- Submissions

Full Text

Environmental Analysis & Ecology Studies

Saccharomyces Cerevisiae and Its Biotechnological Applications

Abdullah M Al Falih*

Department of Botany and Microbiology, College of Science, King Saud University, Saudi Arabia

*Corresponding author: Abdullah M Al-Falih, Department of Botany and Microbiology, College of Science, King Saud University, P.O. Box. 2455 Riyadh 11451 Saudi Arabia

Submission: September 29, 2021; Published: October 14, 2021

ISSN 2578-0336 Volume9 Issue2

Abstract

The review has been extensively on the biological activities of yeast, focusing on the various uses of renewable feed stocks and their conversions into fuels and chemicals to cope with the increasing demand on sustainability issues around the world. Saccharomyces cerevisiae is the best studied eukaryote and a valuable tool for most aspects of basic research on eukaryotic organisms. S. cerevisiae is one of the most popular cell factories and has been successfully used in the modern biotechnology industry to produce a variety of substances such as ethanol, organic acids, amino acids, enzymes and therapeutic proteins. This review will focus on how to use different sustainable solutions to overcome the different environmental impacts on yeast. With a wide range of current developments and future prospects in yeast biotechnology explored and its applications and potentials discussed in general.

Keywords: Yeast, Fermentation, Biotechnology, Industry and Saccharomyces Cerevisiae

Introduction

People have used yeasts and other microorganisms to produce many foods and drinks

since ancient times. Bread is a result of the microbial fermentation of the sugars to produce

carbon dioxide, which is released into the dough making the bread puffy. The human interest

and attempt to benefit from the activities of microorganisms dates back to prehistoric times,

but these activities were not used in industry until around the middle of the twentieth century

as a result of the cooperation that arose between microbiologists, engineers and capital owners

to develop industries based on the use of Microorganisms. Microbes are also essential in the

production of beer and wine, as the sugars are converted into alcohol. Microbial fermentation

is also a step during the chemical process of recycling waste. The raw materials used in the

industry vary and the most important of which are the following: corn steeper extract. barley,

cellulose, starch, grab, alcoholic products, soybean seeds, hydrocarbons and sucrose [1].

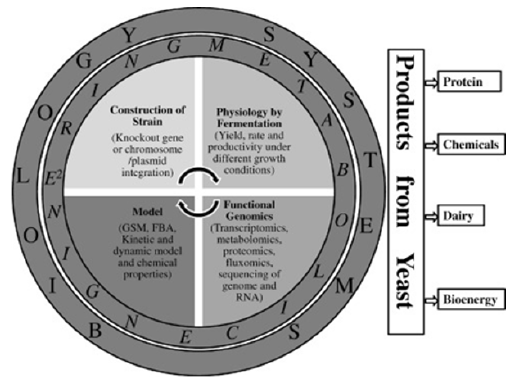

Figure 1 illustrates a general approach whereby metabolic engineering within a systems

biology framework can play a vital role by using genetic modification to build the strain with

the help of the metabolic model approach and further improve it by fermentation to obtain all

growth materials as analysis of different omics will help further to obtain better insights for

the model refinement.

Figure 1: A general metabolic engineering approach for different industrial productions (Nandy and Srivastava 2018).

Baker’s Yeast Biotechnology

Baker’s yeast has been used since ancient times since people knew bread and made it

an essential component of their food. Certain strains of Saccharomyces cerevisiae are now

used to improve the taste, consistency and texture of the dough. This yeast breaks down

(fermentation) the sugars, resulting in alcohol and CO2 bubbles that remain trapped in the

dough, which increases the size of the dough and inflates it. Usually, an amount of yeast is

added to the mixture of flour and water, an amount of salt and some sugar, then the dough

is left to ferment at a temperature of about 25 °C. During this period, the yeast breaks down the sugars in the dough into a mixture of alcohol and carbon

dioxide. Carbon dioxide gas in the bread, which gives the bread its

distinctive texture. Humans have resorted to the use of yeasts in

many matters, such as the production of antibiotics to treat diseases

caused by pathogenic microorganisms, as well as the production of

many important food or industrial materials such as bread, dairy

products, pickles, vitamins, enzymes, acids, proteins, fats and

steroid of vehicles, as happened with the Germans in World War II.

