- Submissions

Full Text

Novel Research in Sciences

Cannibalisation as a Mechanism of the Motion in MIRCE Science

Jezdimir Knezevic*

MIRCE Akademy, UK

*Corresponding author: Jezdimir Knezevic, MIRCE Akademy, Woodbury Park, UK

Submission: July 07, 2021;Published: August 02, 2021

.jpg)

Volume8 Issue5July, 2021

Abstract

The main objective of this paper is to examine the cannibalisation process, removing a required component from a designated system and installing it in an unserviceable system, as a mechanism of the motion of a functionable system in MIRCE Science. It impacts on the function ability work done and resources consumed during a given interval of calendar time. Although the cannibalisation process improves profitability or readiness of functionable systems, it can also lead to increased costs and disruption, divert resources from other activities and create additional technical and financial risks. Thus, cannibalisation is one of the drivers of profitability that could be predicted by applying the MIRCE Profitability Equation, which considers the whole organization as a single analytical scheme. It is a huge improvement in respect to current practices where the whole business process is addressed through a collection of a large number of self-standing models that address a few influential parameters at a time. An example of cannibalisation in the Royal Navy is given in the paper.

Keywords:Cannibalisation; Functionability; Profitability; Readiness

Introduction

The philosophy of MIRCE Science is based on the premise that the purpose of existence of any functionable system is to deliver the expected work. The work is considered to be done when measurable functionality (function, performance and attributes) is delivered through time, like annual miles travelled, monthly units produced, daily energy supplied and similar. The main business of any business is to stay in business by providing revenue-generated work. Hence, the three least liked words in the commercial aviation business are Aircraft on Ground (AOG). The following example is one of the possible scenarios of AOG: a passenger aircraft is due to depart, on a scheduled flight, at 16:00 with 235 fare-paying passengers. The pre flight test has shown that a safety critical avionics module has failed, which is not on the Minimum Equipment List. To meet operational requirements and to dispatch the aircraft on time it is necessary to replace a defective component. The regular maintenance procedure is completed by issuing a replacement component from the inventory and releasing the aircraft into service after its installation. However, the on-line mechanics investigation has concluded that a replacement part is not available in the inventory. An interrogation of the airline’s available inventory reveals that the module required could be delivered in 14 hours’ time. This means that another aircraft has to be found to deliver the scheduled flight or that the 235 passengers and the crew have to be taken care of in local hotels till the needed component arrives. The other option is to authorise a cannibalisation (robbery) process. It means that the required component is removed from a designated aircraft (the donor aircraft), inspected, and installed on the unserviceable aircraft (the receiver aircraft. When the work is completed, the aircraft is dispatched into regular service. An AOG can happen at any time, anywhere in the world, and when it does, every minute the aircraft sits on the ground is critical.

The main business of any defence organisation in any country is to satisfy the defence requirements by providing an operation ready weapon system. They focus on a fleet’s readiness and the budget allocated for maintaining inventories of spare parts. Hence, all military services rely extensively on cannibalisation and consider it to be a normal part of fleet maintenance. A recent study identified approximately 850,000 documented US Air Force and Navy cannibalisations that consumed 5.3 million maintenance hours, during the period of five-year [1,2]. While cannibalisation provides a short-term solution that makes a functionable system operational, its long-term impacts can be significant. The main objective of this paper is to address cannibalisation as a mechanism of the motion of a functionable system in MIRCE Science, which uniquely describes and predicts time emerging functionability performances of functionable systems, like: work done, resources consumed and consequential profitability in the private sector or operational readiness in defence sectors. The body of knowledge presented here is of a generic nature, which means that is applicable to any work delivering functionable system.

Fundamentals of MIRCE Science

According to MIRCE Science, at any instant of calendar time, any functionable system could be in one of the following two functionable states:

a) Positive Functionable State (PFS), a generic name for a state in which a functionable system is doing work.

b) Negative Functionable State (NFS), a generic name for a state in which a functionable system is not doing work.

In MIRCE Science work done by a functionable system is uniquely defined by the trajectory it traces thorough MIRCE Space [1]. Mathematically, it is a continuous three-dimensional space containing discrete points, each representing a functionable state that a functionable system could be found in at any instant of time and the corresponding probabilities. The motion of a functionable system through functionable states is governed by the following two types of actions:

a) Negative Functionable Action (NFA) that causes occurrences of Negative Functionable Events (NFE) at which functionable systems are compelled to move to NFS.

b) Positive Functionable Action (PFA) that causes occurrences of Positive Functionable Events (PFE) at which functionable systems are compelled to move to PFS.

