- Submissions

Full Text

Evolutions in Mechanical Engineering

Technical-Economic Aspects of the Units Creation and Exploitation for Ladle Treatment of Cast Iron and Steels

Protasov AV*and Sivak BA

Department of SSC VNII Met mash, Russia

*Corresponding author:Protasov AV, Department of SSC, VNIIMETMASH, Russia

Submission: March 18, 2019; Published: May 13, 2019

ISSN 2640-9690 Volume2 Issue5

Abstract

Modern secondary steelmaking represents the wide set of technological processes and aggregates, devices and systems. Many of them are characterized by considerable cost and needs in expensive service. Various variants of technical-economic advantages are shown, which are achieved by different ways as by production, as by exploitation of metallic products by customers. The concrete technical-economic advantages are shown at the sample of melt treatment by injection of metallurgical wire with different fillers.

Keywords: Steel; Cast iron; Ladle; Furnace; Melt; Economy; Expenditure; Technology; Heating; Deoxidation; Modification, Bath stirring, Casting

Introduction

Ladle treatment of steels is an inalienable part of modern steelmaking production and universal mean for considerable improvement of working properties of metallic products, as well as for increasing of production technical-economic and ecological factors of production. During many decades large number of the various technological processes and units for secondary steelmaking and their modification was created, many of them have lost its urgency and already are not used in newly built shops, because the economic considerations mainly, as they not fully correspond to the main goal of any industrial production - the creation of product, competitive on broad market with high properties and characteristic and/or minimum production expenses.

Most convincingly check by time was passed by the units “ladle-furnace” (LF) with electric arc heating of metal and vacuum degassing unit of ladle and circulation (RH) type, providing possibility deep degassing especially necessary at production of low carbon steels. The creation and exploitation of the ladle treatment unites needs in considerable expenses, because that type of aggregate and its technological possibilities must be chosen taking into consideration the production conditions and market perspectives at the base of detailed analyses of exist or new production.

The technological possibilities and, accordingly, the cost of concrete aggregates, as exploitation cost in dependence of used technical means by one the same process type may differ in very wide limits. Modern processing of fluid steel in ladle presents itself broad set of the technological processes and unit, as well as devices and systems, many from which possesses by considerable cost and need in high-priced service.

As a rule, the technological equipping and, accordingly, the concrete unit capital and current cost in dependence of used technical means by the same type of process can alternate in wide range, by that for different technological task: introducing of reagents, bath stirring, metal heating, vacuum creation etc. considerable set of alternative technical decisions with vide range of constructive peculiarities, cost, indexes of expenditure and technological effectiveness is created and mastered at practice. For example, the reagent introduction into melt may be fulfilled at the kind of pigs, pieces, granules, powder, monometallic or powder wire; the stirring - by inductor, gas blowing through one or a few tueres, top (dipped or not- dipped), by argon or nitrogen; the vacuum creation above melt - by means of mechanical, steam-ejector or combined pump; the metal heating- by arc of AC or DC or chemical method by burning of fuel etc. According to modulus principle for concrete metallurgical task it is necessary to choose from existing base of used technical decisions the most effective and economical for given conditions. The economical effectiveness of secondary steelmaking aggregates can differ at the vide range depending on market situation, concrete production conditions and type of chosen equipment. Such technological parameters as: heat intensiveness, vacuum depth (residual pressure above melt), velocity of circulation, power of vacuum pump, slag regime, quantity and intensiveness of reagent introduction exerts considerable influence on products quality and production indexes.

Together with task of products quality improvement and widening of produced steels assortment metallurgists are staying in front of necessity of the increasing production effectiveness, including reduction of expensive materials consumption. The economic effectiveness of secondary steelmaking aggregates may differ in wide limits in dependence of market situation changing and demand for high quality products, concrete condition of production and choose of equipment for secondary treatment.

