- Submissions

Full Text

Modern Concepts & Developments in Agronomy

Clonal Variation in Moisture Content in Populus Deltoides Peeling Logs

RC Dhiman* and JN Gandhi

Wimco Seedlings (ITC-PSPD), India

*Corresponding author:RC Dhiman, Wimco Seedlings (ITC-PSPD), Rudrapur, Uttarakhahnd, India

Submission: March 25, 2024;Published: May 10, 2024

ISSN 2637-7659Volume14 Issue 2

Abstract

P. deltoides is one of the major commercially grown species for production of peeling logs in India. Currently around 35 million poplar saplings are planted annually on farmland in integration with agriculture crops in North India. A significant share of poplar logs is used for peeling fresh/green without storage. This study presents clonal variation in moisture content in freshly felled logs of 14 clones and also in 1st basal log to 7th sequential log made from the main stem. Moisture content both on dry weight and fresh weight basis had significant differences among the studied clones. WIMCO 81 recorded significantly higher tree height (22.24m) and DBH (27.72cm) whereas WSL 42 recorded significantly low height (18.51m) and DBH (19.34cm). Moisture Content on Dry Weight Basis (MCDW) varied from a maximum of 128.34% in WIMCO 81 to a minimum of 83.15% in S7C4 whereas on fresh weight basis (MCFW) it varied from 55.21 in WSL 39 to 45.17% in S7C4. There was a gradual and significant decrease in MCDW and MCFW from 1st to 7th log with basal 1st log recording a maximum of 115.71% MCDW and 53.49% MCFW. Maximum of 49.34% MCFW was recorded in 1st basal log and a minimum of 48.34% MCFW in 6th log. Both MCDW and MCFW formed 3 homogeneous groups i.e., a, b, & c and within each group there were non-significant differences among clones.

Keywords:

P. deltoides; Clone; Log; Moisture content; Peeling; VeneerIntroduction

Many exotic poplar species were introduced in India during early 1950s and their field trials were conducted in some states [1]. Of these and some others introduced latter, a few clones of P. deltoides exhibited reasonable success in some northeastern states near foothills of the Indian Himalayas that paved the way for their organized farming during mid 1970’s. The tree initially was grown on forest land and subsequently the safety match industry -WIMCO Ltd. promoted it on farmland by integrating it with agriculture crops in agroforestry. Currently, there are only notional plantations on forest land and around 99% of it is grown on farmland where its culture and marketing are taking place similar to agriculture crops. The tree was originally grown for a production cycle of 20 years, is currently grown for 12 years on forest land and between 2-8 years on farmland. The major share of poplar is now routinely harvested between 3 to 3.5 years with some stray cases of harvesting around 2 years age and around 5% over 5 years age. Currently, the poplar-based agroforestry is generating net returns up to Indian Rs. 2 lakh/acre/year [2]. Cost of production of both tree and crops is recovered from crop returns grown under poplars and income from trees is considered as net returns. The tree was initially promoted for matchwood production under contract farming model [3] but its culture gradually expanded with its major wood finding usage in peeling industry and some share in other 3 dozen products [4]. Currently around 35 million poplar saplings are planted annually, and the major use of its wood is for making plywood, match splits, ice-cream spoons & sticks, toothpicks and some others. Out of over 3300 panel industrial units exiting in the country, around 1000 peeling and plywood units are located in poplar growing region for which poplar wood is a major cost component and lifeline for this segment of industry in North India.

Poplar is partially harvested in 2 small windows when there are no agriculture crops on farmland. These windows exist just before sowing agriculture crops during October-November months in prewinter season and soon after harvesting crops during April-May months in post-winter season. Its wood is also available around the year as many farmers opportunistically harvest poplar trees anytime during the year when market rates are high and also when they need money for some of their hard-pressed financial needs [5]. The operational chain for production and marketing of poplar wood is now well developed. Poplar trees on harvesting are converted into tradable grades of which peeling logs above 16 inches in mid girth are segregated for veneer industry. Fresh logs on conversion are directly dispatched from farmer’s fields to mill gates and wood markets. Many small mills and those not wellorganized ones procure fresh logs for immediate consumption and avoid maintaining large in-house log inventory. Mills with large production capacities procure logs in bulk from wood markets and large growers and store them in log yards till they are processed. Poplar grown on forest land and institutional land is usually harvested by the state forest agencies around winter season and its logs remain in temporary and permanent wood depots for varying durations to complete their measurement, segregation, transport and auction to purchasers that at times may take a few months for reaching the mills. The gap between harvesting and processing logs may vary as short as single day for freshly procured logs to around half year or sometimes longer for stored logs. Logs during storage phase undergo many changes and the major one is decrease in their moisture content if not preserved in water. Moisture content in wood is influenced by genetic factors [6,7] besides some others those may include environment, season of harvesting, locality of growing trees, duration between harvesting and processing etc. Clonal variation in poplar is well reported for making plywood [8] and Match splints [9]. This paper presents the moisture content in logs of 14 commercially grown clones in addition to that in 1st basal log to the 7th sequential log obtained from the main stem.

