- Submissions

Full Text

Journal of Biotechnology & Bioresearch

Development of Nutritious Ready to Eat Fish Spread from Harpodon Nehereus and its Shelf- Life Extension Using Gamma Irradiation

Aarti S. Kakatkar*, Raj Kamal Gautam, Prashant K. Mishra, Vivekanand Kumar, Ashika Debbarma and Suchandra Chatterjee

Seafood Technology Group, Food Technology Division, FIPLY, Bhabha Atomic Research Centre, Mumbai, India

*Corresponding author: Aarti S. Kakatkar, Seafood Technology Group, Food Technology Division, FIPLY, Bhabha Atomic Research Centre, Mumbai, India

Submission: March 02, 2022;Published: May 13, 2022/p>

Volume3 Issue5May, 2022

Abstract

Modern life style demands convenient Ready To Eat (RTE) and nutritious food. A nutritious RTE fish spread with high protein (12-14%), low fat (3-5%) and no sugar was developed using Bombay Duck (Harpadon nehereus ). The shelf life of fish spread was extended by 60-days using combination of cooking, gamma irradiation (5kGy) and chilled storage (4 °C) whereas, non-irradiated fish spread had a shelf-life of 8-days. The product was analyzed in terms of microbial, biochemical, organoleptic and nutritional content. The microbial load of control sample increased to 7.35 ± 0.43 log cfu/g after 8-days indicating spoilage; while irradiated samples showed a reduced microbial growth during entire storage period; gradual increase in biochemical indices but no significant change in the organoleptic or nutritional quality of radiation processed samples during storage. Thus, the developed fish spread with longer shelf-life is suitable for all consumers including infant, young, old, diabetics and health conscious.

Keywords:RTE; Fish Spread; Nutritious; Shelf-life; Harpodon nehereus; Gamma irradiation

Introduction

Consumers’ demand for healthy food products is increasing worldwide. New products must fit not only the consumer needs, but also their lifestyle and income [1]. Modernization has led to increase in number of working personnel with higher income, education, better consciousness towards quality, freshness, nutrition, hygiene and health. This has necessitated supply of healthy, wholesome, nutritious diet consisting of low salt, low sugar, high protein and high fiber without compromising the taste. More emphasis is on development of convenient, minimally processed, ready to eat and easily available foods. Muscle food products are an essential component of a balanced diet in the developed countries. Their principal components, besides water, are proteins and fats, with substantial contribution of vitamins and minerals. Muscle proteins are of high nutritional quality due to their high Biological Value (BV) and bioavailability [1]. Fish is the most nutritious consisting of proteins, long chain Omega-3 fatty acids, vitamin D, selenium and iodine. This awareness has increased the demand for fish amongst the rich and the poor as a cheap and readily available source of nutrition. However, few convenient, RTC(Ready to Cook)/RTE fish products available in the supermarkets that include fish patties, fish burgers, cutlets, sausages etc. [2].

Spreads are pastes in food preparations prepared well in advance or may be eaten directly as nut spreads, fruit pastes, cocoa butter spreads. These are very popular amongst all age groups; they may be either prepared bland for babies or spicy for aged and may be used as spreads in sandwiches [3]. Japan, the “greyest” country is leading in preparation of such food like kamaboko for the elderly by modifying the gel strength of the fish paste to make it suitable for their chewing. However, such foods are limited and expensive [4].

RTE meat products have become increasingly popular nowadays worldwide due to convenience, nutritional adequacy and good taste. For example, Norwegian Government observed there was high demand for tasty, ready to eat, microbiologically safe and nutritious food from hospital patients, school children, private households and canteens. However, only canned mackerel in tomato and pickled herring are the two well-known fish spreads present in the Norwegian markets. Hence, development of new variations in fish spreads was required [5,6]. Consumers in India accept new varieties in spreads with the launch of products such as almond, cashew nut and seed-based spreads. These products are perceived to be healthier as they are made of fruits, nuts and seeds while competing strongly against spreads made of butter and margarine which contain high amounts of fat. However, there is a demand for meatbased spreads like fish spread which is not available at present. The Compound Annual Growth Rate (CGAR) of spreads is expected to reach INR23.7 billion by 2022 [7].

