- Submissions

Full Text

Environmental Analysis & Ecology Studies

Use Microorganisms and Smart Control System to Process Livestock Wastes to Improve the Environment of Livestock Farms after Complete Fermentation

Yang Chia Shih1 and Chung Hsung Shih2*

1Department of Medical Laboratory Science and Biotechnology, Asia University, Taiwan, ROC

2Department of Animal Science and Biotechnology, Tunghai University, Taiwan, ROC

*Corresponding author: Chung Hsung Shih, Honorary Professor, Department of Animal Science and Biotechnology, Tunghai University, No.2, Lane 25, Guozhong 1st Rd., Dali District, Taichung 407224, Taiwan, ROC

Submission: December 13, 2021; Published: December 17, 2021

ISSN 2578-0336 Volume9 Issue4

Abstract

This study is to use the intelligent temperature control system with the traditional livestock excrement treatment plant Bank Silo to establish a new type of microbial combination that has been added and screened. It contains a mixture of nitrifying bacteria, Trichoderma, filamentous fungi and mixed starter of lactic acid bacteria. By establishing a system to regulate the most suitable growth conditions for microorganisms (such as aeration, humidity, temperature and pH), so that they can multiply and metabolize rapidly, and convert the organic matter contained in the waste matrix into small molecular substances, reducing the fermentation of traditional composting time, reduce the production of odor, and reduce the breeding of mosquitoes. At the same time, according to the collected various parameters, the development of modular production technology and the establishment of fermentation conditions have achieved extremely good results in the production of standardized products and the improvement and protection of the environment.

Keywords: Microorganisms; Smart Control System; Livestock Waste; Fermentation

Introduction

For many years, the treatment of animal husbandry waste resource recovery and reuse has been a common problem and goal for animal husbandry and government pollution prevention and control units [1]. Proper treatment can not only solve the environmental pollution of livestock excrement, but also can effectively use waste resources and improve the soil quality of farmland, restore the vitality of the soil and the environment, and reduce the use of chemical fertilizers and pesticides, which is beneficial to the production of organic agriculture [2]. With the selected high-quality microorganisms, the organic matter contained in the livestock excrement matrix is converted into small molecular substances and humus, which reduces the fermentation time of traditional composting and improves the sanitation of the manufacturing environment [3]. The selection of aerobic microorganisms is high temperature resistant (50~60 ℃) Bacillus which can decompose protein and cellulose [4]; Trichoderma has the ability to secrete lignocellulose decomposing enzyme, which can promote the cellulose in compost degradation accelerates the maturation of compost [5]. Filamentous fungi have the ability to secrete extracellular enzymes, and their hyphae can grow interspersed in the pile, physically destroying the compact structure of the pile, and the enzymes secreted by itself, or other flora chemical degradation methods can be used to increase the maturity of compost [6].

Keratinolytic bacteria can decompose poultry feathers or pig and cattle hair to produce a large amount of amino acids [7]. Lactic acid bacteria can regulate pH and conductivity. A good compost production technology of modularized artificial intelligence is established by a variety of bacteria and fermentation control system technology [8], which can effectively treat livestock excrement on a large scale, and then transform it into organic fertilizer that can be applied to different production scales and create high value. This is the fundamental way to solve the pollution of livestock products, so as to directly protect the land and the environment, indirectly optimize the life of the community and protect the health of all of us.

Case Presentation

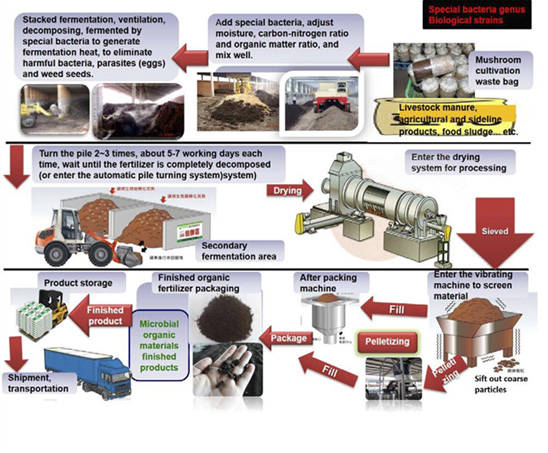

Livestock waste is not only large in quantity, high in moisture, but also very complicated. In order to make it compatible with the good development conditions of microorganisms and the standardization of finished products in the future and the regulatory conditions set by the government, it is necessary to adjust the carbon to nitrogen ratio (C/N) and organic matter. It is extremely important to add the compound microbial powder in the amount of only one thousandth of the amount and mix it evenly. After the mixing is completed, it can be placed in the Bank Silo for fermentation and timely ventilation by inject air. The rapid mass reproduction of microorganisms and the use of nitrogen and carbon sources as nutrients for the division and reproduction of microorganisms, without exhausting harmful gases and odors such as ammonia, CO2 and H2S. The design of the place of operation and the procedure of actual operation are shown in Figure 1.

