. [6] research found that with the increasing temperature, the absorbance of OH bonds in liquid water also shows a proportional increase trend. This discovery provides an important reference for infrared spectroscopy to detect water content (Figure 2).

Several Typical Methods

Different methods can be used for detecting oil-water twophase flow, such as capacitive inductance, radiographic, ultrasonic, microwave, spectral and capacitance tomography imaging technology. These methods are commonly used in industrial production processes, but they also have their respective limitations and challenges in practical applications.

Capacitance and inductance technology

The capacitance and conductivity detection method is a commonly used method for oil-water detection. The basic principle of the conductivity method is that oil, as an insulator, has no conductivity, while water, as a salty mineralized substance in the oil production process, has certain conductivity. By measuring the conductivity of the oil-water mixture, it is possible to determine the oil content of the mixture. The basic principle of the capacitance method is based on the different dielectric constants of water and oil. Water typically has a dielectric constant of 81.5, while crude oil generally has a dielectric constant between 1.86 and 2.38. When a mixture of oil and water with varying oil content passes between the two plates of the capacitor, it causes changes in capacitance. The oil content can then be calculated by measuring the electric current. Bo et al. [7] measured the conductivity of oil-water mixtures at different temperatures using distillate properties of crude oil and derived a relationship between oil content and conductivity. This method maintains an error within 2% for oil-water mixtures with a water content of 90%. Zhonghao et al. [8] proposed a new method for measuring water content in oil using conductivity.

This method solves the problem of complex flow patterns affecting measurement results by adding a vane cyclone separator to the measuring tube. The experimental results show that the maximum error of this method in measuring liquid film thickness is only 4.86%. Hongwei et al. [9] proposed a new method for measuring oil content in oil-water two-phase laminar flow in horizontal wells by combining turbine and capacitor technology in a multi-point measurement. By verification, the experimental results are consistent with the expected values, with an average moisture content error of 2.373%. Xinhe et al. [10] proposed a capacitancebased detection technology for measuring the oil-water interface of aviation kerosene, which improves the accuracy of oil-water interface detection. The capacitance inductance measurement method for measuring oil-water mixed liquids has the advantages of low cost, fast response and simple structure. It was widely used in oilfield production processes during the 1990s. Both measurement methods are susceptible to factors such as corrosion and the liquid under test adhering to the measuring device, which can adversely affect the accuracy of the measurement parameters. Moreover, in practical applications, variations in the flow patterns of oil-water liquids can also cause differences in measurement results, leading to significant errors. Consequently, relying solely on these two methods is no longer sufficient to meet the demands of modern petroleum production processes.

Radiographic measurement methods

The radiation measurement method involves observing the attenuation of a portion of the energy of the measured fluid when it is irradiated by the radiation source. This makes it possible to calculate the proportion of the substance in the fluid and determine its composition. Pap HJ [11] was the first to attempt combining spectroscopy and X-ray technology to achieve accurate determination of oil content in water. Qiuguo et al. [12] proposed a method for measuring the water content of crude oil with extremely high resolution and accuracy. This method is based on the intensity attenuation characteristics of γ rays passing through a medium and involves accurately estimating the water content of the liquid under test by measuring the number of transmitted rays.

Panpan et al. [13] proposed a method for monitoring the upper and lower limits of the oil-water interface using the ray method to provide an alert when the interface reaches a certain position. Lin et al. [14] designed a real-time measurement and display system based on X-rays, which can more effectively monitor the state of oilwater two-phase flow and display the water content of the flow in real-time. Haozhe et al. [15] applied the principle of ray attenuation to identify the thickness of light and heavy oil and water layers, as well as the thickness of emulsion layers in different groups. Lei et al. [16] conducted a comprehensive investigation of the distribution of oil-water saturation and its corresponding measurement methods using X-CT scanning technology, verifying that the patterns of water saturation distribution and permeability curves are accurate. Runxi et al. [17] and his team conducted research and found that a crude oil moisture analyzer designed by photon ray source technology, based on γ rays, can achieve high measurement accuracy even when the water content of crude oil is between 0% and 98%. The measurement accuracy is found to be within -2.98% to +2.98%. The radiation measurement method for measuring oil and water content offers the advantages of high measurement accuracy and non-destructive testing. However, this method has several drawbacks, such as high cost and maintenance expenses, poor detection stability and the potential health risks associated with radioactive substances. As a result, it has not been widely adopted.

