- Submissions

Full Text

Novel Techniques in Nutrition and Food Science

Evaluation of Biscuit Produced from Composition of Wheat and Africa Walnut Flour

Olanipekun Bosede Folake, Adelakun Oluyemisi Elizabeth*, Anie Precious I and Fajuyi Folasade O

Department of Food Science and Engineering, Ladoke Akintola University, Nigeria

*Corresponding author:Adelakun Oluyemisi Elizabeth, Department of Food Science and Engineering, Ladoke Akintola University, PMB 4000, Ogbomoso, Nigeria

Submission: July 16, 2018;Published: July 31, 2018

ISSN 2640-9208 Volume2 Issue3

Abstract

Nigeria depends majorly on wheat grain importation to meet the need of the wheat- based products industry. In order to conserve foreign exchange earnings of the government there has been an increasing effort to encourage domestic wheat production. Presently, about 10% of the total wheat requirements are produced locally while the remaining is imported. However, in recent times efforts have been focused on the use of locally available unfertilized cereals, legumes and tubers for the production of wheat-based products such as biscuits and bread. This study is aimed at production and evaluation of biscuit from locally available food materials.

Composite flour was produced using varying proportion of wheat flour to African walnut flour in the proportion of 100:0, 90:10, 80:20, 70:30, 50:50 and then analyzed for chemical properties, functional properties and microbial properties. Biscuit was produced from the composite flours and analyzed for sensory attribute. All data generated in the study were analysed statistically. The chemical composition result indicated increasing level of moisture, protein, fat and crude fibre while there was decrease in carbohydrate as the proportion of walnut increases. Functional analysis result indicated an increasing level of bulk density, swelling index and water absorption. The microbial analysis showed absence of E. coli in the samples. Sensory evaluation of the biscuit showed that the samples produced from 90:10 wheat-walnut flour was comparable to the sample produced from 100% wheat flour in terms of the overall acceptability.

keywords: Wheat; African walnut; Composite flour; Biscuit; Sensory properties

Introduction

In recent times, most school children and adults rely on snacks as they can hardly wait for breakfast before leaving early in the morning for schools and office work respectively. This has necessitated in producing highly acceptable snack foods with high nutritional quality that are also affordable by potential consumers. Biscuit, a common snack has become a traditional and significant food in many countries [1]. Their varieties in form and taste combined with long shelf-life and convenience of use have perpetuated their popularity. Biscuits enriched with protein have been developed for special feeding programmes, usually for children in developing countries [2]. Biscuits also as a deliberate source of energy are made and stored for use as a food supplement for disaster relief [3] and as a strategic store for military emergencies. Traditional biscuits are all made from wheat flour. Small quantities of other meals or starches may have been added to give a special flavour or structural properties. However, as biscuit making is spreading to countries where wheat is not in abundance or constitutes an expensive imported material, it is necessary or desirable to consider other materials that may be used to make biscuits or biscuit like products. In research to finding alternative flour, there is an equally important need to supplement the cereal flour with flours from legumes to improve the protein intake of the consumers.

Tetracarpidium conophorum, known as ‘Asala or Awusa’ by the Yorubas in western part of Nigeria is a woody perennial climber that belongs to the family Euphorbiacea. Its common name is African walnut. It is found in Uyo, Akamkpa, Akpabuyo, Lagos, Kogi, Ajaawa-Ogbomoso and Ibadan. T. conophorum plant is cultivated principally for the nuts which are cooked and consumed as snacks [4]. A bitter taste is usually felt upon drinking water immediately after eating the nuts which could be attributed to the presence of chemical substances such as alkaloids. It is contained in a pod which may house one to three shelled nuts. The shells could be black or brown from the plant, the nut is whitish upon cracking from the shell and the nut has a thin layer in between two halves of the nut. African walnut is listed as one of the lesser known food stuff (Achievement, 1998), even though it was reported to be high in protein (22.8-23.5) and fat (41.5-50) contents [5].

