- Submissions

Full Text

Novel Research in Sciences

Effects of 3D Virtual Garment Pattern Simulation Technology on Students’ Learning Quality

Ah Pun Chan1*, Ho Yin Cheung2, Wai Ching Chu3 and Kai Yuen Cheong4

1Lecturer, Fashion Design Programme, Hong Kong

2Part-time lecturer, Technology and Higher Education Institute of Hong Kong, Hong Kong

3Associate Professor, Fashion Design Programme, Hong Kong

4Assistant Professor, Innovative and Information Technology Program, Hong Kong

*Corresponding author: Ah Pun Chan, Lecturer, Fashion Design Programme, Hong Kong

Submission: July 19, 2021;Published: July 30, 2021

.jpg)

Volume8 Issue4July, 2021

Abstract

3D virtual garment simulation technology in apparel design, virtual fitting, pattern drafting, and production management contributes significantly to retail sales. It is widely used in the product development stage for apparel design. Combined with computer-aid manufacturing system, it significantly shortens the numerous trials and errors in the sampling process and provides a positive impact on the clothing industry by effectively creating individualized products in fashion items with short product life cycles. To fulfill the industry’s increasing demand for technical designers with skills using 3D virtual garment simulation software, students need to start training in their undergraduate studies. A pedagogy for 3D virtual garment simulation learning methods needs to be developed to help refine course structure and outline to undergraduate students how to meet the high demands in the industry on achieving the concept of customer orientation with proper garment fitting. This study recruited a total of 154 undergraduate students from two different design streams: womenswear design and knitwear design. A focus group interview was conducted to confirm and refine the items in the structured questionnaire and served to assert or explain the quantitative data through triangulation, which was based previous research findings from other researchers. The findings of this study showed that some technical skills must be learnt before using or learning 3D virtual garment simulation software.

Keywords:Learning experience; Pedagogy of 3D virtual simulation technology; Apparel size fitting; Customer orientation

Structured Practitioner Notes

What is already known about this topic

a) 3D virtual garment simulation technology significantly shortens the numerous trials and errors in the sampling process

b) increasing demand for technical designers with skills using 3D virtual garment simulation software

c) a pedagogy for 3D virtual garment simulation learning methods has not yet been explored.

What this paper adds

a) learning quality on using a 3D virtual garment prototyping software upon completion of a course from Hong Kong fashion undergraduate students

b) the relationships among various factors, which affects the learning outcomes of using a 3D virtual garment prototyping software

c) a framework for further study

Implications for practice and/or policy

a) suggested solution from the findings improve the course structure of 3D virtual garment simulation learning

b) problem-solving capability (SOLV) affects intention to use (INT) and outcomes (OUT)

c) performance evaluation of 3D simulation (EVAL) effects on intention to use (INT)

Introduction

Garment fit is one of the limitations of mass customization in the apparel industry. 3D virtual garment simulation technology together and 3D body scanning became a potential enabling technology, which creates individualized products [1]. To bring positive impact to the sustainable clothing industry, [2] proposed that 3D technology and anthropometric data can streamline the fit of products and improve supply chains environmentally, socially, and economically. It can also achieve a more sustainable development in garment fit. Petrova & Ashdown [3] and Loker et al. [4] highlighted the importance of body scanning in mass customization development by applying those technologies. Gupta et al. [5] proposed that 3D shape data analysis technologies will be more accessible in the next few decades. Therefore, understanding the relationship between body dimension and apparel dimensions using virtual garment simulation is fundamental for satisfying high customer demands in the apparel industry. In higher education, pattern drafting training relies on 2D paper-based methods for training in terms of liner tape measurements and alteration. 3D virtual garment simulation and 3D body scanning technology are seldom used for improving the learning outcomes and quality of pattern technology and prototyping skills. Fulfilling the high degree of customer needs requires designers to consider the elements of “personalization, one-to-one marketing, mass customization and co-creation” to offer premium products from a company to its customers [6]. Without proper training and learning experience for undergraduate students, they may not be able to achieve the concept of customer orientation in their future work. The purpose of this study is to understand the learning quality of Hong Kong fashion undergraduate students use of 3D virtual garment simulation technology. The significance of this study is to help develop a pedagogy for 3D virtual garment simulation learning methods, refine course structure, and outline to undergraduate students how to meet the high demands of the industry on achieving the concept of customer orientation with proper garment fitting. Proper training on how to create accurate sizing of garments is seen as an ideal communication tool between manufacturers, retailers, and consumers. By offering the “perfect fit” product to customers, the concept of customer orientation can be achieved.

Nowadays, 3D virtual garment simulation technology from apparel design, virtual fitting, pattern drafting, and production management contributes significantly to retail sales [7]. An accurate and efficient sizing system with a good understanding of fit is the only way to cater to consumers’ needs in traditional garment prototype development [5]. However, the numerous trials and errors in the sampling process are ineffective in short product life cycle fashion items. The application of 3D virtual garment simulation software with body scanning technology, on the other hand, may provide a positive impact on the clothing industry and create individualized products sustainably and effectively [1,8]. These technologies can streamline the fitting procedures of products and improve the supply chain environmentally, socially, and economically [2], as well as become important in the fashion industry in the earlier stages of prototype development [9]. 3D virtual garment simulation software consists of 2D pattern drafting, 2D pattern grading, 3D virtual simulation, and 3D sewing. They take into consideration the fabric’s physical properties, the texture effects, prototype fitting tension. It also eases evaluation for buyers when showcasing full rotation views with visual draping effects because no real prototyping is needed [10-13]. The approved designs can be transferred to the production line immediately, which shortens the communication, development, and production lead time between supplier and buyer.