Ultrasonic measurement method

The ultrasonic measurement method for determining the oilwater content operates on the principle of studying the different propagation characteristics of ultrasonic waves in oil-water mixtures with varying moisture content (such as amplitude, frequency and phase changes), to determine the proportion of various components in the liquid being measured [18]. A common method for estimating the content of a medium is to observe the transmission, reflection, scattering and time-of-flight of ultrasound as it passes through the liquid. Chengcheng et al. [19] proposed an ultrasonic scattering method for measuring the content of oilwater two-phase flow, using a non-intrusive method to maintain the flow state of the liquid. Experimental results demonstrate that this method provides high measurement accuracy. Yizhe et al. [20] simulated and modeled a liquid with a dual continuous dispersed flow. The simulation model is tested using the principle of ultrasonic attenuation and the relationship between the ultrasonic attenuation signal and varying oil contents is determined. Wei et al. [21] designed a transmission-type ultrasonic testing system to measure the oil-water solution in horizontal pipelines. The results demonstrate that the transmission attenuation signal of ultrasonic is linearly proportional to the holdup of oil-water two-phase flow. Qian et al. [22] developed a flow field simulation model for oilwater two-phase flow using the finite element analysis method and conducted simulation research on the ultrasonic attenuation signals received by liquids with varying concentrations of oil content.

The results demonstrate the feasibility of using the ultrasonic attenuation method to measure the content of oil-water twophase flow within a certain range of oil content. The ultrasonic measurement method is capable of measuring the moisture content of oil-water two-phase flow with sparse and dispersed flow characteristics. Its advantages include non-contact operation and non-destructive testing. However, the accuracy of the ultrasonic measurement method can be significantly affected under hightemperature and high-pressure conditions due to limitations in the installation location and working environment of the transducer. Additionally, ultrasonic attenuation is effective only within certain ranges of oil content and may not be able to measure the entire range of oil content. Therefore, the application range of the ultrasonic measurement method is somewhat limited.

Microwave measurement method

The microwave measurement method utilizes the highfrequency dielectric properties of substances to measure the dielectric constants of the oil and water phases in an oil-water twophase flow. It obtains information on amplitude and phase through the attenuation of the measured liquid’s energy, enabling inference of the content of the measured liquid. Microwave resonant cavities, single frequency, as well as the variable frequency transmission techniques can be effectively employed to measure the content of substances [23]. Marrelli et al. [24] designed a fully measurable instrument for monitoring water content. The instrument employs microwave attenuation and phase shift data to calculate the volume fraction ratio of mixed liquids containing oil, gas and water. It is not affected by factors such as temperature and mineralization. Yaozhong et al. [25] conducted simulation validation of the microwave method for measuring the water content of crude oil. The experimental results demonstrate that when the oil-water mixture is uniformly distributed, the dielectric constant exhibits a linear relationship with the water content. However, this simulation only targets specific oil-water mixture contents and does not achieve measurement across the full range of contents. Penguin et al. [26] investigated the variation of the dielectric constant of oilwater mixtures with temperature using the microwave phase shift method.

