- Submissions

Full Text

Evolutions in Mechanical Engineering

Aircraft Isolation Cabin Design for Virus Affected Conditions

Amir Shahneh*

Centre of Aeronautics, Cranfield University, UK

*Corresponding author:Amir Shahneh, Centre of Aeronautics, Cranfield University, UK

Submission: February 28, 2024;Published: March 22, 2024

ISSN 2640-9690 Volume5 Issue2

Abstract

The Novel Coronavirus 2(SARS-cov-2 or Covid-19) is a highly infectious disease that has bought about a global pandemic causing great distress amongst human life across the globe. Covid-19 is an airborne virus primarily transmitted by respiratory droplets when in close contact with an infected person. Due to the pandemic, many sectors and industries were affected. The industry most affected is the Airline Industry. With travel restrictions imposed by the governments of different countries, there has been a significant reduction in civil air travel which resulted in the grounding of many commercial aircraft. Which in turn caused a huge financial crisis for many airlines globally. With travel restrictions being eased by different countries the aviation industry is slowly recovering. However, the danger of getting an infection during air travel has not been reduced. Due to this, the fear of air travel is noticed among passengers and crew. Although the risk of transmission is less in aircraft because of HEPA filter, a high number of ACH (Air Change Per Hour) and airline-imposed restrictions (i.e. masks, sanitation, pre-flight temperature screening). The installation of an Isolation Cabin on aircraft will further reduce the risk of onboard transmission up to a predicted value of 25%.

Keywords:Isolation cabin; COVID-19; Airborne virus; Airbus A350

Introduction

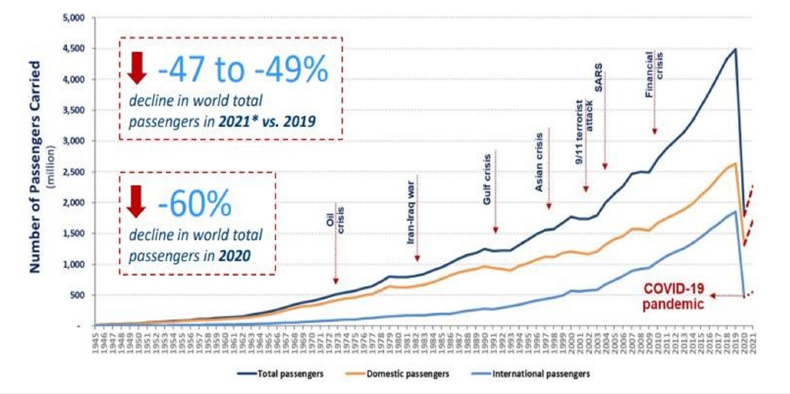

Air travel is a vital means of transport for passengers and cargo. Without air transport, it is highly impossible to connect major cities of various countries across the continents. As per International Civil Aviation Organization (ICAO), Civil Aviation Statics of the world and ICAO staff statistics show an increase of 2.9 billion passengers travelled by air in 18 years from 2001 to 2019 [1]. The numbers were estimated to increase rapidly by 2021, but the numbers were affected abnormally due to the Covid-19 Pandemic. The number of passengers scheduled to travel by air in the year 2020 pre-pandemic was 4.723 billion and post-pandemic it dropped to 1.763 billion which is the worst decline of the numbers in aviation history [2]. There was a decline of 60% of air travelers in 2020 as shown in Figure 1 [3]. This rapid decline in air travelers has caused a massive revenue loss for airlines. Many airlines across the world had to lay off employees or declare bankruptcy, airports, and airline manufacturing companies were also affected by the pandemic. The Novel Coronavirus 2(SARS-CoV-2) is a very contagious disease that caused the COVID- 19 pandemic. Air transport has played a significant role in spreading the virus across the world. The main reason for the spread was the lack of understanding of the Novel Coronavirus 2(SARS-CoV-2) disease transmission during the initial breakout of the virus. There were no precautions in place in the aviation industry when Coronavirus 2 was discovered due to which many symptomatic and asymptomatic individuals infected by the virus traveled, which resulted in the rapid spread of the virus across the globe. The World Health Organization has declared COVID-19 as a pandemic on 11th March 2020. Since then, the virus has been evolving and many variants of the virus have been detected across the world. This has been recorded as the deadliest virus in history, with 221 million people being infected and 4.48 million deaths as of 08/09/2021 [4]. Due to this, governments across the world have restricted international and domestic air travel. This resulted in the grounding of aircraft and huge losses to the airline industry.

