- Submissions

Full Text

Progress in Petrochemical Science

Crosslink Density Study on Rubber Vulcanizates Using a Dynamic Mechanical Analyzer

Ajay C*, Reshma Pal, Saikat Das Gupta and Rabindra Mukhopadhyay

Hari Shankar Singhania Elastomer and Tyre Research Institute, India

*Corresponding author:Ajay C, Hari Shankar Singhania Elastomer and Tyre Research Institute (Hasetri), Mysuru-570016, India

Submission: May 03, 2023;Published: May 09, 2023

ISSN 2637-8035Volume5 Issue3

Abstract

A quantitative method of measuring crosslink density by using a Dynamic Mechanical Analyzer (DMA) is described here in this study. This method is based on the measurement of storage modulus on cured vulcanizate samples through a simple temperature sweep. The Molecular weight between crosslinks and the crosslink density obtained by DMA was further compared with the solvent method using the Flory-Rehner approach. The selected rubber matrix was Natural Rubber (NR) and the study was carried out by the conventional vulcanization system. The cure time varied proportionately below and above the tC90 obtained through rheometric study at wide intervals.

Keywords:Modulus; Vulcanizate; Temperature; Molecular weight; Natural rubber

Abbreviations:DMA: Dynamic Mechanical Analyzer; NR: Natural Rubber; CV: Conventional Vulcanization

Introduction

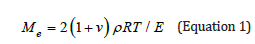

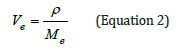

The Crosslink density is an important requirement for understanding the functional properties of rubber vulcanizates. During crosslinking, polymer segments from different polymer chains get interconnected by covalent/ionic linkages. Conventional Vulcanization (CV) is the most common curing approach in industries. The change in crosslink density will have a direct influence on the Mechanical properties, which are the governing parameters for the performance of the final products like tyres. There are different techniques available to detect the crosslink density like Mooney Rivlin, Thiol-amine method, Dynamical flocculation model, Temperature Scanning Stress Relaxation, NMR method, etc. [1]. The conventional method of determination of cross-link density by the Flory-Rehner Equation is the most common approach [2]. Flory-Rehner described the mixing of polymer and liquid molecules as predicted by the equilibrium swelling theory. This process is time-consuming and needs interaction parameters in which most cases are not available. In this study, the mixing of rubber compounds was carried out in two stages (Master and Final) in a 1.5L volume Laboratory Banbury mixer (Stewart Bowling, USA) having a two-wing tangential rotor with a temperature control unit. Initially, the natural rubber along with the peptiser (DBD) was added into the mixer and masticated for the 30s. Followed by, the carbon black, process oil, zinc oxide, stearic acid, and process aids, were added to the mixer. The master batch was dumped after a total of 300s. The dump temperature (display) of the master batch compounds was found to be between 140 and 145 °C. The master batch compound along with the curative package, viz, sulfur, TBBS, and DPG was added into the mixer at 0s and dumped after 180s. The observed display dumb temperature of the final batch compound was found to be between 90-95 °C. The tensile slabs were compression moulded at different cure rate by using Hydraulic curing press (Hind Hydraulics, India). Based on the tc90’ (min.) value from the rheometric study, slabs were cured at 20% to 200% (at an interval of 20%) and 300% of tc90’ (min.) respectively for this study. Crosslink density measurements through the swelling method are performed and calculated by using Flory-Rehner Equation1 for comparison with Dynamic Mechanical AnaCrimson lyzer measurements. Crosslink density measurements by Dynamic Mechanical Analyzer are performed through a Temperature Sweep. The Molecular weight between the crosslinks was calculated by using the following equation [3].

Where, Me is Molecular weight between the crosslinks (g/mol) by using Dynamic Mechanical Analyser, v is the Poisson ratio (0.5), is the Polymer density in (g/cc), R is the gas constant, T is the absolute temperature and Eʹ is Storage Modulus (MPa) from Dynamic Mechanical Analyzer.