3D virtual simulation prototyping software combined with the computer-aid manufacturing system is widely used in the product development process for apparel design. It will be more accessible in the next few decades [5]. To fulfill the increasing demand for technical designers using 3D virtual garment simulation, students need to prepare their training in their undergraduate studies. An example course content may include 2D pattern drafting, grading, 3D stitching, design details application, fabrication and texture selection, prototype virtual simulation, and 360-degree virtual presentation [11-13]. The identification of learning quality and outcomes on the application of traditional 2D pattern drafting skills onto 3D virtual garment simulation is highly desired. On the other hand, another critical parameter determining the fit and comfort of a garment is the ease allowance [14]. Garments with the right amount of ease could satisfy consumers’ expectations in fit. It influences how garment forms fit on the body, which is determined by style, comfort, movement, and perception of fit [15]. Accurate and efficient sizing of garments must be built based on a good understanding of fit, in which understanding body sizes and shapes are the best way to cater to consumers’ needs. However, the justification of ease allowance to apply onto 2D patterns are limited to evaluate in traditional 2D pattern drafting under the existing body dimension of human subjects in different regions [16].

Theoretical Background

According to Huang’s [17] study, the theory of constructivism is one of the important paradigms for the learners to develop new knowledge through the connection of their past knowledge and present study [17,18]. The knowledge of using 3D prototyping relies on knowing the linkage between 2D pattern skills and other technical skills, as well as 3D simulation techniques for students. To assimilate the application techniques from 3D virtual garment simulation software, it is essential to provide suitable training with appropriate course content for developing the new knowledge using the learned skills together with the corresponding variables under the theory of constructivism.

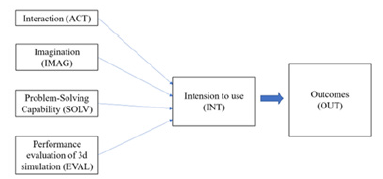

Based on the constructivist theory, the learning process provides authentic knowledge and a positive learning experience to learners [18,19]. This theory emphasizes the implication and extension of using and applying some constructs, which includes interaction (ACT); imagination (IMAG); problem-solving (SOLV), and performance evaluation (EVAL) for achieving the learning purposes on 3D garment virtual prototyping [18,20-28]. The concept of interaction (ACT) among the people and the environment during the learning process was suggested by Vygotsky’s [29] theory of cognitive development. Further to this concept [17,18,20,26] used Vygotsky’s theory in their studies and concluded that interaction provides a significant contribution in learning of 3D garment virtual prototyping. The learning features of virtual reality software consist of “immersion, interaction and imagination”, which were defined by Burdea and Coiffet [22]. The findings from [17,18,20] confirmed with the proposed concept from [22] that the construct of interaction (ACT) and imagination (IMAG) are the important features in constructivist theory for evaluating the learning outcome on 3D garment virtual prototyping. Dewey [30] proposed the important theory of using a problem-solving approach for learning in their study. The value of this construct was significantly ascertained by the studies of [17,18] that it is an important outcome from the constructivist approach. The extension of this theory of problem-solving approach was successfully developed into the Problem-Based Learning (PBL) approach for enhancing the teaching using multimedia [21,28]. The effectiveness of using 3D apparel simulation software of its 3D visualization relies on repeated training and performance evaluation (EVAL) throughout the overall training [27]. Bayar [20] believed that it improves the skills under the constructivist theory. Previous studies affirmed that constructs of interaction (ACT); imagination (IMAG); problemsolving (SOLV) and performance evaluation (EVAL) provides significant impacts to intention to use (INT) on learning and using 3D garment virtual simulation software.

However, the constructivist theory emphasizes the learning effect of incorporating the previously learned knowledge with the new training, the new 3D course and previous garment technology training are considered to refine its teaching methods and approaches. The evaluation of implementing those skills and abilities on 3D virtual garment prototyping upon completion of the course from Hong Kong fashion undergraduate students is not yet conceded. In academic research, [31] focused on analyzing the trend of using a 3D application in the garment industry, and [32] improved the accuracy of virtual simulation. Dunne [33] suggested an improvement plan on pattern drafting techniques on pants by using 3D virtual garment simulation software. Only a few studies evaluated students’ feedback on the effectiveness of CAD pattern course development skills [20,27]. The improvement of pedagogy on a 3D virtual software course and its content from actual learning outcomes and difficulties in applying 2D pattern skills and other technical skills onto 3D simulation applications has not yet been explored. Therefore, the conceptual framework of this study proposed to investigate the relationship between each construct and its impacts on the intention to use 3D software. Furthermore, the dimension of learning outcomes from fashion design students was the first time for involving in learning effectiveness measurement. Based on the above literature and our proposed conceptual framework, the research question of this study is as follows:

RQ1: What are the results of learning quality on using a 3D virtual garment prototyping software upon completion of a course from Hong Kong fashion undergraduate students?

