- Submissions

Full Text

Novel Research in Sciences

Photocatalytic Degradation of Methylene Blue Using Silver Nanoparticles Synthesized from Gymnema Sylvestre and Antimicrobial Assay

Murali Santhosh Kumar, Supraja N and David E*

Department of Biotechnology, India

*Corresponding author: E David, Department of Biotechnology, India

Submission: July 22, 2019; Published: September 25, 2019

.jpg)

Volume2 Issue2September 25, 2019

Abstract

Products from recycled textile wastes have the benefit of low raw material and manufacturing costs. Potential of needle punched nonwovens using fibre wastes for effective sound absorption has been studied with two different thickness levels. Needle punched nonwoven materials of coir, waste cotton, polyester, viscose, acrylic blends were assessed for their efficacy on damping the noise levels. Experimental results reveal that coir and cotton / viscose nonwoven materials are suitable for moderate (1600–2500 Hz) and high frequency (2000 Hz–4000 Hz) applications respectively, while cotton / polyester and polyester / viscose / acrylic blends are suitable low to moderate frequency (800–1200 Hz to 1600–2500 Hz) applications.

Keywords: Coir damping; Frequency; Reverberation; Sound

Introduction

Noise control and its principles play an important role in creating an acoustically pleasing environment, using various techniques and different materials. In the sound insulation process, conversion of acoustic energy into heat takes place, in terms of oscillation of air molecules in the interstices of the porous material, frictional losses and loss of momentum. Yakir et al. [1] suggested the numerical methods for calculating the acoustic performance using the theory of Zwikker and Kosten, of the sound propagation through porous media. Chen et al. [2] proved that noise absorption of material depends on the efficiency of the material structure to dampen the sound wave reflection. Nonwoven composites with activated carbon fibers as the surface layer have significantly higher sound absorption co-efficient than the glass fiber surfaced composites in both low (100–1600 Hz) and high frequency (1600 – 6400 Hz) ranges. Shoshani et al. [3] found that, between 250 – 1000 Hz, the noise absorption co-efficient of tufted carpets, backed by several layers of stitch bonded nonwoven, were significantly higher than those of unbacked carpets, where noise absorption depends on the thickness of backing. Shoshani et al. [4] found that as the air gap between tufted carpet covering and the wall increases the noise absorption capacity significantly in the low and medium frequency range, 250 Hz < f < 1000 Hz. Lou et al. [5] proved that the sound absorption efficiency of the composites decreases with higher composite density, especially for medium and high frequency sound waves, due to reflection of the incident sound waves. Young Joo Na et al. [6] suggested the use of microfiber-fabrics due to the high surface area, for sound absorption applications. However, the potential use of needle punched nonwovens produced with textile waste materials has not explored to the significant extent [7].

Materials and Methods

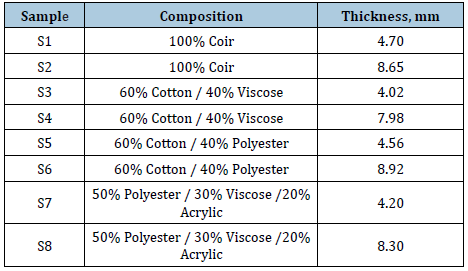

Cotton, coir, polyester, viscose, acrylic fibres and their blends (Table 1), from commercial production process wastes, were used for producing nonwoven by needle punching technique, using parallel laid webs. The wastes were collected from carding machine, were recycled using Willlow machine, on weight basis (M/s Ammayappa Nadar Mills, Thalavaipuram, Tamil Nadu). Dilo (Germany) needle punching machine (PSG Foundry, Coimbatore, Tamilnadu) was used with the working width of 600 mm, using compressive Batt feeding system. Two needle boards, with 12 needles per inch, were used with 170 strokes per minute with the delivery speed of 0.25 meter per minute using sandwiched carded web and the distance between needle bar and base plate was maintained at 10mm. Depth of needle penetration was maintained at 2.5 cm.

Table 1:Construction details of needle punched nonwoven materials.

Thickness of the samples were measured using ASTM D 1777 96 (2002 - webs), average 10 values were taken for the report and analysis purpose. A reverberation chamber (Acoustic Laboratory, PSG College of Technology, Coimbatore), as explained in the literature by Na et al 6, equipped with a loud speaker, microphone and sound level meter was used to measure reduction in the sound levels using different nonwovens samples. Reverberation room absorption was measured before and after placing the test specimen inside the room.