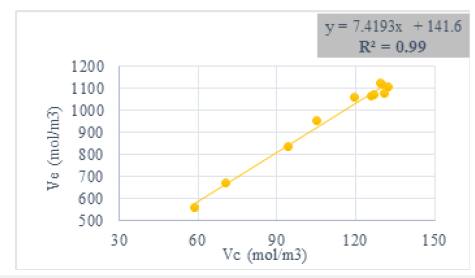

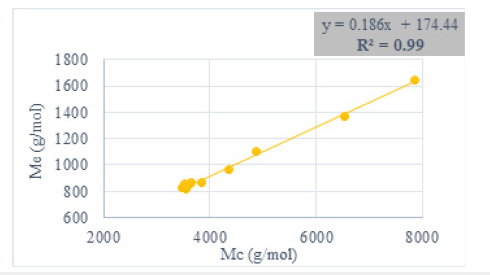

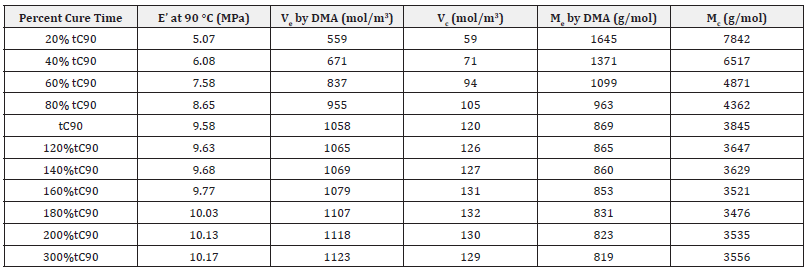

Where Ve is crosslink density per unit volume in mol/cc by Dynamic Mechanical Analyzer Method and Me obtained from Equation 1. Temperature sweep of cured rubber vulcanizates was performed by using a Dynamic Mechanical analyzer from ACOEM, France. Cured test pieces were subjected to a Temperature from 60 °C to 120 °C at the constant dynamic strain of 0.2% and at a frequency of 1Hz. The tests were carried out in tension mode. The specimen for tension mode was punched out from the slabs. The specimen dimension was a strip of 25mm in length, 10mm in width, and 2.0mm ± 0.2mm in thickness. The test length was 10mm ± 1.0mm with the remainder of the strip in the grips. Table 1. Crosslink Density by Swelling is always lesser compared to DMA studies. However, the trend remains the same. There is an increase in the crosslink density upon increasing the cure rate in both studies Figure 1. Chemical crosslinks are studied in Swelling Method whereas both the Physical and Chemical crosslinks have been measured in the DMA Study Figure 2 [4].

Figure 1:Cross Link Density Study DMA vs Swelling Study.

Figure 2:Molecular Weight Between Crosslinks DMA vs Swelling Study.

Table 1: NR CV study.

Conclusion

The results show a good correlation between the Crosslink density measurement study using Dynamic Mechanical Analyzer and the conventional Flory-Rehner approach. In addition to the crosslink density measurements, understanding the molecular weight between the crosslinks is also possible by using DMA Method. The test method is less time-consuming and involves very few assumptions compared to the swelling method.

Acknowledgement

The authors would like to thank the Management of Hari Shankar Singhania Elastomer and Tyre Research Institute for granting permission to publish this work.

References

- Blume A, Kiesewetter J (2019) Determination of the crosslink density of tire tread compounds by different analytical methods. KGK Kautschuk Gummi Kunststoffe 72(9): 33-42.

- Bryan Ellis, Welding GN (1964) Estimation, from Swelling, of the Structural Contribution of Chemical Reactions to the Vulcanization of Natural Rubber. Part II. Estimation of Equilibrium Degree of Swelling. Rubber Chemistry and Technology 37(2): 571-575.

- Evan MC, Steven DR, Douglas W, Citters V, Dartmouth College, Hanover, New Hampshire, USA.

- Çakmak EG, Dalgakiran D, Guner FS (2018) Castor oil and PEG-based shape memory polyurethane films: effect of chain extender amount on some polymer properties and performance. Turkish Journal of Chemistry 42(4): 1161-1173.

© 2023 Ajay C. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)