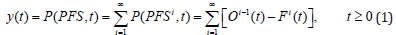

MIRCE Mechanics is a part of MIRCE Science that focuses on the scientific understanding of the mechanisms that generate positive and negative functionable actions, which uniquely define a time evolution of functionable systems though MIRCE Space. A full understanding of these mechanisms is essential for the predictions of expected performances of functionable systems using MIRCE Science Equations, like work done and resources consumed. MIRCE Science Equations are mathematical expressions of the motion of functionable systems through MIRCE Space, developed by Knezevic [1]. They enable predictions of the expected work to be done by an operationally defined functionable system, together with the resources required, which when converted into monetary values present the expected cost and revenue, from the birth of the system to its retirement. According to MIRCE Science the probability of a functionable system being in PFS, at a given instant of time t, is defined by the MIRCE Functionability Equation [3], which defined the motion of a functionable system through MIRCE Space, thus:

where:

Oi (t) = P(TPEi ≤ t) is the probability that the time to ith PFE will take place between the birth of a system and a given instant of time t.

Fi (t) = P(TNEi ≤ t) is the probability that the time to ith NFE will take place between the birth of a system and a given instant of time t.

The positive work done, PW(T), by a given functionable system presents the amount of time it is expected to be in PFS consuming necessary operational resources (personnel, energy, material, facilities, equipment and similar) during the stated interval of time T, can be calculated by making a use of the following expression: [1]

The numerical value of the above expression, when applied to an operationally defined functional system type, presents the amount of time it is expected to be in PFS delivering expected: function, performance, and attributes. Correspondingly, the negative work done, NW(T), by a given functionable system presents the amount of time it is expected to be in NFS consuming necessary maintenance resources (personnel, material, spares, facilities, energy, equipment and similar) during the stated interval of time T, can be calculated by making use of the following expression:

The numerical value of the above expression, when applied to an operationally defined functional system type, presents the amount of time it is expected to be in NFS not delivering expected: function, performance or attributes.

Managing spare parts demands in commercial aviation

Mitigating the impact of an AOG situation is a daily challenge of an aviation fleet management process, which takes detailed planning, preparation and data. The following strategies are effectively used by many airlines to eliminate or reduce the impact of an AOG, regarding provisioning of spare parts:

a) Spare parts stock: By analysing the system usage data and identifying components prone to causing AOG-related issues, an inventory of spare components can be obtained to anticipate them.

b) Fly-a-way kit: Some airlines maintain a flyaway kit that contains items that have demonstrated a statistically high chance of becoming faulty. They are available immediately during grounding at outstations.

c) Partnerships: Airlines often develop partnerships with companies operating at stations where they have flights. The best partner is another airline based in that station or one that operates from the same country and maintains a similar fleet.

d) Cannibalisation: a process consisting of removing the required component from a designated aircraft (the donor aircraft), inspecting and installing it on the unserviceable aircraft (the receiver aircraft).

e) Although the mechanism of each strategy listed above is studied in MIRCE Science, this paper is focusing on cannibalisation only.

The Anatomy of Cannibalisation

Cannibalisation involves removing components from a donor system that could be in operation or in maintenance and transferring them to the recipient system. It could involve moving an interchangeable part or more complex components through the following steps:

i. Safe isolation of the part from the donor’s system,

ii. Provision of a back-up system’s function fully to ensure the integrity,

iii. Removal of other components and modules to gain the access the desired part,

iv. Repositioning other systems and equipment to clear a path to move the

v. cannibalised part,

vi. Physical movement of the part to a new location and packaging it to prevent damage during transit, when applicable vii. Dispatch of the part to the recipient, which may be in the same location or elsewhere.

The recipient’s team then repeats the above-described process, while the donor is left with a defect in NFS. However, if the part remains unavailable when the donor requires it, for example to become operational or undergo specific maintenance, the cannibalisation process may have to be repeated.

Technical impact of cannibalisation

Cannibalisation creates additional engineering risks for both the cannibalised components and those components removed to get access to them within the donor and recipient system. The engineering teams may need to conduct additional systems testing to ensure system integrity. The resulting risks could be summarised as following:

i. Defects: Some cannibalised components have been damaged while being removed, transported or reinstalled.

ii. Reduced service life: Repeatedly transferring the same part between systems may reduce its service life due to maintenance induced error or transport damage.

iii. Loss of warranties: Cannibalisation may invalidate warranties where components are used for a purpose beyond that intended, as perceived by the original equipment manufacturer.