The inalienable part of the business-planning of new aggregates is production completeness assessment, that is determined by custom properties, claiming at inner and outer market, and relatively low first cost of products, allowing to receive income when realizing.

In modern conditions the simplest and essential factor of the effectiveness estimation is a pay-back period of the capital embedding, which can be is approximately determined from expression:

where: K-capital investments;

To-period of creation and mastering of new equipment;

N-annual output;

E1-economy of specific expenditure by metal producer;

E2-economy of specific expenditure by consumer (additional profit).

Thereby, when making the new equipment for secondary processing by liquid steels, on the one hand, necessary to increase the technological possibilities for the reason maximum expansion working characteristics of product for consumer (the expansion to account complex and responsible marks by steels, increasing of the purity and homogeneity by steels, improvements working characteristic), with other-follows to shorten the prime cost of production, including working expenses at melting and casting, herewith reduce the cost of the equipment for the ladle processing and accordingly, value of the depreciation charge, minimize the working expenses. So, decision on construction of the new unit, choice of its type and technical equipment must be taken with provision for need market and solved technological problems. The attempts to subject to the ordinary marks become highpriced secondary to processing bring the facilities about irrational spending.

Economy of production expenses

A. The economical effectiveness of secondary steelmaking is displayed directly in steelmaking production, where the considerable reduction of cost price is achieved by the next items:

B. The reduction of expensive reagent consumption due to more strictly proportioning and increasing of their assimilation degree;

C. The economy of energy consumption by secondary steelmaking due to heat loss reduction;

D. The economy of expenses for refractory materials and lining repairing because of ladle lining durability;

E. The widening of technological possibilities due to complex technical means for dosed introduction of reagents, stirring, blowing and heating devices;

F. The reduction of rejects by the chemical composition and surface defects reduction and receiving of setting chemical composition.

G. The expenses economy is achieved for refractory materials buying and repairing of lining due to the increasing of furnace lining durability;

H. The capacity of furnace is increased due to mutual time of standing idle, connected with lining repair.

The concrete values of economy by separates items must be determine taking into account used materials and energy carriers, constructive peculiarities of equipment and local conditions. In the process of continuous casting of metal, treated in the ladle, due to narrow temperature interval, low content and globular form of non-metallic inclusions fluidity considerably improves and specific expenditure indexes are reduced. Using aggregates ladle-furnace with the possibility metal holding under heating it is possible to synchronize work of the main aggregates of shop, that promotes length of serial casting and decreasing (excluding) of non-planned breaks.

Technical-economic efficiency of cast iron and steel processing by injection wire

The concrete technical-economic advantages reached both at production, and when using of metallic products are shown on example of the processing melt powdered or monolithic metallic wire. In steel production, especially of high-quality steel for responsible purposes at now injection of wire, filled by SiCa, Al, B, Al, rare-earth and other chemically active elements is used widely by ladle treatment as in structure of the traditional complex aggregates, as in the kind of separate devices - the tribe-apparatus, that are used by the steel treatment in ladle, tundish ladle or crystallizer of continuous casting machines, in the ingots and foundry shops. Treatment by injection wire additionally increases the effectiveness of the traditional secondary steelmaking. The technical-economic advantages from use of powder wire in comparison with blowing of powder in stream of argon and introducing of pieces are repeatedly discussed in many samples. By the expert data, only replacement power blowing by introduction of powder wire economy of current expense reaches 3$/t [1]. Due to small-dispersed fraction of reagents and their introduction to the lowest layers of melts the further increasing of elements assimilation degree and exactness of chemical composition are achieved.

By that the widening of produced steel grades including the complex and expensive is achieved. In last years the row of special high-quality appeared, that can be produced only with using of dosed quantity of powder wire with various filler, for example steels with normal contents of Ca and increased relented content of S. Owing to that boiling of bath is absent the mass of melt can be increased by 10-15% with appropriate production capacity increasing. The intensification of production by means of a few simultaneously introduced wires, work synchronization of steelmaking furnaces, secondary steelmaking aggregates and continuous casting machines by according increasing of casting serial promote the production capacity increasing. Because of the very limited mass of necessary equipment (about 5 times) the capital and current expenses considerably lower. The possibility of practically full volume of ladle (90-95%) promotes to productivity increasing and reduction of specific indexes of consumption, while the possibility of use ladles of small volume (5-20t) essentially widens diapason of the equipment technological possibilities.

