- Submissions

Full Text

Novel Research in Sciences

Establishing A Superplastic Constitutive Model in Ultralight Microduplex Magnesium-Lithium Alloys

Furong Cao1,2*, Shuting Konga1 and Nanpan Guoa2

1School of Materials Science and Engineering, Northeastern University, China

2State Key Laboratory of Rolling and Automation, Northeastern University, China

*Corresponding author: Furong Cao, School of Materials Science and Engineering, State Key Laboratory of Rolling and Automation Northeastern University, China

Submission: August 11, 2022;Published: August 22, 2022

.jpg)

Volume11 Issue5August, 2022

Abstract

The constitutive model on superplastic ceramics is extended to superplastic metallic alloy, e.g. superplastic Mg-Li alloys. The newly established constitutive model is suitable for predicting typical super plasticity forming of Mg-Li alloys with high R-square of 0.99679.

Keywords:Mg-Li alloy; Super plasticity; Constitutive model; Deformation mechanism

Introduction

Super plasticity means the ability of a material to exhibit high ductility or elongation, typically elongation more than 400% under the condition of grain size smaller than 10μm, temperature higher than 0.5Tm where Tm is the absolute melting point [1,2]. During the early time, Ball A et al. [3], Mukherjee AK et al. [4], Gifkins RC [5], and Langdon TG [6] had proposed the superplastic mechanism of grain boundary sliding accommodated by dislocation slip, grain boundary ledge, and grain boundary nearby dislocations, and Ashby MA et al. [7] proposed the superplastic mechanism of grain boundary sliding accommodated by diffusion. They validated their models in simple system alloys. In recent years, Cao FR et al. [8] proposed a superplastic constitutive model and validated the equation in superplastic Mg-8Li alloy. Recently, Moshtaghioun BM et al. [9] proposed a superplastic constitutive model based on the energy of disclination dipoles and grain misorientation rotation and validated the model in typical ceramics. However, as we know, no one except the present authors establish a superplastic constitutive model in ultralight magnesium-lithium (Mg-Li) alloys. Hence, it is necessary to establish a superplastic constitutive model in Mg-Li alloys.

Mg-Li super plasticity has been studied for many years, and most reports are on the experimental superplastic behavior and microstructural evolution. To the best of the author’s knowledge, little report is available establishing a superplastic constitutive model in Mg-Li alloys, no matter whether the alloy is simple system alloy or complex system alloy. Inspired by the report of Moshtaghioun BM et al. [9] in superplastic ceramics, we are going to extend this model to the metallic alloys, in particular, link this model to the experimental results of superplastic Mg-Li alloys. For this reason, this work is launched to establish a constitutive model in superplastic Mg-Li alloy.

Modeling and Results in Mg-Li Alloys

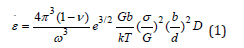

The superplastic model derived by Moshtaghioun BM et al. [9] is expressed as the following:

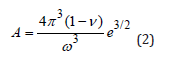

where ε ̇ is the strain rate, ν is Poisson’s ratio, G is the shear modulus, b is the magnitude of Burges vector of dislocation, σ is the true stress, D is the diffusivity, ω is the grain misorientation, k is Boltzmann’s constant, T is the absolute temperature, and d is the grain size. Here, the dimensionless constant A is expressed as:

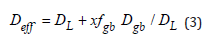

Moshtaghioun BM et al. [9] do not mention whether diffusivity D is lattice diffusion or grain boundary diffusion. Here, effective diffusivity, Deff, is given by [10]

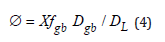

Where DL is the lattice diffusivity, x=10-2 for super plasticity, fgb=πδ⁄d, δ is the grain boundary thickness, =2b, and Dgb is the grain boundary diffusivity. Atomic diffusion mechanism is judged by the following formula

when ∅>1, grain boundary diffusion dominates the diffusion

process; when ∅<1, lattice diffusion dominates the diffusion

process.

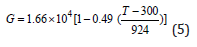

Shear modulus of Mg is given by [11]

where T is the absolute temperature in Kelvin.

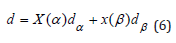

For dual phase Mg-Li alloy, the average grain size is determined

by the following relation

where x(α) and x(β) are the volume fraction of α-Mg phase and β-Li phases, respectively. The volume fraction of α-Mg phase and β-Li phase is determined by metallographic level rule according to binary Mg-Li phase diagram [12].

