- Submissions

Full Text

Novel Techniques in Nutrition and Food Science

Physicochemical Properties of Legumes Flakes (Chickpeas and Faba Beans) Preparing at Deferent Methods

D Elbar*, N Belguej, K Benahmed, A Akssa and S Hamady

Center for Scientific and Technical Research on Arid Regions Omar El-Bernaoui Biskra (C.R.S.T.R.A), Algeria

*Corresponding author:D Elbar, Center for Scientific and Technical Research on Arid Regions Omar El-Bernaoui Biskra (C.R.S.T.R.A), Algeria

Submission: June 23, 2022;Published: July 19, 2022

ISSN:2640-9208Volume6 Issue4

Abstract

In the present paper, an evaluation has been made for preparing the flakes of legumes (chickpea and faba bean) at deferent processes of cooking, where the analysis indicate that the physical properties and chemical compositions (Moisture, Ash, Fat, Protein and total carbohydrates) of the flakes of soaked chickpea (Cps) and soaked faba bean (Fbs) are proximate to flakes of chickpea flour (Cpf) and flakes of faba bean (Fbf) at significant differences (P<0.05); were observed between the two type of cooking flakes. Major minerals contents (K, Ca, Na and Mg) and minor elements (Fe) were detected in flakes chickpea flour and flakes faba bean flour at elevated levels than that observed in flakes of soaked legumes. The investigation of the organoleptic evaluation of sensory characteristics for samples of the flakes from the soaked chickpea Cps and soaked faba bean Fbs, the flakes from the flours of chickpea Cpf and flours of faba bean Fbf represent no considerable difference between control, replacement levels regarding appearance, color, taste.

Keywords: Chickpea; Faba bean; Processes of food preparation; Flakes; Physicochemical compositions

Introduction

Legumes occupy an important role in human

nutrition because they are significant nutritional foundation of healthy protein, and are great sources of fiber, complex carbohydrates, vitamins and minerals [1-3]. Pulses are low in fat and glycaemic index [4] and is relatively free from anti-nutritional factors [5]. New research on legumes consumption has been shown to protect against certain cancers, high cholesterol, type 2 diabetes and obesity [6]. Where the significance of pulses was recognized with the Food and Agriculture Organization of the United Nations [7] declaring 2016 the international year of the pulse [8], promoting the role of pulses in the sustainable supply of healthy food [9]. Inclusion of legumes in the daily diet has many beneficial physiological effects in controlling and preventing various metabolic diseases where are generally consumed after various processes like soaking, cooking, milling, roasting, puffing, and germinating. Effect of cooking methods on some of the quality parameters of the finished products has been studied by different researchers like: Nergiz et al. [8], Demet Güzel et al. [9], and Singh U et al. [10].

Among the grain legumes, faba bean (Vicia faba L.) and chickpea (Cicer arietinum L.) are the world leading grain legumes and are the used as rich source of proteins. Faba bean and chickpea are a high yielding legume with good nutritional profile, being consumed by humans. Chickpeas (Cicer arietinum L.) are the third-most commonly consumed legume in the world and are one of the most important sources of vegetable proteins in the human diet [11]. World annual chickpea production has been as much as 14 million tonnes in recent years with a gross production value of US$ 9 billion per year on average from 2016 to 2019 [12].

Faba beans are commercially available as whole deshelled kibble or flours and are widely consumed in the Middle East and Mediterranean. Faba bean world production averaged 5.3 million tonnes in recent years with a gross production value of US$ 1.7 billion per year on average from 2016 to 2018 [12]. The application of flaking to pulses is not new. Patents for pulse flaking date from the early 1900s [13]. Many pulse flake patents claim to reduce flatulence and flavor issues using drum and roller flaking [13,14]. Over the last century, a wide range of processing steps have been used to make pulse flakes ranging from simple soaking, heating, rolling and drying, through to multi-ingredient blends utilizing high-pressure steam or extrusion cooking and cold pellet formation. More recent patents have emulated the same process used for cereal flakes, including formulation, cooking, drying, pellet forming, flaking, drying, and toasting/frying the flakes.

For this reason in our study, we prepared legumes (faba bean, chickpea) similar to corn flakes as a snack food at different procedures of cooking and investigate the effect of these procedures on some important physicochemical and nutritional properties.

Materials and Methods

Sample collection

Chickpea (Cicer arietinum L.), faba bean (Vicia faba L.), were obtained from a legume processing company in BISKRA, ALGERIA. They were all harvested in 2019; these legumes seeds were manually cleaned to remove foreign materials and damaged grains.