The amino acid and fatty acid components of the nut and the use of its leaf juice for the treatment of prolonged and constant hiccups has been reported [6] while the impact of traditional processing on the nutrient and sensory qualities of the nut has also been reported [7]. Though the nuts are generally eaten in Nigeria, much work has not been reported on its use as composite flour in various baked product. Therefore, African walnut, with its inherent nutritional and therapeutic advantage, could serve as good alternative to cassava in baking industry. With the progressive increase in the consumption of biscuit, bread and other baked products in many countries, the composite flour programme, especially in developing countries, has the potential to conserve foreign exchange, provide nutritious food to more people at affordable cost and widen the utilization of indigenous crops in food formulation. Thus, this study evaluated the proximate composition and physico-chemical of flour and sensory properties of biscuit produced from wheat -African walnut composite flour at varying levels of African walnut substitution (10-50%).

Materials

African walnut was purchased at Oja-oko market, Ogbomoso, Oyo state. Wheat flour and other principal ingredients like yeast, sugar, fat and salt were also obtained from a local market at Oja- Wazo Market, Oyo state, Nigeria.

Production of walnut flour

The whole African walnut was washed thoroughly to remove any adhering contaminants, cooked in a steel pot for two hours to remove the shells. The de-shelled walnuts were reduce into smaller sizes with the aid of stainless steel knife, then blanched in hot water for 5 minutes before draining. After blanching, the walnuts were dried in a cabinet dryer at 60 ˚C for 5 hours to remove moisture, then milled and sieved to produce the African walnut flour.

Production of biscuit

Five blends of flour were prepared by mixing African walnut flour with wheat flour in the percentage proportions of 0:100, 10:90, 20:80, 30:70, and 50:50 (Table 1). Biscuit was produced from the five blend formulations as described below.

Table 1: Formulation of wheat and African walnut composite flour

The biscuits were prepared using each ratio of mixed wheat flour and African walnut flour. 100% wheat flour was used as control. All samples of biscuits contained 30g sugar, 25g fat (margarine), 1.5g baking powder, 4g vanilla flavour, 0.5g salt, 30g whole egg and small quantity of water. Each sample was mixed with sugar, margarine and salt manually for 3-5 minutes to get creamy dough. The other ingredients except water were then incorporated. The measured amount of water was added gradually using continuous mixing until good textured, slightly firm dough was obtained. The dough was kneaded on a flat clean stainless metal table for 4 minutes. The mixture was manually rolled into sheets and cut into shapes using biscuits cutter. The dough was baked in an oven at 180 OC for 10mins. The biscuit was allowed to cool and then packaged [8].

Analysis

The Chemical analysis of the composite flour mixes were analyzed for moisture content, crude protein, crude fat, ash and crude fibre content according to the method described by [9]. The carbohydrate content of the flour mixes was determined by difference. The bulk densities of the composite flour mixes were determined by the method of [10], swelling capacity was determined by the method described by [11] and the method described by [12] was employed in determining the water absorption capacity of the flour mixes.

Sensory evaluation

Sensory attributes evaluated include flavour, colour, crispiness, appearance, sweetness, after taste attributes, texture, and overall acceptability. The biscuit samples were served to 20 panellists comprising the students and staffs of the Department of food Science and Engineering, Ladoke Akintola University of Technology Ogbomoso, Oyo State, Nigeria. The panellists were asked to score each sample on the nine-point hedonic scale.

Results and Discussion

Chemical composition

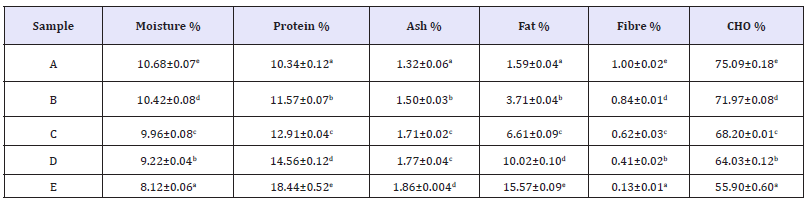

The effect of walnut flour substitution at different proportion on the proximate composition of wheat flour is shown in Table 2. It could be seen that the moisture content of the samples ranged from 8.12% to 10.68%. The low moisture observed for the five formulations was a good indicator of their potential to have longer shelf life. It is believed that materials such as flour and starch containing more than 12% moisture have less storage stability than those with lower moisture content, for this reason, a water content of 10% is generally specified for flours and other related products [13]. As the walnut flour was added to the wheat flour, it tended to bind moisture, thereby reducing the moisture content of the composite flour samples as seen in Table 2.