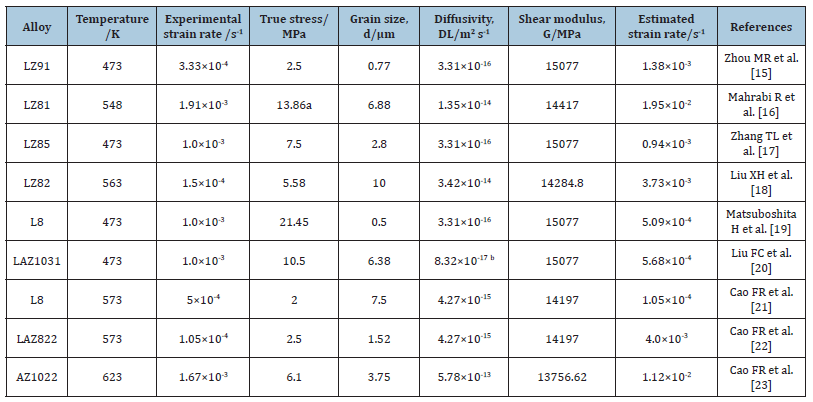

To estimate the strain rate using model (1), experimental and physical parameters and estimated strain rates in different superplastic Mg-Li alloys are listed in Table 1. ω=4°=0.07 radian. ν =0.28 [13]. b=0.321nm [13]. k=1.38 x 10-23 J/K. Diffusivity D such as DL and Dgb is calculated by the diffusivity formulae in our previous work [14]. Calculation as per Eq. (4) shows that lattice diffusion, DL, dominates the diffusion process.

Table 1:Experimental and physical parameters and estimated strain rates in different superplastic Mg-Li alloys.

a: Conversion of shear strain rate and stress to normal strain rate and stress.

b: Corrected by phase ratio of α-Mg: β-Li=0.08:0.92.

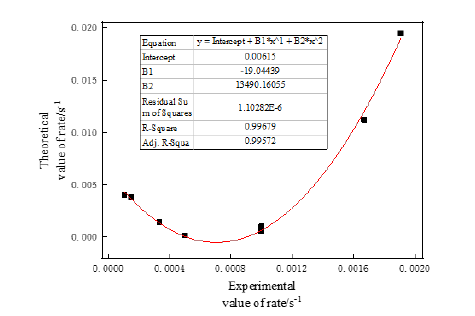

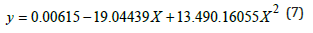

Figure 1 presents the relation of theoretical strain rate and experimental strain rate. According to Figure 1, the following formula is obtained.

Figure 1:Relation of theoretical strain rate and experimental strain rate.

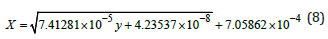

The R-square is 0.99679, indicative of high correlation. Based on Eq. (7), x is solved as follows.

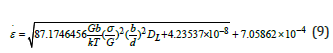

Since true strain rate is experimental strain rate, the following constitutive model is obtained.

Eq. (9) is the constitutive model that is suitable for superplastic Mg-Li alloys. As shown in Table 1, the scope of application of this model is suitable for micro duplex alloy with typical super plasticity. The scope of grain size ranges from ultrafine-grained to fine-grained alloy [15-23]. Estimation of strain rate in Ref. [18] indicates that larger derivation between experimental strain rate and estimated strain rate appears when pronounced dynamic grain growth occurs. Hence, the microstructure should be thermal stable without dynamic grain growth. In addition, the new model is not suitable for quasi-super plasticity or super plasticity-like Mg-Li alloys whose elongations are in the range of 200~300%. It is worth mention that a few reports [24-26] on typical super plasticity of Mg-Li alloys are not collected in Table 1 because they are lack of individual experimental data. The other relevant reports on typical super plasticity of Mg-Li alloys not mentioned in Table 1 are in like manner.

Conclusion

The constitutive model of Moshtaghioun BM et al. [9] report on superplastic ceramics is extended to superplastic metallic alloy, e.g. superplastic Mg-Li alloys. The newly established constitutive model is suitable for predicting typical super plasticity forming of Mg-Li alloys with high R-square of 0.99679.

Acknowledgement

This work is supported by National Natural Science Foundation of China (Grant no. 51334006).

References

- Kawasaki M, Figueiredo RB, Langdon TG (2016) The requirements for super plasticity with an emphasis on magnesium alloys. Adv Eng Mater18(1): 127-131.

- Langdon TG (2009) Seventy-five years of super plasticity: Historic developments and new opportunities. J Mater Sci 44(22): 5998-6010.

- Ball A, Hutchison MM (2013) Super plasticity in the aluminum-zinc alloy. J Met Sci 3(1): 1-7.

- Mukherjee AK (1971) The rate controlling mechanism in super plasticity. Mater Sci Eng 8(2): 83-89.

- Gifkins RC (1976) Grain-boundary sliding and its accommodation during creep and super plasticity. Metall Trans A 7(8): 1225-1231.

