- Submissions

Full Text

Novel Techniques in Nutrition and Food Science

Production and Quality Assessment of Composite Bread Using Wheat Flour and Coconut Flour

Adomako C, Asante RO* and Odoom W

Faculty of Applied Sciences, Department of Food/Postharvest Technology, Koforidua Technical University, Ghana

*Corresponding author:Regina Ofori Asante, Faculty of Applied Sciences, Department of Food/Postharvest Technology, Koforidua Technical University, Ghana

Submission: May 30, 2023;Published: June 27, 2023

ISSN:2640-9208Volume7 Issue3

Abstract

There is an increasing demand for Fiber-rich food and food ingredients. In this study, coconut, which is high in dietary fiber was processed into flour (CF) and substituted at 20%, 30%, and 100% levels for Wheat Flour (WF) in composite bread formulation. A 100% WF bread was used as a control. Sensory evaluation was conducted using a 5-point hedonic scale with 25 panelists evaluating the bread based on color, texture, taste, flavor, and overall acceptability. This study was focused on the use of coconut and wheat composite flour in the production of bread. Proximate analysis of the coconut flour, physical properties, and sensory characteristics of the composite bread samples was studied. Results obtained showed that the bread volume increased significantly in sample B (20% CF 80%WF) (240.26±0.00cm3) and it compared favorably with the control (100%WF). Besides, the specific bread volume observed in this study ranged from 0.94 to 1.55cm3/g. The sensory analysis conducted showed that there were significant differences (P<0.05) between the control and the composite bread samples in the sensory attributes of color, texture, flavor, taste, and overall acceptability. Again, it was realized that sample B was the most preferred sample in terms of its color, texture, flavor, taste, and overall acceptability. This was followed by sample C. My least preferred was the 100%CF bread.

Keywords:Production; Quality assessment; Coconut flour; Wheat; Composite bread

Introduction

Coconut (Cocos nucifera) from the Arecaceae family contains higher amounts of dietary fiber and other nutrients [1]. Coconut is low in digestible carbohydrates and contains no gluten [2,3]. Coconut has been found to have a glycemic lowering effect [4]. Low glycemic index food particularly food containing high dietary fiber, has been demonstrated to moderate post-prandial blood glucose and insulin responses enhancing the blood-glucose and lipid concentrations in humans, and patients having diabetes mellitus [4]. Moreover, coconut is well-known for the production of coconut milk, coconut oil, and flour; the flour can be utilized to produce several delicious pies, cookies, cakes, bread, snacks, and desserts [2]. Besides, the press cake from coconut oil processing is used as animal feed. Coconut-Pulp Flour (CF) is flour made from a by-product of coconut milk-based food products. One method to improve the nutritional and functional value of CF prior to use is by modification through the fermentation process [5,6]. The flour contains no gluten and high fiber, which can be considered functional potential food. The flour can provide not only value-added income to the country but also a nutritious and healthy source of dietary fiber [7,8]. The flour can be utilized to produce various food products, such as cookies, biscuits, brownies or bread. Bread is a food product based on Wheat Flour (WF) which poses flexible use and appropriate vehicle that can combine with various ingredients like CF for the formulation of composite flour [7,9] CF contains no gluten, therefore produce bread with poor characteristics. The main objective of the study was to assess the nutritional quality of coconut flour and its application in composite bread production. Specifically, the work will determine the proximate composition of coconut flour, the physical properties of the bread produced, and conduct a sensory evaluation on the bread sample.

Materials and Methods

Source of raw materials

The Wheat Flour (WF) used was commercial baker’s grade produced by Takoradi Flour Mills (All-Purpose (Plain) Flour, Ghana). Margarine, Baker’s yeast, iodized salt, and colorless granulated sugar were purchased from a local market in Koforidua, Ghana. Coconut used was purchased from the Agatha market in Koforidua.

Preparation of coconut flour

Coconut fruits were sorted and processed to extract coconut milk by blending the pulp in a liquidizer containing 0.5L of boiled water for 3-5min until the pulp was fairly smooth. The milk was then separated from the meal using a cheesecloth and the resulting residue was washed thoroughly with boiling water to enhance the complete removal of milk and oil from the residue. It was drained, sun-dried (14% moisture), and ground using a miller (model HL 3294/C Phillips) to obtain fine flour.