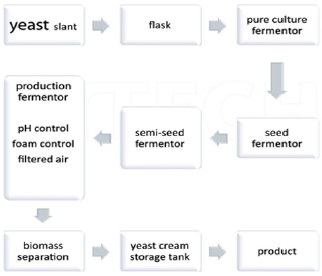

Baker’s yeast is simply beer yeast produced via a submerged

fermentation process carried out in the presence of oxygen (Figure

2). Aerobic conditions favor yeast cell production, which is not of

interest to ethanol producers, but is important when a large amount

of cell mass must be produced.

Figure 2: Baker’s yeast production process.

Some sugars are directly available to the yeast, as the flour

itself contains about 2% of the available sugars in addition to the

sugars that are added, such as sucrose and cane sugar, and then

substituted for the sugars from wheat grain starch by two types

of enzymes, alpha-amylase and-amylase. Which is one of the basic

ingredients of the flour and is activated by water and the beta

amylase splits the starch from the ends into two units of glycose

to give maltose, which is a double sugar, and at the same time the alpha-amylase breaks down the long chain from the inside to

separate it into several short chains, giving the beta-amylase the

opportunity to act on it, resulting in a mixture of maltose and

glucose. Yeast converts glucose into alcohol and carbon dioxide.

Maltose is often fermented by yeast at the end of the fermentation

process when all other sugars are consumed. Disaccharides such

as sucrose and maltose are degraded by hydrolytic enzymes in the

cell into monosaccharides. Although some types of yeast can grow

on starch, they are less effective than other types that grow on

monosaccharides and disaccharides [2,3].

Although the main function of yeast is to increase the size of the

dough, it has some other effects [4].

In the dry yeast manufactured by the old methods, a sugar

solution must be added and kept at a temperature of 26-32 °C for

6-12 hours until the cells become active in number large enough to

carry out the fermentation process. As for the yeast manufactured

by modern methods, it can be used directly without the need for

previous treatment.

It should be noted that the global production of baker’s yeast

reaches more than two million tons annually, and it is present in

several forms, including pressed yeast, active dry and instantaneous

dry, and these pictures differ from each other in the degree of

activity and the extent of stability [5].

Beverage and Food Biotechnology

In the European countries yeast biotechnology, a one million tonnes is produced annually, and about 30% of which is exported globally. The worled market’s annual growth rate was 8.8% from 2013 to 2018. S. cerevisiae has been an essential component of human life because of its extensive use in food and beverage fermentation industry in which it has a high commercial significance. A discussion on the contribution of S. cerevisiae in wine, bread and cocoa fermentations follows, highlighting approach such as the process of biochemical reactions that take place in the yeast cell and whose products determine the terminal products, the traits that strains should have in order to be successful starters and the potential of exploiting native strains in industry. In recent years, there is an alternative vinifications employing mixed yeast inocula of S. cerevisiae and non-Saccharomyces species as cultural fermenter starters. So several researchers and many biotechnological industries have turned to vinification processes involving fermentations with mixed yeast inocula. As non-Saccharomyces inocula have served member species of several genera as shown in Table 1, among them Candida, Debaryomyces Hanseniaspora, Issatchenkia, Metschnikowia, Pichia, Kluyveromyces/Lanchancea, Torulaspora, Wickerhamomyces. The mixed starters of these yeasts are applied in a co-, or sequential fashion and often in varying ratios of cell numbers.

Table 1: Mixed starter cultures of S. cerevisiae with non-Saccharomyces species leading to improved organoleptic traits [22].

