- Submissions

Full Text

Journal of Biotechnology & Bioresearch

Recent Advances in Artificial Intelligence Models for Bioprocess Application

Vazida Mehtab1,2, Nipon Sarmah1,2,3 and Sumana Chenna1,2*

1Department of Process Engineering & Technology Transfer, CSIR-Indian Institute of Chemical Technology, Hyderabad-500007, India

2Academy of Scientific and Innovative Research (AcSIR), Ghaziabad 201002, India

3Chemical and Environmental Engineering, School of Engineering, RMIT University, Melbourne VIC - 3001, Australia

*Corresponding author: Sumana Chenna , Department of Process Engineering & Technology Transfer, CSIR-Indian Institute of Chemical Technology, Academy of Scientific and Innovative Research (AcSIR), India

Submission: April 01, 2022;Published: May 24, 2022

Volume3 Issue5May, 2022

Introduction

In the recent past, there was a paradigm shift from deterministic modelling to data-driven modelling with the increased application of different Artificial Intelligence (AI) algorithms for different subfields of bioprocess engineering.

AI models are generally trained to learn the complex nonlinear dynamic patterns of microbial

and enzymatic processes and use them mainly for

A. Prediction of key process output variables,

B. Evaluating optimal operating parameters that maximizes the process performance

C. On-line monitoring and control of bioprocesses and thereby minimizing the time,

effort and resources and leading to bioprocess safety and sustainability.

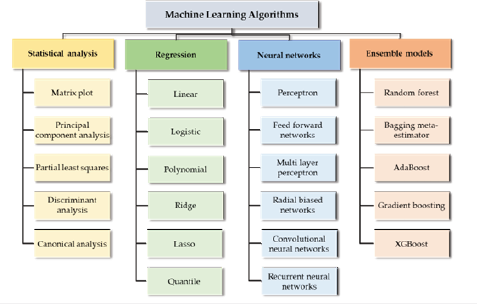

Figure 1: Classification of machine learning algorithms.

AI models can be briefly classified into four major groups based on their model structure and mathematical algorithms involved i.e., statistical analysis, regression models, neural networks, and ensemble models, they can be chosen judiciously depending on the process characteristics and application requirement. Figure 1 gives the broader outline of different AI algorithms and several of these models were used for improving the efficiency of various bioprocesses. They include the utilization of statistical models named here for data preprocessing, dimensionality reduction and also to investigate the trends, patterns, and relationships in the data [1], while regression models were used to effectively determine the underlying relationship (linear or non-linear) between the predictor and response variables [2]. Neural networks are the computing systems with interconnected nodes that mimic the functionality of neurons in human brain, and they are trained to recognize hidden patterns and correlations of several bioprocesses [3]. Ensemble modelling is another class, which considers the creation of multiple diverse models to predict an outcome, by using either different algorithms or different training data sets [4].

AI models for Different Bioprocess Domains

AI algorithms demonstrate a great potential in handling high dimensional data, recognizing the complex nonlinear data patterns, data visualization, classification etc. This section covers the recent advancements in the application of various AI tools in the field of bioprocess system engineering [5].

Prediction of key process output variables

State estimation is a primary area of focus in the application of AI in field of bioprocess engineering. Artificial Neural Networks (ANN) are the most widely used models for the prediction of important process output variables such as product conversion, yield, biomass growth etc, from the easily measurable input operating conditions such as feed flow rates, concentration , temperature, pH, rpm etc. The reported studies include ANN application for real time and off-line prediction of microalgal biomass nutrient and lutein concentrations produced by Desmodesmus sp [6], estimation of microbial fuel cell biofilm communities and bioreactor performance [7], performance prediction of an osmotic membrane bioreactor for simultaneous reduction of salt accumulation and membrane fouling [8] and estimation of filtration performance and membrane fouling in an osmotic membrane bioreactor [9]. Further, an Adaptive Neurofuzzy Inference Systems (ANFIS) and ANN was developed for estimating transmembrane pressure in anaerobic membrane bioreactorsequencing batch reactor during biohydrogen production [10]. The other reported models include random forest predictor model for estimation of key chemical–biological features affecting bioreactor performance [11], Extreme Gradient Boosting (XGBoost) model for predicting the nutrient removal in an anaerobic-anoxicoxic membrane bioreactor (A2O-MBR) [12], gradient boosting regression model for the prediction of microbial growth curves of Candia antarctica for lipase production [13].