Figure 1:World passenger traffic evolution 1945-2021* [1]. Major international events and the impact of it on the passenger traffic. COVID-19 pandemic has bought a 60% decline in passenger count. The red dotted line shows the gradual increase in passenger count.

With the relaxation of air travel restrictions by some countries, the airline industry is recovering slowly. However, there is still a risk of getting infected by the virus in the aircraft. Since air enters the cabin through the above inlets and flows downhill to outlets on the floor. Further, air enters and exits the cabin in the same or adjacent seat rows. Because there is less airflow forward and backward between rows, respiratory particles are less likely to travel between them. Seatbacks act as a physical barrier, allowing most individuals to remain reasonably still, with little face-toface contact. Despite large numbers of passengers, the number of suspected and confirmed cases of COVID-19 transmission between passengers aboard planes around the world appears to be low [5]. Temperature testing and/or questions about symptoms (fever, loss of smell, chills, cough, shortness of breath) can be done at airports and on board; enhanced cleaning and disinfection; contactless boarding/baggage processing; use of physical barriers and sanitization in airports; physical distancing in airports and during boarding; Face coverings or masks; passenger separation when possible; food and beverage service adjustments to reduce contact; control of access to aisles and bathrooms to minimize contact; limiting exposure of crew members to infection; and facilitation of contact tracing in the event of a passenger developing infection [5]. Despite all the measures taken to prevent the spread of the virus, there is still a high chance of getting infected while traveling. There are procedures in place to separate the infected passenger on the aircraft in case of detection during the flight, but there is no proper isolation done in such a case. In case an emergency arises where an infected passenger is unable to breathe and needs medical attention onboard such as oxygen or ventilator support; there is no equipment or very limited equipment on board to support the infected passenger and in such cases, the aircraft might have to make an emergency landing. Emergency landings cost a lot for the airlines and are very time-consuming and most of the airlines prefer to avoid it if possible. The solution for this problem is to have an on-board Isolation Cabin (IC) that can be used to isolate the infected passenger and provide medical support during the flight avoiding any medical emergency landings and avoiding the spread of the virus to other passengers on-board. This project investigates the design of such IC on the Airbus A350 series a modern widebody long-haul civil aircraft [6].

In case a passenger or crew is detected with symptoms of Covid-19 during flight, a series of urgent activities need to be done. The infected passenger needs to be isolated and contained during the remaining duration of the flight. To achieve this an isolated cabin was designed that can accommodate up to two passengers at a time. This cabin is equipped with medical equipment to support infected passengers. An emergency oxygen tank present in the isolation cabin will be able to provide oxygen to two passengers at a time for the entire duration of an average long-haul flight. In case of severity, there is a ventilator system onboard that can also support the passengers. The oxygen system and the ventilator system present on board are portable to provide flexibility during on-boarding and off-boarding the isolation of cabin passengers. The location of the cabin is at the aft of the aircraft to avoid disturbance to other passengers and to have easy access to the aft doors. Aircraft being a pressurized tube with centralized Environment Control System (ECS) the risk of the virus being circulated within the cabin is high. Although there are measures in place to restrict the infected passengers and crew there is still room for passengers with infection boarding an aircraft. Modern aircraft have substantially quicker airflow than regular indoor buildings. Fresh air from the atmosphere around the aircraft makes up half of it, while the other half is re-circulated. ECS system on the aircraft provides a mixture of fresh and re-circulated air during the flight. Re-circulated air is passed through the highly efficient HEPA filter which removes contaminants [7]. However, there still is a risk of spreading the virus to the cabin in case of failure of the HEPA filter. In this project, a modification to the ECS system was proposed and was achieved with the help of a non-return valve that off-boards the air from the isolation cabin directly without passing it through the recirculation system. The modification of the system is done on a very small scale and in a very cost-efficient manner to find favor among airlines. The isolation cabin is equipped with modern avionics that can provide real-time information to the crew about the isolation cabin. The medical equipment installed in the isolation cabin can be remotely controlled both on-board and off-board with the help of the avionic. Visual and audio communication can be established with the passengers in the isolation cabin.

