- Submissions

Full Text

Examines in Marine Biology & Oceanography

Microalgae as a Potential Source of Biofuels and its Current Advances

Chandan Haldar*, Raju Ram, Shyam Kumar and Lakan Lal Menna

ICAR Central Institute of Fisheries Education, India

*Corresponding author: Chandan Haldar, ICAR Central Institute of Fisheries Education, Versova, Andheri West, Mumbai, Maharashtra, India 400061

Submission: April 26, 2018 ;Published: June 01, 2018

ISSN 2578-031X Volume2 Issue1

Abstract

Sustainable production of renewable energy is passionately debated worldwide since it is progressively understood that first-generation biofuels are primarily produced from food crops. Mostly oilseeds do not contain enough amount of fat content to achieve targets for biofuel production. These concerns have increased the attention in developing second-generation biofuels produced from non-food feed stocks such as microalgae, which potentially offer high-fat content. The advantages of biofuel over fossil fuel are they are less toxic, biodegradable and lower emission greenhouse gases. This article reviews the current status of microalgae use for biodiesel production, including their cultivation, harvesting, and processing. The economic development of the world is hugely dependent on fossil fuel supplies which are constrained not only by partial availability but also generate high levels of pollution.

Because of the limited fossil fuel, concerted efforts have been started to search for alternative bio fuels like biodiesel, bio ethanol and since the diesel is being used massively in industrial commercial, fisheries, agriculture, and other sectors. So, the production and consumption of biodiesel from oil seeds crops have been getting renewed interest in recent years in India to overcome the drawbacks of oil from oilseed crops. Biodiesel produced from micro-algae has several benefits over the above resources due to higher algal biomass and oil yields and the need of non-arable land for its growth. Industrial and municipal wastewaters can be applied for farming of microalgal oil that can be used for the production of biodiesel to entirely displace petro diesel. The micro algal biomass has been reported to yield high oil contents and has the diesel production. Accordingly, a lot of R & D work has been initiated for the growth, harvesting, oil extraction and conversion to biodiesel.

keywords: Oil extraction; Biodiesel production; Microalgal species; Cultivation; Harvesting; Supercritical fluid extraction

Introduction

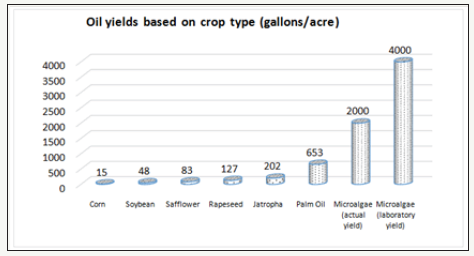

Figure 1: Oil production from different crops.

Microalgae or microphytes are unicellular species which exist individually, or in chains or groups in freshwater and marine systems, both in the water column and sediment. Depending on the species, their sizes may vary from a few micrometers (μm) to a few hundred micrometers. It has been estimated that about 2 to 8 lakhs of species in many different genera exist of which about 50,000 species are studied till date. As microalgae contain relatively high oil content, so they are recognized as potentially useful sources for biofuel production [1]. The algae fuel, algal biofuel, or algal oil is the best alternative of liquid fossil because of the high growth rate of microalgae compared to terrestrial crops, and mass culture of algal can be done in non-arable lands using non-potable saline water and waste water. Also, algae fuels are an alternative to commonly known biofuel sources, such as corn and sugarcane. Like fossil fuel, algae fuel also releases CO2 when burnt, but algae or plants also removed CO2 from the atmosphere via photosynthesis during their growth. They use light and carbon dioxide (CO2) to create biomass in the form of triglyceride which is the main sources of biofuel (Figure 1).