Evaluating optimal operating parameters that maximizes the process performance

Further, there is an increasing interest in the integration of AI and optimization algorithms for bioprocesses since 2009 and has been at a consistently high level since 2014. It remains a hot topic in latest bioprocess research, starting with the development of scientific methods for sensor placement, going through data storage and processing architectures, and ending with AI and optimization algorithms [14]. Several bioprocesses were optimized based on AI models, that include maximizing the insulinase production from sugarcane using ANN [15], lipase production from organic solid waste by anaerobic digestion using ANN [16], enhancing the productivity in processing of surimi with citric acid using an integrated Particle Swarm Optimization (PSO) and back propagation-ANN [17], improving bioH2 production during the dark fermentation using multilayer perceptron ANN with response surface methodology [18]. Further, in a recent study an AI approach namely ActiveOpt is proposed to intelligently guide experiments to arrive at an optimal phenotype with minimal measured datasets [19].

On-line monitoring and control of bioprocesses

AI models can effectively capture the inherent nonlinearities of complex biochemical processes and can be used in developing efficient monitoring and control strategies. A synergetic growth is found in the application domains of AI and nonlinear control in addressing a wide variety of bioprocess monitoring and control problems [20]. Some of the reported studies include, a multivariate sensor for the on-line monitoring of a microalgal bioreactor system by integrating the Raman spectra with Support Vector Regression (SVR) to maximize the oil productivity [21,22], control of a semicontinuous batch-fed bioreactor used for yeast fermentation using a new partially supervised Reinforcement Learning (RL) algorithm [23]. Further, a low-cost, flexible, and reliable foam sensor concept for bioreactor applications was proposed for foam emergence in bioreactors based on image analysis using deep Convolutional Neural Networks (CNNs) [24]. Furthermore, process monitoring, and fault diagnosis has become an important component of advanced bioprocess operation, which involves real time detection of the occurrence of any fault (abnormal deviation), finds its root cause and brings the process back to normal operation without effecting process performance. AI algorithms proved quite effective in learning the patterns of different fault scenarios and the underlying dynamics. For instance, a random forest based classifier was used for the diagnosis of faults in a fed batch bioreactor for penicillin production [22] and in a microfabricated bioreactor automated through online characterization of adherent cell culture growth based on image analysis [25].

Conclusion and Future Scope

There is a huge scope for the application of different AI methods that effectively extracts the valuable hidden information in the experimental data and can be used to enhance the performance of various bioprocesses. Conventional bioprocess experimental approaches need to be integrated with efficient AI techniques and implement them for the development of robust and accurate representative models, and employ them for effective bioprocess optimization, monitoring, and control. The entire process requires deeper understanding of the bioprocess, systematic experimental planning and data generation, data pre-processing and key variable identification followed by appropriate model training and its implementation. The fast-growing biotechnology industry in providing alternate sustainable solutions offers great opportunities for the implementation of various AI algorithms in solving complex biochemical problems and there by leading to rapid discovery of new bioprocesses with reduced effort and resources.

Acknowledgement

The first and second author acknowledges the Council of Scientific and Industrial Research (CSIR), New Delhi, India, for financial support in the form of fellowship (CSIR Award No. 31/14(2760)/2018-EMR-I and 31/GATE/14(30)/2017). Authors acknowledge Director CSIR-IICT for the support (IICT/ Pubs./2022/170).

References

- Yoo CK, Lee IB (2006) Nonlinear multivariate filtering and bioprocess monitoring for supervising nonlinear biological processes. Process Biochemistry 41(8): 1854-1863.

- Hassan SS, Farhan M, Mangayil R, Huttunen H, Aho T (2013) Bioprocess data mining using regularized regression and random forests. BMC Syst Biol 7(Suppl 1): S5.

- Gadkar KG, Mehra S, Gomes J (2005) On-line adaptation of neural networks for bioprocess control. Comput Chem Eng 29(5): 1047-1057.

- Liu Y, Gunawan R (2017) Bioprocess optimization under uncertainty using ensemble modeling. J Biotechnol 244: 34-44.

- Marani A, Jamali A, Nehdi ML (2020) Predicting ultra-high-performance concrete compressive strength using tabular generative adversarial networks. Materials (Basel)13(21): 4757.