RQ2: What are the relationships among various factors, which affect the learning outcomes of using a 3D virtual garment prototyping software?

Methodology

In this study, the research design and framework were based on the theory of constructivism [17,18], which was applied and modified by Bayar’s [20] study on measuring the skills of interaction (ACT), Imagination (IMAG), problem-solving capability (SOLV), performance evaluation, and intention to use (INT) from students’ ability on 3D virtual garment simulation software skills for further evaluation on design students in Hong Kong. In this study, mixed methods study was adopted. A focus group interview with 5 womenswear design students and 5 knitwear design students was used in a preliminary exploratory study. It served to confirm or explain the quantitative data through triangulation. Besides, the questionnaire items were piloted in a focus group interview. The finalized questionnaire was completed by a total of 154 undergraduate students who studied womenswear design (n= 75) or knitwear design (n=79), who learned 3D virtual garment simulation software from a tertiary institution.

Questionnaire Design

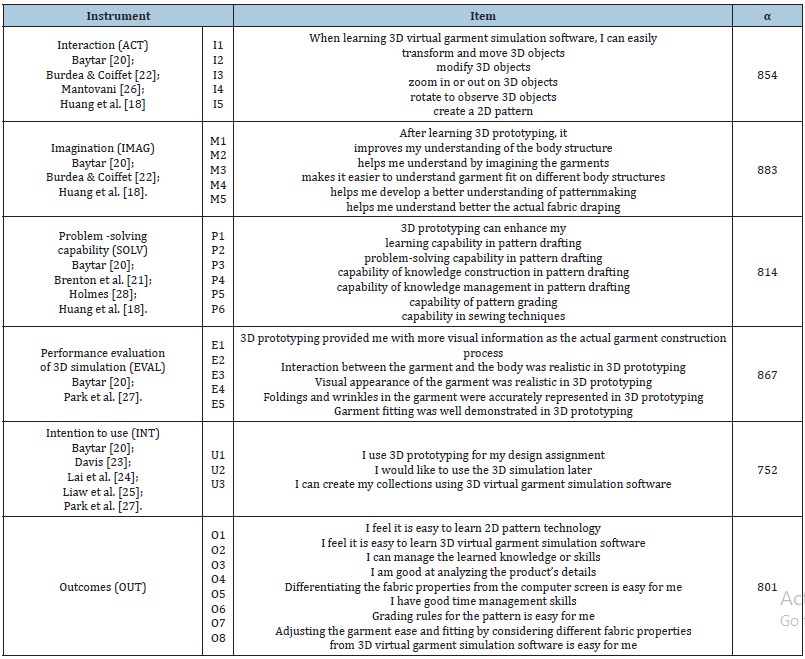

Based on previous studies [17,18,21-28] and the research questions in this study, five dimensions from previous research are utilized for examining the significant performance of students when using 3D virtual garment simulation software on creating 3D collections and 2D pattern. Together with the results from the focus group interview, six dimensions of measures with 33 items were applied to the questionnaire, which consists of interaction (ACT), imagination (IMAG), problem-solving capability (SOLV), performance evaluation, and intention to use (INT) in future, as well as self-evaluation of learning outcomes (OUT) after using 3D virtual garment simulation software (Table 1). A five-point Likert-scale with strongly disagree (1) to strongly agree (5) was implemented for all items. Apart from the proposed items in previous research, additional items from the focus group findings were adopted in the questionnaire. For instance, for the interaction instrument : “When learning 3D virtual garment simulation software, I can easily create a 2D pattern” (I5); for the imagination (IMAG) instrument: “After learning 3D prototyping, it helps me understand better the actual fabric draping” (M5); for the problem-solving instrument: “3D prototyping can enhance my capability of pattern grading and sewing technique” (P5, P6); for the performance evaluation (EVAL) instrument: “Garment fitting was well demonstrated in 3D prototyping” (E5); for the intention to use (INT) instrument: “I use 3D prototyping for my design assignment” and “I can create my collections using 3D virtual garment simulation software” (U1, U3); and 8 new items for evaluating the learning outcomes: “skills on drafting 2D pattern skills and using 3D virtual simulation software”, “managing the learned knowledge or skills”, “analyzing the product’s details”, “differentiating the fabric properties from the computer screen”, “time management skills”, “grading rules technique”, “adjusting the garment ease and fitting by considering different fabric properties” (O1-O8), were added into the questionnaire.

Table 1: Dimension of measures and reliability analysis.

Results and Discussion

Descriptive analysis and independent samples-Mann- Whitney U test of each dimension

154 students from two different design streams (group A: womenswear, and group B: knitwear) took the 3D virtual garment simulation software of the CLO system module with the same course structure and outline during their undergraduate study. The reliability test shows that there is high data dependability and consistency for interaction (ACT), imagination (IMAG), problemsolving capability (SOLV), performance evaluation, and intention to use (INT) in the future, as well as self-evaluation of learning outcomes (OUT) after using 3D virtual garment simulation software. Cronbach’s alpha is .854, .883, .814, .867, .752 and .801 respectively.

