- Submissions

Full Text

Modern Research in Dentistry

Cast Metal Occlusal Surface: A Case Report

Jieun Lee*

Department of Prosthodontics, The University of Texas Health Science Center at Houston, USA

*Corresponding author: Jieun Lee, Department of Prosthodontics, The University of Texas Health Science Center at Houston School of Dentistry, USA

Submission: February 07, 2020;Published: March 05, 2020

ISSN:2637-7764Volume5 Issue1

Abstract

A 69-year-old male patient reported to the UTHealth Prosthodontics with the chief complaint of decreased chewing efficiency and the instability with continuous use of his dentures. He was concerned with the functional efficiency of the dentures and not so much about esthetics. The patient was found to have a completely edentulous maxilla with a residual ridge morphology of minimal buccal vestibule and reduced hamular notch. The mandible had one root tip with a reduced residual bone height. The maxillomandibular relationship was Class III. Pt had a history of radiation in the head region with skin cancer of BCC, SCC, and Melanoma since 2008. Frequent attrition of the teeth may either be due to self-induced excessive chewing. Treatment options offered

(1) denture or implant supported overdenture,

(2) denture or implant supported overdenture with metal occlusal surface, and

(3) implant supported fixed prosthesis.

Pt chose a two-implant supported overdenture with a metal occlusal surface for the mandible. Therefore, the denture with the metal occlusal was planned to address patient's concern. It also improves the degree of masticatory ability and prevents the attrition of the teeth. This case report described a technique that uses custom made occlusal portions as the patterns for casting base metal occlusal surfaces. Metal has been reported to cause minimal wear to opposing occlusal materials. This technique is considered in cases where the prosthetic occlusion is in contact with enamel, composite resin, porcelain, metal, or a combination of such materials. Instead of individual units, a single joint unit is fabricated to improve the retention and provide easy finishing and polishing of the casting. This case report presents a simple and relatively inexpensive procedure for the construction of metal occlusal surfaces on complete dentures.

Keywords: Metal occlusal; Implant; Prosthesis; Overdentures

Abbreviations: BCC: Basal Cell Carcinoma; SCC: Squamous Cell Carcinoma; COPD: Chronic Obstructive Pulmonary Disease; TMJ: Temporomandibular Joint; VDO: Vertical Dimension of Occlusion; VDR: Vertical Dimension of Rest; Cr-Co: Chromium-Cobalt

Introduction

The use of acrylic resin denture teeth has been criticized due to the rapid occlusal wear that may lead to changes in centric occlusion, temporomandibular joint disturbances, loss in chewing efficiency [1], loss of vertical dimension of occlusion [2] and therefore can result in denture instability. The extent of wear varies depending on the clinical situation and the amount of time the prosthesis has been in use. Various articles [2,3] describe the construction of metal occlusal surfaces for the patients having the history of occlusal attrition, bruxism, orofacial tardive dyskinesia, self-induced excessive chewing, and idiopathic parafunctional mandibular movement. A metal occlusal surface may be indicated,

- When constructing a denture that is to be opposed by reconstructed dentition with gold occlusal surfaces.

- When constructing a complete denture, removable partial denture or overdenture with a functionally generated path concept in which modification of the denture teeth is necessary to place the occlusal surface and core in harmony and

- To reinforce and strengthen the denture.

Case Presentation

A 69-year-old male patient reported to Advanced Prosthodontics at the University of Texas Health Science Center at Houston School of Dentistry with the chief complaint of decreased chewing efficiency and the instability with continuous use of his dentures. He was more concerned with the functional efficiency of the dentures and not so much about aesthetics. On clinical examination, the patient has a completely edentulous maxilla with a residual ridge morphology of minimal buccal vestibule and reduced hamular notch. The mandible had one root tip with a residual bone height of 11-15mm (Figure 1). The maxillomandibular relationship was Class III. History showed that the patient was wearing the complete maxillary denture and a tooth-supported mandibular overdenture. For over 25 years, he got his denture made twice due to frequent attrition of the teeth and instability of the denture.

Figure 1: Patient’s maxilla and mandible in pretreatment stage.

Pt recently had an extraction of the lower root tip. He also has a history of COPD, hepatitis C, hypertension, anemia, GERD, and radiation therapy in the head region with skin cancer of BCC, SCC, and Melanoma since 2008. He also was a previous smoker of 15 years. With the clinical examination and history, it was concluded that the frequent attrition of the teeth could either be due to self-induced excessive chewing, but no tenderness or discomfort of the TMJ joint or muscles of mastication. Several treatment options were described to the patient like

- denture or implant-supported overdenture,

- denture or implant-supported overdenture with a metal occlusal surface, and

- implant-supported fixed prosthesis.

The patient wanted an economical, with the best functional efficiency and had no time constraint. Also, he was further interested in two implant-supported overdentures for the mandible. Therefore, the metal occlusal surface denture was chosen to address the patient's concern with improved the degree of mastication and prevents the attrition of the teeth.