Table 2: Proximate properties of wheat-walnut flour.

Means with the same superscript along the same column are not significantly different (p< 0.05)

Sample A=100% Wheat flour; B=90% wheat flour+10% African walnut flour; C=80% wheat flour+20 African walnut flour; D=70% wheat flour+30% African walnut flour; E=50% wheat flour+50% African walnut flour

The crude protein content of the flour samples ranged from 10.34% to 18.44%. The crude protein content of the five formulations was significantly different (p< 0.05) from each other. Sample E (50% wheat flour and 50% walnut flour) had the highest crude protein content (18.44%) followed by sample D (70% wheat flour and 30% walnut flour) (14.56%). Sample A (100% wheat flour) had the least crude protein content (10.34%). This could be attributed to the high percentage of protein content of the walnut flour as reported in literature which are 35.6% [14] 21.6% [15], and 21.65 [16]. This result indicated that the aim of supplementation which was to increase the protein content was achieved while producing a more shelf stable product due to its lower moisture content.

The ash content of the flour samples ranged from 1.32% to 1.86%., with sample A having the least percentage while sample E has the highest percentage. High ash content as a result of walnut flour addition to the wheat flour could imply increase quantity of minerals in the flour samples. The fat content ranged from 1.59% to 15.57%. The fat content for the five samples were significantly different (p < 0.05) from each other. Sample E (50% wheat flour and 50% walnut flour) had the highest fat content of 15.57% followed by sample D (70% wheat flour and 30% walnut flour) which had a fat content of 10.02% and sample A (100% wheat flour) had the least fat content (1.32%). This could be attributed to the high percentage of oil in African walnut flour. N die et al. [15] had reported a level of 47.7% in African walnut.

The crude fibre content of the flour samples ranged from 0.13% to 1.00% and was significantly different from each other at 0.05% level significance. From Table 2, it could be seen that sample A had the highest percentage of fibre (1.00%) compared to other samples, but at 10% substitution of walnut flour to the wheat flour, it tended to reduce to 0.84%. The carbohydrate content ranged from 55.90% to 75.09%. The carbohydrate content for the five samples was significantly different (p< 0.05) from each other. Sample A (100% wheat flour) showed a very high percentage of carbohydrate content of 75.09%. As the walnut flour addition to the wheat flour increased, corresponding decrease in carbohydrate content were observed in the composite flour samples. A lower content of carbohydrate (16.9%) in African walnut could be responsible for this [15].

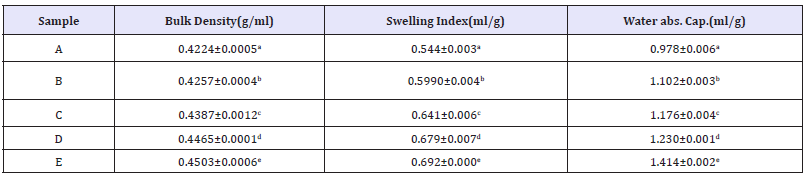

Functional Properties

The effect of walnut flour substitution at different proportion on the functional properties of wheat flour is shown in Table 3. The bulk density of the flour samples was found to range from 0.4503% to 0.4224%. Sample E (50% wheat flour and 50% walnut flour) (0.4503%), was significantly different from other samples because it had the highest bulk density, closely followed by sample D (70% wheat flour and 30% walnut flour) (0.4503%). Sample A (100% wheat flour) had the least value (0.4224%). The change in bulk density is generally affected by the particle size and the density of the flour [17].

The swelling capacity of the flour blends ranged from 0.544%g to 0.692%. Sample E (50% wheat flour and 50% walnut flour) was significantly different from other flour samples at (p< 0.05) and had the highest value (0.692%) while Sample A (100% wheat flour) (0.544%) had the lowest value. Walnut flour tended to increase the swelling capacity of the flour samples at different levels of substitution. Moorthy & Ramanujam [18] reported that the swelling capacity of flour granules is an indication of the extent of associative forces within the granule. The variation in the swelling capacity indicates the degree of exposure of the internal structure of the starch present in the flour to the action of water [19].

