- Submissions

Full Text

Progress in Petrochemical Science

The Requirement Change of Korea Government About HIPS

Jinhyung Park , Sangki Kim, Youngse Kim, Sang-Wook Han and Kyoshik Park*

Safety Health Convergence Engineering Department, Soongsil University, Korea

*Corresponding author:Kyoshik Park, Safety Health Convergence Engineering Department, Soongsil University, 369 Sangdoro Dongjakgu Seoul, Korea

Submission: March 29, 2023;Published: April 25, 2023

ISSN 2637-8035Volume5 Issue2

Abstract

The proper flare stack design becomes a big issue after refinery plant explosion accident in USA in 2005. API 521 was upgraded several times for better flare stack design after 2005. Safety Instrumented Level (SIL) 3 High Integrity Protection System (HIPS) is important equipment to reduce flare load capacity according to API 521. Korea government reviewed and approved the flare stack design from 2005 based on API 521, but Korea government started to require stricter supplementation based on IEC 61511 than API 521 after flare stack overload incident in 2017. Even though SIL 3 HIPS plays an important role to prevent flare stack overload while the flare stack capacity is below maximum flare load, Korea government require HAZOP report, LOPA report, Safety Requirement Specification (SRS), SIL verification report and Functional Safety Management System (FSMS) to keep SIL 3 properly during HIPS lifecycle.

Keywords:Flare stack; API 521; IEC 61511; SIL; HIPS

Abbreviations:

HIPS: High Integrity Protection System; SIL: Safety Integrity Level; BP: British Petroleum; API: American Petroleum Institute; IEC: International Electrotechnical Commission; SRS: Safety Requirement Specification; FSMS: Functional Safety Management System; PSV: Pressure Safety Valve; HAZOP: Hazard and Operability; LOPA: Layer of Protection AnalysisIntroduction

Flammable liguid was overflowed on the blowdown drum of refinery plant and 15 workers were dead and dozens of workers were injured in USA in 2005 [1]. The accident investigation report say that the design load capacity of blowdown drum was not enough, so the blowdown drum overflowed after Pressure Safety Valve (PSV) opened by overpressure on raffinate splitter tower in isomerization unit. SIL 3 HIPS was required to prevent the overflow in undersized pressure relieving and depressuring systems on revised API recommended practice 521 after this accident. HIPS is one of Safety Instrumented System (SIS) to prevent the explosion incident by overpressure or overtemperature. Korea government swiftly adapted the revised API 521 and SIL 3 HIPS started to be applied to the undersized flare stack or vent gas scrubber of refinery, petrochemical, chemical plants in Korea from 2005 [2]. Unfortunately the flare stack overload incident occurred in one of petrochemical plants which SIL 3 HIPS was installed in Korea. Even though there was no fatality and injury by this incident, the Korea government took this incident seriously [3]. Korea government thought that the wrong management of HIPS may disable the function of HIPS, so the stronger requirements about the management of HIPS should be enforced [4]