Results and Discussions

Damping of nonwovens materials, in terms of decibels, at different frequency levels showed a bell-shaped curve in the case coir nonwovens materials for both the thicknesses of the specimen. Interestingly, in both the cases, the maximum damping (10 – 11 dB) was observed at the frequency of 2000 Hz with marginal difference (Figure 1a). On the other hand, in the case of cotton / viscose blend (Figure 1b), different trends were observed in low and high thickness nonwoven materials. In the case of higher thickness, significantly higher damping effects, up to 162%, were observed compared to that of lower thickness nonwoven samples at 3000 Hz, which narrowed down at higher frequencies, akin to the results reported earlier [3,4].

Figure 1:

In the case of cotton / polyester blended nonwovens materials, the damping effect apparently increased at lower frequency levels i.e. 400 – 1200 Hz and beyond that levels, the effect appeared to stabilize without any significant improvement further. However, there was marked difference between low and higher thickness nonwovens samples, where samples of higher thickness demonstrated higher damping potential (Figure 1c). In the case of tertiary blend of polyester with viscose and acrylic, a significant difference in noise reduction was observed in the 1200 – 1600 Hz frequencies between lower and higher thickness nonwoven materials (Figure 1d). On either side of this frequency levels, no appreciable differences were obtained in these samples.

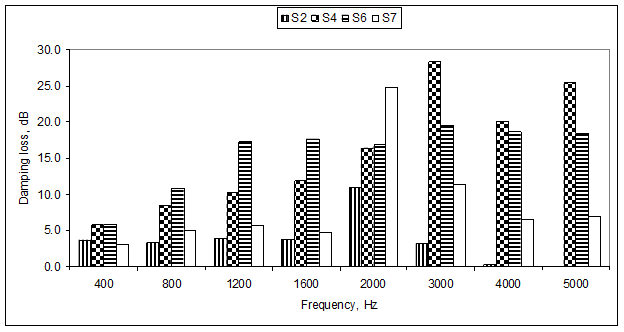

A comparison of all the samples, at their best performance level, showed interesting observations (Figure 2). Coir fibres, which are normally coarser compared to cotton, polyester, viscose and acrylic exhibited lower damping potential, which can be correlated to the earlier observations made by Na et al. [6] and the difference increased at higher frequency levels used in the present study i.e. 4000 – 5000 Hz.

Figure 2:

Conclusions

Efficacy of nonwovens materials in damping the sound shows that needle punched nonwovens can be potentially used in sound-insulation applications. Composition of nonwovens and their thickness play major role in reducing noise levels. Compared to coir fibre based nonwovens materials, cotton blends with viscose or polyester, polyester blends with viscose and acrylic show good damping potential that can be exploited in the frequency range of 2000 – 4000 Hz, where the reduction in sound levels was significant. The reduction of sound, in terms of dB, appeared to reach the saturation in all the specimens beyond certain levels of the frequencies, which may be further enhanced by nonwoven of microfibre wastes. Nevertheless, further detailed analysis, involving measurement of porosity and nonwoven density, may be pursued for further optimization of the sound absorption properties of the nonwoven’s materials.

Acknowledgement

The authors acknowledge the Tamil Nadu State Council for Science and Technology, Chennai for extending the financial grant to carry out the above work as a part of the funded project, PSG College of Technology, Coimbatore and M/s Ammayappanadar Mills, Thalavaipuram for providing their processing facilities.

References

- Yakir S & Yakov YnA, Text Res J (1999) 69: 519-526.

- Chen Y & Jiang N, Text Res J (2007) 77: 785-791.

- Shoshani Y Z, Text Res J (1990) 60: 452-456.

- Shoshani Y Z, Wilding M A, Text Res J (1991) 61: 736-742.

- Lou C W, Lin J H & Su K H, Text Res J (2005) 75: 390-394.

- >Na Y J, Lancaster J, Casali J, Cho G, Text Res J (2007) 77: 330-335.

- Sengupta S, Indian J Fibre Text Res (2010) 35: 237-242.

© 2019 Saravanan D. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)