- Submissions

Full Text

Journal of Biotechnology & Bioresearch

Development Trends in Bioleaching Techniques Based on Patents Analysis

Lirong Geng, Dan Zhao, Guojing Zhang, Shuangjun He, Tao Liu and Lei Yan*

Heilongjiang Provincial Key Laboratory of Environmental Microbiology and Recycling of Argo-Waste in Cold Region, College of Life Science and Biotechnology, Heilongjiang Bayi Agricultural University, Daqing, 163319, PR China

*Corresponding author:Lei Yan, Heilongjiang Provincial Key Laboratory of Environmental Microbiology and Recycling of Argo-Waste in Cold Region, College of Life Science and Biotechnology, Heilongjiang Bayi Agricultural University, Daqing, 163319, PR China

Submission: February 10, 2023;Published: February 23, 2023

Volume4 Issue4February , 2023

Abstract

Bioleaching refers to the process of leaching valuable metals from minerals or other materials using microorganisms. It is widely used in metallurgy, mineral processing, chemical engineering and environmental engineering. This paper surveys the global patents in the field of bioleaching based on Soo PAT patent search and analysis. Results reveal that the worldwide bioleaching techniques show a decreasing trend after an initial increase but that the number of US patent applications is still in an advantageous position. The bioleaching field experienced a rapid development period in the early 20th century and then entered a stage of large-scale industrialization. The global research and development institutions with advantages in bioleaching-related patents are mainly concentrated in enterprises. Bioleaching is a multidisciplinary integrated field. Its related patents focus on the production and refining of metals in the field of chemical metallurgy. They are tightly associated with soil remediation, chemical or physical processes, and related equipment.

Figure 1:

Keywords: Bioleaching; Patent analysis; Soo PAT search; Development trends; Application

Introduction

With the development of science and technology, traditional metallurgical techniques, such as electrometallurgy, pyrometallurgy, and hydrometallurgy, have encountered some issues, including high-energy consumption and serious pollution. In addition, conventional metallurgical processes have been unable to meet technical needs due to the reduction in mineral resources. As a new alternative technique, bioleaching is an ore beneficiation method that uses microorganisms to extract useful metals from ores. Depending on the mineral, chemical attack is by a combination of ferric iron and acid (protons), whereas the role of the microorganisms is to generate the ferric iron and acid. Bioleaching produces pregnant leach solution with many major impurities. The leach solution must be purified and metals selectively recovered to reach even a low-quality product. This strategy for metal recovery is known as bioleaching because the metal is solubilized in the process. This technique is suitable for the leaching of lean-grade ores, mining waste, ores below the lowest industrial grade but above the cut-off grade, and difficult-to-mine, difficult-to-beneficiate, or difficult-to-smelt ores [1]. It has the advantages of simple equipment, convenient operation, low cost, low energy consumption, environmental friendliness, and the ability to extract multiple metals at the same time. In addition, bioleaching has good application prospects in the removal of heavy metals from sludge and the recovery of components with reutilization value from electronic waste [2,3].

In 1947, the role and nature of microorganisms regarding bioleaching was revealed [4]. In 1950, a copper mining company Kennecott in the United States of America (USA) began to study the heap bioleaching of primary copper sulfide ores below the lowest industrial grade but above the cut-off grade. They obtained the first bio metallurgy patent in history in 1958, thus officially starting the modern industrial application process of bioleaching [5,6]. In the 1980s, there were 20 applications for relevant patents in the USA alone, and bioleaching techniques developed rapidly. At the end of the last century, Chile applied copper bioleaching techniques most often and successively established large-scale heap bioleaching sites in Cerro Colorado and Quebrada Blanca [7]. The first commercial operation of heap bioleaching was installed at Doxing copper mine in China in 1997 [8]. Thus far, bioleaching techniques have been applied on a large scale in the industrial production of copper, and uranium. Many countries have paid more attention increasingly to the development of related techniques. Among them, the USA, with 28.29% of global bioleaching patents, ranks first, followed by China. As a legally protected form of intellectual property rights, patents carry the achievements of scientific and technical innovation and can more quickly reflect the latest cutting-edge science and technology. According to research results published by the World Intellectual Property Organization, more than 90% of information regarding the latest inventions and innovations is reflected in patent literature. In the process of scientific research, paying attention to the research development of related patents can not only improve the starting point of study but also save 60% of research and development time and 40% of research funding [9-11]. Therefore, the statistical analysis of patents related to bioleaching techniques can help researchers better understand the development trends in bioleaching technique research.