Material and Methods

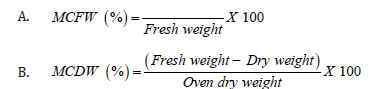

A field trial of 14 clones was established in a randomized block design with five replications in Pavan Poplar Ltd. Farm, Uttarakhand, India. The trees were harvested at 7.5 years age, converted into standard length logs of 245cm and marked from 1st log from the base to the last log from the upper positions of the stem. Tree height and diameter at breast height (DBH) were recorded just before falling. Three trees with 7 standard logs per replication were selected and 5cm wide discs were taken from the basal portion of each log and marked with permanent marker to maintain their identity. The fresh weight of each disc was recorded immediately and thereafter all of them were kept in the oven for drying. The dry weight of each disc was taken when there was no more loss in weight. The moisture content of discs was estimated using the following formulas:

Were,

MCFW = Moisture content on fresh weight basis

MCDW = Moisture content on dry weight basis

Ratio between A and B was calculated as A/B. ANOVA was performed to compare the mean values for clones and logs separately and inferences drawn.

Result

The data in Table-1 indicates significant differences in all the four studied parameters viz., tree height, DBH, moisture content on dry basis & fresh weight basis among the clones. WSL 20 recorded significantly higher tree height (23.08m) and clone WIMCO 81 significantly higher DBH (27.72cm) compared to other clones. WSL 42 recorded significantly lower value for both height (18.51m) and DBH (19.34cm) among the clones. WSL 20 along with 11 other clones viz., G48, S7C4, L49, WIMCO 81, WSL 39, UDAI, S7C8, S7C15, S7C20, WSL 22 and WSL 32 were in group “a” within which there were non-significant differences in tree height. There were 4 clones in group “b” and 1 clone in group “c” forming two other homogenous groups statistically at par for tree height within each group. For DBH, clone WIMCO 81 recorded maximum and significantly higher DBH (27.17cm), and clone WSL 42 minimum and significantly lower DBH (19.34cm) among the studied clones. There were 7 groups viz., a, b, c, d, e, f and g for DBH that include 1, 4, 2, 5, 4, 1; and 1 clone respectively as homogeneous groups in moisture content.

Table 1:Clonal variation in tree growth and moisture content parameters.

Moisture Content on Dry Weight Basis (MCDW) varied from a maximum of 128.34% in clone WIMCO 81 to a minimum of 83.15% in S7C4 and the difference between these clones was statistically significant. Clone S7C4 had non-significant differences within group “e” constituting 5 other clones viz., WSL-A/26, G48, S7C8, S7C15 and WSL 22. There were 5 groups i.e., a, b, c, d and e having 3, 7, 5, 5 and 6 number of clones respectively within which there were nonsignificant differences among clones. Some clones overlapped in some groups based on the critical difference for their comparison.

Moisture Content Based on Fresh Weight Basis (MCFW) had only 3 groups, i.e., a, b and c with statistically different moisture content with clone WSL 42 overlapping in a and b groups and clone WSL-A/26 overlapping between b and c groups. WSL 39 recorded maximum of 55.21% MCFW that was statistically at par with that of L 49, WIMCO 81, UDAI, WSL 42, S7C20, WSL 32 and WSL 20. Two clones viz., WSL-A/26 and WSL 42 were in two groups; 3 clones viz., S7C20, WSL 32 and WSL 20 in group b whereas 5 clones viz., SL-A/26, G48, S7C4, S7C8, S7C15, and WSL 22 were in group c and all these clones were statistically at par for MCFW within respective group.

Data in Table-2 indicates significant differences between logs in moisture content from 1st to 7th position on the stem. Basal 1st log recorded maximum of 115.71% MCDW and 53.49% MCFW which were significantly higher than other logs made from the upper portion of the stem. 1st and 2nd log had non-significant differences in moisture content for both MCDW and MCFW. There were non-significant differences in MCDW among 4th to 7th log and also in MCFW among 3rd to 7th log. There were 3 groups, i.e., a, b and c for both MCDW and MCFW with a few clones overlapping in other groups.