Table 3 the result obtained for water absorption capacity ranged from 0.978% to 1.414%. Water absorption capacity is the ability of flour to absorb water and swell for improved consistency in food. It is desirable in food systems to improve yield and consistency and give body to the food [20]. Sample E (50% wheat flour and 50% walnut flour) was significantly different from other samples at (p< 0.05) because it had the highest capacity to absorb water and also sample A (100% wheat flour) was significantly different from the other samples at (p< 0.05) because it has the least capacity of absorbing water. The effect of low water absorption capacity of the flour samples was probably due to the loose association of amylase and amyl pectin in the native granules of starch and weaker associative forces maintaining the granules structure [21].

Table 3:Functional properties of wheat-walnut flour.

Means with the same superscript along the same column are not significantly different (p< 0.05)

Sample A=100% Wheat flour; B=90% wheat flour+10% African walnut flour; C=80% wheat flour+20 African walnut flour; D=70% wheat flour+30% African walnut flour; E=50% wheat flour+50% African walnut flour

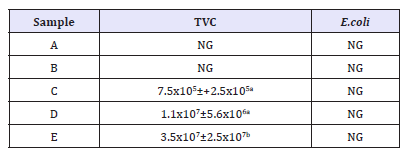

Microbial Analysis

The result of the microbiological analysis of the sample is shown in Table 4, no visible growth was observed in sample A and sample B. Total Viable Count showed growth for sample C, D and E after 48hrs this could be as a result of the increasing level of protein and fat as shown in Table 2. Adams & moss [22] reported that spoilage organisms grow faster in medium that is highly nutritious.

Table 4:

Means with the same superscript along the same column are not significantly different (p< 0.05)

Sample A=100% Wheat flour; B=90% wheat flour+10% African walnut flour; C= 80% wheat flour+20 African walnut flour; D=70% wheat flour+30% African walnut flour; E=50% wheat flour+50% African walnut flour

Consumer Acceptability Study

Figure 1:Sample A.

Figure 2:Sample B

Figure 3:Sample C.

Figure 4:Sample D.

Figure 5:Sample E.

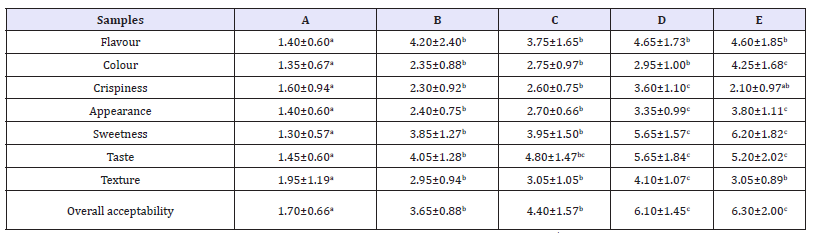

The data obtained from the sensory evaluation was analyzed using Analysis of Variance (ANOVA). The attributes evaluated for sensory are flavour, colour, crispiness, appearance, sweetness, taste, texture, and overall acceptability. The most accepted sample by the panellist was determined from the result. This was done based on the panellist response in Table 5. The panellists showed preference for (Figure 1) sample A followed by (Figure 2-5) sample B, C, D and E in terms of flavour, texture, taste, crispiness, colour, appearance and sweetness. The inherent aftertaste flavour of the composite biscuit may have accounted for the lower rating by the panellists. For the overall acceptability sample B had the highest percentage next to control sample A, Sample B therefore, competed favourably with sample A. Table 5: Sensory evaluation of wheat-walnut biscuit.

Table 5:Sensory evaluation of wheat-walnut biscuit.

Means with the same superscript along the same column are not significantly different (p< 0.05)

Sample A=100% Wheat flour; B=90% wheat flour+10% African walnut flour; C=80% wheat flour+20 African walnut flour; D=70% wheat flour+30% African walnut flour; E= 50% wheat flour+50% African walnut flour

Conclusion

The result obtained from the study has shown that supplementing wheat flour with walnut flour resulted in considerable improvement in the protein and fat content of the flour. The result also indicates that biscuit sample produced from formulation of 90% wheat flour and 10% walnut flour was accepted by the consumer. In conclusion, the work has revealed that supplementing wheat flour with walnut flour considerably increased the protein and fat contents. Hence, they can find useful application in pastries like biscuit and other snacks.