Compared with the patent databases, such as the Derwent Innovations Index (DII), United States Patent and Trademark Office (USPTO) and European Patent Office (EPO), the Soo PAT platform (http://global.soopat.com/Patent/Index), which integrates more than 130 million patents in 108 countries and regions globally, has more abundant resources [12]. The Soo PAT platform includes five search modules such as general search, advanced search, International Patent Classification (IPC) search, citation search, and patent family search. Users can search by region and directly analyze the search results. The Soo PAT platform has highly visualized data, providing a better user experience than the DII, USPTO and EPO. In this review, the Soo PAT platform was used as the data source, and bioleaching was used as the keyword to search bioleaching-related patents registered with a patent office. A total of 1,626 patents were found in 326 large groups. Soo PAT new world analysis and IPC taxonomy were used to perform statistical analyses on the retrieved results, and data processing software, such as Excel and Origin, was used to perform quantitative and visual analyses on the relevant bioleaching technique patents.

Overall Situation Analysis of the Patent Application

Ranking of patent applications

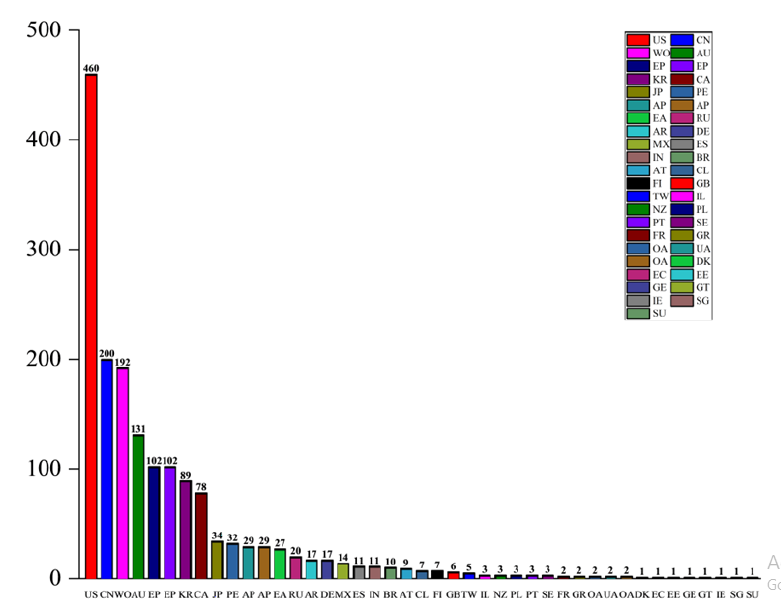

There are many patent offices belonged to international organizations, any country and some regional government, the same patent may be included in these patent offices. Therefore, each of these patent offices included the patients were considered. From 1985 to 2020, the number of countries in the world applying for bioleaching technique patents increased; there was a total of 1,626 patent applications, and the main applicants were industrial and mining enterprises and individuals. The number of bioleaching technique patent applications in the first 15 years did not exceed 20-30 patents/year. It grew exceptionally slowly, and the peak of the overall trend of patent applications occurred in 2000 (104 patents). Since then, countries have gradually increased their investment in research and development of bioleaching techniques, but the number of applications still tended to decline, maintaining approximately 40 patents per year. The top two countries in terms of the number of applications were the United States and China, with 460 and 200 patents, respectively (Figure 1). From the above results, it can be seen that countries in the world applying for patents in the field of bioleaching innovation each have their own advantages, showing significant differences in technique traits. For example, the patent applications from the USA focus on innovative research that provides different forms of microorganisms to participate in the bioleaching steps to obtain optimal leaching efficiency and yield so that sufficient sulfide mineral particles in a heap are biologically oxidized. In contrast, the patent (CN2000815262) from China mainly address the shortcomings of traditional wet leaching processes, such as the treatment of refractory metal residues with high-sulfur and high-arsenic content, by providing methods with a short and simple operation, high metal recovery, and low operating costs to recover rare metals from these metal residues.

Figure 2:Ranking of patent applications all over the world (US-United States, RU-Russia, WO-World Intellectual Property Organization, SE-Sweden Eniro MX-United Mexican States, EP-European, AR-Argentina, AU-Australia, INIndia, CN-China, ES-Reino de España, KR-Korea, AT-Austria, ZA-South Africa, BR-Brazil, CA-Canada, FI-Finland, JP-Japan, CL-Chile, PE-Peru, TW-Taiwan, AP-African Regional Industrial Property Organization, GB-Great Britain, EA-Eurasian Patent Organization, PL-Poland, IL-Israel, NZ-New Zealand, DE-Die, Bundesrepublk Deutschland, PTPortuguesa).

