- Submissions

Full Text

Environmental Analysis & Ecology Studies

A Gate-to-Gate Life Cycle Assessment of Match Industry for Wood Consumption and Wood Waste Generation

Nazish Huma Khan*, Mohammad Nafees and Tooba Saeed

Department of Environmental Sciences, Pakistan

*Corresponding author: Nazish Huma Khan, Department of Environmental Sciences, Pakistan

Submission: September 22, 2020Published: December 22, 2020

ISSN 2578-0336 Volume7 Issue5

Abstract

Industrial development and urbanization have increased the demand for fresh wood which has affected the production rate of industries. This study was aimed to evaluate the Life Cycle Assessment (LCA) of wood-based industries at Hayatabad Industrial Estate, Peshawar. For this purpose, the match industry was studied for its inputs and outputs. The practice of waste reduction and its management was also monitored. Data was measured on-site, through field survey. The industry manager was interviewed, and the industry was kept under observation for one complete cycle of the manufacturing process. The input data contains the items such as wood, cardboard/paper, and plastic @18,029Kg/day. Water is also used. The output data contain product @30,000 cartons and the waste @2842Kg/day, respectively. The solid waste management system was observed improper. The wood-waste of the match industry is a raw material of chipboard and paper industries, but it is not shared. To lower the demand of fresh wood, it is therefore recommended a proper mechanism for waste sharing among wanted firms.

Keywords: Poplar wood; Wood-waste; Splint size; Community; Raw-material; Wanted firms

Introduction

Industrialization plays a vital role in the economic development of a country. Industries have mass production and provide employment opportunities to society Azam et al. [1]. Among different types of industries, match industries have great importance in the everyday life of humans Wisniak [2]. At the time of independence, Pakistan had only 2 match factories. In 2014, Pakistan ranked as 3rd number for export of safety match and earned 18.5 million US dollars. The rate of exported safety match was 10,040 tons with a share of 8% in world exports Khan [3]. The Match industry is totally wood based. Wood has many applications and is often in competition with other materials like plastic, steel etc. Different industries are in progress to make up this sector Petersen & Solberg [4]. Pakistan has limited wood resources with 4.9% of land under forest Nazir & Olabisi [5]. The average wood consumption estimated for the country is 47.73 m3. Out of total, 17.9% of wood was counted for Khyber Pakhtunkhwa by the year 2010. Industrial development has increased the demand for fresh wood, and it is very difficult for wood-based industries to meet their needs Siddiqui & Khan [6]. Wood shortage and low state of forests are challenges for Pakistan. Therefore, Pakistan must import wood to meet the rising demand. According to Forestry Sector Management Plan (1992), the wood shortage was recorded 15 m3 by the year 1992 and increased to 29.36 m3 in 2003, 34.12 m3 in 2010 and 43.9 m3 by 2018 (GOP, 1992: GOP, 2005).

Most match production industries are working in the province of Khyber Pakhtunkhwa. Poplar wood is the basic input used in match industries. Wood is supplied from nearby areas of the province and thus helping to meet the demands of wood-based industries Khan [3]. Under sympathetic consideration, the export of wood-based products from Pakistan to Afghanistan has affected the country’s economy, the industrial sector and increased the rate of wood import Zaman & Ahmad [7]. In Hayatabad Industrial Estate, 17 match industries are established. According to Sarhad Development Authority (SDA), the number of functional match industries is 15 and each factory needs wood for their processing. Due to industrial development and urbanization, the increasing demand for fresh wood has affected the production rate of industries. As the industrial estate (HIE) is facilitated with basic services and much work has been carried out on the industrial process but still there is a need to do work on the waste management approach. Life Cycle Assessment is an emerging tool for sustainable waste management Rebitzer et al. [8].

This concept measures the environmental performance in terms of total input and outputs of a particular process in the whole life cycle Blengini & Garbarino [9]. There are five approaches which define the LCA as

i) Cradle to grave (from resources extraction to disposal),

ii) Cradle to gate (commodities),

iii) Gate to gate (involved specialized unit processing studies),

iv) Gate to grave (market studies) and

v) Well to wheel for automotive fuels Schenck [10]. The Life Cycle Inventory (LCI) is an important component of the LCA study, which identifies the quantity of raw materials, energy flow, production level and waste emission (solid, liquid or gas) during the manufacturing process. The inventory analysis is a gate-to-gate approach that involves the data collection and calculation methods to measure the inputs and outputs of a product throughout its life cycle Hubbard & Bowe [11].