India is the second largest producer of fish. Bombay duck, (Harpodon nehereus) is a key contributor in Indian marine fish landings along North-West and North-East coast. Bombay duck production was 1,17,213 tons in 2019, contributing nearly 3-4% of the total marine landings of India [8]. Bombay duck is a very soft and highly perishable fish due to high moisture content (94%) leading to loss to fishermen. It is relished by different sections of people as table fish and also valuable as laminated or dried form [9]. Due to its high perishable nature, popularity and glut harvest, it is essential to convert fish into a value-added product with higher shelf-life.

A joint study group of FAO/IAEA/WHO has recommended that food irradiated with any dose is safe and nutritionally adequate. Food irradiation has been used as safe and effective method of preservation of different types of food commodities [10]. Nowadays, preservation of food using gamma irradiation and treatments like edible coatings, modified atmosphere, chilled storage etc. is popular. This may result in synergistic effects reducing level of one or all the treatments [11]. The objective of study was to develop a nutritious, RTE spread using this easily available, low cost and tasty fish with high shelf life.

Materials and Methods

Fish

Fresh beheaded, eviscerated and deboned fish (Bombay duck or, 6kg) was purchased from local market and brought to laboratory on ice. The fish was further cleaned by chilled water (4 °C) and cut into small pieces. The fish was steamed under 15psi pressure at 121 °C for 10min (retorted) to inactivate the inherent bacterial population, spores, and enzymes which helped to stabilize the product. It also softens the fish muscle which makes easier for removal of soft muscular bones. The steamed fish meat was homogenized for 5min in laboratory blender (Sumeet, India). The final weight of the homogenized mince was 3kg.

Ingredients

The spice ingredients added for 1kg fish were fresh onion (25%), garlic (2.4%), ginger (1%), green chilies (3%), coriander leaves (3.5%) were washed, finely chopped salt (0.2%) All the ingredients were sautéed with two table spoon of refined vegetable oil for 5 min.

Preparation of spread

The steamed and homogenized fish meat was further sautéed with above ingredients and further cooked for 10min. After cooling, homogenized again for 5min in laboratory blender (Sumeet, India) to yield a fine paste. The yield of the spread was 750g/kg. The fish spread samples (50g) were packed in Polypropylene (PP) containers (Trend plast Pouch Pack Private Limited, Mumbai) of 3.5mm height x 1.2mm thickness x 70mm diameter and sealed using multilayered aluminium foil lid by cup sealer (Aman engineering works, Mumbai) set at 250 °C. The developed product is shown in Figure 1.

Figure 1:Ready to eat fish spread.

Irradiation and storage studies

Initially, fish spread was irradiated with gamma radiation at different doses (0, 2, 5 and 7kGy). Based on sensory analysis, 5kGy dose was chosen for further experiments (data not shown). Twenty- five samples (50g each) were irradiated at a dose of 5kGy in ice in food package irradiator (Atomic Energy of Canada Ltd, with a 60Co source at a dose rate of 3kGy/h) while twenty samples (50g each) served as control. The dose measurements were done using Fricke dosimeter [11]. Both the samples were stored at 4 °C and analyzed on 0, 8, 16, 30, 45 and 60 days for quality and acceptance by microbiological, biochemical and organoleptic analysis.

Nutritional composition

Nutritional composition of RTE fish spread was validated through National Accreditation Board for Testing and Calibration Laboratories (NABL) certified laboratory (Ram Krishna Bajaj CFBP consumer education and testing center, Mumbai, India).

Microbiological analysis

Samples were analyzed for Total Bacterial Count (TBC) and Total Mold Count (TMC) as described earlier [12]. Briefly, 25g sample was homogenized in 225ml of sterile physiological saline. After appropriate serial dilutions, 1.0ml of sample was pour-plated on plate count agar (HiMedia, India). The colonies were counted after 48h of incubation at room temperature (30 °C). For total mold count, 100μl of appropriate dilution was spread plated on Rose Bengal Chloramphenicol agar (HiMedia, India) and colonies were counted after 48h of incubation at room temperature (30 °C).