References

- Manley DJR (1996) Technology of biscuits, crackers and cookies. Duncan Manley Limited, Stanford, USA.

- Water L (1987) Studies on the proximate composition and effect of flour particle size of acceptability of biscuits produced from blends of soybeans and plantain flours. J Namoda Technol 3(2): 17-22.

- Young AS, William CV, Victor GI (1985) Physico-chemical and nutritional properties of cereal-pulse blends for bread making. Nutrition and Health 16(3): 183-194.

- Oke OL (1995) Leaf protein research in Nigeria Ibadan, University Press Ibadan, Nigeria.

- Osogie AU, Okoye WL, Oluwagose BO, Dowodu OA (1986) Chemical quality parameters and fatty acid composition of oils of some underexploited tropical seeds. Nigerian Journal of Applied Sciences 4: 151- 162.

- Oyenuga VA (1997) Nigeria Food and Feeding Stuffs. University Press, Ibadan, Nigeria.

- Nwokolo EA (1987) Composition and availability of nutrients in some tropical legumes. Ibadan Phacco Publishers, USA.

- Whitley PR (1970) Biscuits manufacture. Applied Science Publishers Ltd, London.

- AOAC (2005) Association of official analytical chemists, (15th edn.) Wincosin, USA, p. 1298.

- Okaka JC, Okorie PA, Ozo ON (1991) Quality evaluation of sun dried yam chips. Tropical Sci 31: 265-275.

- Leach HW, Maccowen LD, Schoch TJ (1989) Structure of starch granules. I-Swelling and Solubility Pattern of Various Starches. Cereal Chemistry 36: 533-544.

- Lawal OS, Adebowale KO (2005) Physico-chemical characteristics and thermal properties of chemically modified Jack bean (Canavalia ensiforms) starch. Carb Polym 60: 331-341

- Eddy NO, Udofia PG, Eyo D (2007) Sensory evaluation of wheat/cassava composite bread and effect of label information on acceptance and preference Journal of Biotechnology 6: 2415-2418.

- Edem CA, Dosumu MI, Bassey FI (2008) Determination of proximate composition, ascorbic acid and heavy metal content of African walnut (Tetracarpidium conophorum). Afr J Environ Pollut Health 6 (1): 59-60.

- Ndie EC, Nnamani CV, Oselebe HO (2010) Some physicochemical characteristics of defatted flours derived from African walnut (Tetracarpidium conoforum): An underutilized legume. Pakistan Journal of Nutrition 9(9): 909-911.

- Ayoola PB, Onawumi OO Faboya OOP (2011) Chemical evaluation and nutritive values of Tetracarpidium conophorum (Nigerian walnut) Seeds. Journal of Pharmaceutical and Biomedical Sciences 11(15): 1-5.

- Karuna D, Noel G, Dilip K (1996) Food and Nutrition Bulletin. United Nation University, Japan, 17: 2.

- Moorthy SN, Ramanujam T (1986) Variation in properties of starch in cassava varieties in relation to age of the crop. Starch-Starke 38(2): 58- 61.

- Ruales J, Valencia S, Nair B (1993) Effect of processing on the physiochemical characteristics of guinea flour (Chenopodium guinea Wild). Starch-Starke 46: 13-19.

- Osundahunsi OF, Fagbemi TN, Kesselman E, Shimoni E (2003) Comparison of the physicochemical properties and pasting characteristics of flour and starch from red and white sweet potato cultivars. J Agric Food Chem 51(8): 2232-2236.

- Lorenz K, Collins F (1990) Quinoa (Chenopodium quinoa), Starch physicochemical properties and functional characteristics. Starch- Starke 42(3): 81-86.

- Adams MR, Moss MO (2000) Food Microbiology. Royal Society of Chemistry, Great Britain.

© 2018 Adelakun Oluyemisi Elizabeth. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)