The research reveals that the dielectric constant of the oilwater mixture decreases as temperature increases, which can affect the accuracy of detection. Zhe et al. [27] designed and built a water retention logging tool using microwave technology. After experimental verification, the tool is found to be capable of accurately measuring the layered oil content in high water-bearing wells. When the water content exceeds 50% or is less than 20%, the measurement accuracy of the microwave water retention logging tool can reach 2%; The microwave water retention logging tool can achieve a measurement accuracy of 2% when the water content exceeds 50% or is less than 20%. When the water content is between 20% and 50%, the measurement accuracy can reach 10%, which can meet the requirements for practical applications. Weiguang et al. [28] and his team successfully measured the oilwater interface of heavy oil using a microwave level gauge. Actual results indicate that this technology has an average error of about 5%, which is more accurate than traditional float-level gauges and can be applied to water cut monitoring in storage tanks. The microwave measurement method has been widely adopted for measuring oil-water two-phase flow due to its non-contact nature, high measurement accuracy and wide measurement range. However, due to the complex structure and high cost of microwave transceiver circuits which require high environmental noise standards and good temperature stability, its application is somewhat limited.

Fluorescence spectroscopy

Fluorescence spectroscopy can be divided into two types: twodimensional fluorescence spectroscopy and three-dimensional fluorescence spectroscopy. The main principle of 2D fluorescence spectroscopy is that most petroleum compounds exhibit fluorescence under specific excitation wavelengths of light. By analyzing the fluorescence intensity of samples with different concentrations, the relationship between fluorescence intensity and oil content can be established using Lambert Beer’s law. 3D fluorescence spectroscopy can provide a wealth of fluorescence information, such as fluorescence intensity, fluorescence spectrum shape, number of fluorescence peaks and wavelength of fluorescence peaks. By analyzing these fluorescence characteristics, quantitative or qualitative analysis models can be established for different types of oil products [29]. Fluorescence spectroscopy analysis has become a popular research topic in the field of petroleum content detection in water due to its advantages, such as simple operation, fast response and non-contact measurement. He LM et al. [30] prepared four different petroleum samples and obtained their fluorescence and light scattering spectra. They then used artificial neural network methods to establish a more accurate mathematical model for predicting oil content in water based on the obtained spectra. Gyeongdong et al. [31] developed a light scattering and TSK fuzzy system for monitoring ship oil discharge. Kim et al. [32] utilized fluorescence detection to monitor the distribution of dispersed oil in pore water.

Massaro et al. [33] developed a new oil-in-water detection system based on optical reflection, which can be used to detect the content of single or multiple types of oil pollutants, as well as oil film thickness. Daying et al. [34] established a mathematical relationship between oil content in water and fluorescence intensity through experiments. They analyzed the fluorescence characteristics of crude oil and petroleum products from multiple regions using specific emission and excitation wavelengths. Shirong et al. [35] investigated the relationship between the fluorescence intensity of different crude oil components and the oil concentration in water. They found that fluorescence quenching occurs when the solution concentration is too high, leading to a nonlinear relationship between fluorescence intensity and solution concentration at high concentrations. Jiang et al. [36] used synchronous fluorescence spectroscopy with a wavelength of 25nm to study different types of crude oil and their weathered samples. They combined cluster analysis methods to successfully identify suspicious oil sources and oil spill samples in sea surface oil spill events, providing a strong basis for further research. Zhicheng et al. [37] analyzed the effect of different concentrations of humic acid on the fluorescence method for measuring oil content in water.

Wang et al. [38] prepared various crude oil samples from the Shengli Oil Field. They combined the synchronous scanning method with three-dimensional fluorescence analysis technology and used different spectral measurement methods to establish the relationship between spectral characteristics and concentration. Experimental results show that the three-dimensional fluorescence method can be used in applications that require high precision and in scenes with high concentrations of oil. Youquan et al. [39] analyzed the three-dimensional fluorescence spectral characteristics of diesel, gasoline and mixed oils. Based on their findings, they proposed a new method that accurately identifies the characteristics of different oil products. This method provides an effective guarantee for the safe use of oil products. Renjie et al. [40] used three-dimensional fluorescence differential spectroscopy to analyze the mixed solvent oil content in diesel. The results demonstrate that this method can accurately measure the solvent oil content. Yan et al. [41] studied the effect of solvents on the threedimensional fluorescence spectra of different types of petroleum and analyzed the relative intensities of multiple fluorescence peaks. This method can be used to identify petroleum types. Yutian et al. [42] used principal component analysis to reduce the dimensionality of spectral features and developed models for different oils using BP neural networks. The goal is to study the identification of mineral oils. Xiao et al. [43] identified the threedimensional fluorescence spectral characteristics of three finished oil ethanol solutions, determined the positions of fluorescence peaks and established the relationship between fluorescence intensity and low-concentration solutions.