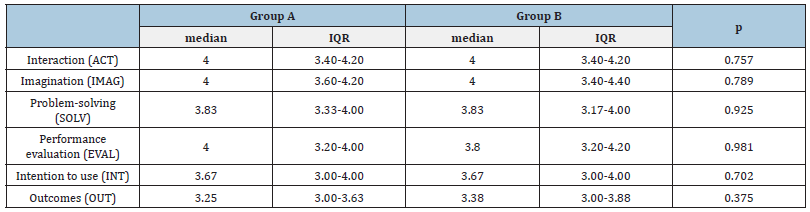

The median and interquartile range of each dimension for group A are 4.00 (3.40-4.20), 4.00 (3.60-4.20), 3.83 (3.33-4.00), 4.00 (3.20-4.00), 3.67 (3.00-4.00), and 3.25 (3.00-3.63). The median and interquartile range of each dimension for group B are 4.00 (3.40- 4.20), 4.00 (3.40-4.40), 3.83 (3.17-4.00), 3.80 (3.20-4.20), 3.67 (3.00-4.00), and 3.38 (3.00-3.88) accordingly. There is no significant difference in their responses for each dimension between the two groups of design students. The corresponding p-values are (p=.757, p<.05; p=.789, p<.05; p=.925, p<.05; p=.702, p<.05; p=.375, p<.05) under the non-parametric independent samples Mann-Whitney U Test (Table 2).

Table 2:Descriptive data and p-value of the two groups of respondents for each dimension.

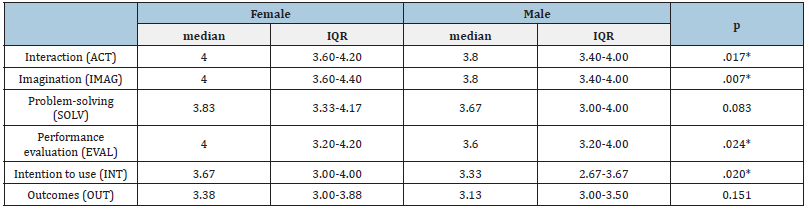

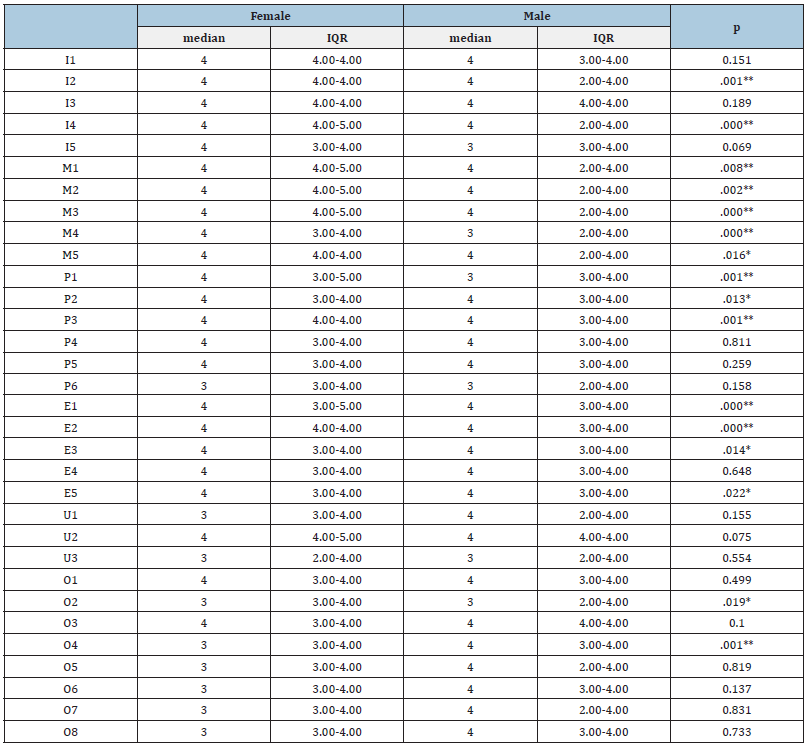

The median and interquartile range of each dimension for female are 4.00 (3.60-4.20), 4.00 (3.60-4.40), 3.83 (3.33-4.17), 4.00(3.20-4.20), 3.67(3.00-4.00), and 3.38(3.00-3.88). The median and interquartile range of each dimension for male are 3.80(3.40- 4.20), 3.80(3.40-4.40), 3.67(3.17-4.00), 3.60(3.20-4.20), 3.33(3.00- 4.00), and 3.13(3.00-3.88) respectively. Significant difference between female and male are found in the dimension of interaction (ACT) (p= .017, p<.05), imagination (IMAG) (p=.007, p<.05), performance evaluation (EVAL) (p=.024, p<.05), and intention to use (INT) (p=.020, p<.05) under the non-parametric independent samples Mann-Whitney U test (Table 3).

Table 3:Descriptive data and p-value of the two gender groups for each dimension.

N=115 (Female), N=39(Male); IQR=interquartile range (25th percentile to 75th percentile)

*p< .05; **p< .01; non-parametric independent samples Mann-Whitney U Test.

