- Submissions

Full Text

Evolutions in Mechanical Engineering

Innovative Method in Recycling Wind Turbine Blades: Mini Review

Azadeh Tavousi Tabatabaei and Seyed Hossein Mamanpush*

Composite Materials and Engineering Center, Washington State University, USA

*Corresponding author:Seyed Hossein Mamanpush, Composite Materials and Engineering Center, Washington State University, Pullman, WA, 99163, USA

Submission: June 15, 2018;Published: June 26, 2018

ISSN 2640-9690 Volume1 Issue1

Abstract

During the past decades many researchers focused on finding a solution for the wind turbine blades that faced end of life but the main challenge for all the previous research was lack of acceptable pathway that was viable economically. Because these blades currently considered as a waste, spending lots of energy and chemical material for them is not an acceptable solution, that is why we suggest an innovative method for solving this problem by considering mechanically recycled wind turbine blades (rWTBs) as a feedstock for making second generation composites.

Keywords: Recycling; Wind turbine blade; Polymer-matrix composite; Glass fiber

Introduction

By increasing the demand for clean energy and specially wind energy, the number of wind turbine blades that faces end of life increase dramatically. Under this circumstance, a significant amount of wind turbine blades will burden or current landfills until a viable recycling strategy is found. Repurposing and recycling of end-of-use wind turbine blade material will bring both an economic and environmental necessity. Options to incinerate or disposal has negative environmental contributions and disregards the potential rWTBs have as a viable feedstock for second generation products. There is a potential to recycle the glass fiber from the thermoset matrix via chemical or thermal treatments, however the resulting fiber is often lower in properties than virgin material and becomes very difficult to disperse into any second-generation product. Mechanical techniques that employ shredders, hammermills, knife-mills, etc. provide a low-cost option to deliver a reliable feedstock. However, the methods and classification procedures within the mechanical refining process are vital parameters to address in order to achieve the maximum potential of the rWTB materials while maintaining minimal energy and costs.

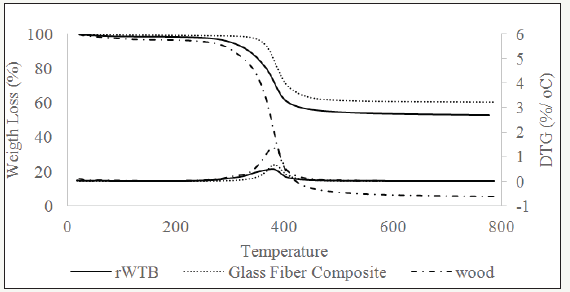

figure 1:TGA curve recorded in nitrogen at heating rate of 20 oC min-1.

*Thermogravimetric Analysis (TGA)

*Derivative thermo-gravimetric (DTG)

We suggest a new pathway for reducing cost of recycling by considering the mechanically recycled wind turbine blades as a feedstock for second generation composites [1-3]. In this method, first we analyzed the material thermally to find the thermal stability of the material and also provide an estimate of the composition of materials within the rWTB (Figure 1). The various size fractions of the rWTB materials were sprayed with resin and water (to obtain the targeted moisture content) within a drum blender. The blended rWTB was then hand-formed and hot pressed to a size of 355 *355mm composites panels (duplicate) with a thickness of 7.62mm. The hot press temperature and time were set as 138°C and 5min accordingly, typical for pMDI composite processing (Figure 2). Mechanical and physical tests (Flexural, internal bonding (IB), water sorption, and thickness swell) were performed based on ASTM D1037-12 and compared with ANSI 208.1-2009. One-way CoANOVA was performed to determine the differences of mechanical properties of fabricated panels. The actual density was used as a covariate to eliminate and effects from the final specimen density. The confidence level was selected as 95%. Duncan grouping was used to identify statistically significance between the means [1-3].

figure 2:

(a) End-of-life wind turbine blade,

(b) Mechanical comminution process,

(c) Hot pressed rWTB composites

References

- Mamanpush SH, Hui Li, Karl E, Azadeh TT (2018) Recycled wind turbine blades as a feedstock for second generation composites. Waste Management 76: 708-714.

- Mamanpush SH, Azadeh TT, Hui Li, Englund K (2018) Data on the mechanical properties of recycled wind turbine blade composites. Data in Brief 19: 230-235.

- Mamanpush SH, Hui Li, Englund K, Azadeh TT (2018) Dataset demonstrating physical properties of recycled wind turbine blade composites. Data in Brief.

© 2018 Seyed Hossein Mamanpush. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)