Financial impact of cannibalisation

Cannibalisation introduces additional work of personnel who are needed to access, remove, transport, install and test the cannibalised part. This can be particularly challenging within systems like aircraft and submarines given the confined space and the need to maintain safety and operational requirements. The extent of additional work varies but can be time-consuming, diverting resources from other work such as scheduled or preventative maintenance and increasing costs. Cannibalisation also involves additional administrative work such as producing temporary operating instructions. According to [4] the analysis of 146 events related to Type 23 Frigate cannibalisations in 2012 identified that an average extra work cost £4,000. In 50% of these cases, work to remove and reinstall cannibalised components was equal to, or greater than, the value of the part itself. In 25% of cases, it was four times greater. In summary, cannibalisation can be an effective way of re-gaining function ability but should only happen when no other solution is available, as it can lead to increased costs and disruption, divert resources from other activities and create additional technical and financial risks.

Example of equipment cannibalisation in the royal navy

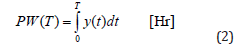

The National Audit Office (NAO), that scrutinises public spending for Parliament and is independent of the UK government, has performed an investigation on when, why and how cannibalisation occurs across the Royal Navy and its impact [5]. Although the Ministry of Defence recognises the adverse impact of cannibalisation, the tight budgetary constraints increase the risk of parts not being available. Hence, the removal of a working part from one piece of equipment, such as a ship or submarine, to put it into another that is in greater operational need is approved practise, that has to be monitored and managed. Between April 2012 to March 2017 there were approved 3,230 instances of cannibalisation, involving 6,378 parts. This was an increase of 49% in the previous five years [5].

In the Table below are shown parts most often repeatedly transferred across ships and submarines of the same class, April 2012 to March 2017 (Source: National Audit Office analysis of Ministry of Defence data (Table 1).

Table 1:

According to auditors, around 40% of ships and submarines receiving cannibalised parts needed them so they could be ready for operations or training. In these cases, equipment cannibalisation rectified issues that would have reduced the operational capability of ships and submarines. The remaining 60% of ships and submarines did not need the parts for operations or training, but were needed in order to, for example, complete planned maintenance work to schedule and cost. In March 2017, the ships operating centre of the MoD’s arm’s-length procurement body Defence Equipment & Support met 55% of part demands from ship and submarine crews by the required date. This was against a target of 75%, while the submarine operating centre met 63% of demands against a target of 80%.

Planning for Cannibalisation

The research performed as a preparation for this paper has shown that although cannibalised components constitute a small proportion of components issued, there is clear evidence that it has impact on profitability in private sectors and capability of functionable systems in the public sector. However, there is a little evidence of systematic considerations and planning for the longterm impacts of cannibalisation when making its strategic decisions on the level of investment in spare parts. One possible reason for this is the fact that there is not a coherent body of knowledge that is able to concurrently address the following activities:

i. Quantitative assessment of the trade-offs between saving measures, such as reducing investment in spares upfront, and the longer-term value-for-money implications relating to cannibalisation,

ii. Accurate prediction of the cost implications, such as for the maintenance of heavily cannibalised equipment, to allocate appropriate long term financial support,

iii. Considerations of any underlying increase in technical risks and subsequent impact on testing during the operational process,

iv. Clarification of commercial arrangements, due to a lack of clarity on the impact of cannibalisation on part warranty. The body of knowledge contained in MIRCE Science enables many of the above listed challenges to be addressed. In the remaining part of the paper, it will be shown how the impact of cannibalisation on the expected profit can be predicted by making use of the MIRCE Profitability Equation.

Impact of Cannibalisation on profitability

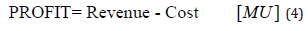

The creation of the MIRCE Functionability Equation enabled the development of the MIRCE Profitability Equation [4] that links the revenue and cost sides of business, by integrating the consequences of system engineering decisions, adopted business methods and project management decisions. In economics a profit is defined as a financial gain quantified as the difference between the amount earned (revenue) and the amount spent in buying, operating, or producing something (cost), expressed through a Monetary Unit (MU), thus:

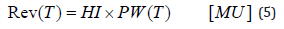

The expected revenue

According to MIRCE Science [1], the expected revenue of a given functionable system, during the stated interval of time, Rev(T), expressed in the Monetary Units (MU), is equal to the product of the Hourly Income generated by the provision of the business function, HI, expressed in monetary units, and the amount of the work done by the system, thus:

The expected cost categories in MIRCE Science

The motion of a given functionable system through MIRCE Space is driven by the execution of functionability tasks, positive and negative, is related to utilisation of physical resources, on one hand, and satisfactions of legal and organisational requirements associated with operation, maintenance and support processes, on the other. Both parts are treated as a cost and are quantifiable in monetary terms. Thus, in MIRCE Science, the following three categories of cost are recognised:

a) Set up costs, which is the total investment necessary to enable operational, maintenance and support systems to be established before the introduction of a system into service. Such costs are generally non-recurring during the life of the item/system. Typically, it is related to the acquisition of: test equipment, training devices, upgrade of facilities, transportation devices, initial tooling and so forth.

b) Fixed costs, which exist irrespective of the number of operational and maintenance tasks performed (eg. test equipment, ground equipment, facility costs, training of personnel and similar). Although fixed costs are assumed to remain unchanged in response to changes in the level of activities, they may change in response to other factors such as price changes.

c) Variable costs, which are dependent upon the quantity of operational and maintenance tasks performed. These costs are usually related to the direct material and direct labour consumed.