Table 2:Log-wise variation in moisture content of poplar peeling logs.

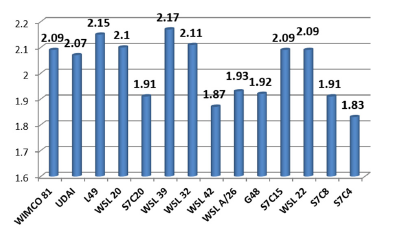

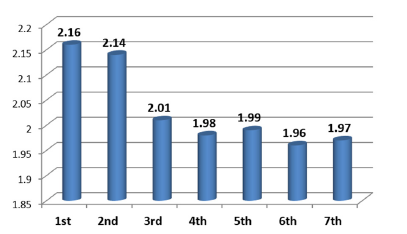

The ratio between MCDW to MCFW for 14 clones varies from a maximum of 2.17 in WSL 39 to a minimum of 1.83 in S7C4 (Figure 1). The average ratio for all the clones was 2.01 and 8 clones viz., WIMCO 81, UDAI, L49, WSL 20, WSL 39, WSL32, S7C15 AND WSL22 were above average and the remaining 6 clones were below this average. The ratio between MCDW and MCFW for 1st to 7th log varied from 2.16 in the 1st basal log to 1.96 in the 6th log (Figure 2). The average ratio was 2.02 with 1st and 2nd logs being above average and remaining 5 logs from upper part of the stem being below average.

Figure 1:Ratio between MCDW and MCFW among 14 clones.

Figure 2:Ratio between MCDW and MCFW between 1st to 7th log made from main stem.

Discussion

Poplar improvement work is fairly advanced in India. New clones are developed for better growth & productivity, wood quality for end products, disease and insect pest resistance and for site match adoption [10]. Each clone is genetically different for adaptive and productive parameters. Clonal variation in growth and productivity has been reported in many studies [1,10] that support the findings of current study.

Moisture content and its loss from logs on harvesting depends on a very large number of factors like species, clones, growing sites, duration after harvesting, harvesting season, thickness, bark thickness, presence of wood defects, local weather conditions and staking of logs [6,11,12]. This study explored the genetic variation in 14 clones which, both on dry weight and fresh weight basis, recorded variation in consonance with some other studies on Diptercoarpus indicus among its 8 genetically different populations [7] and in case of 20 progenies of Eucalyptus grandis [6]. Moisture content in D. indicus on dry weight was reported between 190.49% to 108.18% on dry weight basis and between 68.42% to 51.11% on green weight basis. D. indicus, like P. deltoides is also used for making plywood and is found in the Western Ghats, India. The findings on D. indicus compared well with our study in which MCDW varied between 128.34% to 83.15% and MCFW between 55.21% and 45.07%.

A fresh layer of cambial tissues is added outside the old layer on the stem of living trees. Age and wood elements including density and moisture content of different cambial layers on the stem are different [13]. In older logs, multiple layers contain variable moisture levels and hence the variation in the ratio between MCDW and MCFW is expected. The ratio between MCDW and MCFW recorded between 1.87 to 2.17 in the current study closely matches with similar ratio between 2.08 to 2.91 in D. indicus. Another similarity in these two studies was that this ratio decreased with decrease in moisture content in both P. deltoids and D. indicus.

Peeling quality of logs to thin layers and slices depends on log quality, machinery and human resources. Dried peeling logs of even good species may not produce good quality veneers if they contain critically low moisture content. Logs with extremely low moisture content produce veneers with less recovery, more splitting and other mechanical defects, higher breakage during handling, higher energy consumption in peeling machines, higher wear and tear of peeling knives, higher consumption of adhesives and other chemicals in making products and unsuitability for some small sized products like match splints in which certain defects increase beyond tolerance limits of some splint quality parameters. Moisture content in wood is an important factor that affects its density and quality. In peeling logs adequate moisture content is good for better peeling yet it needs high energy consumption for drying highly wet veneers. Moisture content and density of wood also affects shrinkage [14]. Veneers made from high moisture content logs may also need an extra margin in thickness for shrinkage while pressing them to make plywood. Thin logs made from the upper part of stem lose moisture faster than the thicker logs obtained from the lower portion of stem. Thin logs thus need early peeling without allowing their storage for a far longer period before they lose moisture quickly. The current study draws support from earlier findings in which log weight loss was directly related to their thickness and that declines from basal log to the upper position logs on the stem [15].