Guangjun T [44] utilized the Singular Value Decomposition (SVD) method to reconstruct the characteristic sequence of the 3D fluorescence spectrum of mineral oil in different types of water based on 3D fluorescence spectrum data. The results show that the singular value characteristic spectrum can effectively capture the main energy features of the three-dimensional fluorescence spectrum. This method can be used to monitor the type of oil contaminant present in water. As mentioned earlier, the 2D fluorescence method is commonly used to measure the oil content of a liquid using ultraviolet fluorescence. Liquid oil content can be quickly calculated based on fluorescence intensity, making it useful in marine oil pollution monitoring and sewage monitoring. On the other hand, the 3D fluorescence method can provide more detailed fluorescence information about the liquid being tested. This method not only allows for the measurement of liquid concentration but also enables the proportion of different types of oil in the liquid to be determined based on the fluorescence information obtained. While fluorescence spectroscopy offers high sensitivity and selectivity, it is susceptible to interference from visible light and quenching will occur when the oil content is high, leading to a significant deviation between absorbance and concentration. Consequently, this method is only suitable for measuring small amounts of oil in water.

Near-infrared method

When an oil-water mixture is irradiated with near-infrared light, a specific absorption spectrum is generated, linearly correlated with the water content in the liquid. As a result, the near-infrared method can be utilized to measure the water content in the mixture. The near-infrared method works by reflecting near-infrared light into the photodetector of a measuring instrument to determine the moisture content of the liquid. When measuring low-water crude oil, the near-infrared method offers several advantages, including high accuracy, fast speed and non-destructive testing [45]. As a result, this method has been widely employed by researchers to investigate the detection of oil-water two-phase flow holdup. Jinqi et al. [46] developed a fiber optic near-infrared moisture content monitoring system that exhibits high accuracy for measuring low moisture content liquids. Jian et al. [47] proposed a spectral ultrasparse representation method for oil-water mixture spectra based on self-correlation. This method is used to screen detection bands and verify the responses of two bands to oil-water mixture flow patterns, which shows a significant correlation between the two bands. Subsequently, Jian et al. [47] proposed a SPA-PLS method for modeling and predicting high water-content crude oil with good accuracy [48]. Xin et al. [49] developed a method for rapid detection of crude oil content using infrared spectroscopy. Various crude oil samples were prepared for the experiment with standard solutions of different water contents and mineralization degrees.

The resulting modeling correlation coefficient R reaches 94.44%. Yufei et al. [50] introduced a detection system based on Attenuated Total Reflectance Fourier Transform Infrared (ATRFTIR) spectroscopy technology, which achieves a Coefficient of Determination (R-squared) of 98% for the modeling and prediction sets. Hongming et al. [51] preprocessed the near-infrared spectral data of crude oil using moving window smoothing, convolutional smoothing and convolutional derivative methods and established a prediction model using partial least squares and SVM (support vector machines). These experimental results demonstrate that the prediction model achieves an extremely high level of accuracy. Although the infrared method has the advantages of high accuracy, fast detection speed and contactless measurement in detecting the moisture content of oil-water two-phase flow, it has not been widely used in industrial production due to its high cost and complex operation.

Electrical capacitance tomography

In recent years, Electrical Capacitance Tomography (ECT) has emerged as a major area of research in two-phase flow detection. The fundamental is that the dielectric constants of oil and water are different such that the capacitance of a measured cross-section will vary as different oil-water mixtures flow through it. By analyzing the changes in capacitance, the distribution of the liquid can be obtained. Image reconstruction methods can be employed to generate an oil-water distribution fitting graph of the cross-section [52]. ECT’s The non-contact, low-cost, and wide-range advantages of ECT have made it a research hotspot in two-phase flow detection. Hossain et al. [53] presented an algorithm that utilizes capacitance tomography to continuously monitor the components of multiphase flow. Unlike conventional methods, this approach does not directly reconstruct the dielectric constant of the imaging area but does employ single-frequency measurements to reconstruct the fractional area/volume of each phase in the multiphase flow and then calculate the dielectric constant image. Rasel et al. [54] classified the flow state of aqueous liquids into continuous flow and dispersed flow and used deep learning to estimate the volume fraction of water in these two flow states.