Production of biofuel

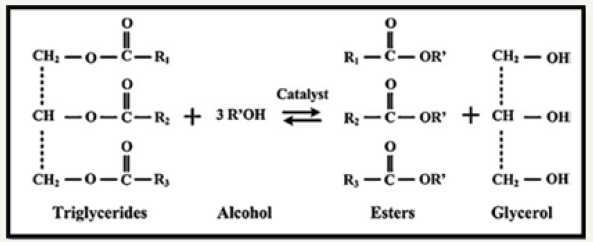

Algal biomass contains mainly three components: proteins, carbohydrates, and lipids/natural oils. Due to the bulk of the natural oil made by microalgae is in the form of triglycerides, which is the right type of oil for producing biodiesel, microalgae are the exclusive focus in the algae-to-biodiesel arena. The triglycerides are used to produce biofuel by the process called trans esterification. In this process, triglycerides are reacted with short chain alcohol (e.g., methanol or ethanol) in the presence of a base catalyst (e.g., KOH and NaOH) to accelerate the production of biofuel. The actual reaction of production of biofuel from the triglycerides is given in Figure 2. Microalgae contain a high amount of unsaturated fatty acids like arachidonic acid, eicosapentaenoic acid, docosahexaenoic acid, gamma-linolenic acid, and linoleic acid. When comparing the lipid yield of algae to vegetable sources, algae can produce between 20,000 and 100,000 liters per hectare.

Importance of biofuel production

The term biofuel is referred to liquid, gas and solid fuels predominantly produced from biomass and biomass is a wide variety of organic and natural resources that include solid biomass, liquid fuels and different types of biogases. Biofuel is produced through modern biological processes such as agriculture and anaerobic digestion but the fossil fuels produced by geological processes from prehistoric biological matter, such as coal and petroleum [2]. Microalgae is an excellent source of biofuel as they contain a high level of oil in the form of triglyceride which converted to biofuel through transesterification. Biofuels include bioethanol, biomethanol, biodiesel, biogas, vegetable oils, biosynthetic gas (bio-syngas), bio-oil, biochar, Fischer-Tropsch liquids, and biohydrogen. The fuel must contain 80% renewable materials to be classified as a biofuel.

Why microalgae as a source of biofuel

Microalgae are capable of all year round production using the non agricultural land. Therefore, oil productivity of microalgae cultures exceeds the yield of the best oilseed crops, e.g., biodiesel yield of 12,000 per hector for microalgae (open pond production) compared with 1190 per ha for rapeseed (Figure 1). Shows the different oil content of plant compares to microalgae. Algae also grow in aqueous media but need less water than terrestrial crops, therefore, reducing the load on freshwater sources. Microalgae can be cultivated in brackish water on non-arable land, and therefore may not incur land-use change, minimizing associated environmental impacts, while not compromising the production of food, fodder and other products derived from crops [3].

Microalgae have rapid growth potential, and many species have oil content in the range of 20-50% dry weight of biomass, the exponential growth rates can double their biomass in periods as short as 3.5 hours. Different cultivable species and their oil content are given in Table 1. With respect to air quality maintenance and improvement, microalgae biomass production can effect biofixation of waste CO2 (1kg of dry algal biomass utilize about 1.83kg of CO2). Nutrients for microalgae cultivation (especially nitrogen and phosphorus) can be obtained from waste water, therefore, apart from providing growth medium, there is dual potential for treatment of organic effluent from the agri-food industry. They coproducts such as proteins and residual biomass produced after oil extraction is also valuable, that may be used as feed or fertilizer, or fermented to yield ethanol or methane. By varying growth conditions of an algal, the biochemical composition of the biomass can be modulated.

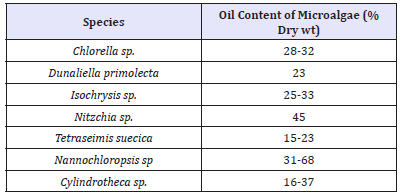

Table 1: Tenacity and elongation under dry and wet conditions.

Therefore, the oil production may be significantly enhanced and microalgae are capable of photobiological production of ‘biohydrogen.’ The outlined combination of potential biofuel production, CO2 fixation, biohydrogen production, and biotreatment of wastewater underscore the potential applications of microalgae. The oil content, availability of standardized culture technology (nutrient requirement, water flow rate, illumination etc), controlled production system and cost (production as well as extraction of oil) are the basic criteria for selection of microalgae for biofuel production. In this case, Chlorophyceae, green algae, are the strain generally preferred by scientists. However, green algae are subject to produce starches in place of lipids and require nitrogen to grow. They have the advantage that they have very high growth rates at 30 ˚C and at high light levels in aqueous solution. Bacillariophyceae, diatom algae, are also favored by researchers. One problem is that the diatom algae require silicon to be present in the growth medium.