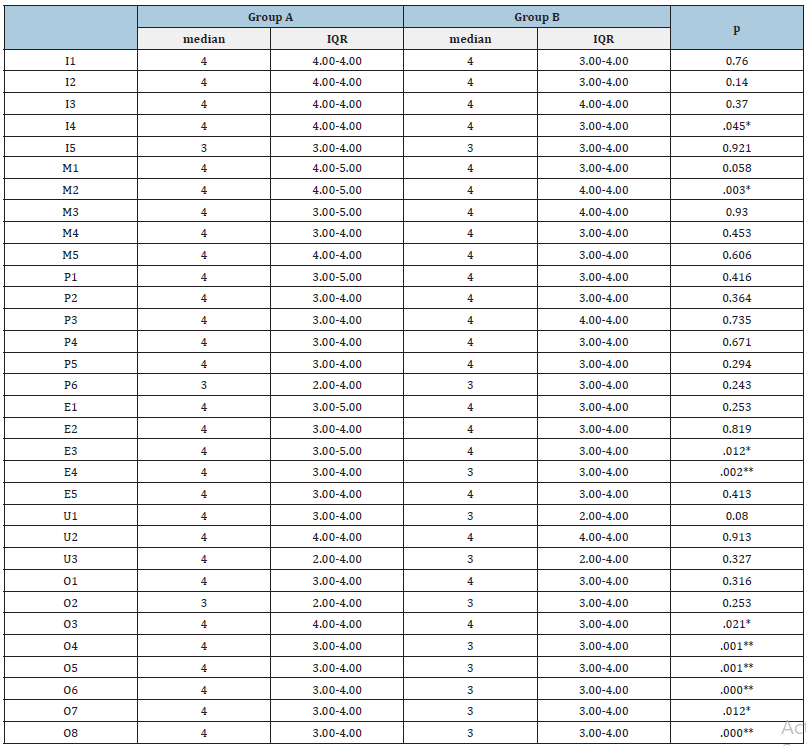

Independent samples-Mann-Whitney U test in two groups of respondents

Even though there is no statistical difference found in each dimension in Table 2, statistical differences are found in item (I4) in the dimension of interaction (ACT), “rotation to observe 3D objects from various perspectives” between the two groups of students (p = .045, p<.05) in Table 4. Items (I2) “modification of 3D objects” and (I4) “rotation to observe 3D objects from various perspectives” also showed a significant difference between the two gender groups (p = .001, p<.01 and p = .000, p<.01 respectively) in Table 5. It shows that male subjects feel it is relatively difficult to control 3D objects than females when using 3D simulation software. Interviewees from the focus group commented that the control keys for the rotation of 3D objects are different from other 3D simulation software. They have to spend more time to familiarize and memorize the control functions and hotkeys for rotating 3D objects to different angles. The interview feedbacks and statistical results affirm the comments from the studies of [20,27] that the repetitive processes in using 3D technology help to reinforce the Imagination (IMAG) skills of students.

Table 4: Descriptive data and p-value of each item in the two groups of respondents.

Group A (N=75), Group B (N=79); IQR = interquartile range (25th percentile to 75th percentile)

Table 5:Descriptive data and p-value of each item in the two gender groups.

N=115 (Femal), N=39 (Male); IQR = interquartile range (25th percentile to 75th percentile)

*p< .05; **p< .01; non-parametric independent samples Mann-Whitney U Test.

In the Imagination (IMAG) dimension, there is a significant difference in item (M2) “better imagination of 3D garment simulation when using 3D prototyping”, between the two groups of students (p=.003, p<.05) in Table 4. There are significant differences in all items (M1 to M5) between the two gender groups (p=.008, p<.01; p=.002, p<.01; p=.000, p<.01; P=.000, p<.01; p=.016, and p<.05 respectively) in Table 5. Male subjects disagree that their skills in understanding body structure, 3D garment draping, the concept of garment fit, pattern drafting skills, and fabric draping can be improved after learning 3D prototyping. The respondents from the focus group interview criticized that before learning and using 3D prototyping, having a good understanding and applications of all those elements are essential to achieve the learning outcomes and enhance the learning effectiveness in using 3D virtual garment simulation software. It highly ascertains the learning effectiveness of the learners utilizing their learned skills onto the new learning processes.

In the problem-Solving Capability (SOLV) dimension, there is no significant difference between the two groups of students in Table 4. However, there are significant differences for items (P1) “capability in patternmaking”, (P2) “problem-solving capability in patternmaking”, and (P3) “capability of knowledge construction in patternmaking” between the two gender groups (p=.001, p<.01; p=.013, p<.05; p=.001, and p<.01 respectively) in Table 5. Regarding the problem-solving capability in using 3D prototyping from students, interviewees mentioned that the grading techniques were not well developed from other taught practical classes. They would get into trouble if they were told to do the grading in the software by themselves. The principle and technique of using 3D stitching in the software are different from the actual garment sewing, therefore the requirement of sewing knowledge is not high at this point.