Detection of food-borne pathogens

Samples were analyzed for the presence of various foodborne pathogens like Escherichia coli, Salmonella species, Listeria species, Yersinia species and coagulase positive Staphylococcus aureus with slight modification [12,13]. Briefly, 25g of sample was pre-enriched in 225ml of the lactose broth for E. coli and Salmonella species and incubated at 37 °C for 24h. Brain heart infusion broth was used for pre-enrichment of Listeria spp. and Yersinia spp. and incubated at 4 °C for 48h. Enrichment of E. coli, Salmonella, L. monocytogenes and Y. enterocolitica, was done using EC broth, Tetrathionate broth, Listeria enrichment broth and Sorbitol bile broth respectively and incubated at 37 °C for 24h. The enriched samples were streaked on selective plates like Violet red bile agar for E. coli, Bismuth sulphite agar, Xylose lysine deoxycholate agar and Hektoen enteric agar for Salmonella spp., Listeria identification agar for Listeria monocytogenes, MacConkey agar for Yersinia enterocolitica. For S. aureus appropriate dilutions from saline were spread plated on Baird-Parker agar and incubated at 37 °C for 24h. The typical and atypical colonies were picked up from each plate and subjected to biochemical tests. All the media required were procured from Hi Media, India.

Biochemical analysis

The freshness of fish spread was analyzed using Total Volatile Basic Nitrogen (TVBN) and Trimethylamine Nitrogen (TMA); lipid per-oxidation was determined using Thiobarbituric Acid Reactive Substances (TBARS) assay as reported previously [11].

Organoleptic analysis

The organoleptic analysis of fish spread was done by 10 researchers familiar with fish and fishery products in the Taste Panel Laboratory in a partitioned compartment of controlled environment room. The panel consisted of 5 females and 5 males (aged 25- 50 years). The members were trained to recognize and score different sensory parameters like appearance, color, texture, odour, taste, after-taste and overall acceptability using 9-point hedonic scale (9- like extremely, 8-like very much, 7-like moderately, 6-like slightly, 5-neither liked nor dislike, 4-dislike slightly, 3-dislike moderately, 2-dislike very much, 1-dislike extremely). The analysis was done in triplicate, scores were averaged, and the results were expressed as web diagram for all the parameters.

Statistical analysis

Three independent experiments were performed in triplicate (n=9) and the results were expressed as mean ± standard deviation. The initial (0 day) and end of storage period (60 days) in control and irradiated samples were compared with two-way ANOVA followed by Duncan’s multiple range test at a 5% significance level while for the comparison of proximate analysis one-way ANOVA was performed followed by Duncan’s multiple range test at a 5% significance level. These statistical analyses were performed with DSAASTAT ver, 1.101 [14].

Results and Discussion

Nutritional composition

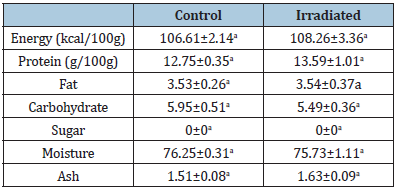

Table 1: Nutritional composition of control and irradiated (5kGy) fish spread.

Results are expressed as Mean±SD. The values are average of 3 independent experiments in triplicates (n=9). Values marked by same letter are not significantly different (P≤0.05).

Convenient, ready to eat, healthy food with high protein, low fat, low sugar is preferred by modern consumers. A low-fat spread using fish gelatin has been prepared previously [15]. The market survey showed that the spreads had higher fat, sugar and low protein content. For example, an eggless sandwich spread had fat content of 38.6%, protein content of 1.6%, sugar content of 8.2% and carbohydrate content of 8.7%; a cucumber carrot sandwich spread had fat content 37.4%, protein 2.0%, sugar content 13.2% and carbohydrate content of 18.2% while tomato onion jalapeno spread was low in fat (1.63%) as well as protein (0.71%) but contained 7% of sugar and 12.71% of carbohydrate. No significant (p > 0.05) difference in nutritional composition of control and irradiated fish spread was observed (Table 1). The RTE fish spread developed by us is sugarless; it has a high protein content of 12-14% and low fat (3-4%) as well as carbohydrate content (5-6%) making the fish spread suitable for diabetics and malnourished consumers. No significant (p > 0.05) difference in nutritional composition of control and irradiated fish spread was observed (Table 1).