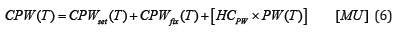

The expected cost of positive work: Following the MIRCE Science cost structure, the cost of doing positive work during the stated period of time, CPW(T), is equal to the sum of the set up cost, CPWset, fixed cost, CPWfix(T) and variable cost that is equal to the product of the Hourly Cost of positive work, HCPW and the duration of the time a functionable system spends in PFS (Equation 2), thus:

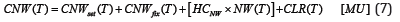

The expected cost of negative work: Equivalent cost for doing negative work (maintenance and storage), during the stated period of time, CNW(T), which is equal to the sum of the set up cost, CNWset, fixed cost, CNWfix(T) and variable cost that is equal to the product of the Hourly Cost of negative work, HCNW and the duration of the time a functionable system spends in NFS (Equation 3), thus:

In the business orientated organisations the time spend in NFS can be translated into monetary value of the revenue lost. Hence, Knezevic [1] has introduced the concept of the cost of lost revenue, during a given interval of calendar time, CLR(T). This lost cost category could be even higher than that of revenue generated due to the potential consequences of the occurrences of NFE to the business and environment. For example, after the Deep Water Horizon the offshore rig explosion that killed 11 workers and caused a 134 million gallons crude oil spillage British Petroleum (BP) was found by the court to have been “grossly negligent”. As a consequence, BP was forced to pay over 20 billion dollars in settlement to cover the environmental damage and other claims by the five Gulf States and local governments. Of course, it was on top of the cost of resources used by them to recover from the disaster. Thus, the final expression for predicting the cost of negative work in MIRCE Science is as following:

The above expression can be used to predict the cost to the business in case of cannibalisation.

The expected profit

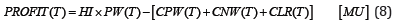

The expected profit to be generated by a given functionable system, during the stated period of time, PROFIT(T), could be calculated by making use of the MIRCE Profitability Equation [5], which also includes the cost of lost revenue, while a functionable system is in NFS, CLR(T), thus:

The above equation is the only one, known to the author, which unifies all aspects of the existence of a functionable system, including the phenomenon of cannibalisation. It unites the whole organisation into a single analytical scheme. It is a huge improvement in respect to current practices where the whole business process is addressed through a collection of a large number of self standing models that address a few influential parameters at a time.

Conclusion

The main objective of this paper was to examine the cannibalisation process, removing a required component from a designated system and installing it on the unserviceable system, as a mechanism of the motion of a functionable system in MIRCE Science. It impacts on the functionability work done and resources consumed during a given interval of calendar time. Although the cannibalisation process improves profitability or readiness of functionable systems, it can also lead to increased costs and disruption, divert resources from other activities and create additional technical and financial risks. Thus, cannibalisation is one of the drivers of profitability that could be predicted by applying the MIRCE Profitability Equation, which considers the whole organisation as a single analytical scheme. It is a huge improvement in respect to current practices where the whole business process is addressed through a collection of a large number of self standing models that address a few influential parameters at a time. The cannibalisation process must be rigorously managed and controlled to maintain regulatory and safety compliance, on one hand, and performing the trade-offs between saving measures, such as reducing investment in spares upfront, and the related longer-term value-for-money implications, on the other. Efficiency is also a priority, because the cannibalisation process is typically applied under operational pressure and tight deadlines. Finally, cannibalisation presents challenging underlying technical risks, subsequent consequences on testing during the operational process and cost implications on the long term financial support of the maintenance of heavily cannibalised components/equipment.

Acknowledgement

The author wishes to thank the American Journal Novel Research in Sciences for support given towards publishing of this paper.

References

- Knezevic J (2017) The origin of MIRCE science. pp. 232.

- Cassady RC (2021) Quantifying the impact of aircraft cannibalisation YR1 UA03-AFRL1. University of Arkansas, USA.

- Knezevic J (2014) MIRCE functionability equation. Int J Engineering Research and Applications 4(8): 93-100.

- Knezevic J (2016) MIRCE profitability equation. Journal of Mechanical Engineering 13(12): 115-122.

- Investigation into equipment cannibalisation in the Royal Navy, UK Ministry of Defence report.

© 2021 Jezdimir Knezevic. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)