Processing methods to preparation of flakes Chickpea and flakes faba bean

A. Preparing the flakes from the soaked chickpea Cps and

soaked faba bean Fbs

a. Soaking of legumes: Soaking of Chickpea and faba bean was

conducted at room temperature (25 ºC) for 12h in fresh

deionizer water was used in all soaking experiments. (Seeds/

water ratio=1/10).

b. Forming into flakes: The soaked chickpea and soaked faba

bean are filtered from water and forming into flakes where

roller gap set to two different widths 800μm-1000μm.

c. Roasting: Roasting and drying the flakes of chickpea and flakes

of faba bean with the oven at 180 °C-200 °C for 18 minutes.

The resulting flakes were analyzed, and the following quality

parameters assessed.

B. Preparing the flakes from the flours of chickpea Cpf and

flours of faba bean Fbf

The samples were separately milled using a hammer mill

(Retch. RM 200.), into flours of 1mm sieve size and preparation

of dough by chickpea flours and faba bean flours in the mixer by

deionizer water and forming into flakes where roller gap set to two

different widths 600μm-900μm.

a) Roasting: Roasting and drying the flakes of chickpea and flakes

of faba bean with oven at 150 °C-180 °C for 20 minutes or 15

minutes. The resulting flakes were analyses and the following

quality parameters assessed,

Physicochemical properties of the flakes of chickpea and flakes of faba bean

1. Water content: The moisture content of flakes chickpea and

flakes faba bean is measured in an isothermal vacuum oven

brand, according to the method described by the AFNOR

standard (NF V 03-707) [15].

2. Ash content: Ashes are measured by complete incineration

to constant weight at 900 °C for three hours in a LINN muffle

furnace, a test portion of 5±0.001g according to the standard

N.F.V03-720 [15].

3. Minerals determination: Mineral contents, magnesium

(Mg), calcium (Ca) and iron (Fe) were determined according

to the method of AOAC [16] using Atomic Absorption

Spectrophotometer, Perkinelmer 2380. The flame photometer

was applied for potassium (K) and sodium (Na) determination

according to the method described by Pearson (1976).

4. Lipids determination: Lipids were determined by the

gravimetric method after extraction with petroleum ether on

a Soxhlet system (Method No: 30-25).

5. Determination of crude fiber: The estimation was done using

the method of Wend.

6. Protein solubility: Protein solubility of raw and processed

flours was determined according to Clemente (1998).

Moisture, protein, fat, crude fiber and ash were determined in

different samples flakes chickpea and faba bean according to

the methods described in the AOAC [16].

The carbohydrate content was calculated by difference on dry basis: [Carbohydrate% =100 − (ash%+ lipid%+ protein%+ crude fiber%)]

All the above analyses were done in triplicate and the results reported on dry matter basis.

Legend

Cp0: chickpea

Fb0: faba bean

Cpf: flakes prepared from chickpea flour

Fbf: flakes prepared from faba bean flour

Cps: flakes prepared from chickpea soaked

Fbs: flakes prepared from faba bean soaked

Results And Discussion

Physical properties and chemical compositions

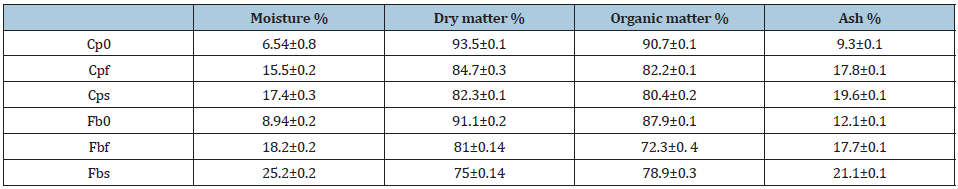

Data in (Table 1) indicate the physical properties and proximate chemical compositions of the legume samples and their flakes used in this study. Moisture, dry matter, and ash content in flakes of soaked chickpea and flakes of soaked faba bean were higher than flakes prepared by chickpea flour and faba bean flour is clarify by the decomposition of soaking water in grain of chickpeas and grain of faba bean. The absorption of water reduces the cotyledons’ glass transition temperature, which then enables the physical and chemical changes to occur during processing. Final moisture level is a key variable in defining flake quality or stability [17]. However, in the data in Table 2 show that the protein, fat and total carbohydrates were detected in flakes of chickpea flour and flakes of faba bean flour is higher level than that found in flakes prepared by soaked legumes this explain by formed after possible chemical modification induced by the soaking the legumes and those cooking. Processing and cooking treatments caused a decrease in protein, crude fiber, fat contents and carbohydrates of legumes chickpea and faba bean, these decreases might be attributed to their diffusion into cooking [18]. These results are in agreement with individuals obtained by Didier R et al. [19].

