- Submissions

Full Text

Progress in Petrochemical Science

Influence of Fly and Sludge Ash in Oily Sludge Gasification

Reem Ahmed1* and Chandra Mohan2

1Department of Chemical Engineering, Petronas University of Technology, Malaysia

2Department of Fundamental and Applied Sciences, Petronas University of Technology, Malaysia

*Corresponding author: Reem Ahmed, Department of Chemical Engineering, Petronas University of Technology, Malaysia

Submission: August 12, 2020;Published: July 29, 2021

ISSN 2637-8035Volume4 Issue2

Opinion

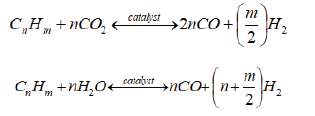

Although the gasification approach has been used as an advantageous route for the production of syngas, the presence of condensable organic compounds or tar in the product gas is invariably problematic [1,2]. The persistent build-up of tar in the flue gas makes the gas unsuitable for particular applications and induces blockages and corrosion in downstream installations, thereby decreasing overall gasification performance. Fuel and catalyst are also applied directly to the gasifier, which works under the pre-set conditions of the reactor, to generate product gas along with liquid tar and solid fly ash [1-4]. This analysis should concentrate on product gas, heating value, fuel gas vol percent, cold gas and carbon conversion efficiency. It will also discuss the effect of catalysts on syngas production in terms of shifting water-gas shift reactions in a favorable forward direction. In addition, this paper would explore the influences of coal fly ash that can be used as an in-bed catalyst [5,6]. Both catalysts can be added directly to the reactor. The presence of a fly and sludge ash catalyst to transform liquid tar into gaseous materials increases the output of hydrogen by transferring the water-gas reaction to the forward direction. Experiments can be performed to assess the catalytic impact of fly and sludge ashes using varying percentages. In this respect, we suggest that the combination of these catalysts with sludge fuel would minimize the agglomeration of metal oxides within the reactor. The goal of this study is to reduce the yield of tar and to increase the production of gas through cheap catalysts. This will increase the output of fuel gases as follows:

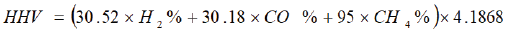

The heating value of the producer gas in (MJ Nm-3), considering the volumetric percentages of gas, is (CO, H2, CH4) as shown below.

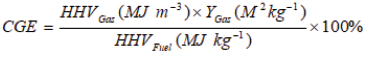

Cold gas efficiency is a standard criterion frequently cited to indicate the energy efficiency of the gasification process, depends on the gas and fuel heating values, CGE is determined by the equation below.

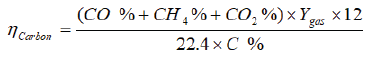

Carbon Conversion Efficiency (CCE) is one of the common performance measures used in the gasification process and is defined as the weight of the carbon content of the producer gas by the weight of the carbon content of the hydrocarbon material. The CCE can be estimated as:

Where C% is carbon percentage of fuel.

References

- Sutton D, Kelleher B, Ross JRH (2001) Review of literature on catalysts for biomass gasification. Fuel Process Technol 73(3): 155-173.

- Han J, Kim H (2008) The reduction and control technology of tar during biomass gasification/pyrolysis: An overview. Renew Sustain Energy Rev 12(2): 397-416.

- Ismail KN, Hussin K, Idris MS (2007) Physical, chemical & mineralogical properties of fly ash. ICXRI-2006: International Conference on X-ray and related Techniques in Research and Industry; Putrajaya Malaysia 4(1-2): 47-51.

- Blissett RS, Rowson NA (2012) A review of the multi-component utilization of coal fly ash. Fuel 97: 1-23.

- Ojha K, Pradhan NC, Samanta AN (2004) Zeolite from fly ash: synthesis and characterization. Bull Mater Sci 27(6): 555-564.

- Arenillas A, Smith KM, Drage TC, Snape CE (2005) CO2 capture using some fly ash-derived carbon materials. Fuel 84(17): 2204-2210.

© 2021 Reem Ahmed. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)