Physical Analysis of Bread Samples

Loaf weight

The loaf weight was determined by weighing the dough before baking and bread loaves after baking, using the laboratory scale (CE-410I, Camry Emperors, China), and the readings were recorded in grams.

Loaf volume

The loaf volume was determined by the Rapeseed seed displacement method. This was done by loading millet grains into an empty box with calibrated marks until they reached the marked level and unloaded back. The bread sample was put into the box and the measured millet was loaded back again. The remaining millet grains left outside the box were measured using a measuring cylinder and recorded as the loaf volume in cm3.

Specific volume

The specific volume (volume to mass ratio) (cm3/g) was thereafter calculated using the equation.

Specific volume cm3/g=Loaf volume/Loaf weight ……. Equation No (1)

Baking process

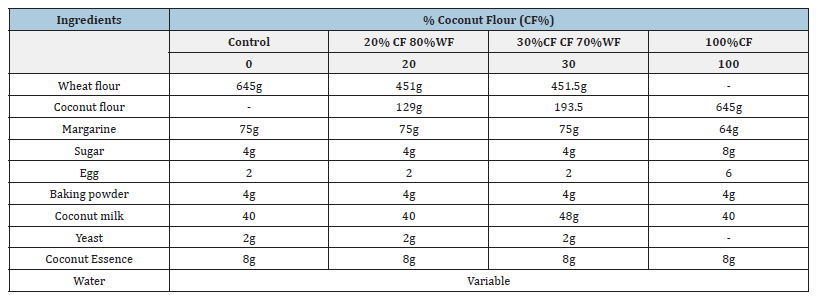

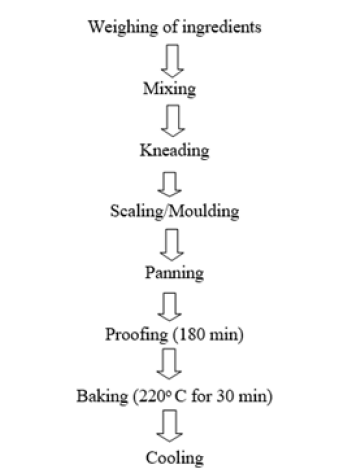

Preparation of the bread was done by dry mixing of wheat flour with different levels (0%, 20%, 30%, and 100%) of Coconut Flour (CF) inclusion. The blends were then passed through a 30-mesh sieve for their uniform mixing. Yeast bread was prepared from all blends and the straight dough development procedure [2] was used with slight modification. The ingredients for two samplers are given in Table 1. Fermentation was conducted at 30-35 °C. The total fermentation period of dough was 180min with first punching after 90min and second after an additional 40min. Baking was done at 220 °C for 30min at a relative humidity of 80%. Figure 1 shows the flow chart of the bread-making process.

Table 1:Baking formula and conditions for the developed bread loaf.

Figure 1.Flow chart of the bread-making process.

Proximate analysis

Moisture content (Oven dry method), fat content (Soxhlet extraction), crude fiber content, and ash (Gravimetric) content were determined according to methods prescribed by AOAC [10]. Protein content was determined by the Kjeldahl method [10]. Carbohydrate content was determined by difference.

Sensory evaluation

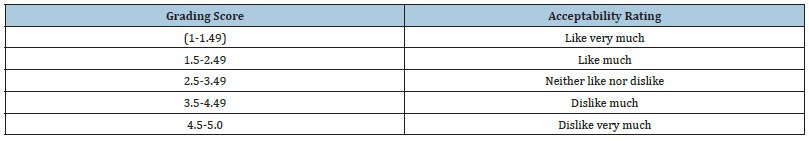

A sensory evaluation was undertaken to assess the bread quality using 20 students as panelists who assessed the sensory attributes of crust color, aroma, taste, texture, and overall acceptability based on a 5-point hedonic scale (Table 2) as described by Ihekoronye & Ngoddy [11]. Samples were coded with three-digit random numbers and served in random order for the panelists. Panelists were asked to rank each quality attribute of the bread.