Wood is hygroscopic in nature that absorbs and loses moisture depending on the surrounding environment [16]. Logs start losing moisture soon after falling and accordingly their peeling quality starts deteriorating. Such logs are invariably moistened using a number of techniques which include constantly spraying water, keeping immersed in fresh/hot water and steaming for improving internal moisture near to fresh logs [14,17,18]. These techniques require high investment in creating infrastructure & maintenance. Besides logs may develop some defects if not preserved properly. WIMCO match industry- the largest single user of poplar logs in India, was procuring a few thousand cubic meter peeling logs in bulk for preserving them under spraying water or keep them immersed in water tanks to maintain their internal moisture content for production of better-quality veneers to make match splints-one of a very small wood product in direct use. At times when logs kept immersed in unregulated and stagnated water may leads to develop serious defects one of which has been developing water borne bacteria causing very pungent smell in logs that subsequently passed on to match sticks and boxes which created serious issues with its marketing. Also, if logs do not get water on their full surfaces due to inadequate water sprays or half immersing, they get attracted by sap stain fungus and pin-hole borers making them unsuitable for peeling [19] causing huge economical losses. The use of fresh logs having moisture content at fiber saturation point is thus a highly desirable, practical and economical option to produce good quality veneers. For bulk users, procuring logs in bulk needed their storing under hygienic conditions to avoid material and economical losses.

References

- ENVIS (2012) Poplars in India. ENVIS Forestry Bulletin 12(1) ENVIS Centre on Forestry. FRI (ICFRE).

- Dhiman RC (2024) Trees transitioning from sacred and scary perception to large scale farming for industrial and economical transformation. Ply Insight.

- Dhiman RC (2015) Contractual arrangements for sustaining agroforestry with special reference to WIMCO’s poplar program. In: SK Dhyani, Ram Newaj, et al. (Eds.), Agroforestry: Present Status and Way Forward, Biotech Books, Chapter 8, ISBN 978-81-7622-349-2. New Delhi, India, pp. 135-168.

- Dhiman RC (2023) Poplar wood marketing and trade. In: Anita T, Sanjay S (Eds.), Poplar Farming Forest Research Centre for Eco-rehabilitation, Biotech Books, Prayagraj, Uttar Pradesh (ICFRE), India, pp. 189-214.

- Dhiman RC (2021) Plantation Forestry. Ind For 147(8): 715-726.

- Wang S, Littell RC, Rockwood DL (1984) Variation in density and moisture content of wood and bark among twenty Eucalyptus grandis Wood Sci Technol 18: 97-100.

- Al-Sagheer A, Devi Prasad AG (2010) Variation in wood specific gravity, density and moisture content of Dipterocarpus indicus (Bedd) among different populations in western ghats of Karnataka, India. International Journal of Applied Agricultural Research 5(5): 583-599.

- Dhiman RC (2004) Poplar wood availability a boon for plywood industry. Ply Gazette 64-72 and 124-136.

- Dhiman RC, Gandhi JN (2006) Clonal variation in poplar wood for making match splints. Journal of Timber Development Association of India 52(1&2): 22-25.

- Dhiman RC, Gandhi JN (2012) Clonal development and diversity in WIMCO’s poplar programme. ENVIS Forestry Bulletin 12(1): 40-48.

- Skaar C (1988) Wood-water relations. Springer-Verlag, New York, India, p. 283.

- Simpson WT, Wang X (2004) Estimating air-drying times of small-diameter ponderosa pine and Douglas-fir logs. Forest Products Journal 54(12): 24-28.

- Sofia Knapic, Jose LL, Sofia Leal, Helena Pereira (2007) Radial variation of wood density components and ring width in cork oak trees. Ann For Sci 64: 211-218.

- Feih1 A0, Godin V (1970) Peeling defects in veneer, their causes and control. Can Dep for For Prod Res Br Tech Note, p. 25.

- Dhiman RC (2010) Weight loss in poplar wood under open conditions and its economical impact. Timber Development Association of India 56: 1-6.

- Frederiksson M (2019) On wood - water interactions in the over-hygroscopic moisture range - mechanisms, methods and influence of wood modification. Forests 10(9): 779.

- Kumar C (2023) Log heating for veneer production: A review of techniques and factors. Department of Agriculture and Fisheries (internal report), Australian Centre for International Agricultural Research: Canberra, Australia.

- Kubinsky Eugen, Milan Sochor (1968) New softening treatment for beech logs before rotary peeling to veneers. For Prod J 18(3): 19-21.

- Dhiman RC (2013) Treatment of fungal infected sap-stain for veneer products. PlyGazette, pp. 92-99.

© 2024 RC Dhiman. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)