- Del Rio-Chanona EA, Fiorelli F, Zhang D, Ahmed NR, Jing K, et al. (2017) An efficient model construction strategy to simulate microalgal lutein photo-production dynamic process. Biotechnol Bioeng 114(11): 2518-2527.

- Lesnik KL, Liu H (2017) Predicting microbial fuel cell biofilm communities and bioreactor performance using artificial neural networks. Environ Sci Technol 51(18): 10881-10892.

- Viet ND, Im SJ, Kim CM, Jang A (2021) An osmotic membrane bioreactor-clarifier system with a deep learning model for simultaneous reduction of salt accumulation and membrane fouling. Chemosphere 272: 129872.

- Viet ND, Jang A (2021) Development of artificial intelligence-based models for the prediction of filtration performance and membrane fouling in an osmotic membrane bioreactor. J Environ Chem Eng 9(4): 105337.

- Taheri E, Amin MM, Fatehizadeh A, Rezakazemi M, Aminabhavi TM (2021) Artificial intelligence modeling to predict transmembrane pressure in anaerobic membrane bioreactor-sequencing batch reactor during biohydrogen production. J Environ Manage 292: 112759.

- Tsai Y, Baldwin SA, Siang LC, Gopaluni B (2019) A comparison of clustering and prediction methods for identifying key chemical-biological features affecting bioreactor performance. Processes 7(9): 614.

- Yaqub M, Lee W (2021) Modeling nutrient removal by membrane bioreactor at a sewage treatment plant using machine learning models. J Water Process Eng 46: 102521.

- Sarmah N, Mehtab V, Pratyusha Bugata LS, Tardio J, Bhargava S, et al. (2022) Machine learning aided experimental approach for evaluating the growth kinetics of Candida antarctica for lipase production. Bioresour Technol 352: 127087.

- Weichert D, Link P, Stoll A, Rüping S, Ihlenfeldt S, et al. (2019) A review of machine learning for the optimization of production processes. Int J Adv Manuf Technol 104: 1889-1902.

- Dilipkumar M, Rajasimman M, Rajamohan N (2014) Optimization, kinetics, and modeling of inulinase production by marxianus var. marxianus. Prep Biochem Biotechnol 44(3): 291-309.

- Selvakumar P, Sivashanmugam P (2017) Optimization of lipase production from organic solid waste by anaerobic digestion and its application in biodiesel production. Fuel Process Technol 165: 1-8.

- Qin T, Liu S, Mao Y, Liu X, Tang X, et al. (2018) PSO-based BP-ANN predictive model of Typhimurium in processing of surimi with citric acid. J Food Saf 38(1): e12420.

- Wang Y, Tang M, Ling J, Wang Y, Liu Y, et al. (2021) Modeling biohydrogen production using different data driven approaches. Int J Hydrogen Energy 46(58): 29822-29833.

- Kumar P, Adamczyk P, Zhang X, Andrade RB, Romero PA, et al. (2021) Active and machine learning-based approaches to rapidly enhance microbial chemical production. Metab Eng 67: 216-226.

- Mowbray M, Savage T, Wu C, Song Z, Cho BA, et al. (2021) Machine learning for biochemical engineering: A review. Biochem Eng J 172: 108054.

- Nadadoor VR, De la Hoz Siegler, Shah SL, McCaffrey WC, Ben-Zvi A (2012) Online sensor for monitoring a microalgal bioreactor system using support vector regression. Chemom Intell Lab Syst 110(1): 38-48.

- Shrivastava R, Mahalingam H, Dutta NN (2017) Application and evaluation of random forest classifier technique for fault detection in bioreactor operation. Chem Eng Commun 204(5): 591-598.

- Pandian BJ, Noel MM (2018) Control of a bioreactor using a new partially supervised reinforcement learning algorithm. J Process Control 69: 16-29.

- Austerjost J, Söldner R, Edlund C, Trygg J, Pollard D, et al. (2021) A machine vision approach for bioreactor foam sensing. SLAS Technol 26(4): 408-414.

- Jaccard N, Macown RJ, Super A, Griffin LD, Veraitch FS, et al. (2014) Automated and online characterization of adherent cell culture growth in a microfabricated bioreactor. J Lab Autom 19(5): 437-443.

© 2022 Sumana Chenna. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)