Owing to considerable reduction of the gas discharge from the ladle and essential decreasing of required capacity of gas cleaning system the cardinal reduction of expenses for nature conservation and favorable conditions for work are provided. The use of the powder wire with expensive fillers - vanadium, niobium, titanium etc., owing to exact stable assimilation is appeared as most economically profitable method of this component’s introduction. The important factor of cost price reduction is the decreasing of rejects. For instance, the use of Ca-Al wire lets to diminish the rejection of steel pipes be 1,5-2,0 times. The essential factor of economy is a reduction of the heat losses by melt in the process of treatment. If by blowing calcium powder through lance temperature melt falls by 50 °С then by introducing of similar amount calcium in the manner of powder wire warm-up losses from around 7 °С. The cost of the equipment for entering the wire forms 5% cost of the equipment for powder injection processing [2]. The treatment of steel by powder wire very positively affects to continuous casting results. At the Moldavian metallurgical plant, where the casting is fulfilled at the bar CCM throw nozzle-feeder with small diameter (15-16mm) after treatment by powder wire the rejection was decreased by 2,5 times and economy 1,04 $/t vas achieved. The modification of metal in crystallizer and tundish by nano-powder wire (TiN, Ti-Cr, TiCN-Fe) increases density and reduction of the chemical inhomogeneity.

The application of powder wire with expensive fillers: V,Nb, FeV, etc. due to strict, stable application is economically most profitable. The processing of cast iron by powder wire now is widely used mainly for desulfurization. By that such advantages of equipment, as simplicity and compactness are obvious. That allows to place the equipment on existing squares in working shops and accordingly to diminish the capital cost. When performing the requirements to technologies cost-performance using the powdered wire with FeV, Fe,Nb, FeMo at different enterprises forms 0,5-2,5$/t [3]. The working expenses on treatment processing of cast iron by wire by 20-40% less than the other way of the processing. The processing of cast iron by wire with Mg-filler founds wide-spread application at metallurgical and foundry shops for production of high-strength cast iron.

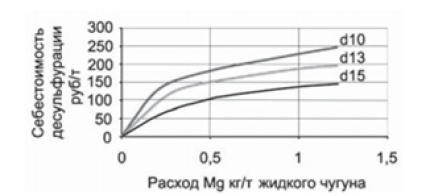

The expenses for processing relate to diameter of the applicable powdered wire and change from cost of the material-a filler. Dependency of the expenses cost from expense magnesium and by different diameter of the wire is shown at Figure 1. The widening of technological possibilities is accompanied by additional expenditures for creation/purchase of new systems and devices, additional amortization assignment, additional expenditures, connected with intensification of production process (increased expenditure of energy carriers? Introduction of more additives (sometimes expensive, for example rare earth), accelerated wear of refractory lining, etc. For example, expenditure of ferroalloys by vacuum deoxidation is diminished on the 50-70%. By that the decreasing of cost price of steel, treated in the ladle, plays the important role. It is achieved by means of: -decreasing of specific expenditure of energy carriers as a result of heating, vacuum degassing, stirring regime optimization;

Figure 1:Dependence of cast iron desulfurization from Mg consumption and diameter of powder wire.