Trend for the number of patent applications

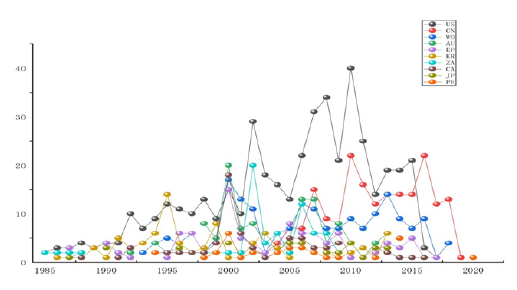

According to the statistical analysis of global patent applications for bioleaching techniques, a trend chart for the number of patent applications in specific research and development directions was plotted (Figure 2). The USA and China were the top two countries in terms of the cumulative number of applications. Bioleaching has always been one of the key areas in the research and development of innovative leaching techniques in the world. From 1997 to 2000, there was exponential growth in the number of patent applications, reflecting the global breakthrough in bioleaching techniques. From 2001 to 2003, the number of patent applications in the field of bioleaching techniques fluctuated. After 2003, it maintained a relatively stable growth rate and reached a new high in 2006. According to statistics, 40 million tons of electronic waste is generated every year, accounting for 5% of the total solid waste worldwide [13]. Facing the current grim situation of the depletion of natural resources, such as expensive metals and rare metals, many academic and industrial communities have paid close attention to new techniques for beneficiation processes that use microorganisms to recycle electronic waste or extract high-value metals from difficult-to-mine mining waste [3]. According to the patent application trends, although the research and development in various countries are continuing and the number of patent applications in the United States is still increasing, the surge in patents has passed. It can be found that each country has entered a period of steady growth, and it is speculated that bioleaching techniques have entered a stage of large-scale industrialization.

Figure 3:Trend for number of patent applications all over the world (S-United States, AU-Australia, ZA-South Africa, CN-China, EP-European, CA-Canada, WO-World Intellectual Property Organization, KR-Korea, PE-Peru, JPJapan).

Competition Situations of Countries and Institutions Applying for Patents

Distribution of patents

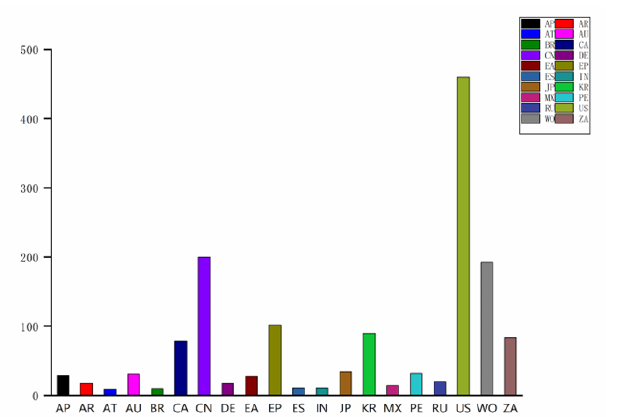

Figure 4:Distribution of patents all over the world (AP-African Regional Industrial Property Organization, ES-Reino de España, AR-Argentina, IN-India, AT-Austria, JP-Japan, AU-Australia, KR-Korea, BR-Brazil, MX-United Mexican States, CA-Canada, PE-Peru, CN-China, RU-Russia, DE-Die Bundesrepublk Deutschland, US-United States, EAEurasian Patent Organization, WO-World Intellectual Property, Organization, EP-European, ZA-South Africa).

In the present analysis, we investigated the distribution of patents according to all the main patent office’s rather than the patent offices located in any country or region. The patent layout reflects the application situation of a certain technical field in the country applying for the patent and, at the same time, grasps the situation regarding market preemption. Bioleaching techniquerelated patents are distributed globally, involving more than 20 countries and regions (Figure 3). Among them, the leading country is the USA, followed by China and the World Intellectual Property Organization. Global applications for bioleaching technique patents are mainly distributed in IPC section C, which deals with chemistry and metallurgy; the number of patents in metallurgy ranks first, 1,452, accounting for 84.76% of the total. Among these patents, a patent applied by BHP BILLITON SA LTD was related to an optimized bioleaching process for heat generation and primary copper sulfide in China. This method is mainly used to actively monitor and control the level of microbial activity of bioleaching bacteria used in the process. In 2008, the inventor KOHR WILLIAMJ invented a technical method for the biological treatment and high-value metal recovery of metal-containing refractory sulfide ores in a non-stirred surface bioreactor. This method has become a mainstream technical development. Applications in subclass C22B3/00 (Extraction of Metal Compounds From Ores Or Concentrates By Wet Processes) fluctuated considerably, and applications in subclass C22B15/00 (Obtaining Copper) increased steadily.