Microbiological analysis

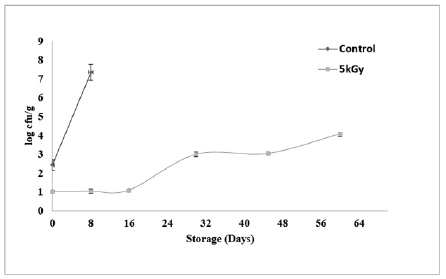

The initial bacterial load of 2.42 ± 0.28 log cfu/g was reduced to 1.01 ± 0.06 log cfu/g in irradiated samples immediately on the zero day. The control samples showed increase in the microbial load on the 8th day of storage to 7.35±0.43 log cfu/g indicating spoilage [16] while, irradiated samples showed a gradual increase to 4.07±0.11 log cfu/g at the end of 60 days storage at 4 °C (Figure 2). Initially, total mold count was absent in both the samples which increased to 2.42 ± 0.28 log cfu/g after 8th day with mold growth visible on the control samples, while irradiated samples were free of mold growth till 60 days of storage. Irradiation at a dose of 5kGy reduced the initial microbial load by 1.41 log cycles and storage at 4 °C prevented growth of bacteria or mold making the spread microbiologically safe and acceptable. Similar results in the reduction of total microbial load and shelf-life extension were observed in irradiated Threadfin bream whole fish [17], Tilapia fillets [18] and Seer steaks [11] on storage at 4 °C. Therefore, irradiation along with refrigerated storage is essential for lower bacterial load and shelf-life extension of the fish spread up to 60 days. The repair mechanism of bacteria is hampered due to various hurdles used in the development of product, which affects their growth and hence, are not able to survive for long [19].

Figure 2:Total bacterial load of control and irradiated (5kGy) on storage at 4 °C. The values are average of 3 independent experiments in triplicates (n=9). The value on the Y-axis denotes total bacterial load in logarithmic scale as log cfu/g.

Fish and fishery products are known to be carriers of different food borne pathogens [20]. Therefore, screening for the presence of important food-borne pathogens is essential to ensure safety of fishery products. The fish spread was free of all the food-borne pathogens tested-E. coli, Salmonella spp, Listeria monocytogenes, Yersinia enterocolitica, and coagulase positive S. aureus. No growth was observed on the selective agar plates indicating that the pathogenic bacteria in and around fish may be low or cooking of raw materials may have helped in lowering the microbial load.

Irradiation is the most widely studied decontamination method in fish species and is utilized in fresh, frozen, canned, dried and cured fish and also in ready-to-eat fish products [21]. There are reports of radiation preservation of minced meat-based product (Pâté) which is similar to RTE fish spread product, produced mainly from a minced mixture of offal (particularly liver), muscle, fat, vegetables, herbs and spices which is cooked at relatively low temperatures [22]. Radiation treatment (2-4kGy) of many RTE foods like dried meat (beef jerky), uncooked and fermented minced meat products (salami), cooked offal or minced meat products (chicken liver pâté or luncheon sausage), and cooked whole meat products (ham) caused reduction of Salmonella spp. or L. monocytogenes [23].

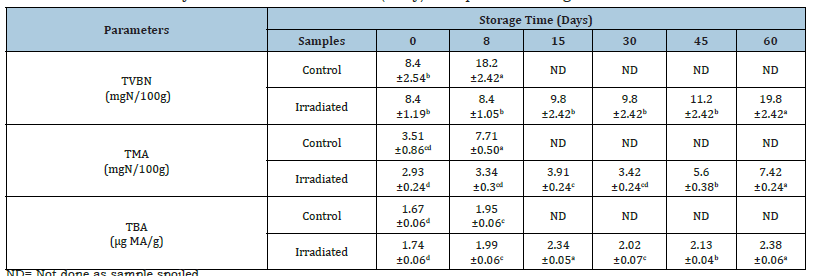

Biochemical indices

The results suggest a positive correlation between increase in the bacterial load and increased TVBN and TMA in fish spread for control samples (Table 2). There was no significant difference (p > 0.05) between the TVBN and TMA values of irradiated samples on storage; however, both control and irradiated samples showed the values within the prescribed limits of 35mg N/100g and 15mg N/100g respectively indicating a fresh original sample [24]. These results are in accordance with other studies [10,25]. TVBN (8.4±2.54 to 18.4±2.42mgN/100g) and TMA (3.51±0.86 to 7.71±0.50mgN/100g) increased in control samples during storage of 8 days while it remained constant for irradiated samples up to 45 days and increased at the end of storage of 60 days (Table 2). Both the control and irradiated samples showed increase in the TBA values from 1.67±0.06μg malondialdehyde/g (MA/g) to 1.95±0.06μgMA/g during storage of 8 days which are near the upper limit of 2μgMA/g [24]. Similar increase in TBA values of irradiated samples have been reported [11] indicating increase in lipid per-oxidation on storage. However, no significant difference (p>0.05) in TBA values was observed between control and irradiated samples on the same day (Table 2). This may be due to low fat content of Bombay duck.