Guibin et al. [55] introduced an ECT image reconstruction algorithm based on a genetic algorithm, with simulation results indicating that the average error of this method for phase holdup measurement is less than 2.5%. Haichao et al. [56] developed a multi-task learning and capacitance imaging method that utilizes neural network and Random Forest regression methods to extract features of the reconstructed image and calculate its phase holdup. The results indicate that the relative error of the phase holdups was kept within 5%. The electrical capacitance tomography method is low-cost, non-contact and non-destructive with a wide measurement range. Therefore, it has been widely employed in the study of phase holdup measurement in two-phase and multiphase flows. However, during image reconstruction, the real-time performance of more complex algorithms is poor and conventional algorithms is difficult to guarantee accuracy. Additionally, the challenges associated with detecting weak capacitance and the soft field characteristics of capacitance measurement [57,58] have yet to be addressed. Hence, this method remains in the progress of laboratory research, which cannot be applied in practical engineering.

Conclusion

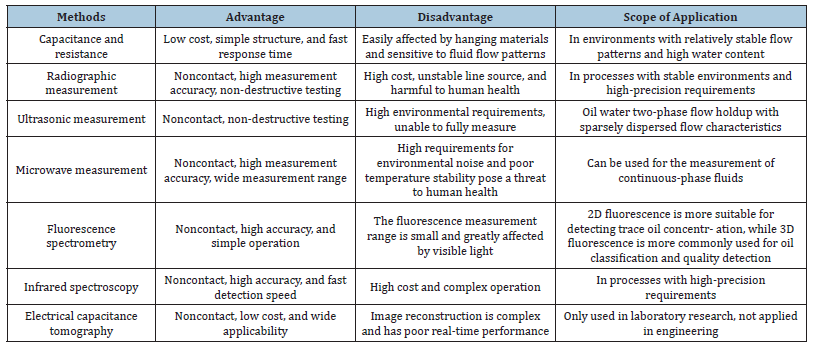

While some oil-water two-phase flow detection methods have been widely adopted in the industrial field, their limitations can make it challenging to meet the increasingly complex process requirements. As such, it is necessary to explore better detection methods or find ways to address their shortcomings. Table 1 provides a summary of the detection methods for oil-water twophase flow. It is evident from this table that addressing the impact of complex environments on measurement results during the measurement process is a key focus of future research on oil-water two-phase flow detection technology. To achieve breakthroughs in this area, the following guidelines of research are illustrated:

Table 1:Summary of measurement methods for oil water two-phase flow detection.

a) Non-contact monitoring has become the mainstream

of oil-water two-phase flow detection research, due to

the challenges posed by contact measurements, such as

susceptibility to interference by hanging materials and the

potential of instrument sensors corrosion over long-term use.

b) Real-time performance is a crucial consideration in oilwater

two-phase flow holdup detection technology, as it is often

applied in the industrial production process to obtain real-time

value of liquid content. Sampling and analysis measurement

techniques with poor real-time performance can rarely meet

the needs of industrial production.

c) Nondestructive testing is essential in the industrial

production process, as the content of the medium is often used

as an indicator for the operator or operating system to proceed

to the next step. If the properties of the detected liquid change,

it will become invalid and lead to significant losses for the

enterprise.

Acknowledgment

This paper is financially supported by the Foundation of nature science of Guangdong (2023A1515012341) and the Foundation of Maoming Green Chemical Industry Research Institute (MMGCIRI- 2022YFJH-Y-053).