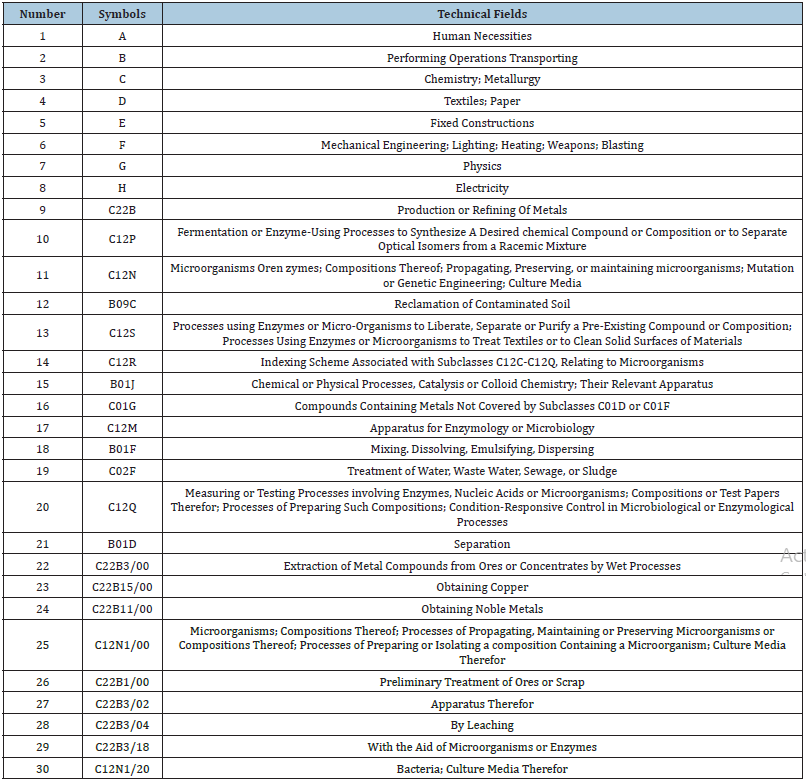

Based on Soo PAT analysis, bioleaching technique patents in all eight sections of the IPC classification were analyzed to understand the global trends in specific research and development directions in the main technical innovation fields involving bioleaching technique patent applications. It can be seen from the number of patent applications for bioleaching in each IPC section that global patent applications for bioleaching are generally associated with sections C (Chemistry; Metallurgy), B (Performing Operations Transporting), and G (Physics) (Table 1). To achieve bioleaching diversification, the invention of a leaching device with low energy consumption, high leaching efficiency, good safety, low operating costs, and capability to operate at normal pressures and temperatures is a critical step in bioleaching metallurgy innovation. Microorganisms and recycled materials are also vital elements for the application of bioleaching techniques, playing pivotal roles in the development of bioleaching metallurgy innovative techniques. Simplification, economization, greenization and diversification will gradually become the trends and directions of the future development of global bioleaching metallurgy techniques.

Table 1:Definition of symbols of ICP in the present study.