Isolation Cabin (IC)

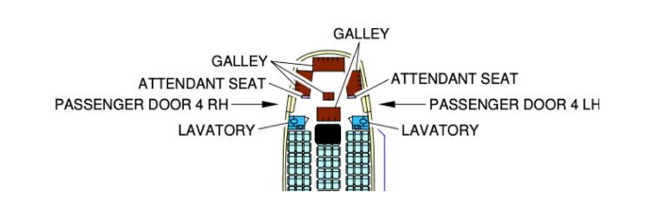

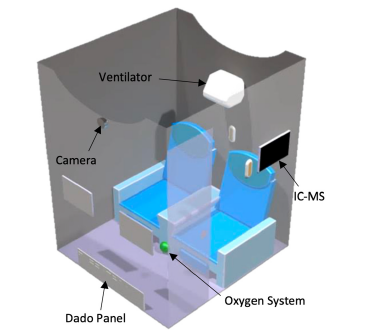

The main objective of the IC is to isolate the air in it from the rest of the aircraft. To achieve that, a separate cabin is designed and placed at the aft position of the aircraft. The IC is installed in the highlight region shown in Figure 2. The location is chosen as it is more convenient for the cabin crew to attend and access the IC without disturbing the passengers. The proximity to the aft passenger door is advantageous as the patient can be loaded and unloaded with ease. Two rows in the middle column must be taken out to accommodate the IC. The structure of the IC has walls on four sides and a foldable door on the left side of the cabin to access it. Two business class-type seats are installed in the IC for the comfort of the passengers. The structure is built using Collins Aerospace product, aero FEATHER which is a honeycomb structural panel. The internal structure of this material is 38% lighter [8]. The IC has a separate airflow inlet from the top of the cabin. The air within the IC does not mix with the air in the main cabin. The cabin is semiairtight which means there is no major leakage of air. However, there is a dado panel ventilation suction at the bottom. The air is removed from the IC with the help of a fan and sent overboard. The cabin has two seats that can recline more than the normal seats for the comfort of the patient. There is enough space for two patients to be accommodated and for the movement of the crew while accessing the IC. The seat is also equipped with a dining tray for the patients to have their meal (Figure 3).

Figure 2:Airbus A350 aft cabin layout [7]. The Black highlighted region shows the location of the isolation cabin on the airbus A350.

Figure 3:Isolation cabin design. CAD design of the isolation cabin.

Key features of Isolation Cabin

A. Business Class seats for the comfort of passengers.

B. IFE Screens for entertainment and communication.

C. Portable Oxygen system with remote control capability.

D. Portable Ventilation with remote control capability.

E. Camara for monitoring without contact.

F. IC–Management Unit to control, monitor, and communicate

with the passengers from outside the IC.

