- Submissions

Full Text

Progress in Petrochemical Science

Enhanced Oil Recovery: Methods and Applications Review

Mansour EM1* and Ragab A2

1Production Department, Egyptian Petroleum Research Institute, Egypt

2Reservoir Engineering Department, Agiba Petroleum Company, Egypt

*Corresponding author: Mansour EM, Production Department, Egyptian Petroleum Research Institute, Cairo, Egypt

Submission: September 10, 2021;Published: October 14, 2021

ISSN 2637-8035Volume4 Issue2

Abstract

Recently, the Enhanced Oil Recovery (EOR) research and implemented projects (pilots/full field) show massive interest from all major E&P companies, especially CO2 injection or flooding in oil reservoirs, to improve the oil recovery of the target reservoirs. Enhanced Oil Recovery (EOR) projects are usually applied after the secondary recovery phase. The Enhanced Oil Recovery (EOR) application is to recover the remaining oil, after the primary and secondary recovery phases, via enhancing the oil displacement and sweep efficiencies. The oil displacement efficiency could be improved by reducing the oil viscosity or lowering the interfacial tension. In contrast, the sweep efficiency could be improved by developing a favorable mobility ratio between the displacing fluid and the remaining oil.

Keywords: Enhanced oil recovery; EOR; Reservoir lithology; CO2; Steam injection; Air injection; Chemical flooding

Abbreviations: EOR: Enhanced Oil Recovery (EOR); HPAI: High-Pressure Air Injection; CHOP: Cold Heavy Oil Production

EOR Overview

The world will encounter a new challenge in the energy field called Enhanced Oil Recovery (EOR) technologies, where discovering hydrocarbon reservoirs will decrease, and nonrenewable energy will play a key role [1]. Therefore, increasing the recovery factors after primary and secondary production in mature reservoirs will be critical in the growing energy demand in the coming years. Many tertiary recoveries (EOR) methods are chemical flooding, gas injection, and thermal flooding [2]. Choosing the best way to increase oil recovery factors by enhanced oil recovery methods depends on recovery parameters screening, such as rock characteristics, availability of injection material, the reservoir fluid type, available equipment, oil properties, and other items [3].

EOR Status

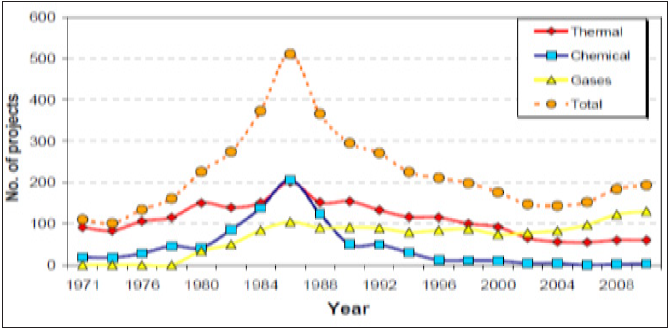

All projects of EOR are strongly influenced by economics and crude oil prices. From the 1980s to 2005, thermal and chemical flooding EOR projects have been in constant decline [4]. Only two projects in 2008 were done in chemical EOR flooding projects. While as a result of increasing High-Pressure Air Injection (HPAI) projects in volatile oil reservoirs, thermal EOR flooding projects have presented a slight increase in 2004. Gas injection flooding projects have remained constant since 1908’s and more development since the year 2000 due to extensive cheap sources of CO2 from natural resources, as (Figure 1) [5]. Different EOR technologies have been evaluated successfully in Karazhanbas (Kazakhstan), Carmópolis (Brazil), and Buracica fields. Buracica field is an onshore volatile oil reservoir with 35 °API. Some flooding projects are reported as air injection from 1978 to 1980, immiscible CO2 flooding injection in 1991, and polymer flooding injection in 1997. On the other hand, Carmópolis field is a heavy onshore crude oil with °API=22. The reservoir was mainly injected by waterflooding and in situ-combustion from 1978 to 1989, steam injection in 1978, polymer flooding from 1969 to 1972, and microbial EOR in 2002 pilot projects.

Figure 1: Evolution of EOR projects in the United States (From Oil & Gas Journal 1976-2008).