Table 2:Biochemical analysis of control and irradiated (5kGy) fish spread on storage at 4 °C.

ND= Not done as sample spoiled

Results are expressed as Mean±SD. The values are average of 3 independent experiments in triplicates (n=9). Different letters in row/

column indicate significant differences (P ≤ 0.05) for each biochemical analysis.

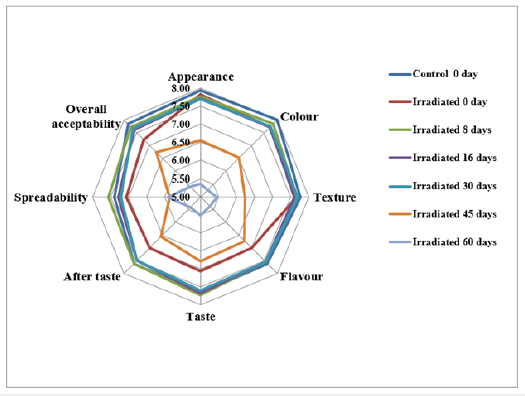

Organoleptic analysis

Organoleptic evaluation is the most popular method to assess freshness and acceptability of fish. Organoleptic properties including visual appearance, color and texture are the first things observed by the taste panelists during analysis. Initially, on 0th day, both control and irradiated samples overall acceptability score of 7.8-7.2 (Figure 3). The sensory web diagram showed no change in the sensory attributes of the irradiated samples on storage up to 30 days. However, on 45th day the score decreased to 6.7 (between like moderately and like slightly). On 60th day, score further decreased to 5.4 (between like slightly to neither like nor dislike). Thus, sensory acceptability decreased as the microbial load increased. Similar correlation between sensory scores and microbiological quality was observed previously [17,26].

Figure 3:Web diagram showing organoleptic evaluation of control and irradiated fish spread on storage at 4 ˚C.

Conclusion

A nutritious and RTE fish spread was developed with readily available fish, Bombay duck using hurdles like cooking, radiation processing (5kGy) and chilled storage (4 °C). The product was microbiologically, biochemically and organoleptically acceptable up to 60 days. Therefore, we suggest a shelf life of 60 days for irradiated RTE fish spread when stored under chilled temperature. The RTE fish spread treated by irradiation with extended shelf-life is pathogen free, soft, protein rich and sugar free, making it suitable for consumption by all including infants, elderly, malnourished, calorie conscious people and diabetics. It can be an ideal breakfast bread spread. Regular use of such spreads may provide desired health benefits without additional dietary supplements.

References

- Tahergorabi R, Matak KE, Jaczynski J (2015) Fish protein isolate: Development of functional foods with nutraceutical ingredients. Journal of Functional Foods 18(Part A): 746-756.

- Pagarkar AU, Joshi VR, Baug TE, Kedar JG (2011) Value addition is need of seafood industries. Fish Coops 23: 8-17.

- Shakerardekani A, Karim R, Ghazali HM, Chin NL (2013) Textural, rheological and sensory properties and oxidative stability of nut spreads-a review. Int J Mol Sci 14(2): 4223-4241.

- Qian J, Ichikawa H (2013) Rheological properties of fish paste products sold on the market in Japan. Bulletin of Faculties of Fisheries, Nagasaki University 94: 17-23.

- Nikmaram N, Budaraju S, Barba FJ, Lorenzo JM, Cox RB, et al. (2018) Application of plant extracts to improve the shelf-life, nutritional and health-related properties of ready-to-eat meat products. Meat Sci 145: 245-255.

- Nofima Norway (2013) Fish spread.

- (2017) Spreads in India. Euromonitor International, London, UK.