Table 1:Chemical composition of legumes and their flakes (Moisture, dry matter, organic matter and ash).

Table 2:Chemical composition of legumes and their flakes (Crude fiber, Fat, Protein, and total Carbohydrates)

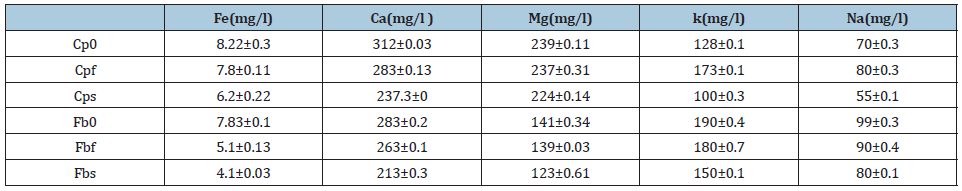

Minerals contents

Minerals contents of chickpea flour and faba bean flour, their flakes and flakes of soaked chickpea and flakes of soaked faba bean were investigated in Table 3. Data showed that major minerals (K, Ca, Na and Mg) and minor elements (Fe) were detected in flakes chickpea flour and flakes faba bean flour at higher levels than that observed in flakes of soaked legumes. The content of Fe, Mg, K, Ca and Na, in raw chickpea flour (8.22mg/l, 312,129,128 and 70mg/l), respectively and faba bean were equal about (7.826mg/l, 282.7mg/l,141mg/l,109mg/l and 0,99mg/l) [20-23]. These levels were decreased as processing methods applied. This decrease is mainly due to the minerals leached from the chickpea seeds and faba bean into the water during soaking treatments. Similar finding was observed [23-28].

Table 3:Minerals contents of chickpea and faba bean flours and their flakes.

Sensory characteristics of corn flakes at different procedure

The organoleptic evaluation of sensory characteristics for the flakes from the flours of chickpea Cpf and flours of faba bean Fbf also the flakes samples from the soaked chickpea Cps and soaked faba bean Fbs, represent the mean scores for appearance, color, taste, tenderness and stickiness for prepared flakes with flours of legumes (chickpea and faba bean) and soaked legumes (chickpea and faba bean) at different levels. The highest values for all sensory characteristics were observed in Flakes samples with chickpea flour. There is no significant difference between replacement levels regarding appearance, color, taste, tenderness and stickiness in flakes samples contained faba bean flours and their soaked faba bean.

Conclusion

Pulse’s ready-to-eat chips may meet consumer demands for healthy, whole foods and clean ingredient labels. Insights int adapting established wheat and corn flake cooking processes to pulses may help address the uptake of flaky legumes and their adoption in the TRE food market. In our work we have studied the development of appropriate processes for preparing legume flakes (chickpeas and faba bean) and adapting the time of cooking with the temperature to have good flakes because the cellular structures and composition of the legumes may restrict hydration and increase content thermal denaturation required for dénaturation and gelatin compared to cereal. These chips of pulses are prepared in two ways (from pulse flour and soaked legumes) and have preserved physic-chemical properties such as natural chickpeas and natural faba bean. Finely they are acceptable halal products for human consumption.

References

- Costa GE, Monici KQ, Reis S, Oliveira AC (2006) Chemical composition dietary fiber and resistant starch contents of raw and cooked pea, common bean, chickpea and lentil legumes. Food Chemistry 94(3): 327-330.

- Wang N, Hatcher DW, Tyler RT, Toews R, Gawalko EJ (2010) Effect of cooking on the composition of beans (Phaseolus vulgaris L.) and chickpeas (Cicer arietinum L.). Food Research International 43(2): 589-594.

- Cuvelier K, Storsley J, Mollard R, Thandapilly SJ, Ames N (2017) A Review of the Impact of Whole Pulses on Glycemic Response. Cereal Foods World 62(2): 53-58.

- Jezierny D, Mosenthin R, Bauer E (2010) The use of grain legumes as a protein source in pig nutrition: A review. Animal Feed Science and Technology 157(3-4): 111-128.

- Hall C, Hillen C, Robinson GJ (2016) Composition, nutritional value, and health benefits of pulses. Cereal Chemistry 94(1): 11-31.