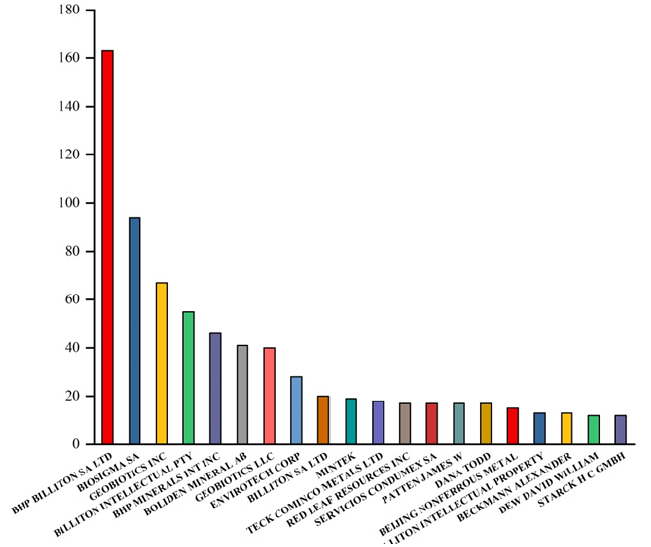

Distribution of applicant institutions applying for patents

Analysis of the institutions applying for bioleaching technique patents around the world can reveal the distribution of the technical strength of the bioleaching industry and the corresponding patent layout. This paper analyzed the top 20 applicant institutions for bioleaching technique patents and found that the USA was the leading region harboring applicant institutions, which is mainly related to the development of the US mineral industry and the degree of recognition of technical innovation. Figure 4 shows the global top 20 patent institutions, including 16 enterprises and four individuals (Figure 4). It can be seen that the top 10 institutions are enterprises which undertake technical innovation in the field of bioleaching. The top 20 institutions all had a relatively high number of applications in C22B (Production or refining of metals) in the top 10 technical fields, indicating that the technical development in the field of metal production and refining is relatively mature. Second, the patent applications from the company BIOSIGMA SA accounted for eight of the top-ranked fields, and those from companies GEOBIOTICS LLC and ENVIROTECH CORP accounted for six, five, and five of the top-ranked fields, respectively, indicating that these four companies have a broad range of patents in the field of bioleaching. At the same time, some companies, such as BHP BILLITON SA LTD, had a large number of patent applications in metal production and refining, indicating that this area will be the focus of enterprise technology activity transfer in the future.

Figure 5:Number of patent applications by major R & D institutions in the world.

The earliest bioleaching technique was applied to the recovery of metals from lean-grade mines, such as uranium and copper [14]. In recent years, the full use of mining waste or mining of low-grade ore deposits has provided the main source of metals [15] and bioleaching has also attracted widespread attention from major companies. Among the global top 20 patent institutions, 12 industrial and mining companies have adopted bioleaching methods, and according to market demand and technical focus, they fully utilize their own advantages, continue to develop bioleaching techniques, and apply them in practice. For example, for a patent in the US for the company BHP BILLITON SA LTD (US7563304B2), the growth limit of microorganisms was determined by measuring the heat release of mine pile. Then one form of carbon was added to the mine pile purposefully, which not only improved the growth rate of microorganisms but also increased the sulfur oxidation rate and heat production. The suitable growth conditions for thermophilic archaea were obtained, and the metal recovery rate was improved substantially. The Geo coat TM technique developed by the company GEOBIOTICS LLC uses the flotation concentrate of refractory gold ores to cover the surface of a block support material, and then a heap is built for bacterial heap leaching oxidation pretreatment. As a result, the treatment rate and subsequent leaching rate for the bioleaching of low-grade siliceous gold ores and chalcopyrite ores was significantly improved, the infrastructure costs of heap bioleaching decreased, and the gold leaching rate from cyanide was as high as 80%-95% [16]. The continuous optimization of the leaching process has provided a good basis for metal leaching, and the selection and application of microorganisms are also important factors for leaching. The BIOSIGMA SA patent (US2007042482A1) reported that the isolated strain Thiobacillus trioxidanes Ligamental DSM 17318 could remove sulfur from metal sulfide ores, and could effectively leach copper from chalcopyrite, covellite, and bornite at ambient temperature.

Situation of the Bioleaching Technical Field

Research and development directions of bioleaching

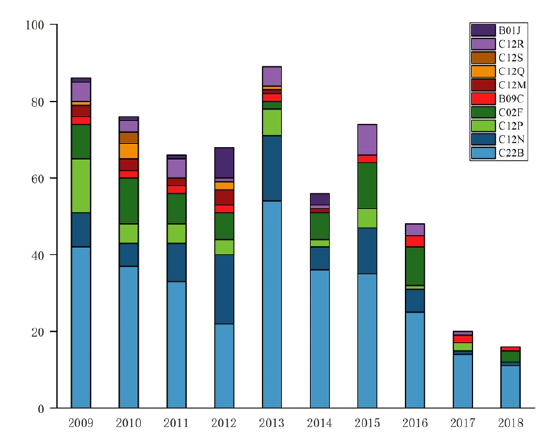

The IPC was used to analyze global bioleaching-related patents, and the number of global patent applications in different technical fields was used as the main parameter. By comparing the patent application number, the top technical contents for critical techniques in each region were established (Figure 5). It was found that the key techniques were mainly concentrated in section C. Among them, class C22B with the largest number of applications (1,076), was considerably higher than those for the second-ranking class C12N (Microorganisms Oren zymes; Compositions Thereof; Propagating, Preserving, or maintaining microorganisms; Mutation or Genetic Engineering; Culture Media) and third-ranking class C12p (Fermentation or Enzyme-Using Processes to Synthesize a Desired chemical Compound or Composition or to Separate Optical Isomers From A Racemic Mixture) (Figure 5). This indicates that metal production and refining is a key research and development field in the bioleaching industry. From the perspective of refinement, the technical development direction of bioleaching was further analyzed, and it was found that in classes C22B, C22B3/18 (with the aid of microorganisms or enzymes), c22b3/02 (apparatus therefor), c22b3/04 (by leaching) and c22b3/00 (extraction of metal compounds from ores or concentrates by wet processes) were the key research and development directions.