Technique

After extraction of the mandibular root tip and healing, preliminary impressions were made with alginate and poured in Type III dental stone to obtain primary casts. Custom acrylic resin trays were fabricated, and border molding was done with a green stick compound. Final impressions were made using PVS impression material for both arches, and impressions were poured with Type IV dental stone. Denture bases and wax rims were made to record face bow transfer and maxillomandibular relationship to a semi-adjustable articulator (Whip Mix). VDO was established by using two methods. In the first method, two points were marked, one on the tip of the nose and the other on an immovable part of the chin. To find the VDR position, the patient has repeated the letter 'M' several times, and then the distance between the points was measured. VDO=VDR minus freeway space (2-3mm). The second method was to create at least 1mm of closest speaking space between occlusal rims. Teeth arrangement was made with Hardy cutters in maxillary posterior teeth and monoplane teeth in the mandibular arch. A try-in confirmed esthetics, VDO, and centric relation. The conventional heat cured acrylic resin was used to fabricate the denture, and following curing, the prosthesis was finished, polished, and were ready to be delivered to the patient. During the clinical remount, a Coble balancer was used to record the centric record with bite registration (Figure 2). Dentures were remounted in the articulator, and the occlusal surfaces of the lower posterior teeth were reduced by 2mm with adequate interocclusal clearance.

Figure 2: During the clinical reamount the Coble balancer was used to record the centric with bite registration.

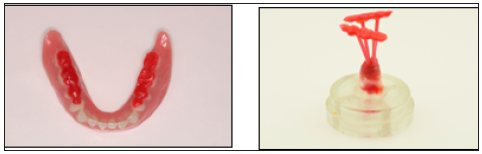

Lateral and protrusive positions were verified the space adequacy with the articulator. DuraLay was added on the prepared denture teeth, and the occlusal surface of the individual teeth was contoured. The DuraLay pattern was carefully removed from the teeth, and sprue formers were attached to the pattern. Patterns were invested with phosphate bonded investment (Figure 3), and the metal casting process was completed using a Cr-Co alloy. After the castings, the metal occlusal surfaces were recovered and polished. The castings were positioned at their respective sites on the denture teeth ensuring that each casting was completely seated (Figure 4). The occlusion was verified in centric, lateral and protrusive positions, and then the castings were cemented with resin cement. During the insertion of the complete denture, the prosthesis was checked for proper border extension, and occlusion in centric, lateral, and protrusive positions. The patient was satisfied with the chewing efficiency and esthetics of the denture. The display of metal is considered to be the main disadvantage of using a metal occlusal surface. Still, the patient was not concerned about the presentation of the metal occlusal because of the satisfaction with the chewing efficiency of the denture –which was his main concern.

Figure 3: DuraLay was added on the prepared denture teeth and the occlusal surface of the individual teeth were contoured. The DuraLay pattern was carefully removed from the teeth and the sprue formers were attached with the pattern.

Figure 4: After diversting the castings, the metal occlusal surfaces were recovered and polished. Polished castings were positioned at their respective sites on the denture teeth ensuring that each casting was completely seated.

Discussion

Metal or gold occlusal surfaces have been reported to cause minimal wear to opposing occlusal materials [4]. This technique is considered in cases where the prosthetic occlusion is in contact with an enamel, composite resin, porcelain, metal or a combination of such materials [5]. Instead of individual units, a single joint unit is fabricated to improve the retention and provide an ease in finishing and polishing of the casting.

This case report presents a simple and relatively inexpensive procedure for construction of metal occlusal surfaces on complete dentures. This case report described a technique that uses custom made occlusal portions as the patterns for casting base metal occlusal surfaces. Acrylic resin is attached to the metal occlusal surfaces via indirect resin processing. During recall evaluation, the patient was satisfied with the functional efficiency of the denture and did not report any problem associated with the metal occlusal denture. Patient was re-evaluated for two implant placements in mandible arch after four months of prosthesis wear.

Acknowledgement

Donald Belles, DDS, MS. Advanced Prosthodontics Program Director. The University of Texas Health Science Center at Houston School of Dentistry.

Maria Gonzalez, DDS, MS. Advanced Prosthodontics Assistant Director. The University of Texas Health Science Center at Houston School of Dentistry.

References

- Wallace DH (1964) The use of gold occlusal surfaces in complete and partial dentures. J Prosthet Dent 14(2): 326-333.

- Koehne CL, Morrow RM (1970) Construction of denture teeth with gold occlusal surfaces. J Prosthet Dent 23(4): 449-455.

- Vergani CE, Giampaolo ET, Cucci AL (1997) Composite occlusal surfaces for acrylic resin denture teeth. J Prosthet Dent 77(3): 328-331.

- Barco MT, Synnott SA (1989) Precision metal occlusal surfaces for removable partial dentures. Int J Prosthodont 2(4): 365-367.

- Elkins WE (1973) Gold occlusal surfaces and organic occlusion in denture construction. J Prosthet Dent 30(1): 94-98.

© 2020 Jieun Lee. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)