In the performance evaluation of 3D simulation dimension (EVAL), there are significant differences in items (E3) “visual appearance of the garment was realistic in 3D prototyping” and (E4) “folding and wrinkles in the garment were accurately represented in 3D prototyping” between the two groups of students (p = .012, p<.05; p = .002, p<.01) in Table 4. However, there are significant differences for items (E1) “3D prototyping provided me as much visual information as the actual garment construction process”, (E2) “interaction between the garment and the body was realistic in 3D prototyping”, (E3) “visual appearance of the garment was realistic in 3D prototyping”, and (E5) “Garment fitting was well demonstrated in 3D prototyping” between two gender groups (p=.001, p<.01; p=.013, p<.05; p=.001, and p<.01 respectively) in Table 5. The garment fitting evaluation, including fabric wrinkles and folding, is critical for the interviewees. They are unable to have sufficient confidence in understanding what the optimum level of garment pressure is and what is the ease of 3D prototype garments, as well as what is the reasonable level of corresponding fabric draping of the fabric to use. Furthermore, it is no doubt that problem-solving (SOLV) using pattern technology [18,20,21,28] and performance evaluation (EVAL) skills on garment fitting, as well as fabric properties [20,27] are important in judging the visual effects of 3D prototyping. Therefore, the effectiveness of garment technology training is a prerequisite for taking advantage of the 3D prototyping learning process.

In the intention to use (INT) dimension, no significant difference was found between the two groups of students (Table 4) or between the two gender groups. Focus group respondents were aware that 3D virtual garment simulation software will be the trend in the next few decades [5], and there is a need to meet the requirements to shorten the product development process from many fast fashion brands, however, the students seldom use 3D virtual garment simulation software in their assignments because there were no special requests from other design module tutors. Moreover, they have a lack of confidence in finishing the 3D prototype by themselves

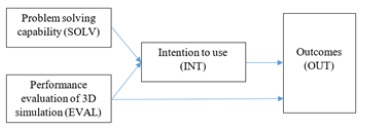

Figure 1:Conceptual framework of this study.

In the outcomes (OUT) dimension, there are significant differences in the items (O3) “I can manage the learnt knowledge or skills”, (O4) “I am good at analyzing the product’s details”, (O5) “differentiating the fabric properties from the computer screen is easy for me”, (O6) “I have good time management skills”, (O7) “grading rules for the pattern is easy for me”, and (O8) “adjusting the garment ease and fitting by considering different fabric properties from 3D virtual garment simulation software is easy for me” between the two groups of students (p=.021, p<.05; p=.001, p<.01; p=.001, p<.01; p=.000, p<.01; p=.012, p<.05; p=.000, p<.01) in Table 4. However, there are significant differences in the items (O2) “I feel it is easy to learn 3D virtual garment simulation software” and (O4) “I am good at analyzing the product’s details” between two gender groups (p=.019, p<.05 and p=.001, p<.01 respectively) in Table 5. The learning performance between womenswear and knitwear students are different in terms of the ability of visualization on 3D prototype and differentiation of the product’s details and fabric properties. The finding also shows that female students feel it is easier to learn 3D virtual garment simulation software and analyze product details than male students (Figure 1).

Regression Analysis

To estimate the relationship between the various factors, the average values of the items were calculated for each of the constructs. Table 6 shows the descriptive analysis of these constructs. The Pearson correlation matrix of these constructs are calculated in Figure 2. The correlation coefficients are shown in the upper triangle, while the pairwise regression plots are shown in the lower triangle. The diagonal shows the density distribution of the constructs. As shown in the figure, some of the correlations are relatively weak. For example, interaction (ACT) correlates relatively weakly with intention to use (INT) (r=0.492) and outcomes (OUT) (r=0.478). Imagination (IMAG) also correlates weakly with outcomes (OUT) (r=0.493).

Table 6: Descriptive statistics of the overall average of each construct.

Figure 2:Correlation matrix of the six constructs.

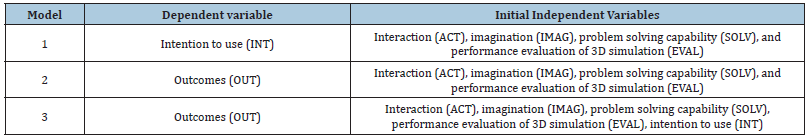

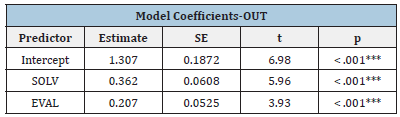

To further investigate the relationship between the constructs, three regression models were analyzed, as shown in Table 7. Model 1 attempts to determine how intention to use depends on Interaction (ACT), imagination (IMAG), problem-solving capability (SOLV), and performance evaluation of 3D simulation (EVAL). Model 2 replaces intention to use (INT) by outcomes (OUT), while the dependent variables are the same as in Model 1. Model 3 is similar to Model 2 except that intention to use (INT) is also used as an independent variable. Note that the independent variables are preliminary for each model because a stepwise regression approach (both forward and backward) was used to remove the poorly fit variables in the end result. The collinearity between intention to use (INT) and the four other independent variables was also handled during the stepwise iterations. Stepwise regression of Model 1 shows that only problem solving (SOLV) and performance evaluation of 3D simulation (EVAL) have statistically significant non-zero regression coefficients, as shown in Table 8. Consistent with Figure 1, interaction (ACT) and imagination (IMAG) are shown to be irrelevant as far as intention to use (INT) is concerned.