Chemical Production Biotechnology

Saccharomyces cerevisiae is widely applied in microbial

biotechnology production of chemicals, metabolites via genetic

manipulation which is relatively easy and experiences from its

wide use in the existing industrial fermentations that might

directly benefit the yeast S. cerevisiae processes [6]. The genetic

engineering strain of S. cerevisiae via metabolic activities under

different metabolism studied for production of various chemicals

of biotechnological industry. While talking about chemical product,

the ethanol should come first which is producing naturally from S.

cerevisiae. This fermentation process is illustrated the production

of ethanol from yeast fermentation where glucose is used as

substrate where one mole of glucose (180g) is converted to two

moles of ethanol (92g) plus two mole of carbon-dioxide (88g)

and it produces energy (26.4 Kcal) from this reaction [7]. Ethanol

or related biofuel or bioenergy will discuss in the last part of this

paper.

Yeast can also be considered as an alternative source of fats. Some

species are able to synthesize and accumulate more than 20% of

the biomass in the form of neutral fats and for this reason it is called

oleaginous yeast. Under conditions of optimal growth or as a result

of genetic improvement, the level of fat accumulation can reach up

to 70%. Oily yeast contains types such as, Saccharomycopsis, Pichia

(Hansenula), Lipomyces, Pseudozyma, Rhodosporidium, Rhodotorula,

Trichosporon, Trigonopsis and Yarrowia [8].

Excretion Products

To obtain excretion products, yeasts are grown on a carbon source such as molasses, and molasses represents the lowest degree of purity on which sucrose is found, and molasses, besides sucrose, contain reduced sugars, mineral salts, organic materials and water, and it is considered a residue of the sugar industry, whether from cane or sugar beet or corn. Many industries depend on molasses, such as the manufacture of various alcohols, yeast and organic acids. The chemical composition and natural properties of molasses varies according to several things, including the type of sugar cane or beet used in industry, climatic factors during the planting season, agricultural factors in terms of soil type, fertilization, and so on. Among the most prominent substances or products excreted from yeast cells during the fermentation process, we mention the production of Ethanol Glycerol as follows [9].

Production of Ethyl Alcohol

It is worth noting that there are many factors that should be

controlled when producing ethyl alcohol. In the forefront comes

to make sure of the strain used and its purity. The fermentation

process is carried out by Saccharomyces cerivisae and must be

highly efficient in the production of alcohol and carbon dioxide, and

its ability to withstand high concentrations in the fermented sugar

and alcohol [10]. The initiator is prepared from the preserved pure

select strain, and several successive activations are carried out from

this culture in a sterile fermentation solution at a temperature of

25-30 °C until cells are sufficient to inoculate 4 liters of the nutrient

medium, then the inoculation steps are transferred from the

laboratory to tanks [11,12].

The sugar concentration used in this industry ranges between

10-18% and the usual concentration is approximately 12%. It is

known that Molasses contains most of the nutrients needed for

fermentation. However, ammonium salts in the form of sulfate or

ammonium phosphate are sometimes added to the fermentation

solution as a source of nitrogen and phosphorous [13].

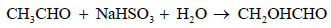

Production of Glycerol

Glycerin is used in the manufacture of medicines and beverages

and in the manufacture of paints and cosmetics. The German

researcher Newporg published his research on the fermentation

that he observed when adding sodium sulfite to alcoholic

fermentation by the yeast. Note that the first observation of glycerin

production during the fermentation process was recorded by

Paster, where it was observed that yeast formed glycerin at a ratio

between 2.5-3.5% of the fermented sugar. The formation of glycerin

depends on the diversion of the alcoholic fermentation process

by withdrawing acetaldehyde when it is formed, so it becomes

unavailable for oxidation of NADH2, which in this case is used to

reduce P-3 - glyceraldehydes. The oxidation of NADH2, or by making

the fermentation medium alkaline, leads to directing NADH2 in the

reaction to reduction. P-3 - glyceraldehydes is commonly used in

the production of Saccharomyces cerevisiae glycerin [14].

With glycerine, ethyl alcohol and acetaldehyde are synthetically

presented with only 20-25% glycerin, and the alcohol and

acetaldehyde are separated by distillation. Note that glycerin

production is increased by the use of acids and alkalis or their salts.