Observation

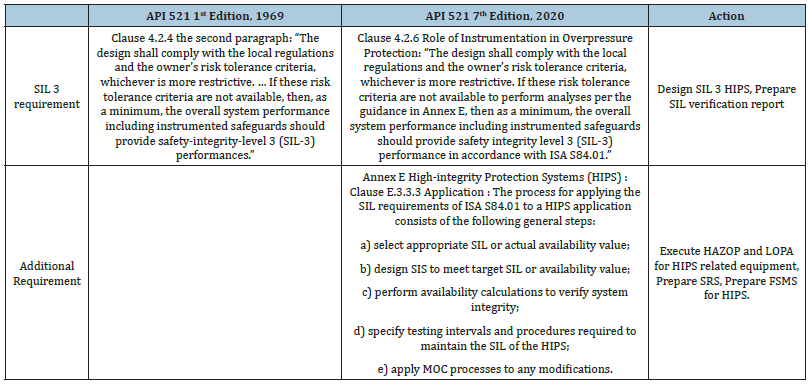

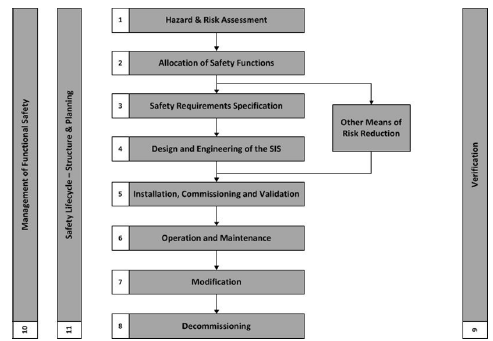

Korea government regulators reviewed IEC 61511, API RP 14C, API 521, etc for stricter requirements about flare stack related HIPS. Especially Korea Occupational Safety & Health Agency (KOSHA) prescribed the additional requirements on the supplements of KOSHA PSM review report from 2020 [5]. Additional requirements about SIL 3 HIPS was described on ‘KOSHA GUIDE D-59-2020 technical guide for design, installation and operation of flare system” which was published in 2020 [6]. Korea government regulators required Hazard and Operability (HAZOP) study report, Layer of Protection Analysis (LOPA) report, Safety Requirement Specification (SRS), SIL verification report, Functional Safety Management System (FSMS) to meet IEC 61511 SIS lifecycle. Especially architectural constraints, Probability of dangerous Failure on Demand (PFDavg), Systematic Capability (SC) were required in SIL verification report based on IEC 61508 part 2 edition 2.0 which was published in 2010 (Table 1). The followings were required to reduce the common cause factor for SIL 3 HIPS based on IEC 61508 part 6 table D.1 scoring programmable electronics or sensor/final elements; separation, diverse redundancy, high self-diagnostic coverage, internal procedures in relation with SIS management, competence, training, safety culture, good environment, etc. SIL 3 HIPS shall be applied for the required equipments on flare stack (or vent gas scrubber) load summary. SRS should include at least 27 detailed requirements including override, reset, process safety time, response time, diverse, separation, etc. It is strongly recommended to include security requirements in SRS based on IEC 61511 edition 2.0 which was published in 2016 [7]. FSMS shall include all detailed procedures about each phase of (Figure 1), [8-10] and all functional safety related procedures like override procedure, reset procedure, proof test procedure, partial stroke test procedure, maintenance procedure, Management of Change (MOC) procedure, startup procedure, verification procedure for each phase, assessment plan and role & responsibility, etc to prevent the incidents caused by wrong management of SIS. API RP 14C requires the separationa and independence between the two level of protection, such as ESD and HIPS, to prevent or minimize the effects of an equipment failure within process.

Table 1:The requirement changes of API RP 521.

Figure 1IEC 61511 SIS lifecycle.

Conclusion

The flareload overload incident in Korea made Korea government reconsider the previous regulations about flare stack and SIS and finally Korea government developed and applied more systematic regulations to prevent similar incident. It is very desirable that the incident investigation methodology of Korea government regulators becomes more sophisticated and the countermeasures to prevent the repetition of similar incident by upgrading regulations with the study of the international standards. As required in IEC 61508 and IEC 61511, only hardwares for fail safe function like SIS are not enough and the proper system to reduce systematic failures and human errors in relation with SIS must be accompanied.

References

- (2014) API Recommended practice 521 pressure-relieving and depressuring systems, (6th edn).

- (2016) IEC 61511 Functional safety-safety instrumented systems for the process industry sector, edition 2.0.

- (2017) API RP 14C Recommended practice for analysis, design, installation, and testing of basic surface safety systems for offshore production platforms, (8th edn).

- KOSHA GUIDE D-59-2020 Technical guide for design, installation and operation of flare system.

- (2010) IEC 61508 Functional safety of electrical/electronic/programmable electronic safety-related systems, (2nd edn).

- KOSHA GUIDE D-69-2020 Technical guide to improve the safety of chemical equipments by SIS.

- (2015) High Integrity Pressure Protection Systems (HIPPS): Design, analysis, justification and implementation. In: Luis M, Garcia G, Flalkowski C, Sud V, Christopher N (Eds.), Safety Control Systems Conference.

- Adams E, Bills G (2000) High integrity protective systems-conclusion: QatarGas plant reflects typical HIPS applications, , Oil & Gas Journal.

- Summers AE (2000) High Integrity Pressure Protective Systems (HIPPS), Chemical Engineering Progress, Loss prevention symposium 2000, Instrument Engineers Handbook, Chapter 2.6, SIS Tech Solutions 3: 1-15.

- (2015) High Integrity Protection Systems-Recommended Practice. International Association of Oil & Gas Producers, IOGPReport 443.

© 2023 Kyoshik Park. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)