Table 7: Variables used in the three-regression model in this study.

Table 8:Regression analysis for Model 1.

Adjusted R-squared = 0.399

*p<0.05; **p<0.01; ***p<0.001.

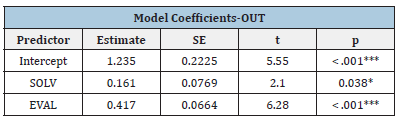

For the dependence of the outcomes (OUT), Table 9 shows again that only problem solving (SOLV)and performance evaluation of 3D simulation (EVAL) are statistically significant factors of outcomes. However, if intention to use (INT)) is also included as an independent variable, as shown in Table 10, then only performance evaluation of 3D simulation(EVAL) and intention to use(INT) remain as the statistically significant factors of outcomes(OUT).

Table 9:Regression analysis for Model 2.

Adjusted R-squared = 0.414

*p<0.05; **p<0.01; ***p<0.001.

Table 10: Regression analysis for Model 3.

Adjusted R-squared = 0.453

*p<0.05; **p<0.01; ***p<0.001.

From these models, it is apparent that

a) Interaction (ACT) and imagination (IMAG) do not affect intention to use (INT) or outcomes (OUT).

b) Problem-solving capability (SOLV) has a direct effect on intention to use (INT), but it does not have a strong direct effect on outcomes (OUT). It is a better model that it acts through intention to use (INT) to impose an indirect effect on outcomes (OUT).

c) Performance evaluation of 3D simulation (EVAL) has a direct effect on intention to use (INT). It then acts through intention to use (INT) to impose an indirect effect on outcomes (OUT), but it also has a direct effect on outcomes (OUT).

These relationships are summarized in Figure 3, which serve as a framework for further study. Comparing with the theories review of constructivist by Hunag [18], the constructs of interaction (ACT) and imagination (IMAG) do not influence the learning of 3D prototyping in this study. Even though [22] mentioned the construct of interaction (ACT) and imagination (IMAG) are the important features in constructivist theory for evaluating the learning outcome on 3D garment virtual prototyping, the interpretation and implication of our findings may be due to the reason that Hong Kong fashion design students usually use the individualist approaches on problem-solving and evaluation for learning the new 3D subjects. They are lacking self-confidence in advanced 3D subjects and unable to assimilate the learned knowledge so that they do not rely on using the collectivist approaches of interaction and imagination among learners, facilitators, and environment during 3D learning processes. The establishment of students’ confidence in using 3D prototyping is critically strengthened by the construct of problemsolving capability and performance evaluation of 3D simulation.

These two skills are necessary to be developed from the previous training on various types of garment technologies, its relationship ascertains the active role of learners using and applying the familiar knowledge effectively onto the new study areas on 3D prototyping, which proposed by Dewey [30], Huang [17], Huang et al. [18] and Park et al. [27].

Figure 3:Research model inspired by the regression analysis.

Conclusion

The above regression analysis proved that problem-solving capability (SOLV) affects intention to use (INT) and outcomes (OUT). Performance evaluation of 3D simulation (EVAL) affects intention to use (INT). It is in no doubt that problem-solving (SOLV) using pattern technology [10,20,21,28] and performance evaluation (EVAL) skills on garment fitting, as well as fabric properties [20,27], are important in judging the visual effects of 3D prototyping. Therefore, the effectiveness of garment technology training is a prerequisite for taking advantage of the 3D prototyping learning process. Nevertheless, many researchers claimed that interacting with 3D objects such as observation, modification, and rotation is essential for the completion of 3D training [18,22,26]. However, based on the above statistical analysis from 154 students, high levels of training for garment fitting evaluation and techniques, including fabric wrinkles and folding, reinforcement of sewing techniques, as well as grading techniques, are critical for reinforcing their basic skills before applying the 3D prototyping. In constructivist theory, the suggested solution for enhancing the learning experience and encouraging to be an active role for students from the findings of this study on learning 3D prototyping process is to extend the course lecture hours and interactive activities to provide more time for student training, so they can familiarize and memorize the control functions and hotkeys for 3D object rotation from different angles.

Park et al. [27] stated that the repetitive processes in using 3D technology help reinforce the imagination (IMAG) skills of students [20]. Motivation in learning interest needs to be enhanced, especially for male students. To comprehend and improve the new 3D learning experience, the ability of technological and comprehensive understanding, knowledge on body structure, 3D garment draping, the concept of garment fit, 2D pattern drafting skills, and fabric draping are essential to effectively achieve the learning outcomes of using a 3D virtual garment simulation software under the constructivist theory. Another training strategy for assimilating the previous knowledge is to enhance the interpretation skills for the optimum level of garment pressure and ease of 3D prototype garments, as well as the understanding of fabric draping of the fabric used before learning 3D virtual garment simulation software. Lastly, creation, it is encouraged to use 3D virtual garment simulation software for other design-related assignments from other subjects to develop students’ confidence in using a 3D prototype. The proposed model in this study is needed for further evaluation and comparison with more data in future.