Table 2:Acceptability ratings.

Statistical analysis

Data was subjected to Statistical Analysis of Variance (ANOVA) at 5% level, and the means were separated using the Duncan Multiple Range Test.

Result and Discussion

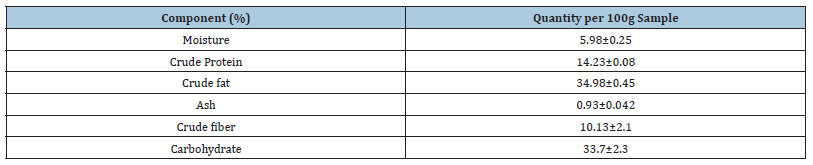

The results obtained from the proximate analysis of the coconut flour are shown in Table 3. The results were quite different from those reported by other authors [12,13]. Different researchers using different methods have come up with different figures for coconut flour composition. The composition of coconut flour depends on the retention of components after the extraction of coconut milk or oil from desiccated coconut and also, the drying method. Therefore, the composition of coconut residue also will change propor tionately. Gunathialake et al. [14] reported that coconut flour contains 7.6% protein, 14% fat, approximately 17% crude Fibre, and 5% moisture. Arancon [15] reported on the nutritional composition of coconut flour as; Protein 13.41%, Moisture 2.80%, Crude Fat 10.23%, and Crude Fibre 19.3%. The differences between results obtained in this work as compared to those earlier reported might be due to the variety of coconut used, edaphic factors the method used in the extraction of the milk or oil as well as the drying method. Other contributory factors may be due to the sun drying method adopted for drying and the homemade procedure used in extracting the milk from the coconut. These might have contributed to the differences in the proximate composition obtained in this study. A higher percentage of fat in the coconut flour (34.98%) was recorded in this work as compared to that of the chemical composition of coconut flour in other studies [14].

Table 3:Nutrient composition of coconut flour.

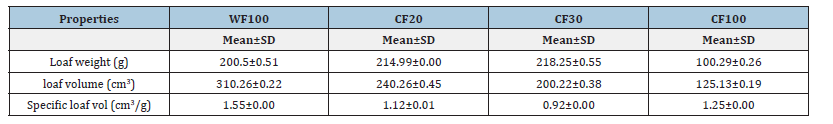

Table 4:The Physical properties of the composite flour bread samples.

Table 4 shows the effect of inclusion levels of Coconut Flour (CF) on the physical characteristics (loaf weight, loaf volume, and specific loaf volume) of the composite flour bread samples. The measurement of weight, volume, and specific volume of bakery products give an indication of the product quality [16]. Bread loaf weight is determined by the quantity of dough baked and the amount of moisture and Carbon dioxide diffused out. Coconut fiber has high water binding macromolecules that compete with starch and other flour ingredients for water. Loaf weights of bread differed significantly (p<0.5) with increased coconut flour inclusion. The values ranged from 100.29g-218g with the highest value (218g) obtained for 30% coconut flour inclusion and the lowest value (100.29g) was recorded for bread prepared with 100% coconut flour. An increase in loaf weight may be attributed to the water added to the flour blends. This additional water was retained in the baked loaf thereby, resulting in heavier loaves. Measurement of loaf volume is regarded as the most significant bread property because it provides a quantitative measurement of baking performance. It is a good measurement of protein quality as well. The loaf volume of the bread samples decreased with an increased level of coconut flour inclusion. A significant reduction (p<0.05) was observed in the loaf volume of the bread from WF100 to CF100. A decrease in loaf volume of bread with an increased level of fluted pumpkin flour and mushroom powder has also been reported [17,18]. The decrease in loaf volume of bread may be due to the dilution effect of coconut flour on the gluten network thereby reducing the gluten strength with a ripple effect of poor carbon dioxide gas formation and retention in the baked dough. The specific bread volume observed in this study ranged from 0.92 to 1.55cm3/g. Though the range seems fairly unimportant, it was evident that significant differences (P<0.05) existed among the bread samples. It was realized that WF100 (control bread) had the highest (1.55 cm3/g) breed-specific volume as compared to the CF100 (100% Coconut flour).