References

- Xiuxin J (1985) Discussion on the principle and application of the capacitance method for measuring water content. Logging Technology 6: 73-80.

- Yaping Z, Xianghong Y (2002) The influence of water salinity and organic matter content on the water content of crude oil. Oil and Gas Storage and Transportation 02: 32-34+60-65.

- Yanpeng X (2018) Research on automatic water cutting system of high water cut crude oil storage tank based on microwave method. Xi'an Shiyou University, China.

- Du E, Zhao L, Zou D, Li R, Wang Z, et al. (2020) Soil moisture calibration equations for active layer GPR detection-a case study especially for the qinghai-tibet plateau permafrost regions. Remote Sensing 12(4): 605.

- Pengmin D, Xiaohui L, Bao T, Yanpeng X (2017) Experimental analysis of the effect of temperature on the detection accuracy of sensors for high water content crude oil. Chemical Automation and Instrumentation 44(06): 568-571+580.

- Yufei Y, Cuiling L, Xiaorong S (2020) Study on the effect of temperature on the water content of crude oil based on ATR-FTIR technology. Applied Chemical Engineering 49(4): 1044-1048.

- Bo Y, Ruida S, Tianyong Z (2019) An improved method for measuring the water content of crude oil based on conductivity method. Journal of Sensing Technology 32(9): 1308-1312.

- Zhonghao L, Xingkai Z, Ruiquan L, Baocheng S, Lamei H (2022) Liquid holdup measurement technology based on the forced annular flow conductivity method. Petroleum Machinery 50(4):101-110.

- Hongwei S, Haimin G, Shuai G, Hangyu S (2020) Measurement method for separated phase flow rate of oil-water two-phase stratified flow in horizontal wells. Petroleum Exploration and Development 47(03): 573-582.

- Xinhe W, Weijie Y, Yuanyuan Z, Tianwei S, Shouxin W, et al. (2021) Application of oil water interface analyzer in automatic sedimentation of aviation fuel storage. Oil and Gas Storage and Transportation 40(5): 581-585.

- Paap HJ (1981) Microwave-gamma ray water in the crude monitor. US Patent No. 4289 029 1981, USA.

- Qiuguo B, Xuebin Z, Chunguo J, Meixiang W, Shoulan G, et al. (2000) γ Ray crude oil low water content measuring instrument. Nuclear Electronics and Detection Technology 4: 269-271+257.

- Panpan H, Dongxi L, Ke C (2019) Research on the monitoring method of oil-water interface in SDPSO platform oil storage system. China Shipbuilding 60(4): 73-82.

- Lin L, Xingzhuo W (2018) Design of a real-time display system for X-ray oil-water two-phase flow measurement. Design and Development 3: 27-28.

- Haozhe J, Yong G, Yizhi T (2020) Research on the separation method of light-heavy components based on the principle of ray attenuation. Industrial Instrumentation and Automation Devices 3: 132-136.

- Lei S, Zhiqi W, Yi P (2017) Comparative study of fluid saturation distribution between X-CT scanning technology and Berkeley Lewett water displacement theory. Science Technology and Engineering 17(32): 87-92.

- Runxi L, Chaoxin Z, Wenqin L (2016) Tracking and evaluation of the application of online monitoring technology for water content in crude oil of Xinjiang oilfield. Petrochemical Technology 8: 80-81.

- Goncalves JL, Paiva TA, Carvalho RD, Venturini OJ (2011) Application of the ultrasonic technique for monitoring and measuring the phase fractions of liquid-gas-solid mixtures. Brasil Offshore, Macae, Brazil.

- Chengcheng L, Xingbin L, Haijun Z (2005) Experimental study on ultrasonic measurement method for nonconcentrated oil-water two-phase holdup. Logging Technology 5: 66-68+89.

- Yizhe S, Chao T, Feng D (2018) Simulation modeling of ultrasonic testing mechanism for oil-water two-phase flow. Journal of Central South University (Natural Science Edition) 49(4): 987-994.