- McDermott J, Wyatt AJ (2017) The role of pulses in sustainable and healthy food systems. Ann N Y Acad Sci 1392(1): 30-42.

- Nisha P, Singhal RS, Pandit AB (2005) A study on degradation kinetics of riboflavin in green gram whole (Vigna radiata L.) Food Chem 89(4): 577-582.

- Nergiz C, Gökgöz E (2007) Effects of traditional cooking methods on some antinutrients and in vitro protein digestibility of dry bean varieties (Phaseolus vulgaris L.) grown in Turkey. Int J Food Sci Technol 42(7): 868-873.

- Güzel D, Sayar S (2012) Effect of cooking methods on selected physicochemical and nutritional properties of barlotto bean, chickpea, faba bean, and white kidney bean. Food Sci Technol 49(1): 89-95.

- Singh U, Jambunathan R (1981) Relationship between total nitrogen and non-protein nitrogen in chickpea (Cicer arietinum L.) seeds. J Agric Food Chemistry 29(2): 423-424.

- Nasir M, Sidhu JS (2012) Common pulses: Chickpea, lentil, mungbean, black gram, pigeon pea and Indian vetch. Dry beans and pulses production, processing and nutrition, pp. 283-309.

- Kao MCJ, Gesmann M, Gheri F (2020) FAOSTAT: Download data from the FAOSTAT database. R package version 2.2. 1.. Food and Agriculture Organization of the United Nations.

- Edward S (1914) Process for preparing leguminous products for edible purposes. US. Patent No. US1088741.

- Bachler FR (1931) Process of making leguminous flakes (U.S. Patent No. US1813268). U.S. Patent and Trademark Office.

- AFNOR (1991) (Association Française de Normalisation). Contrôle de la qualité des produits alimentaireS : céréales et produits céré Ed. AFNOR.

- AOAC (2000) Official Methods of Analysis of A.O.A.C. International Published by A.O.A.C. International Suite 400 2200 Wilson Boulevard Arlington, Virginia 22201-3301, USA.

- Sinha SK, Kumar M, Kumar A, Bharti S, Shahi VK (2013) Antioxidant activities of different tissue extract of Faba bean (Vicia faba L.) containingphenolic compounds. Legume Res 36(6): 496-504.

- Rugheim AME, Abdelgani ME (2012) Effect of microbial and chemical fertilization on yield and seed quality of faba bean (Vicia faba). Int Food Res J 19(2): 417-422.

- Rémond Didier, Walrand Stéphane (2017) Les graines de légumineuses: caractéristiques nutritionnelles et effets sur la santé. Innovations Agronomiques.

- Roy F, Boye JI, Simpson BK (2010) Bioactive proteins and peptides in pulse crops: Pea, chickpea and lentil. Food Research International 43(2): 432-442.

- Abbas SMN, Plummera JA, Siddique KHM, White P, Harris D, et al. (2008) Cooking quality of faba bean after storage at high temperature and the role of lignins and other phenolics in bean hardening, LWT 41(7): 1260-1267.

- Alajaji A Saleh, Tarek AAE (2006) Nutritional composition of chickpea (Cicer arietinum L.) as affected by microwave cooking, and other traditional cooking methods 19(8): 806-812.

- Wang N, Hatcher DW, Gawalko EJ (2008) Effect of variety and processing on nutrients and certain anti-nutrients in field peas (Pisum sativum). Food Chemistry 111(1): 132-138.

- Wang N, Hatcher DW, Toews R, Gawalko E (2009) Influence of cooking and dehulling on nutritional composition of several varieties of lentils (Lens culinaris). LWT-Food Science Technology 42(4): 842-884.

- Gupta DK, Tripathi RD, Rai UN, Dwivedi S, Mishra S, et al. (2006) Changes in amino acid profile and metal content in seeds of Cicer arietinum L. (chickpea) grown under various fly-ash amendments. Chemosphere 65(6): 939-945.

- Gates F (2007) Role of heat treatment in the processing and quality of oat flakes. University of Helsinki.

- Guo W, Tiwari G, Tang J, Wang S (2008) Frequency, moisture and temperature dependent dielectric properties of chickpea flour. Biosystems Engineering 101(2): 217-224.

- Wood JA (2009) Texture, processing and organoleptic properties of chickpea fortified spaghetti with insights to the underlying mechanisms of traditional durum pasta quality. Journal of Cereal Science 49(1): 128-133.

© 2022 D Elbar. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)