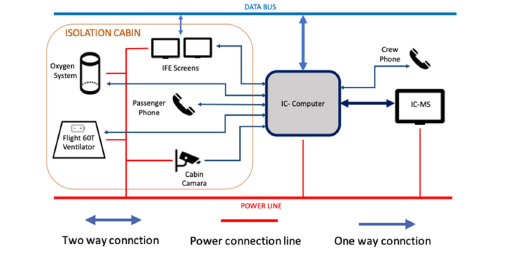

IC is equipped with Aerox 2D (13 CuFt) Portable Oxygen System with Aithre Altus Meso [9]. The tank has a 400L capacity and can provide pure oxygen to two patients at a time for 27hrs. The system can be remotely monitored and controlled (Figure 4). A Fight Medical-Flight T60 portable ventilator system [10] is all fitted in the IC. It has battery backup and can be monitored and controlled remotely. It can support one patient at a time. Medical equipment fitted in the IC does not need a professional to operate them, with basic training and with the help of a hand manual it can easily be operated by anyone. The equipment is connected to the onboard avionic systems as shown in the avionics architecture. The Isolation Cabin-Computer (IC-C) is the heart of the system which processes all the information received from other systems and transmits the required data to the monitor and control systems. The IC-C is connected to the main data bus of the aircraft via a two-way data link. This will be useful to get access to the Internet, provide data to Integrated Vehicle Health Management (IVHM) system and communication with the flight crew and the ground. The IC-C is connected to the Isolation Cabin-Management System (IC-MS), this system is located on the left wall of the IC. (Figure 5) IC-MS is used to monitor and control the systems. It is a touch screen interface, which is accessed and operated by the crew. The patient can use the IFE to send messages to the crew IC-MS, this will be useful when the patient is on oxygen or ventilator support and is unable to talk. The IC is also equipped with a phone which can be used to communicate with the crew outside. A camera is fitted inside the IC to monitor the situation inside virtually. The provision of the camera in the cabin will keep the crew safe from getting infected. The camera is connected to the data bus via the IC-C.

Figure 4:Aerox 2D portable oxygen system [9].

Figure 5:Medical-Flight T60 portable ventilator system [10].

Figure 6:Isolation cabin avionic system architecture. Blueline shows the data transmission lines with directions between different equipment and the main data bus of the aircraft. The Redline shows the power supply lines to different equipment.

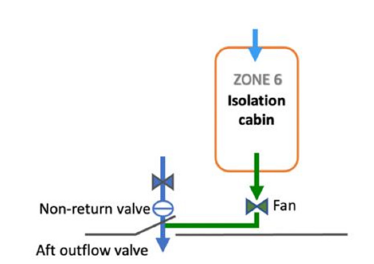

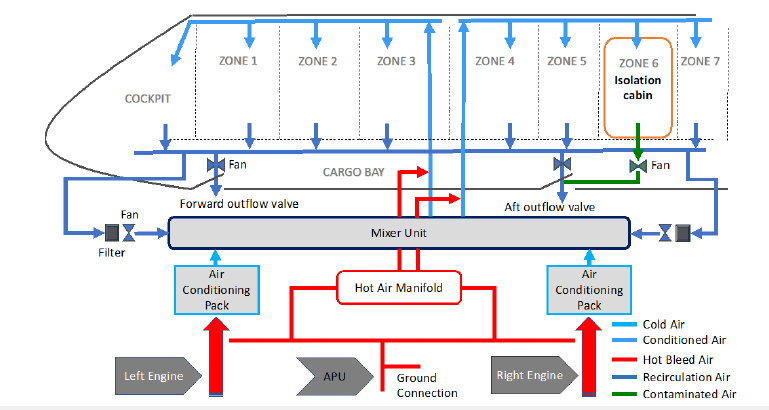

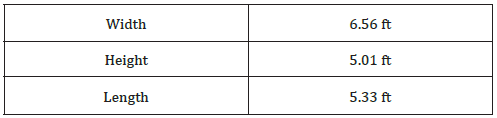

The ECS system on the Airbus A350 is modified in such a way that the air from the IC does not get re-circulated and sent into the cabin. The main purpose of this design is to prevent the contaminated air to be re-circulated into the cabin (Figure 6). The contaminated air from the IC is sent overboard to prevent the spread of the virus. The IC is designed to have a common air intake from the air distribution system and a separate exhaust from the bottom of the IC with help of dado panels and a fan. IC-ECS system is designed in a way that it works with the existing system in the aircraft with minimal modification. The air to the IC is fed through the air distribution system. This air distribution system is modified to have a separate air intake for the IC that is taken from the zone- 6 distribution duct (Figure 7). This air enters the IC from the top and exits from the bottom. The used air is sucked out from the IC through the dado panel with help of a fan. The sucked air is passed through a duct and sent overboard with the help of an aft outflow valve which is installed on the aircraft. There is a non-return valve installed to the aft outflow valve duct so that the flow is only in one direction and the contaminated air does not get mixed with the air taken for the re-circulation (Figure 8).