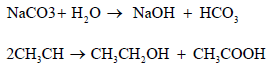

There are several known methods for producing glycerin by

fermentation, and in all the methods they use a basic environment

that contains fermentable sugar, to which the necessary salts and

nutrients are added, and then pollinate the environment with a

culture of yeast and keep it at a temperature of 30-37 °C to form

additives of the year. The first method produced by the Germans,

in which sodium sulfite is added to the fermenting liquid, usually

the acetyldehyde is reduced to ethyl alcohol, but with the addition

of sodium sulfite, it reacts with the acetaldehyde and turns it into

a stable compound that is not amenable to receiving hydrogenhydroaldehyde.

To reduce the acetaldehyde to ethanol it goes to the

reduction of the glyceraldehyde-3-phosphate fraction to glycerin

[15].

Glycerin is then obtained by distillation and then purified by

distillation under a certain pressure.

As for the second method for producing glycerin, it is known

by the American method, in which an environment of sugars is

fertilized with the selected strain of yeast and incubated at the

appropriate temperature, and a substance that gives an alkaline

effect, such as sodium carbogamate, is added gradually according to

the speed of its disappearance. Ethyl This reaction is known as the

Cannizzro reaction and the duration of fermentation ranges from

five days to a week.

Compounds Made by Special Reactions

In nutritional biotechnology, the “phenotype” should be considered a fundamental characteristic when developing methods for selecting yeast. Functional traits are what matters most in a particular ecosystem when looking at the mechanisms of general microbiology. Previous studies have been extensively researched over the past decades through specialized research on the chemical determination of compounds derived from the metabolic activity of yeasts. From these studies it can be concluded that many Fermentation products, including ethyl and acetate esters, Higher alcohols, Fatty acids, Lactones and Sulfur compounds [16]. Among the materials produced by special reactions, compounds made by special reactions, which are popular in yeast cell reactions, we mention Ephedrine, as well as hydrocarbon derivatives, in addition to what are known as radioactive biochemical [17].

Dairy Products Biotechnology

One of dairy products is cheese, that is found usually in most

complex nature, fascinating, and diverse foods. Some strains of yeast

culture which are Kluyveromyces lactis and Debaryomyces hansenii

have been reported actively grown on soft-cheese model curds

[18,19] by taking a month periods for the ripening. Also, kefiris

reported as fermented milk product beverage, which is produced

by fermenting grains of the kefir through symbiotic interaction of

bacteria and yeasts exist in kefir grains. Some yeast strains have

been reported such as K. marxianus, Candida kefyr, D. hansenii

and K. lactis var. Kefir has shown the therapeutic characters as a

natural product beverage. These yeasts are actively involved in

development of favorable kefirsensory properties [18].

Other dairy product, koumiss is slightly alcoholic yeast

fermented mare’s milk beverage. Koumiss is produced by applying

a natural mixed starter of lactic acid bacteria and a strain of yeasts.

It is processing for aroma, texture, as well as the nutrients beneficial

to people health is done by using Saccharomyces cerevisiae and

other yeast strains such as Candida pararugosa, Dekkera anomala,

Geotrichum sp., Issatchenkia or-ientalis, Pichia deserti-cola, P.

fermentans, P. manshurica, P. membranaefaciens, Kazachstania

unispora, and Kluyveromyces marxianus [20]. Acidophilus- yeast

fermented milk has found to vary from Indian Dahlmainly in kind

of microbes involved, flavor, body texture, consistency, antibacterial

activity and chemical composition. In this beverage product the

yeast strains such as Saccharomyces cerevisiae and Saccharomyces

boulardii has been added to put the antioxidant characteristics of

fermented milk and enhance the viability of bacterial strain. This

beverage product has a lactic acid content (1·5 to 2.0%) that help in

cure of human stomach disorder [21].