From the LCA perspective, there is no study conducted in Pakistan that considered wood waste of match industries in a systematic manner considering the environmental aspects. Within this context, the idea of LCA presents itself as an important factor for sustainable thinking and will hopefully contribute to environmental improvements in this sector. The study was an attempt to evaluate the match industry in the light of Life Cycle Assessment (LCA) for wood consumption, production, and waste generation.

Method

To know about the wood demand and its waste level, one of the match industries was investigated for life cycle assessment, located at Hayatabad Industrial Estate, Peshawar.

Input/raw material of match industry

To know about the type and quantity of inputs/raw material used, the industry was visited for its processing. Some open questions were asked from the manager about the areas from where the raw material is being supplied, the industry demand, type of loading vehicles and production level as per day and per year respectively.

Output/production of match industry

To know about the output, the industry was kept under observation for one complete shift/cycle. During Manufacturing, waste is generated in each step and was considered important to quantify. Measurement of waste was taken on the spot, using an electronic scale. Besides wood, cardboard/paper and plastic waste is also generated and were quantified as per day.

Size and packing of match splints

The poplar wood was identified for its specific length and width, required for match sticks. The debarked wood and woodsheet size such as length, width and weight were determined using an electronic scale and measuring tape. The final product (match sticks) was also measured for size and number.

Life cycle inventory analysis

Inventory analysis includes determining the inputs and outputs of the match industry as gate-to-gate life cycle analysis. The main emphasis was on wood usage, raw material consumption, and waste production in each step of the product life cycle. The constructing flow diagram was made to identify the quantities of input and output of materials flow in terms of resource consumption, production, and wastages.

Water usage and sampling

Water is used during the manufacturing process (for chemical mixing) of matchstick. During chemical preparation, some water is wasted and discharged into the industrial drain. This wastewater was sampled to find its characteristics. Total 4 water samples were collected weekly in a month. These samples were collected in 2L clean plastic bottles and were carried to the laboratory for analysis.

Table 1: Standard water quality parameters determination methods and instruments.

To know about the pollution level, wastewater samples of match industry were analyzed for physicochemical parameters. The parameters were pH, electrical conductivity (EC), total dissolved solids (TDS), total suspended solids (TSS) and biochemical oxygen demand (BOD5) by adopting the standard methods for examination of water and wastewater APHA [12]. Heavy metals were also determined using the Atomic Absorption Spectrophotometer. The analyzed heavy metals were cadmium (Cd), chromium (Cr), lead (Pd), nickel (Ni) and copper (Cu), shown in Table 1.

Statistical analysis

For data interpretation, statistics were applied using Sankey beta software for diagrammatic representation of data for Life Cycle Assessment of Match Industry.

Analysis of variance (ANOVA)

To find the significance level among dependent variables (parameters) in wastewater samples, analysis of variance was employed, using SPSS software with a 95% confidence level.

Result and Discussion

Input/raw material in match industry

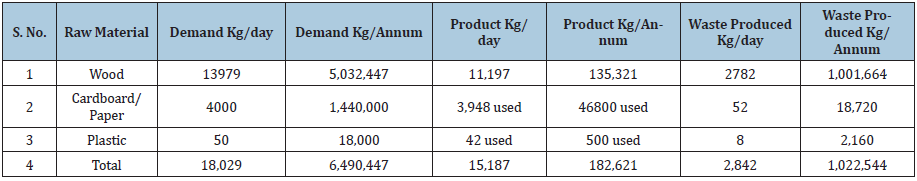

The industry uses wood as basic raw material. Wood is provided to industries by contractors form the nearest areas of Peshawar, Charsadda and Mardan. The product is supplied to local and international markets. The wood consumption of industry is estimated as 13979Kg/day and 5,032,447Kg/annum respectively. The quantity of total raw material required for industry is calculated as 18,029Kg per day. Cardboard, wrapping paper, plastics, and chemicals (phosphorous, Potash etc) are the other raw materials required by the match industry. Each industry consumes a considerable quantity of cardboard/paper for packing and wrapping purposes depend upon the production capacity of the plant. The quantity of these raw materials required for industry is 4000Kg cardboard/paper and 50Kg plastic Table 2. About 20-liter water is used in chemical preparation.

Output of match industry

The industry output includes product and waste emissions. The production rate of industry is 11,197Kg per day (30,000 cartons). Total waste generated during production processes includes @2,842Kg/day (1,022,544Kg/annum), Table 2. The cardboard and plastic usage is 3,948Kg and 42Kg per day respectively. The workers were observed without any proper health safety measures. While water is discharged as wastewater, containing chemicals.

Table 2: Raw material and waste of match industry.