- Wei Z, Chao T (2016) Design and test of transmission oil-water two-phase flow ultrasonic testing system. Journal of Central South University (Natural Science Edition) 47(9): 3252-3257.

- Qian S, Feng D (2016) Test method for ultrasonic attenuation of oil-water two-phase flow. Journal of Central South University (Natural Science Edition) 47(2): 647-653.

- Bolomey JC, Pichot C (1990) Microwave tomography: From theory to practical imaging systems. International Journal of Imaging Systems and Technology 2(2): 144-156.

- Marrelli JD, Siddiqui F (1996) Method and apparatus for determining water-cut and gas fraction in three-phase mixtures of oil water and gas,

- Yaozhong X, Jianrong W (2015) Simulation of microwave measurement of water content in crude oil. Journal of Anhui Electronic Information Vocational and Technical College 14(2): 41-45.

- Pengmin D, Xiaohui L, Bao T (2017) Experimental analysis of the influence of temperature on the detection accuracy of high water content crude oil moisture sensor. Chemical Automation and Instrumentation 44(6): 658-671.

- Zhe Y, Lin W, Bingchao C (2016) Microwave water holdup logging tool. Petroleum Technology Forum 011(z1): 40-42.

- Weiguang L, Chunhui H, Yicheng W (2017) The application of microwave level gauge in measuring the oil-water level of the cold low separation tank in residual oil hydrogenation unit. Chemical Automation and Instrumentation 44(11): 1033-1035.

- Qinglong S (2022) Application of molecular fluorescence spectroscopy technology in crude oil and petroleum products. China Petroleum and Chemical Standards and Quality 42(09): 160-162.

- He LM, Padilla LL, Lieberman SH, Andrews JM (2003) Rapid in situ determination of total oil concentration in water using ultraviolet fluorescence and light scattering coupled with artificial neural networks. Analytica Chimica Acta 478(2): 245-258.

- Gyeongdong B, Jaewoo C, Moon-Ho C, Kim S (2010) On-line monitoring of oil in water using transmitted-scattered lights and clustering-based hierarchical TSK fuzzy systems. IEEE World Congress on Computational Intelligence, Barcelona, Spain, pp. 18-23.

- Kim M, Yim UH, Hong SH, Jung JH, Choi HW, et al. (2010) Hebei spirit oil spill monitored on-site by fluorometric detection of residual oil in coastal waters off Taean, Korea. Marine Pollution Bulletin 60(3): 383-389.

- Massaro A, Ekuakille AL, Caratelli D, Palamara I, Morab FC, et al. (2012) Optical performance evaluation of oil spill detection methods: Thickness and extent. IEEE Transactions on Instrumentation and Measurement 61(12): 3332-3337.

- Daying X, Shikui Z, Baohua L (2002) Experimental study on fluorescence characteristics of mineral oil in water. Yellow Sea and Bohai Sea Oceans 20(2): 91-98.

- Shirong X, Ming D, Jian Z (2009) Fluorescence method for determining oil content in oilfield wastewater. Petroleum and Natural Gas Chemicals 38(3): 258-261.

- Jiang FH, Zhao M, Han B, Zheng L, Wang XR, et al. (2011) Application of synchronous fluorescence in identification of spilled oil at sea. Spectroscopy and Spectral Analysis 31(1): 154-157.

- Zhicheng C, Wenqing L, Nanjing Z (2008) Research on rapid measurement method for oil concentration in water. Spectroscopy and Spectral Analysis 28(6): 1332-1335.

- Wang C, Wang X, Wang Y, Gao J, Zheng R (2006) Fluorescence analysis of crude oil samples based on different spectral approaches. Spectroscopy and Spectral 110 Analysis 26(4): 728-732.

- Youquan Z, Xuefeng L, Ying L (2012) Study on fluorescence contour line characteristic spectrum analysis of petroleum fractions. 33(6): 1275-1280.

- Renjie Y, Xiaoxuan X, Liping S (2006) Determination of solvent oil in diesel by three-dimensional fluorescence spectroscopy difference spectroscopy. Spectroscopy and Spectral Analysis 26(1): 94-96.