Yeast and Biofuels Biotechnology

Saccharomyces cerevisiae yeast strains have shown cell factory

nature [22,23]. Many genetically modified or metabolic engineering

ome strains of Saccharomyces cerevisiae have been turned into

a producer of higher alcohols such as 1-butanol and iso-butanol,

farnesene, bisabolene, and biodiesel, Bioethanol is alcoholic

beverage and two carbon organic compounds, produced by genetic

engineered strain S cerevisiae ATCC 20602 in 7.5-l vessel, that

having glucose media, operated in fed-batch mode [24].

In an aerobic fermentation condition, ethanol concentration

(20g l-1) was recorded while in an anaerobic system, ethanol

concentration was reported 85g l-1 in 70 h with higher cell

viability (88%). 1-Propanol is a primary alcohol with three carbon

compounds. It has high numbers of octane and suitable for engine

fuel use. While production of propanol has been reported too

expensive to be a common engine fuel. So, suitable microorganism

strain should be selected for biosynthesis of 1-propanol. The yeast

strain influence has found to be very strong forn-propanol and less evident for the production of other alcohols. Increased production

of n-Propanolin yeast strains has recorded due to having an

impaired ability for formation of hydrogen sulfide [7].

Saccharomyces cerevisiae has been found to utilize not

only glucose but also xylose as sugar component. Now a days

researchers are trying to develop a modified engineered strain

of the yeast Saccharomyces cerevisiae which can have 2-Keto acid

decarboxylase and alcohol/aldehyde dehydrogenase in metabolic

engineering and can develop 2-ketobutyrate compound to generat

more quantity of 1-Propanol. Isopropanol or dimethyl carbinol is a

flammable chemical with a strong odor and colorless. It has a wide

industrial application and household usages, also involved in an

ingredient of some chemicals such as detergents, antiseptics and

disinfectants [25,26].

Conclusion

The yeast Saccharomyces cerevisiae is shown to be the best studied microorganism and one of the common widely used eukaryotes in a variety of industrial production processes, such as bread, ethanol, beverage and food biotechnology. Optimization of pathway and construction can be achieved by using metabolic engineering with revolutionized next generation sequencing and together improve the DNA synthesis technique [27]. This review, describe the combination of both systems biology, biotechnology and attraction metabolic engineering. Also known as synthetic biology as a powerful framework to elaborate various industrial applications consisting mainly pharmaceuticals, chemical, dairy and biofuel.

References

- Duan SF, Han PJ, Wang QM, Wan Qiu Liu, Jun Yan Shi, et al. (2018) The origin and adaptive evolution of domesticated populations of yeast from Far East Asia. Nat Commun 9: 2690.

- Assi Clair BJ, Koné MK, Kouamé K, Berthiot L, et al. (2019) Effect of aroma potential of Saccharomyces cerevisiae fermentation on the volatile profile of raw cocoa and sensory attributes of chocolate produced thereof. European Food Res Technol 245: 1459-1471.

- Carbonetto B, Ramsayer J, Nidelet T, Judith L, Delphine S, et al. (2018) Bakery yeasts, a new model for studies in ecology and evolution. Yeast 35(11): 591-603.

- Meersman E, Struyf N, Kyomugasho C, Zahra JK, Jihan SS, et al. (2017) Characterization and degradation of pectic polysaccharides in cocoa pulp. J Agric Food Chem 65(44): 9726-9734.

- Heitmann M, Zannini E, Arendt E (2018) Impact of Saccharomyces cerevisiae metabolites produced during fermentation on bread quality parameters: A Review. Crit Rev Food Sci Nutr 58: 1152-1164.

- Anusith T, Noppan P, Yusuf C, Maythee S, Penjit S (2019) Lipid production by the yeast Lipomyces starkeyi grown on sugars and oil palm empty fruit bunch hydrolysate. Biomass Conversion and Biorefinery 11: 1197-1210.

- Nandy SK, Srivastava RK (2018) A review on sustainable yeast biotechnological processes and applications. Microbiological Research 207: 83-90.