A. Decreasing of flux, deoxidation and alloying reagents due to lowering of melting loss of elements, increasing of assimilation degree and accuracy of weight dosing;

B. Increasing of refractory lining durability and appropriate decreasing of expenditure for refractory materials and repairing of lining;

C. Increasing of productivity and lowering specific expenditure for treatment.

Considerable economy is achieved as a result of rejects reduction and improving of indexes of all melting shop. In the steelmaking department significant effect is achieved in connecting with transfer of refining operations to secondary steelmaking aggregates, due to cutting out of melting cycle, productivity increasing and lowering of specific expenditure for melting, excluding the necessity in metal overheating in the furnace etc. By continuous casting as a result of steel treatment in the ladle due to maintaining of narrow temperature interval, lowering of nonmetallic inclusions and improvement of surface quality, the length of casting series is increased, The necessity of billet inspection and grinding is excluded, the possibility of casting and rolling direct combining is secured. Estimating the effectiveness of investment, it is should evidently to take into consideration the distant perspectives, connected with world tendencies: the cycling fluctuations of demands for metal productions, prices for raw materials and energy carriers. Such factors as tendency of productions with high additional cost share and increasing of demands for high-technology machine-building products will promote to secondary steelmaking development.

The estimation of competitiveness a necessary part of to their product, which is the sale made metal products, receptions of the profit and recoupment of the made investments. Metallurgical wire: powder or monolithic, filled with Si, Ca, Al, Mg, B and other chemically active elements widely used, especially by production of high-quality steel and iron. The powdered wire is a most perspective direction for sphere- forming treatment of cast iron by production of highly durable cast iron with globular graphite. The possibility of use of practically full filled ladle (90-95%) promotes the increasing of capacity and lowering of specific consumption indexes, besides that the possibility of application of small ladles (5-20t) considerably videns the diapason of equipment technical properties. By the application of wire power of gas-cleaning structures may be by 2-5 times less. Its cost reaches half of desulfurization department cost. At the steelmaking shops considerable decreasing of cost by next items: Decreasing of expensive reagents consumption because of application degree increasing.

Changing of Al-pigs by aluminum wire diminishes expenditure by 30-50%. The economy of energy consumptions in the process of treatment due to decreasing of heat losses. Funds economy for refractory materials and lining repairing due to durability of ladle lining increasing. The widening of technological possibilities by means of complex reagent application and many-pass apparatuses. Reduction of rejects by chemical composition, surface defects, due to decreasing of non-metallic inclusions and increasing of alloying elements dosing accuracy. For instance, Ca-Al wire application allowed to lower of tubes rejection by 1,5-2 times. The widening of assortment products by complicated and expensive grades of steel. The row of special high-quality marks of steel, that can be produced only with strictly dosed quantities of powder wires with various fillers, for example, steels with normal content of Ca and reglamentedraising contents S. The cardinal decreasing of expenses for nature protection is reached.

Lower (appr. In 5times) capital and working expenses due to small mass and cost of equipment. The increasing of steelmaking shop productivity due to the manufacture intensification, including simultaneously introduction of several wires, securing synchronization of arc furnaces, ladle treatment aggregates and continuous casting machines by appropriate increasing of serial continuous casting time.

The significant effect is reached by the steel fluidity improvement. So, for instance, in condition of the Moldavian metallurgical plant, where casting is realized on small bar CCM through glasses-feeders of small diameter (15-16mms), rejection marriage was reduced after introduction of new technology in 2,5 times and is reached economy 1,04 $/t. The minimal metal consumption and corresponding cost of the equipment promotes the reduction of the depreciation charge.

Expense economy by customer

Among the main income indexes from ladle treatment installation the important meaning belongs to possibility of new, more complicated grades steel production with high quality and additional payment for the improving of properties by exploitation. Some items from possible economy are estimated enough exactly, for example, from mass and cost of metallic construction due strength property improving. However, estimation of full economy by consumer from such items, as increasing of durability, decreasing of breakage probability, reduction or exception of spoilage etc., is very hard, that’ s why calculated estimation is always is lowered.

