- Submissions

Full Text

Novel Research in Sciences

Injection Moulding of Bipolar Plates for Fuel Cells in Trucks and Busses

Thorsten Hickmann*1*

Managing Director of Eisenhuth Gmbh & Co. KG, Germany

*Corresponding author: Thorsten Hickmann, Managing Director of Eisenhuth Gmbh & Co. KG, Germany

Submission: Janaury 11, 2021;Published: February 05, 2021

.jpg)

Volume5 Issue4January, 2021

Abstract

The topic of renewable energies is currently playing a growing role. The topic of fuel cells and hydrogen has been identified by both the European Union and the Federal Government as a central field of action. When implementing fuel cell systems for cars and trucks, the cost implications must also be considered at all times. Especially for the latter, graphite bipolar plates are particularly suitable in truck and bus applications. Against this background, a detailed consideration of this component must be realized from the very beginning in a highly way of automatic production. For this reason, injection moulding is a good way for an automized production of graphitic bipolar plates.

Keywords: Injection moulding;Bipolar plate;Graphite;Fuel cell;Car fuel cell stack;Truck fuel cell stack

Introduction

When it comes to the processability of highly filled plastic compounds, a compromise must be found between good flowability on the one hand and special properties such as electrical conductivity on the other. The flowability and thus the processability is an essential cost determinant when it comes to manufacturing costs. The better the flowability of the highly filled plastic, the easier it is to process and the lower the manufacturing costs. Suitable compounds are an essential starting material in electrochemical applications [1]. These are plastics that are highly filled with graphite and carbon black and thus have electrically and thermally conductive properties [2].

Discussion

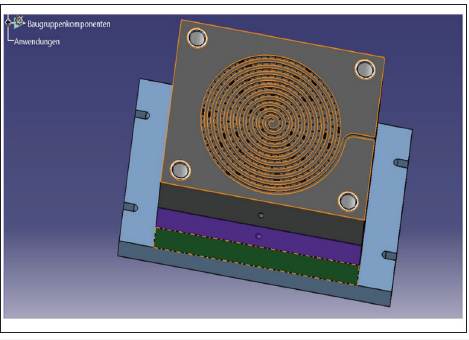

Graphite compounds are thus a reliable material for bipolar plates, especially in truck applications. The compounds meet the special requirements in terms of corrosion resistance (partly with coating), availability as well as resource efficiency [3]. In order to find out which formulation of the materials is suitable, several series of tests were carried out. Therefore, two standard tools were used: One is a „spiral tool“, the other is a test rod tool. With the spiral tool (Figure 1), it is possible to test the viscosity [4]. With the parts from the test rod tool, on the one hand, the mechanical strength of the components can be tested [5], and on the other hand, the electrical conductivity.

Figure 1: Spiral tool.

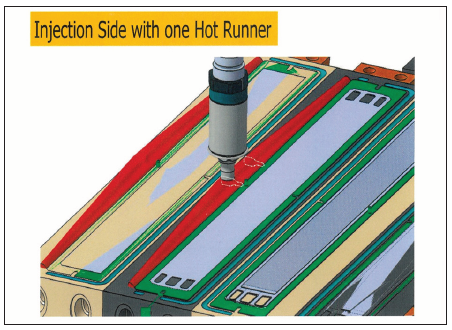

The task now is to transfer this knowledge to series production. The focus is on a mould for bipolar plates, the electrically conductive components required to build a fuel cell stack. In view of the explosively increasing quantities, it is important to produce an injection mould. The corresponding mould can be seen in the picture. The task is to investigate. How a single mould and a fourcavity mould behave. The four-cavity mould naturally has a positive effect on the number of pieces. In contrast, the multiple mould makes high demands with regard to the design of the mould (Figure 2). The following applies to the 4-cavity mould: The precise production of bipolar plates from highly filled graphite compounds has been a major technical challenge to date, especially for fuel cells. Due to the high injection pressures and short flow paths of the compound melt required in the injection moulding process, the production of larger bipolar plates is currently extremely difficult. It is therefore all the more important to examine the process in detail: starting with the design, the simulation carried out, the production of the mould and finally the injection moulding process itself.

Figure 2: Quadruple components.

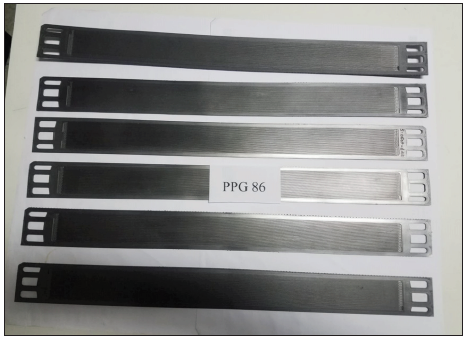

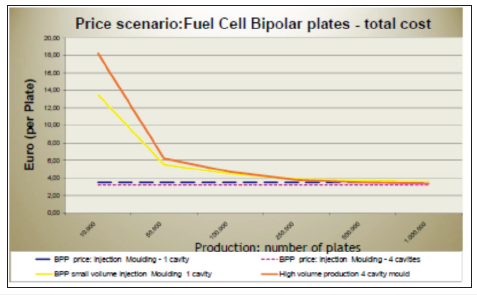

This project was realised and the parts manufactured. The components (Figure 3) are 660mm long and 70mm wide, the size is designed according to the automotive application. So what does the cost structure look like? In the figure, the costs for a single form and a quadruple form have been compared. If we now look at the manufacturing costs and take into account the tooling costs, we get the figures from Figure 4. Here we can see that the final price of the panel is well below 4 euros, i.e. 3.50 euros (1-cavity mould) or 3.25 euros per piece (4-cavity mould). If the tooling costs are taken into account, an approximation at this price is already reached at 250,000 bipolar plates. As a rule, the Autobil stacks have an average cell count of 470 cells. This means that with 250,000 cells, just 531 stacks could be produced. With one stack per vehicle, there would be 531 vehicles. This makes it clear that from the early stages of vehicle production, consideration must be given to largely automated production of the bipolar plates. This can be realised accordingly through the injection moulding process.

Figure 3: Parts from the mould.

Figure 4: Price scenario.

Conclusion

At present, more than ever, the topic of fuel cells and hydrogen has been identified as a central field of action by both the European Union [5] and the German government. The focus is on the development and optimisation of fuel cells for passenger car applications, but also more recently for trucks and buses. Especially for the latter, graphite bipolar plates are virtually predestined. This means that the frequently used system components (such as the membrane unit and bipolar plate) have to be manufactured with a high degree of automation from the early initial stage, from a series production point of view. The injection moulding process is particularly well suited for such a high-level automation task in the production of graphite bipolar plates. In this respect, a costefficient design is more than appropriate already in the early phase.

References

- Larminie J, Dicks A (2000) Fuel cell systems explained, first edition. Wiley, New York, USA.

- Bonnet M (2013) Plastics technology. Springer Verlag, ISBN: 978-3-658-03139-8, Hamburg, Germany.

- Hickmann T (2008) Plastic applications in PEM fuel cells. VDI Reports, No 2035, Berlin, Germany, pp. 81-83.

- Mohrdieck C, Venturi M, Breitrück K (2017) Mobile applications. In: Töpler J & Lehmann J (Eds.), Hydrogen and Fuel Cell, Springer Verlag, Germany, ISBN: 978-3-662-53359-8.

- (2020) EU-Kommission: Press remarks by President von der Leyen on the occasion of the adoption of the European Climate Law, 04th march, Brussels, Belgium.

© 2021 Thorsten Hickmann. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)