- Peter J, De Chiara M, Friedrich A, Jia XY, David P, et al. (2018) Genome evolution across 1,011 Saccharomyces cerevisiae Nature 556(7701): 339-344.

- Matallana E, Aranda A (2017) Biotechnological impact of stress response on wine yeast. Lett Appl Microbiol 64(2): 103-110.

- Mina M, Tsaltas D. (2017) Contribution of yeast in wine aroma and flavour. In: Morata A, Loira I (Eds.), Yeast.

- Magalhaes da Veiga Moreira I, de Figueiredo Vilela L, da Cruz Pedroso Miguel MG, Cledir Santos, Nelson Lima, et al. (2017) Impact of a microbial cocktail used as a starter culture on cocoa fermentation and chocolate flavor. Molecules 22(5): 766.

- Romano P, Capece A (2017) Starter Cultures in Food Production. Wine Microbiology, pp. 255-282.

- Mira H, de Pinho MN, Guiomar A, Vitor Geraldes (2017) Membrane processing of grape must for control of the alcohol content in fermented beverages. J Membr Sci Res 3: 308-312.

- Hittinger CT, Steele JL, Ryder DS (2018) Diverse yeasts for diverse fermented beverages and foods. Curr Opin Biotechnol 49: 199-206.

- Castro Alayo EM, Idrogo VG, Siche R, Fiorella P Cardenas Toro (2019) Formation of aromatic compounds precursors during fermentation of Criollo and Forastero cocoa. Heliyon 5(1): e01157.

- Money NP (2018) The Rise of Yeast: How the Sugar Fungus Shaped Civilization. Oxford University Press, UK.

- Perez TR, Rantsiou K, Perrone B, Elisabeth NT, Querol A, et al. (2017) Ecological interactions among Saccharomyces cerevisiae strains: insight into the dominance phenomenon. Sci Rep 7: 43603.

- Nielsen J (2019) Yeast systems biology: Model organism and cell factory. Biotechnol J 14(9): e1800421.

- Mota-Gutierrez J, Barbosa-Pereira L, Ferrocino I, Luca Cocolin (2019) Traceability of functional volatile compounds generated on inoculated Cocoa fermentation and its potential health benefits. Nutrients 11: 884.

- De Bellis P, Rizzello CG, Sisto A, et al. (2019) Use of a selected Leuconostoc Citreum strain as a starter for making a ‘Yeast-Free’ bread. Foods 8(2): 70.

- Ruiz J, Kiene F, Belda I, Daniela F, Domingo M, et al. (2019) Effects on varietal aromas during wine making: A review of the impact of varietal aromas on the flavor of wine. Appl Microbiol Biotechnol 103(18): 7425-7450.

- Ho VTT, Fleet GH, Zhao J (2018) Unravelling the contribution of lactic acid bacteria and acetic acid bacteria to cocoa fermentation using inoculated organisms. Int J Food Microbiol 279: 43-56.

- Kruis AJ, Gallone B, Jonker T, Astrid EM, Irma MH, et al. (2018) Contribution of Eat1 and Other Alcohol Acyltransferases to Ester Production in Saccharomyces cerevisiae. Front Microbiol 9: 3202.

- Mohd ASH, Abdulla R, Jambo SA, Hartinie M, Jualang AG, et al. (2017) Yeasts in sustainable bioethanol production: A Review. Biochem Biophys Rep 10: 52-61.

- Longo R, Blackman JW, Torley PJ, Suzy YR, Leigh MS, et al. (2017) Changes in volatile composition and sensory attributes of wines during alcohol content reduction. J Sci Food Agric 97: 8-16.

- Pilgrim C, Vierhout R (2017) Status of the worldwide fuel alcohol industry. In: Walker GM, Abbas C, Ingledew WM (Eds.), The Alcohol Textbook 6: 1-22.

- Parapouli M, Vasileiadis A, Afendra AS, Hatziloukas E (2020) Saccharomyces cerevisiae and its industrial applications. AIMS Microbiol 6(1): 1-31.

© 2021 © Abdullah M Al Falih. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)