The results of the specific volume of bread found in this study show that there was a considerable decrease in the specific volume of bread as the level of coconut flour inclusion increased. The lowest value (0.92cm3/g) obtained was for 30% CF inclusion. This can be attributed to the perceptual addition to wheat flour. Other studies have revealed that gluten-free flours when combined with wheat flour weaken the gluten network formed during the mixing and kneading of the dough [19], thus causing the specific volume of bakery products to decrease [20].

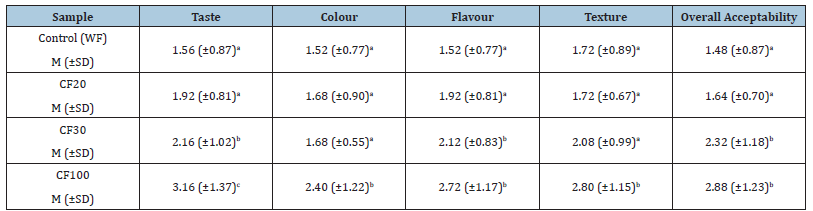

Sensory evaluation

Results of the sensory evaluation of bread samples containing different levels of coconut flour substitution as compared to the control are shown in Table 5. The results of bread color and texture did not show a consistent pattern for all the bread samples, and there was no significant difference (P >0.05) between the control and the other bread samples. The brown colors of whole wheat bread and composite breeds have been reported by several authors [21]. The brownish bread appearance could be directly related to the increase in fiber content. Moreover, browning of the bread could also occur due to caramelization and Maillard reactions, as the protein contributed by coconut flour must have reacted with sugar during the baking process Dhingra & Jood [22]. The scores for texture (softness and chewiness) of the composite bread samples, increased with an increase in coconut flour substitution when compared to the control sample (WF100). The bread with 20% coconut flour substitution (CF20), had the best texture score. The baking conditions (temperature and time variables); the state of the bread components, such as fibers, starch, protein (Gluten) whether damaged or undamaged, and the amounts of absorbed water during dough mixing, all contribute to the final texture of the bread.

Table 5:The Physical properties of the composite flour bread samples.

The whole coconut flour bread sample resulted in poor taste and texture scores. For all the sensory attributes (the texture, color, flavor, taste, and overall acceptability) assessed, sample CF100 (100% coconut flour) was least preferred among all the samples. Most of the panelists liked the coconut flavor from the coconut flour in the composite bread. The sensory evaluation also revealed that bread samples with coconut flour substitution up to 20% (CF20) was scored higher for overall acceptance even though the control sample was still preferred. The baking properties of composite flour are often impaired as well as the organoleptic attributes of the products, because of the dilution of the gluten content. Thus, different combinations of both synthetic and organic improvers such as malt flour, vital wheat gluten, and ascorbic acid can be included in dough formulation to improve the baking and sensory qualities of the products [23-25].

Conclusion

In conclusion, composite bread with coconut flour substitution (20% and 30%) was found to be relatively nutritious because of the high protein, crude fat, and crude fiber content of the coconut flour incorporated as compared to the control sample (100% wheat flour). However, the scores for the organoleptic attributes like taste, aroma, texture (mouth feel), and color were generally inferior to that of the control bread. Therefore, the control bread had better overall acceptability scores than the coconut composite bread. The composite bread would serve as a functional food because of the high fiber content. Hence, Coconut flour appears to be promising in bakery products, and it may be a suitable material for the substitution of wheat flour in product preparation. The application of coconut flour as a functional food in food products may prevent some of the prevailing chronic diseases, and also inspire the food industry to produce value-added products from coconut flour. This will help improve the production and promotion of the coconut industry.

- DebMandal M, Mandal S (2011) Coconut (Cocos nucifera L.: Arecaceae): In health promotion and disease prevention. Asian Pacific Journal of Tropical Medicine 4(3): 241-247.

- Ramaswamy L (2014) Coconut flour-a low carbohydrate, gluten free flour. International Journal of Ayurvedic and Herbal Medicine. Inter Science 4(1): 1426-1436.

- Bayalan DD (2000) The economics of production, utilization, and marketing of coconut flour from coconut milk residue. CORD 16(1): 1-8.