Karazhanbas field is a heavy onshore oil with °API=19. The reservoir is reported by steam injection, polymer flooding, insitu combustion with foam injection. Karazhanbas field was also developed by waterflooding, CHOPS, or Cold Heavy Oil Production. The 1980s is the best time for chemical EOR flooding in sandstone reservoirs, where polymer flooding was the most applied method in 1990. In sandstone reservoirs, polymer flooding EOR is still the essential EOR chemical process [6]. There is a large scale of polymer flooding projects in Canada (Pelican Lake field), Argentina (El Tordillo Field), Canada (Horsefly Lake Field), Brazil (Voador offshore Field), China with around twenty projects (e.g., Gudong, Gudao , Daqing, Karamay fields and among others), the U.S. (North Burbank, Oklahoma field) and India (Jhalora Field). During the 1980s, polymer flooding was developed in North Burbank to increase oil recovery in 19-mature wells [7]. Also, India has a polymer flooding in Sanand field. Also, Marmul Field documented a polymer flooding in Oman; twenty years later, a large-scale study is in progress. Several EOR chemical processes other than polymer flooding, such as ASP flooding, have been studied and examined in Daqing for more than 15 years [8]. Gudong, Karamay, Liahoe, and Shengli fields are other examples of Chinese ASP projects documented in the literature. During the last decade, additional EOR chemical flooding was recorded as [9-11].

A. ASP flooding in Viraj Field, India, West Kiehl, Sho-Vel-Tum, Cambridge Minnelusa, and Tanner fields in the U.SA.

B. AP flooding projects in David Pool field in Canada and Xing Long Tai Oil Field in China.

Recently, a reservoir with specific characteristics in Mexico was selected to simulate the mature field performance with thermal pilot projects are theorized. As a consequence of this study, it had been proven that at specific conditions and adding up incentives package, there is a win-win schema where the operators and government obtain higher revenues than exploiting conditions of the fields only with natural depletion. So in Mexico, the potential for Enhanced Oil Recovery (EOR) is characterized by 80% than the total production from mature fields [12].

Conclusion

Thermal recovery methods, exclusively steam injection, still dominate as the preferred Enhanced Oil Recovery (EOR) method for heavy oil reservoirs. Gas injection methods continue to be the preferred recovery process in condensate gas reservoirs, offshore fields, and fields in remote locations without access to gas markets. CO2 injection is the most method attraction in EOR methods and potentially as a sequestration strategy in recent years. But still, EOR projects by CO2 are primarily concentrated in the U.S. and associated with CO2 natural sources. But chemical EOR methods have been made a small impact on the world’s oil production throughout the last decades. Even with the increasing research on chemical flooding by a different approach to improving oil recoveries in carbonate formations, these projects are not expected to impact global oil production soon.

References

- Mansour E, Al-Sabagh AM, Desouky SM, Zawawy FM, Ramzi M (2019) A laboratory investigation of carbon dioxide-enhanced oil recovery by focusing on CO2-oil physical properties. Egyptian Journal of Petroleum 28(1): 21-26.

- Mansour E, Al-Sabagh AM, Desouky SM, Zawawy FM, Ramzi M (2016) Experimental approach of minimum miscibility pressure for CO2 miscible flooding: Application to Egyptian oil fields. International Journal of New Technology and Research (IJNTR) 2(5): 105-112.

- Alvarado V, Manrique E (2010) Enhanced oil recovery: An update review. Energies 3(9): 1529-1575.

- Mansour E, Al-Sabagh AM, Desouky SM, Zawawy FM, Ramzi M (2018) A new estimating method of minimum miscibility pressure as a key parameter in designing CO2 gas injection process. Egyptian Journal of Petroleum 27(4): 801-810.

- Ragab A, Mansour EM (2021) Enhanced oil recovery: Chemical flooding. Geophysics and Ocean Waves Studies, pp. 1-51.

- Chakabaev S (1978) Injection of water thickened by polyacrylamide-Industrial experiment in the karazhanbas field. 1: 7-12.

- Brigham WE, Castanier LJH and T.O.R.P. Mechanisms, (Reservoir Engineering Section) In-situ p. 171.

- Antoniady D (1993) Chg thermal recovery methods at the former su oil-fields. 10: 24.

- Chang H, Zhang ZQ, Wang QM, Xu ZS, Guo ZD, et al. (2006) Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the people's republic of China. Journal of Petroleum Technology 58(2): 84-89.

- Zhijian Q, Zhang Y, Zhang X, Dai J (1998) A successful ASP flooding pilot in Gudong oil field. SPE Improved Oil Recovery Conference.

- Qi Q, Hongjun G, Dongwen L, Ling D (2000) The pilot test of ASP combination flooding in Karamay oil field. International Oil and Gas Conference and Exhibition in China.

- Espinola O, Nunez F, Malibran PT (2021) Proposal EOR fiscal incentives to increase the recovery factor in Mexican fields implementing enhanced oil recovery methods through sensitivity analysis with different contracts. SPE Trinidad and Tobago Section Energy Resources Conference.

© 2021 Mansour EM. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)