Figure 6:Trend in research and development direction of bioleaching patent.

In bioleaching, using the characteristics of microorganisms to realize applications in various directions has been the focus of research and development. For example, in a patented bio-chemical two-stage reactor leaching process, iron-oxidizing bacteria can be used to oxidize Fe2+ to Fe3+. Fe3+ is transferred to the chemical reactor by physical methods, and then the leached product enters the bioreactor and oxidizes Fe2+ to Fe3+. This cycle is repeated to achieve a combination of biological and chemical reactions and obtain a better leaching result. In the era of accelerated information equipment replacement, electronic waste has become a typical solid waste, and improper treatment can seriously affect the ecological environment and human health [17]. Shin et al. [18] used microorganisms or their metabolites to interact with metals in electronic waste and achieved secondary recovery of metals through oxidation, reduction, dissolution and complexation [18].

Trends in research and development directions of bioleaching

Analysis of the trends in research and development directions of bioleaching-related patents is an essential means to understand the technical hotspots and development directions. According to annual changes in the technique classification by the bioleaching industry, the research and development direction has always been concentrated in section C, of which class C22B dominates. The number of applications reached a maximum of 117 in 2000 (Figure 5), indicating that the world has made great progress in the production of metals. In the past 10 years, bioleaching has become a hot research topic; its development trend is shown in Figure 5. Over time, the number of various patent applications has generally declined, suggesting that bioleaching-related techniques have been mature and that the technical improvements have been small. Patents in class C22B have always accounted for the largest proportion each year, followed by patents in section C12N. In addition, in class C22B, C22B3 (Extraction of Metal Compounds from Ores or Concentrates by Wet Processes), C22b15 (Obtaining Copper) and C22b11 (Obtaining Noble Metals) are the main Research Directions; In Class C12n, C12n1 (Microorganisms or Compositions Thereof; Processes of Preparing or Isolating a composition Containing A Microorganism; Culture Media Therefor) is the focus of research and development. With rapid development in modern biotechnology, genetic engineering methods are widely used in microorganisms, plants, and animals. These methods select and modify, i.e., change the structure and characteristics of target genes in vitro [19]. A microbial carrier that can be used in different genera or species was constructed by genetic engineering means, and acidophilic Thiobacillus was obtained via electroporation (US2009035864A1). Screening and obtaining excellent strains for leaching is important for biomining. The scientific researchers used genetic engineering to modify leaching bacteria in terms of arsenic resistance and mercury resistance, and their metal tolerance performance was significantly improved, allowing them to have more significant advantages in leaching applications [20,21]. It can be seen that modifying organisms at the molecular level and obtaining ideal traits through genetic construction technology will be a hot research topic in the future.

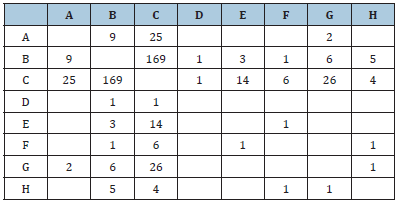

Correlation Analysis of Bioleaching Patents

Table 2 and Table 1, respectively, provide the correlation matrix between the eight sections and the specific meanings of these sections. The frequency of correlations in Table 2 refers to the frequency of occurrence of a section when it is associated with another section. It can be seen from Table 1 that the frequency of correlations was highest between sections B and C, CBC = 169, followed by CCG = 26 and CAC = 25. For example, the bioleaching of copper from copper sulfide ores mentioned in two patents, i.e., heap bioleaching of low-pyrite-content copper sulfide ores (CN105648213B) and extraction of copper from mixed copper ores (CN1208480C). They both refer to crush the copper ore first, followed by microbial heap leaching. The copper-containing leaching solution was further extracted, and high-purity copper was obtained on a cathode via an electrochemical reaction. Many researchers have combined bioleaching processes with engineering techniques, developed critical technologies for bio metallurgy, and engineered heap bioleaching techniques for secondary/primary copper sulfide ores based on existing industrial processes. The techniques and equipment for the bioleaching of low-grade complex nickel-cobalt sulfide ores and the separation and extraction of low-concentration high-impurity leaching solutions have been developed. The highefficiency bioleaching reactors for refractory concentrates have been manufactured. Additionally, the interdisciplinary integration of biology, chemistry, and metallurgical techniques has been realized. As a result, the industrial application of bio metallurgy techniques has become increasingly mature and broader.