How to obtain more Lipid production

Lipid accumulation in algae is generally occurred during times of environmental stress, including growth under nutrientdeficient conditions. It has been observed that in few cases that the lipid content can be enhanced by imposing nitrogen starvation. Biochemical studies have found that acetyl-CoA carboxylase (ACCase), which is a biotin-containing enzyme that catalyzes a primary step in fatty acid biosynthesis, might be involved in the regulator of the lipid gathering process [4]. So, it might be likely to rise lipid production rates by accumulative the action of this enzyme by genetically modified microalgae. When algae are grown under optimal conditions, they synthesize fatty acids principally for esterification into glycerol-based membrane lipids which make up about 5-20% of their dry cell weight (DCW). In unfavorable environmental or stress conditions for growth, many algae changed their lipid biosynthetic pathways and induced for formation and accumulation of neutral lipids (20-50% DCW), mainly in the form of triacylglycerol (TAG) [5]. It has been found that TAG biosynthesis pathway may play a more active role in the stress response of microalgae. After being synthesized, TAGS are generally deposited in densely packed lipid bodies that are located in the cytoplasm of algal cells. Nile red fluorescence is a technique that has been used in some microalgae as a rapid screening method to detect TAG presence as well as to determine the relative neutral lipid content (Figure 2).

Figure 2: Transesterification.

The major chemical stimuli include nutrient salinity, growth medium pH, and starvation. The temperature and light intensity is the major physical stimuli. Temperature plays a major role in the fatty acid make-up of algae. With decreases in temperature, there is an increase in unsaturated fatty acids. Total lipid content in algae has also been shown to affect by temperature. Similarly, when there is a rise in temperature, the amount of saturated fatty will also increase. Nitrogen limitation is also the single most critical nutrient affecting lipid metabolism in algae. For the production of diatoms, silicon is important in the lipid. Generally, low light intensity causes the formation of polar lipids, particularly the membrane polar lipids that are associated with the chloroplast. However, high light intensity causes a decrease in the total polar lipid content with a concomitant increase in the number of neutral storage lipids, mainly TAGs.

Generations of biofuel production

There are mainly 4 generations of biofuel production is available. In “First-generation” or conventional biofuels are biofuels made from food crops grown on arable land. Here, the sugar, starch, or vegetable oil obtained from the crops is converted into biodiesel or ethanol, using transesterification, or yeast fermentation. In second generation biofuels are fuels manufactured from various types of biomass like any source of organic carbon. The sugars and vegetable oils found in arable crops was used for the production of the first generation biofuels; second generation biofuels are made from lignocellulosic biomass or woody crops, agricultural residues or waste plant material (from food crops). Microalgae used as a source of biofuel in the third generation as they contain ahigh level of oil content. Like in third-generation biofuels, fourth-generation biofuels are also made using the non-arable land, but unlike thirdgeneration biofuels, they do not require the damage of biomass. This class of biofuels includes electrofuels and photobiological solar fuels.

Cultivation of algae

The effective culture system of microalgae should consist of the following criteria: effective illumination area, optimal gas-liquid transfer, easy to operate, low contamination level, low capital and production cost and minimal land area requirement. There are different types of culture systems like Photoautotrophic: light as energy and CO2 as inorganic carbon source Open cultivation system and Closed Cultivation Systems (Photobioreactors) incorporates a light source to provide photonic energy. Heterotrophic: utilize organic substrate (e.g. glucose, acetate, glycerol) as both energy and carbon source and Mixotrophic: grow either via phototrophic or heterotrophic pathway, depending on the concentration of organic carbon sources and light intensity [6]. Open cultivation systems include raceway ponds culture where a large open water raceway track where algae and nutrients are pumped around by a motorized. The depth of these ponds is similar to the raceway ponds which is about 25-30cm deep. Shallow Ponds is very large in size and area ranges from 1 hectare to 1.5 hectares, with an average depth of 20-32cm.

For the small-scale production of algae cultivation, deep ponds or tanks are used. The pond is usually less than 10 square meter with a depth of 50cm or more. Microalgae production based on closed photobioreactor technology. Closed systems include the flat plate, tubular, and column photo bioreactors. The costs of closed systems are higher than open pond systems. One suggestion is the use of a ‘hybrid’ system making use of both closed and open systems in a two-stage production strategy; first using closed systems to produce high-quality concentrated inoculums for much larger open systems to improve cost-effectiveness. This strategy is being employed in the production of the commercially important pigment astaxanthin from the red alga Haematococcus pluvialis on a large scale.