- Yan Z, Shiyuan Z, Ping L (2009) Discussion on the identification of crude oil indicators by 3D fluorescence spectroscopy. Spectroscopy and Spectral Analysis 29(12): 3335-3338.

- Yutian W, Yanlin Z, Jinyu W (2010) Research on oil identification technology based on three-dimensional fluorescence spectrum feature analysis. Acta Photonica Sinica 39(7): 1330-1333.

- Xiao X, Zhang YJ, Wang ZG, Jin D, Yin GF, et al. (2010) Experimental studies on three-dimensional fluorescence spectral of mineral oil in ethanol. Spectroscopy and Spectral Analysis 30(6): 1549-1554.

- Guangjun T (2008) Feature extraction and spectral reconstruction of three-dimensional fluorescence spectra of mineral oils in water. Spectroscopy and Spectral Analysis 28(14): 895-899.

- Qingling L, Jun P, Dedong T (2014) Overview of crude oil water content measurement technology. Journal of Chongqing University of Science and Technology (Natural Science Edition) 16(5): 89-92.

- Jinqi W, Yong Z, Rui L (2006) A high-precision measurement method for low water content in crude oil based on near-infrared spectral absorption. Piezoelectricity and Acousto Optics 5: 514-516.

- Jian H, Yuzhao L, Zhimin C, Qiang L, Haiwei M (2019) Ultra sparse representation method for infrared spectroscopy measurement of crude oil moisture content. Journal of Instrumentation 40(06): 78-85.

- Jian H, Yuzhao L, Zhimin C, Qiang L, Haiwei M (2019) Near-infrared spectral water content analysis of high water cut crude oil by SPA-PLS. Spectroscopy and Spectral Analysis 39(11): 3452-3458.

- Xin D, Xiaorong S, Cuiling L (2020) Infrared spectroscopy rapid detection technology for water content in crude oil. China Testing 46(1): 50-55.

- Yufei Y, Cuiling L, Xiaorong S, Jingwei W, Xin D, et al. (2020) Measurement method of crude oil moisture content based on ATR-FTIR spectroscopy. Sensors and Microsystems 39(12): 134-136.

- Hongming L, Yujuan L, Zhicheng Z, Ying S, Zhe L, et al. (2021) A near-infrared spectral detection and analysis method for the water content of oilfield crude oil. Spectroscopy and Spectral Analysis 41(02): 505-510.

- Rasel RK, Straiton B, Marashdeh Q, Teixeira FL (2021) Toward water volume fraction calculation in multi-phase flows using electrical capacitance tomography sensors. IEEE Sensors Journal 21(6): 7702-7712.

- Hossain MS, Abir MT, Alam MS, Volakis JL, Islam MA (2020) An algorithm to image individual phase fractions of multiphase flows using electrical capacitance tomography. IEEE Sensors Journal 20(24): 14924-14931.

- Rasel RK, Straiton BJ, Solon A, Marashdeh QM, Teixeira FL (2021) Deep learning based volume fraction estimation for two-phase water-containing flows. IEEE Sensors, Sydney, Australia, pp. 1-4.

- Guibin Z, Deyun C, Xiaoyang Y (2002) Genetic algorithm-based image reconstruction algorithm for two-phase flow capacitance tomography. Computer Simulation 05: 36-38.

- Haichao Y, Gonghe H, Chengcheng L (2023) Two-phase flow parameter measurement method using multi-task learning and electrical capacitance tomography. Journal of Xi'an Jiaotong University 57(03): 202-211.

- Rasel RK, Chowdhury SM, Marashdeh QM, Teixeira FL (2022) Review of selected advances in electrical capacitance volume tomography for multiphase flow monitoring. Energies 15: 5285.

- Wrasse AN, Santos EN, Silva MJ, Wu H, Tan C (2022) Capacitive sensors for multiphase flow measurement: A review. IEEE Sensors Journal 22(22): 21391-21409.

© 2023 Hu Shaolin. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)