Acknowledgement

The authors wish to thank the Technological and Higher Education Institute of Hong Kong for funding this research project (THEi Seed Grant Scheme, Project No. SG1819104), and all interviewees who participated in the study as well as the Centre of Sustainable Design and Environment from RGC project (Ref. UGC/ IDS 25/16) for providing the instrument and software support.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

- Fralix M (2001) From mass production to mass customization. Journal of Textile and Apparel, Technology and Management 1(2): 1-7.

- Sizemic (2012) A service developed to commercialize Size UK data.

- Petrova A, Ashdown SP (2008) Three-dimensional body scan data analysis body size and shape dependence of ease values for pants' fit. Clothing and Textiles Research Journal 26(3): 227-252.

- Loker S, Ashdown S, Carnrite E (2008) Dress in the third dimension: Online interactivity and its new horizons. Clothing and Textiles Research Journal 26(2): 164-176.

- Gupta D, Zakaria N (2014) Anthropometry, apparel sizing and design. (2nd edn), Woodhead Publishing, UK.

- Alt R, Ehmke JF, Haux R, Henke T, Mattfeld DC, et al. (2019) Towards customer-induced service orchestration-requirements for the next step of customer orientation. Electronic Markets 29: 79-91.

- Nayak R, Padhye R (2018) Artificial intelligence and its application in the apparel industry. In: Automation in Garment Manufacturing. Woodhead Publishing, UK, pp. 109-138.

- Chang YS, Chien YH, Lin HC, Chen MY, Hsieh HH (2016) Effects of 3D CAD applications on the design creativity of students with different representational abilities. Computers in Human Behavior 65: 107-113.

- Ashdown S (2013) Not craft, not couture, not ‘home sewing’: Teaching creative patternmaking to the iPod generation. International Journal of Fashion Design, Technology and Education 6(2): 112-120.

- Boorady LM, Hawley JM (2008) The wonders of technology: Teaching becomes virtual. Clothing and Textiles Research Journal 26(2): 131-142.

- https://browzwear.com/

- https://www.clo3d.com/

- EFI Optitex (2020) Fashion design software: 2D/3D CAD CAM.

- Chen Y, Happiette M, Bruniaux P, Ng R, Yu W (2006) Estimation of ease allowance of a garment using fuzzy logic. Fuzzy Applications in Industrial Engineering, Springer, Germany, 201: 367-379.

- Li WH (2013) An investigation of design preferences and interrelationship between aesthetics and fitting concerns in Hong Kong menswear fashion. Doctoral dissertation, The Hong Kong Polytechnic University, China, p. 276.

- Chan ACK (2014) The development of apparel sizing systems from anthropometric data. Anthropometry, Apparel Sizing and Design, pp. 167-196.

- Huang HM (2002) Toward constructivism for adult learners in online learning environments. British journal of educational technology 33(1): 27-37.

- Huang HM, Rauch U, Liaw SS (2010) Investigating learners’ attitudes toward virtual reality learning environments: Based on a constructivist approach. Computers & Education 55(3): 1171-1182.

- Jonassen DH (1994) Thinking technology: Toward a constructivist design model. Educational technology 34(4): 34-37.

- Baytar F (2018) Apparel CAD patternmaking with 3D simulations: impact of recurrent use of virtual prototypes on Students’ skill development. International Journal of Fashion Design, Technology and Education 11(2): 187-195.

- Brenton H, Hernandez J, Bello F, Strutton P, Purkayastha S, et al. (2007) Using multimedia and Web3D to enhance anatomy teaching. Computers & Education 49(1): 32-53.

- Burdea GC, Coiffet P (2003) Virtual reality technology. (2nd edn), John Wiley & Sons, USA.

- Davis FD (1989) Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Quarterly 13: 319-340.

- Lai CM, Huang HM, Liaw SS, Huang WW (2009) A study of user’s acceptance on three-dimensional virtual reality applied in medical education. Bulletin of Educational Psychology 40(3): 341-362.

- Liaw SS, Huang HM, Chen GD (2007) Surveying instructor and learner attitudes toward E-learning environments. Computers & Education 49(4): 1066-1080.

- Mantovani G (2003) VR learning: Potential and challenges for the use of 3D. Towards cyberpsychology: Mind, cognitions, and society in the Internet age, pp. 208-225.

- Park J, Kim DE, Sohn M (2011) 3D simulation technology as an effective instructional tool for enhancing spatial visualization skills in apparel design. International Journal of Technology and Design Education 21(4): 505-517.

- Holmes J (2007) Designing agents to support learning by explaining. Computers & Education 48(4): 523-547.

- Vygotsky LS (1978) Mind in society: Development of higher psychological processes. In: Cole, et al. (Eds.), Mind in society.

- Dewey J (1916) Democracy and education: An introduction to the philosophy of education.

- Sayem ASM, Kennon R, Clarke N (2012) Resizable trouser template for virtual design and pattern flattening. International Journal of Fashion Design, Technology and Education 5(1): 55-65.

- Lee E, Park H (2017) 3D virtual fit simulation technology: Strengths and areas of improvement for increased industry adoption. International Journal of Fashion Design, Technology and Education 10(1): 59-70.

- Dunne L (2012) 3D simulation and the apparel design curriculum.

© 2021 Hui-Wen Huang. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)