Table 2:The incidence matrix between sections of ICP.

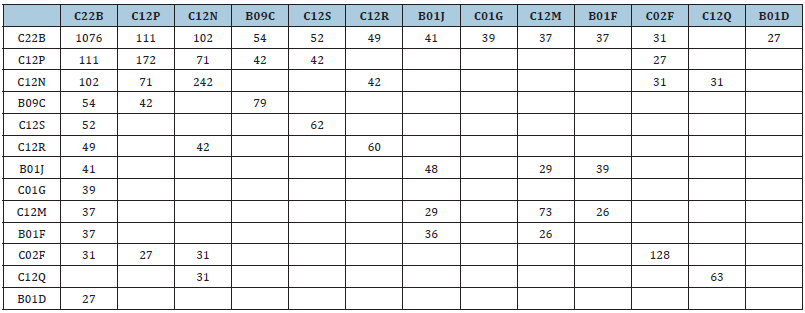

Table 3 shows the 20 pairs of classes with the highest frequency of correlation. It can be seen from Table 2 that the frequency of correlations between C22B and C12P was the highest, reaching 111 times. That is, 111 patents belonged to both classes C22B and C12P. There were 11 subclasses associated with class C22B, including C12N, C12P, C12S (processes using enzymes or micro-organisms to liberate, separate or purify a pre-existing compound or composition; processes using enzymes or microorganisms to treat textiles or to clean solid surfaces of materials), B09C (reclamation of contaminated soil), C12R (indexing scheme associated with subclasses C12C-C12Q, relating to microorganisms), B01J (chemical or physical processes, catalysis or colloid chemistry; their relevant apparatus), C01G (compounds containing metals not covered by subclasses C01D or C01F), C12M (apparatus for enzymology or microbiology), B01F (mixing. dissolving, emulsifying, dispersing), C02F (treatment of water, waste water, sewage, or sludge), and B01D (separation), and the total frequency of correlations were as high as 580.

Table 3:The incidence matrix between classless of ICP.

Biometallurgy is a multiphase and multifield coupling process involving a gas phase, liquid phase, solid phase, temperature, and leaching environment. It mainly uses microorganisms for bioleaching and their metabolites to oxidize Fe2+ and sulfurcontaining compounds to Fe3+, H2SO4, and metal corrosion agents, thus directly or indirectly leaching useful minerals from ores [22]. For example, patent US20050256221 proposed the use of six stain DSM 16786 to leach ores or concentrates containing metal sulfide minerals and a leaching process based on using the bacteria or a mixture containing bacteria. The key to bio metallurgy is to cultivate exclusive and efficient bacteria and improve the leaching capability of bacteria. Microbial activity, oxidation capability, and adaptability have been greatly improved after modifications [23]. At the same time, efficient and enhanced leaching using microorganisms is a significant development direction for bio metallurgy. Bioleaching using mixed microbes or microbial communities can improve the leaching efficiency of metals. Moreover, bioreactors are multifunctional devices that simulate the biological function of microorganisms for bioleaching and can achieve a high degree of unity between the growth and reproduction of microorganisms and efficient leaching of ores [24]. As science and technology have developed, a large number of interdisciplinary subjects have formed. The boundaries between them are not very clear. The research fields are intertwined and strongly correlated. As an essential form of technical achievements, patents must also reflect the overlap, penetration, and integration among various technical fields.

Conclusion and Perspective

This paper has summarized and analyzed the development of bioleaching techniques in general and has reached the following conclusions. The SOOPAT platform records the patents of main international organizations and national patent offices. Among, the USA has an advantage in the number of bioleaching patent applications with 460 patents. The first bioleaching-related patent in China was approved in 2000, and the number of approved and applying patents had steadily increased over the past 15 years. Enterprises are the leading research and development institutions applying for global bioleaching-related patents. They summarize the practical experience, continuously improve their technological innovation capabilities, and are the main contributors to the increase in patent applications. From the technical direction and correlation analysis, bioleaching technology is interdisciplinary and integrates physics, chemistry, biology, and engineering. However, in the current chemical and metallurgical fields, the production and extraction of metals and leaching processes using microorganisms are the main research directions of bioleaching industries. Although significant progress has been made in the research and industrial application of bioleaching, in-depth study regarding the efficient breeding of bioleaching bacterial species, basic theory and engineering techniques for the bioleaching process, and the use of bio metallurgy technologies are important future development directions. The industrial application of bio metallurgy techniques is becoming increasingly mature and broad.