- Langdon TG (1994) A unified approach to grain boundary sliding in creep and super plasticity. Acta Metall Mater 42(7): 2437-2443.

- Ashby MA, Verrall RA (1973) Diffusion-accommodated flow and super plasticity. Acta Metall 21(2): 149-163.

- Cao FR, Ding H, Hou HL, Yu CP, Li YL (2014) A novel superplastic mechanism-based constitutive equation and its application in an ultralight two-phase hypereutectic Mg-8.42Li alloy. Mater Sci Eng A 596: 250-254.

- Moshtaghioun BM, Bejarano-Palma JA, Garcí DG (2020) Disclination dipoles are the holy grail for high temperature superplasticity in ceramics. Scr Mater 185: 21-24.

- Watanabe H, Mukai T, Kohzu M, Tanabe S, Higashi K (1999) Effect of temperature and grain size on the dominant diffusion process for superplastic flow in an AZ61 magnesium alloy, Acta Mater 47(14): 3753-3758.

- Kawasaki M, Kubota K, Higashi K, Langdon TG (2006) Flow and cavitation in a quasi-superplastic two-phase magnesium-lithium alloy. Mater Sci Eng A 429(1-2): 334-340.

- Friedel J (1964) Dislocations. Pergamon Press, Oxford, UK.

- Nayeb-Hashemi AA, Clark JB, Pelton AD (1984) The Li-Mg (lithium-magnesium) system. Bull Alloy Phase Diagr 5(4): 365-374.

- Cao FR, Ding H, Li YL, Zhou S, Cui JZ (2010) Super plasticity, dynamic grain growth and deformation mechanism in ultralight two-phase magnesium-lithium alloys. Mater Sci Eng A 527(9): 2335-2341.

- Zhou MR, Morisada Y, Fujii H, Wang JY (2020) Pronounced low-temperature super plasticity of friction stir processed Mg-9Li-1Zn alloy. Mater Sci Eng A 780(7): 139071.

- Mehrabi R, Mahmudi H, Miura (2019) Super plasticity in a multi-directionally forged Mg-Li-Zn alloy. Mater Sci Eng A 765: 138274.

- Zhang TL, Tokunaga T, Ohno M, Wu RZ, Zhang ML, et al. (2018) Low temperature super plasticity of a dual-phase Mg-Li-Zn alloy processed by a multi-mode deformation process. Mater Sci Eng A 737: 61-68.

- Liu XH, Zhan HB, Gu SH, Qu ZK, Wu RZ, et al. (2011) Super plasticity in a two-phase Mg-8Li-2Zn alloy processed by two-pass extrusion. Mater Sci Eng A 528 (19-20) 6157-6162.

- Matsunoshita H, Edalati K, Furui M, Horita Z (2015) Ultrafine-grained magnesium-lithium alloy processed by high pressure torsion: Low-temperature super plasticity and potential for hydroforming. Mater Sci Eng A 640: 443-448.

- Liu FC, Tan MJ, Liao J, Ma ZY, Meng Q, et al. (2013) Microstructural evolution and superplastic behavior in friction stir processed Mg-Li-Al-Zn alloy. J Mater Sci 48: 8539-8546.

- Cao FR, Cui JZ, Wen JL, Lei F (2000) Mechanical behavior and microstructure evolution of superplastic Mg-8.4wt pct Li alloy and effect of grain size and phase ratio on its elongation. J Mater Sci Technol 16(1): 55-58.

- Cao FR, Xue GQ, Zhou BJ, Wang SC (2019) High‑temperature deformation behavior of duplex Mg-41Li-1.80Al-1.77Zn Alloy Processed by Friction Stir Processing. Met Mater Int 25: 570-583.

- Cao FR, Xue GQ, Xu GM (2017) Super plasticity of a dual-phase-dominated Mg-Li-Al-Zn-Sr alloy processed by multidirectional forging and rolling. Mater Sci Eng A 704: 360-374.

- Furui M, Kitamura H, Anada H, Langdon TG (2007) Influence of preliminary extrusion conditions on the superplastic properties of a magnesium alloy processed by ECAP. Acta Mater 55(3): 1083-1091.

- Kim WJ, Kim MJ, Wang JY (2009) Ultrafine-grained Mg-9Li-1Zn alloy sheets exhibiting low temperature super plasticity. Mater Sci Eng A 516(1-2): 17-22.

- Yang HP, Zhang X, Chen P, Fu MW, Wang GC, et al. (2019) Investigation on the enhanced maximum strain rate sensitivity (m) super plasticity of Mg-9Li-1Al alloy by a two-step deformation method. Mater Sci Eng A 764(2019): 138219.

© 2022 Furong Cao. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)