Figure 1: On-site manufacturing process of microbial organic materials.

Figure 2: Increased temperature caused nematodes and maggots to crawl out of the fertilizer surface.

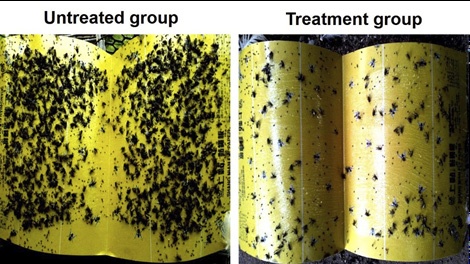

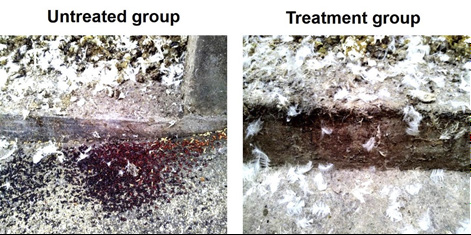

After the above collection and treatment, the common pests in chicken farms such as maggots, flies, dark beetle (Alphitobius diaperinus, Darkling beetle) and small mealworm (Lesser mealworm) will be greatly reduced or disappeared as shown in Figure 2 to Figure 4.

Figure 3: Effectiveness of reducing flies on site (pcs/hour).

Figure 4: Reduce maggots and pupae on site.

Discussion

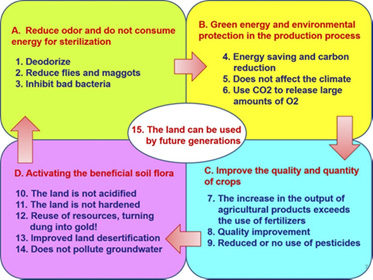

Although the Complete Fermentation mode of processing livestock waste with microorganisms and smart control system will increase some cost, this technology and method can truly achieve the 15 results and effects shown in the Figure 5 to optimize our lives. Isn’t it a good thing to protect the environment and protect the limited land of the earth, so that the land can be brought back to life and for generations to survive and use forever?

Figure 5: The technology and method can truly achieve the 15 results and effects.

References

- Martinez J, Dabert P, Barrington S, Burton C (2009) Livestock waste treatment systems for environmental quality, food safety, and sustainability. Bioresour Technol 100(22): 5527-5536.

- Alvarenga P, Palma P, Mourinha C, Farto M, Dores J, et al. (2017) Recycling organic wastes to agricultural land as a way to improve its quality: A field study to evaluate benefits and risks. Waste Management 61: 582-592.

- Eden M, Gerke HH, Houot S (2017) Organic waste recycling in agriculture and related effects on soil water retention and plant available water: a review. Agronomy for Sustainable Development 37(11):

- Jamali H, Sharma A, Roohi, Srivastava AK (2020) Biocontrol potential of Bacillus subtilis RH5 against sheath blight of rice caused by Rhizoctonia solani. J Basic Microbiol 60(3): 268-280.

- Sarangi S, Swain H, Adak T, Bhattacharyya P, Mukherjee K, et al. (2021) Trichoderma-mediated rice straw compost promotes plant growth and imparts stress tolerance. Environmental Science and Pollution Research 28(32): 44014-44027.

- Baron NC, Rigobelo EC, Zied DC (2019) Filamentous fungi in biological control: Current status and future perspectives. Chilean Journal of Agricultural Research 79(2): 307-315.

- Reyes A, Ambita ID, Batalon JL, Aba BL, Cortes A, et al. (2018) Isolation and characterization of keratinolytic bacteria from soil samples of poultry waste dumping site. International Journal of Agricultural Technology 14(7): 1787-1800.

- Echarrafi K, Harhouri HEI, Ben AM, Rais Z, Hassani IEI, et al. (2018) Mixture design formulation for optimized composting with the perspective of using artificial intelligence optimization algorithms. Journal of Applied Science and Environmental Studies 1(2): 53-64.

© 2021 © Chung Hsung Shih. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)