Disclosure statement

All authors declare that they have no conflict of interest.

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Guojing Zhang, Shuangjun He and Tao Liu. The first draft of the manuscript was written by Lei Yan and Dan Zhao. Review and editing of the manuscript was written by Lei Yan. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

References

- Anna P, Eric V, Jakub K (2018) Perspectives regarding the use of metallurgical slags as secondary metal resources-A review of bioleaching approaches. Journal of Environmental Management 219: 138-152.

- Zhang S, Yan L, Xing W, Zhang Y, Wang W, et al. (2018) Acidithiobacillus ferrooxidans and its potential application. Extremophiles 22(4): 563-579.

- Baniasadi M, Vakilchap F, Nazanin BH, Seyyed MM, Sebastien F (2019) Advances in bioleaching as a sustainable method for metal recovery from e-waste: A review. Journal of Industrial and Engineering Chemistry 76: 75-90.

- Ghosh S, Mohanty S, Akcil A, Sukla LB, Das AP (2016) A greener approach for resource recycling: Manganese bioleaching. Chemosphere 154: 628-639.

- Roberto FF (2017) Copper heap bioleach microbiology-progress and challenges. Solid State Phenomena 262: 250-254.

- Surabhi M, Ankur G, Rajendra S (2017) Bioleaching and biomining. Principles and Applications of Environmental Biotechnology for a Sustainable Future 393-423.

- Gentina JC, Fernando A (2016) Copper bioleaching in Chile. Minerals 6: 23.

- Yang SR, Xie JY, Qiu GZ, Hu YH (2002) Research and application of bioleaching and bio oxidation technologies in China. Minerals Engineering 15(5): 361-363.

- Petra M (2013) Patents and innovation: Evidence from economic history. Journal of Economic Perspectives 27(1): 23-44.

- Josh L (2002) Patent protection and innovation over 150 years. American Economic Review 92: 221-225.

- Holger E (2003) Patent information for strategic technology management. World Patent Information 25(3): 233-242.

- Wang F, Lin LF, Yang Z (2014) An ontology-based automatic semantic annotation approach for patent document retrieval in product innovation design. Applied Mechanics Materials 446: 1581-1590.

- Veit HM, Bernardes AM (2015) Electronic waste: generation and management. Electronic Waste 3-12.

- Birendra KY (2019) Application of bioleaching for recovery of valuable product. International Journal of Research in Engineering, Science and Management 2: 202-203.

- Wong L, Menzies A, and Ordóñez JI (2020) Bionanomining: Biotechnological synthesis of metal nanoparticles from mining waste-opportunity for sustainable management of mining environmental liabilities. Applied Microbiology and Biotechnology 104(5): 1859-1869.

- Natarajan KA (2019) Biotechnology for environmentally benign gold production. Horizons in Bioprocess Engineering, pp. 263-299.

- Akram R, Natasha, Shah F, Muhammad ZH, Abdul W, et al. (2019) Trends of electronic waste pollution and its impact on the global environment and ecosystem. Environmental Science and Pollution Research 26(17): 16923-16938.

- Shin D, Jeong J, Lee S, Pandey BD, Lee JC (2013) Evaluation of bioleaching factors on gold recovery from ore by cyanide-producing bacteria. Minerals Engineering 48: 20-24.

- Acevedo F (2002) Present and future of bioleaching in developing countries. Electronic Journal of Biotechnology 5(2): 18-19.

- Liu XM, Lin JQ, Zhang Z, Bian J, Zhao Q, et al. (2017) Construction of conjugative gene transfer system between E. coli and moderately thermophilic, extremely acidophilic Acidithiobacillus caldus MTH-04. Journal of Microbiology and Biotechnology 17(1): 162-167.

- Banerjee PC (2004) Genetics of metal resistance in acidophilic prokaryotes of acidic mine environments. Indian Journal of Experimental Biology 42(1): 9-25.

- Kumar PS, Yaashikaa PR (2020) Recent trends and challenges in bioleaching technologies. Biovalorisation of Wastes to Renewable Chemicals and Biofuels, pp. 373-388.

- Mario V, Axel S, Wolfgang S (2013) Progress in bioleaching: Fundamentals and mechanisms of bacterial metal sulfide oxidation. Applied Microbiology and Biotechnology 97(17): 7529-7541.

- Hubau A, Minier M, Chagnes A, CatherineJ, Charline S, et al. (2020) Recovery of metals in a double-stage continuous bioreactor for acidic bioleaching of printed circuit boards (PCBs). Separation and Purification Technology 238: 116481.

© 2023 Lei Yan. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)