- Trinidad PT, Mallillin AC, Valdez DH, Loyola AS, Mercado AFC, et al. (2006) Dietary fiber from coconut flour: A functional food. Innovative Food Science and Emerging Technologies 7(4): 309-317.

- Erminawati, Sidik W, Listanti R, Zulfakar H (2017) Formulation and characterization of bread using coconut-pulp flour and wheat flour composite with addition of xanthan-gum. IOP Conf Series 102: 1-5.

- Igbabul BD, Bello FA, Ani EC (2014) Effect of fermentation on the proximate composition and functional properties of defatted coconut (Cocos nucifera L.) flour. Journal of Food Science 3(5): 34-40.

- Muthia F, Ninik R (2013) Research Article, Department of Science Food Nutrient Faculty of Medical Diponegoro University Semarang, Indonesia.

- Sujirtha N, Mahendran T (2015) Production, quality assessment and shelf-life evaluation of protein-rich biscuits made from blends of wheat and defatted coconut flours. Proceeding of the 2nd International Conference on Agriculture and Forestry 1(1): 19-27.

- Olapade AA, Oluwole OB (2013) Bread making potential of composite flour of wheat-Acha (digitaria exilis staph) enriched with cowpea (vigna unguiculata walp) flour. Nigerian Food Journal 31(1): 6-12.

- AOAC (2016) Official Methods of Analysis. 20th (edn), Association of official analytical chemists. Washington DC, USA.

- Ihekoronye AI, Ngoddy PO (1985) Integrated food science and technology for the tropics. Macmillan, India.

- Weiss EA (2000) Oilseed Crops. 2nd (edn). Blackwell Science Ltd. Victoria, Australia, pp. 165-203.

- Potter N, Hotchkiss J (2006) Food Science. 5th (edn), CBS Publishers and Distributors, Daryangaji, New Delhi, India.

- Gunathialake KDPP, Yalegama C, Kumara AAN (2009) Use of coconut flour as a source of protein and dietary fibre in wheat bread. Asian Journal of Food and Agricultural Industry 2(3): 382-391.

- Arancon RN (1999) Coconut flour: Coconut information International 6(1): 1-8.

- Maneju H, Udobi CE, Ndife J (2011) Effect of added brewers dry grain on the physico-chemical, microbial and sensory quality of wheat bread. Journal of Food Nutrition 1(1): 39-43.

- Agu HO, Ukonze JA, Paul KA (2010) Quality characteristics of bread made from wheat and fluted pumpkin seed flour. Nigerian Food Journal 28(1): 188-198.

- Okafor JNC, Okafor GI, Ozumba AU, Elemo GN (2012) Quality characteristics of bread made from wheat and Nigerian oyster mushroom (pleurotus plumonarius) powder. Pakistan Journal of Nutrition 11(1): 5-10.

- Taha AOM (2000) The Role of sorghum flour starches (amylose/amylopectin) in composite bread quality. MSc Thesis, University of Khartoum, Sudan.

- Malomo SA, Eleyinmi AF, Fashakin JB (2011) Chemical composition, rheological properties and bread making potentials of composite flours from breadfruit, breadnut and wheat. African Journal of Food Science 5(7): 400-410.

- Singh R, Singh G, Chauhan GS (2000) Nutritional evaluation of soy fortified biscuits. Journal of Food Science and Technology 37(2): 162-164.

- Dhingra S, Jood S (2001) Organoleptic and nutritional evaluation of wheat breads supplemented with soybean and barley flour. Journal of Food Chemistry 77(4): 479-488.

- Rodríguez R, Jiménez A, Fernández BJ, Guillén R, Heredia A (2006) Dietary fibre from vegetable products as source of functional ingredients. Trends in Food Science and Technology 17(1): 3-15.

- Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, et al. (2011) Dietary fibre and fibre-rich by-products of food processing; characterisation, technological functionality and commercial applications: A review. Food Chemistry 124(2): 411-421.

- AACC (1969) Approved Methods of AACC. 8th (edn), Paul MNS: American Association of Cereal Chemists, USA.

© 2023 Asante RO. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)