Extraction of lipids from microalgae

After bulk harvesting algae are allowed of solar drying after that the dried algae used for lipid extraction as the presence of water inhibits several downstream processes, such as lipid extraction & transesterification. Microalgae contain a thick cell wall. A mechanical press is not useful to microalgae biomass which is effective to extract oil from terrestrial energy. Chemical solvents such as n-hexane, methanol, ethanol and mixed methanolchloroform (2:1v/v) (Bligh and Dyer method) are effective to extract microalgae lipid, but the extraction efficiency is highly dependent on microalgae strains. n-hexane is sometimes inefficient to extract microalgae lipid. This is because microalgae lipid contains a high concentration of unsaturated fatty acid while n-hexane is a non polar solvent. n-hexane, methanol and chloroform are highly toxic compounds that can cause safety and health hazards if proper precaution steps are not taken.

Supercritical fluid extraction

The fundamental principle of Supercritical fluid extraction is reaching a certain phase (supercritical) that is outside the critical point of a fluid, where meniscus is separating the liquid and vapor phases disappear leaving only single homogeneous phase. It is suitable for wet-paste microalgae biomass. At supercritical phase, thermophysical properties such as density, diffusivity, viscosity and dielectric constant of fluid will change drastically depending on pressure and temperature. Consequently, the changes of the thermophysical properties transform the fluid into a super-solvent and thus, improve extraction and reaction efficiency. Several supercritical fluids that are currently being explored are ethylene, CO2, ethane, methanol, ethanol, benzene, toluene and water. It has many advantages over chemical extraction such as non-toxic and provides a non-oxidizing environment to avoid degradation of extracts, low critical temperature (around 31 °C) which prevent thermal degradation of products. Low surface tension and high diffusivity which allows penetration of pores smaller than those accessible by chemical solvents and Easy separation of CO2 at ambient temperature after extraction. However, the main disadvantages of supercritical-CO2 are associated with high cost of operation and safety-related issues.

Conclusion

It is a truth that currently the use of microalgae as a source not only of bioenergy but also of other metabolites of high value is developing intensively in numerous countries of the world such as the USA, China, Germany, and Spain, only to mention a few. The energy transition can be a mechanism that also desires the development of algae-based third-generation biofuels and biorefineries. Among the points that require further development to make this happen are.

A. The selection of species is recommended to be obtained locally because geographical conditions may favor their handling and production. The genetical modification still has problems to be determined on productivity and environmental safety because of their proliferation.

B. The use of shared systems (open system and photobioreactors) is a measure that improves both the quality and the productivity of the species; the geographical location and their environmental conditions are determinants for efficient production.

C. The non-invasive harvest methods (supercritical CO2, sonication, and filtration) have the benefit of acquiring the best quality biomass, however, face large-scale technological barriers as well as high energy consumption.

D. Making the method of extraction and conversion to biodiesel actually renewable and therefore environmentally friendly, they have to look for catalysts as well as solvents that also come from sustainable and renewable systems, for example, bio-ethanol or biomethanol for the transesterification process. In the future, these solvents also may come from microalgae.

E. To confirm the implementation of bio-refineries favorable, it requires an in-depth life cycle analysis, evaluating mainly the inputs, processes, and products as well as the possibility of recirculating or reusing wastes like biomass, heat, gas, and water.

It is essential to achieve the synergy among concepts of zero waste, industrial symbiosis, and the combination of renewable energies. It is fundamental to achieve a new sustainable industrial concept that is responsible for the environment and the society.

References

- Chinnasamy S, Bhatnagar A, Hunt RW, Das KC (2010) Microalgae cultivation in a wastewater dominated by carpet mill effluents for biofuel applications. Bioresource technology 101(9): 3097-3105.

- Chisti Y (2007) Biodiesel from microalgae. Biotechnology Advances 25(3): 294-306.

- Hill JE, Nelson E, Tilman D, Polasky S, Tiffany D (2006) Environmental economic and energetic costs and benefits of biodiesel and ethanol biofuels. Proc Natl Acad Sci U S A 103(30): 11206-11210.

- Miao XL, Wu QY (2006) Biodiesel production from heterotrophic microalgal oil. Bioresour Technol 97(6): 841-846.

- Mujeeb MA, Vedamurthy AB, Shivasharana CT (2016) Current strategies and prospects of biodiesel production: A review. Adv Appl Sci Res 7(1): 120-133.

- Spolaore P, Joannis Cassa C, Duran E, Isambert A (2006) Commercial applications of microalgae. J Biosci Bioeng 101(2): 87-90.

© 2018 Chandan Haldar. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)