- CMFRI Annual Report (2020) Central Marine Fisheries Research Institute, Cochin, Kerala, India

- Kakatkar A, Sharma A, Venugopal V (2003) Hydration of muscle proteins of Bombay duck (Harpodon nehereus) during acetic acid-induced gelation and characteristics of the gel dispersion. Food Chemistry 83(1): 99-106.

- Ehlermann DAE (2016) Wholesomeness of irradiated food. Radiation Physics and Chemistry 129: 24-29.

- Kakatkar AS, Gautam RK, Shashidhar R (2017) Combination of glazing, nisin treatment and radiation processing for shelf-life extension of seer fish (Scomberomorous guttatus) Radiation Physics and Chemistry 130: 303-305.

- Kakatkar AS, Gautam RK, Nagar V, Karani MN, Bandekar JR (2010) Incidence of food-borne pathogens in fresh water fish from domestic markets of Mumbai. Fishery Technology 47(2): 195-200.

- BAM (2020) Bacteriological Analytical Manual (BAM). US Food and Drug Administration, Mary Land, USA.

- Onofri A (2007) Routine statistical analyses of field experiments by using an excel extension. Proceedings 6th National Conference Italian Biometric Society: Statistics in Life and Environmental Sciences, Pisa, Italy, pp. 93-96.

- Cheng LH, Lim BL, Chow KH, Chong SM, Chang YC (2008) Using fish gelatin and pectin to make a low-fat spread. Food Hydrocolloids 22(8): 1637-1640.

- (2017) Food safety and standard authority of India-3rd amendment regulations.

- Jeevanandam K, Kakatkar A, Doke SN, Bongirwar D, Venugopal V (2001) Influence of salting and gamma irradiation on the shelf life extension of threadfin bream in ice. Food Research International 34(8): 739-746.

- ElGhafour SA, Zakar AH (2017) Impact of gamma irradiation on the quality of tilapia fish (Oreochromis niloticus) stored under refrigerated condition. International Journal of Chem Tech Research 10(2): 573-581.

- Leistner L (2000) Basic aspects of food preservation by hurdle technology. Int J Food Microbiol 55(1-3): 181-186.

- Venugopal V, Doke SN, Thomas P (1999) Radiation processing to improve the quality of fishery products. Crit Rev Food Sci Nutr 39(5): 391-440.

- Andoni E, Ozuni E, Bijo B, Shehu F, Branciari R, et al. (2021) Efficacy of non-thermal processing methods to prevent fish spoilage. Journal of Aquatic Food Product and Technology 30(2): 228-245.

- Jørgensen F, Sadler-Reeves L, Shore J, Aird H, Elviss N, et al. (2017) An assessment of the microbiological quality of lightly cooked food (including sous-vide) at the point of consumption in England. Epidemiology and Infection 145(7): 1500-1509.

- Szczawińska ME (2017) Application of ionizing radiation for control of Salmonella in food. In: Mihai Mares (Eds), Current Topics in Salmonella and Salmonellosis, IntechOpen, London, UK.

- Connell JJ (1990) Methods of assessing and selecting for quality. Control of fish quality, (3rd edn), Fishing News Books, Oxford, UK, pp. 122-150.

- Hocaoǧlu A, Sükrü DA, Gümüs, T, Demirci M (2012) Effects of gamma irradiation on chemical, microbial quality and shelf life of shrimp. Radiation Physics and Chemistry 81(12): 1923-1929.

- Chouliara I, Savvaidis IN, Riganakos K, Kontominas MG (2005) Shelf-life extension of vacuum-packaged sea bream (Sparus aurata) fillets by combined γ-irradiation and refrigeration: Microbiological, chemical and sensory changes. Journal of Science Food and Agriculture 85(5): 779-784.

- Tahergorabi R, Matak KE, Jaczynski J (2015) Fish protein isolate: Development of functional foods with nutraceutical ingredients. Journal of Functional Foods 18(Part A): 746-756.

- Pagarkar AU, Joshi VR, Baug TE, Kedar JG (2011) Value addition is need of seafood industries. Fish Coops 23: 8-17.

- Shakerardekani A, Karim R, Ghazali HM, Chin NL (2013) Textural, rheological and sensory properties and oxidative stability of nut spreads-a review. Int J Mol Sci 14(2): 4223-4241.