The indexes economy from use ladle treatment processing the fluid metal, achieved at consumer:

A. The increasing of durability and working life;

B. The Reduction or excluding of breaks;

C. The improvement of workability in machine-building, etc.

The Introduction of Steels of New Generation and Production Technologies for Automobile Sheets

Using efficient vacuum-oxygen degassing in the RH-unit in combination with original methods of the rolling and heattreatment allowed to solve a problem receptions competitive domestic sheets for automobile industry. As a result of this work on MMK and CherMK variety of technology production high-quality economical steels for automobile sheets of more than 30 grades is mastered. This has allowed to provide 100% supply of highquality sheets to domestic auto enterprises, including “AvtoVAZ” and “KamAZ”, it’s processing and to stop import. The volume of the consumption of auto-sheets with perfected feature at AVTOVAZ” has exceed 2400 thou. t, at “KAMAZ”-250 thous.t, that has brought the reduction of the expenses by the refusal of import purchase by (with provision for differences in the price and renting MMK and CherMK more then on 8,5 млрд rub. Besides, abbreviated expenses at fabrication basket are decreased because of reduction on 40% point of the welding to account of the mastering large scale stampings. This also promotes the fuel economy, improvement of the ecology’s indexes [4].

Besides that, the expenses by the manufacturing of bodies are reduced due to large-scale stamping, welding simplification, decreasing of automobile mass, that also promote to fuel economy and improvement of ecology. For organization of the mastered type automobile sheets delivery to foreign consumers Russian metallurgical enterprises organize works by metal production acceptation by foreign companies. For this purpose, foreign company are given sample of the initial lots or are delivered initial lots automobile steels. It was received approval of such consumers, as Renault, Hyundai, Volkswagen, General Motors and others for different groups of the marks of steels. In particular, have obtained approval 24 positions MMK and more than 27 positions CherMK”. As a result of introduction mastered automobile steel sheets of the new generation and technology their production is received total economic effect more than 10,5 billion rub. Total volume of production such steel for period 2004-2011 has formed more than 3,5 mlnt. Besides, the mastering by metallurgical industry of high-quality steel has allowed the metallurgical combine to appear on world market, competing with foreign companies. The Significant economy is reached as a result of reductions of the rejects and improvements of the factors of the work whole shop. in consequence of reduction of melting cycle length, the technological problems, directed on increasing of competitiveness production.

Conclusion

A. The use of secondary steelmaking allows considerably increase completeness of metallic products and the economical effectiveness of steelmaking production due to decreasing of production cost price at the all stages, including semi-products in furnace and continuous casting of steel.

B. The modern treatment of liquid steel in the ladle represents the wide set of technological processes and aggregates< devices and systems, many of them is characterized by considerable cost and needs in expensive service.

C. The decision of new aggregate creation, its type choice and technological equipping must be taken with consideration of the market demands and at the base of detailed analysis of all stages production. The complex treatment of ordinary steels guides to the unnecessary expenses.

D. Module principle of equipment creation allows to choose from the wide set of elaborated technological means the most suitable for production task decision without unnecessary cost price production increasing.

Such factors, as trend of the increase the share of product with high added cost and increasing demand for high-tech machine-building product must promote development secondary steelmaking.

References

- Golubtsov VA, Voronin AA, Roschin VE (2005) Comparasion of steel modification methods by secondary treatment. 8th congress of steelmakers. Nizhny Tagil Tchermetinformacia, pp. С411-C417.

- Mayer H (1994) Application of powder wire introduction by steel and casting. 2nd congress of steelmakers Lipetzk. Tchermetinformacia, pp. С240-C241.

- Protasov AV, Komolov IV Протасов АВ, Komolov IV (2015) Technicaleconomic aspects of metallurgical powder application. Chernie metally, pp. С11-C17.

- Rodionova IG, Uglov VA, Zaitzev AI, Protasov AV, Mishnev P et al. (2014) New generation of automobile sheet steel for domestic automobile manufacture and improved metal product competitiveness. Metallurgist 58(3-4): 184-193.

© 2019 Protasov AV. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)