Figure 7:Isolation cabin non-return valve architecture. The light blue line on the top is the air inlet into the Isolation Cabin. The green line is the air outlet from the cabin to the aft outflow valve with help of a fan. The blue line on the left is the used air from the cabin. A non-return valve prevents the air from going back into the aircraft.

Figure 8:Isolation cabin-ECS architecture. Hot air shown is shown in red is taken from the engine, ground, and APU depending on the phase of the flight and sent to the air-conditioning packs and hot air manifold. Cooled air and re-circulated air are mixed in the mixer Unit. Using hot air from the hot air manifold the air is bought to the desired temperature before sending it to the distribution system. Used air from the cabin is sent to re-circulation via filter and fan through the bottom of the cabin. The remaining air is off-boarded through the outflow valves. Air entering the Isolation cabin is exhausted via. Greenline and is off-boarded directly through the aft outflow valve.

Mass flow rate calculation

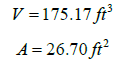

The volume and area of the isolation cabin as per Table 1 is:

Table 1:Dimensions of Isolation cabin.

Airbus A350 is manufactured using composite materials which enable them to operate at lower cabin altitude around 5000 to 6000ft [11]. Where the pressure is approximately 12.3 psi

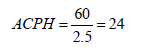

The ECS system on this aircraft can renew air every 2-3min (avg 2.5min) [12]:

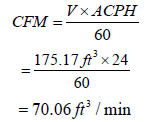

Where ACPH is air change per hour [13]. The airflow rate of the isolation cabin is given by:

Where CFM is cubic feet per minute [14]. The humidity on the Airbus A350 is around 15 °C at cruise altitude.

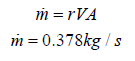

Mass flow rate is given by:

Advantages of IC

a) This design is much cheaper.

b) Does not need another outflow valve.

c) The pressurization of the aircraft is not affected.

d) Makes use of the existing system.

1.1. Disadvantages of IC

A. The flow cannot be controlled independently.

B. IC Pressure cannot be regulated independently.

Conclusion

The covid-19 pandemic has brought an unexpected change in the aviation world. One of the first affected due to the pandemic was the aviation sector. Many aircraft had to be grounded, many aircraft were also sent to long-time storage. Employees working in the sector were laid off and many airlines were declared bankrupt.

The year 2020 and 2021 have been recorded as one of the worst years for the aviation industry in history. The pandemic has affected human life in a major way. More than 375 million people have been affected by the virus, causing 5.6 million deaths as of January 2022. The IC is designed with sophisticated technology to contain the contaminated air and send it overboard without using it for re-circulation. This has been achieved by designing an Isolation Cabin and modifying the ECS. The introduction of Isolation cabin and IC-ECS in the aircraft will open a safer way to travel. It assures reducing the spread of the virus within the aircraft and provide medical support to infected individuals simultaneously. But it does not assure to arrest the spread of the virus in the aircraft. This reduction of transmission can be possible only when the individuals adhere to the rules and inform the crew when they develop symptoms during the flight. Isolation Cabin is not only limited to being used for COVID-19 but can be used in the future for any contagious diseases.

References

- Air transport, passengers carried, World Bank Group, Washington DC, USA.

- Passenger air traffic each year.

- (2023) Effects of novel coronavirus (COVID-19) on civil aviation: Economic impact analysis. Economic Development-Air Transport Bureau.

- Dong E, Du H, Gardner L (2020) An interactive web-based dashboard to track COVID-19 in real time. The Lancet Infectious Diseases 20(5): 533–534.

- Pombal R, Hosegood I, Powell D (2020) Risk of COVID-19 during air travel. JAMA American Medical Association 324(17): 1798–1798.

- (2018) What is so special about the airbus A350 and Boeing 787 dreamliner?

- (2021) @Airbus A350 aircraft characteristics airport and maintenance planning AC.

- (2021) AeroFEATHERTM honeycomb panels.

- (2021) Aerox aviation oxygen systems.

- (2021) Flight 60-flight medical.

- Bagshaw M, Illig P (2019) The aircraft cabin environment. (4th edn), Travel Medicine, Elsevier, Amsterdam, Netherlands, pp. 429-436.

- (2022) A350 family, Airbus Passenger Aircraft.

- Air changes per hour.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)