- Qian J, Ichikawa H (2013) Rheological properties of fish paste products sold on the market in Japan. Bulletin of Faculties of Fisheries, Nagasaki University 94: 17-23.

- Nikmaram N, Budaraju S, Barba FJ, Lorenzo JM, Cox RB, et al. (2018) Application of plant extracts to improve the shelf-life, nutritional and health-related properties of ready-to-eat meat products. Meat Sci 145: 245-255.

- Nofima Norway (2013) Fish spread.

- (2017) Spreads in India. Euromonitor International, London, UK.

- CMFRI Annual Report (2020) Central Marine Fisheries Research Institute, Cochin, Kerala, India

- Kakatkar A, Sharma A, Venugopal V (2003) Hydration of muscle proteins of Bombay duck (Harpodon nehereus) during acetic acid-induced gelation and characteristics of the gel dispersion. Food Chemistry 83(1): 99-106.

- Ehlermann DAE (2016) Wholesomeness of irradiated food. Radiation Physics and Chemistry 129: 24-29.

- Kakatkar AS, Gautam RK, Shashidhar R (2017) Combination of glazing, nisin treatment and radiation processing for shelf-life extension of seer fish (Scomberomorous guttatus) Radiation Physics and Chemistry 130: 303-305.

- Kakatkar AS, Gautam RK, Nagar V, Karani MN, Bandekar JR (2010) Incidence of food-borne pathogens in fresh water fish from domestic markets of Mumbai. Fishery Technology 47(2): 195-200.

- BAM (2020) Bacteriological Analytical Manual (BAM). US Food and Drug Administration, Mary Land, USA.

- Onofri A (2007) Routine statistical analyses of field experiments by using an excel extension. Proceedings 6th National Conference Italian Biometric Society: Statistics in Life and Environmental Sciences, Pisa, Italy, pp. 93-96.

- Cheng LH, Lim BL, Chow KH, Chong SM, Chang YC (2008) Using fish gelatin and pectin to make a low-fat spread. Food Hydrocolloids 22(8): 1637-1640.

- (2017) Food safety and standard authority of India-3rd amendment regulations.

- Jeevanandam K, Kakatkar A, Doke SN, Bongirwar D, Venugopal V (2001) Influence of salting and gamma irradiation on the shelf life extension of threadfin bream in ice. Food Research International 34(8): 739-746.

- ElGhafour SA, Zakar AH (2017) Impact of gamma irradiation on the quality of tilapia fish (Oreochromis niloticus) stored under refrigerated condition. International Journal of Chem Tech Research 10(2): 573-581.

- Leistner L (2000) Basic aspects of food preservation by hurdle technology. Int J Food Microbiol 55(1-3): 181-186.

- Venugopal V, Doke SN, Thomas P (1999) Radiation processing to improve the quality of fishery products. Crit Rev Food Sci Nutr 39(5): 391-440.

- Andoni E, Ozuni E, Bijo B, Shehu F, Branciari R, et al. (2021) Efficacy of non-thermal processing methods to prevent fish spoilage. Journal of Aquatic Food Product and Technology 30(2): 228-245.

- Jørgensen F, Sadler-Reeves L, Shore J, Aird H, Elviss N, et al. (2017) An assessment of the microbiological quality of lightly cooked food (including sous-vide) at the point of consumption in England. Epidemiology and Infection 145(7): 1500-1509.

- Szczawińska ME (2017) Application of ionizing radiation for control of Salmonella in food. In: Mihai Mares (Eds), Current Topics in Salmonella and Salmonellosis, IntechOpen, London, UK.

- Connell JJ (1990) Methods of assessing and selecting for quality. Control of fish quality, (3rd edn), Fishing News Books, Oxford, UK, pp. 122-150.

- Hocaoǧlu A, Sükrü DA, Gümüs, T, Demirci M (2012) Effects of gamma irradiation on chemical, microbial quality and shelf life of shrimp. Radiation Physics and Chemistry 81(12): 1923-1929.

- Chouliara I, Savvaidis IN, Riganakos K, Kontominas MG (2005) Shelf-life extension of vacuum-packaged sea bream (Sparus aurata) fillets by combined γ-irradiation and refrigeration: Microbiological, chemical and sensory changes. Journal of Science Food and Agriculture 85(5): 779-784.

© 2022 Aarti S Kakatkar. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)