Wood-waste generated by match industry

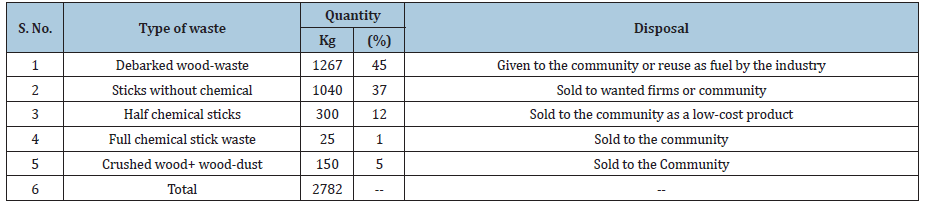

As wood is the basic raw material used in the match industry therefore it undergoes various processing to make the final product. Wood-waste is produced in different forms such as debarked wood, match sticks (sticks without chemical, sticks with half chemical and full chemical), crushed wood and wood-dust respectively. The total quantity of wood-waste generated is 2782Kg/day. This includes 45% (1267Kg) debarked wood, 37% (1040Kg) missed sticks without chemical, 12% (300Kg) sticks with half chemical, 1% (25Kg) full chemical sticks and 5% (150Kg) crushed wood and wood-dust respectively (Table 3). The debarked wood is reused as fuel in the furnace inside the industry. The missed sticks are sold to the community at low cost.

Table 3: Type of wood-waste generated by match industry.

Size, packing and current product price

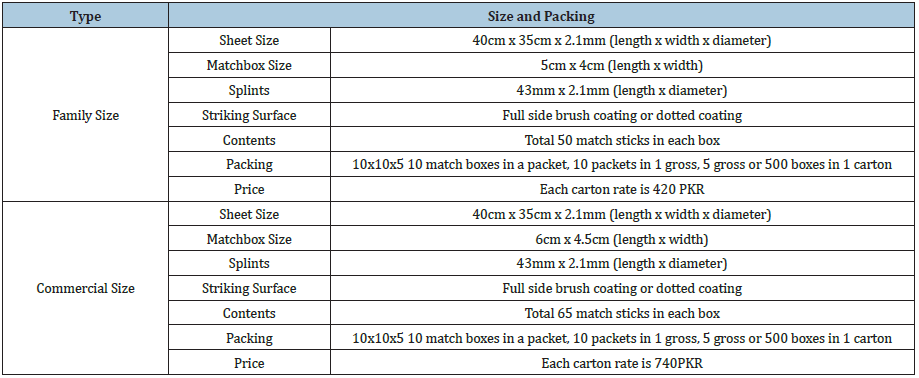

Truck is used for bringing raw material to industry and container is used to supply product for marketing. The capacity of the vehicle is counted as 9072Kg (10 tons) for truck and 13608-1814Kg (15-20 tons) for containers, respectively. The poplar wood is cut into pieces of 45-50cm long. This wood contains about 70-75% moisture content. The desirable billet size for match factory varies from 50cm in diameter and 75-150 m in length. The wood after debarking is crushed into sheets of 40cm long and 2.1mm in diameter. The sheet is further cut into equal size of small sticks. The size of match sticks is 43 mm in length and 2.1mm in diameter. Match industries prepare two types of matchboxes, available to markets. The family/classic size and commercial size matchbox, containing 50 and 65 sticks in each box respectively. The price of classic and commercial matchboxes is ranged as 420 and 740PKR as per packet/ carton (A packet consists of 1 gross or 500 matchboxes) respectively (Table 4).

Table 4: Size and packing of match splints.

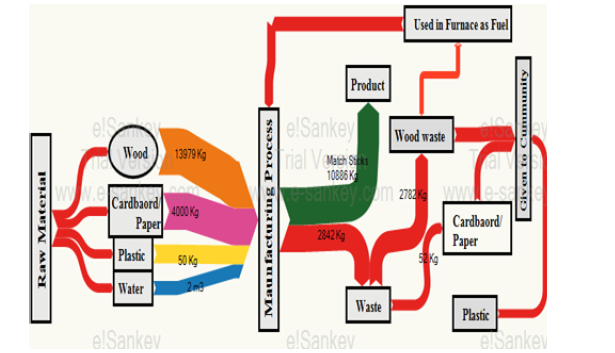

Life cycle assessment and waste management

The life cycle of the match industry involved from wood, cardboard, plastic and water consumption to produce the final product of match sticks and some wastes (Figure 1). The total required input is 18,029Kg to give 10886Kg product (30,000 cartons) per day. The quantity of waste generated was measured as 2842Kg/day. The waste is disposed of improperly. The missed match sticks (without chemical) are important raw materials of chipboard and paper industries. But these industries are located at a distance of 4-5Km for which transportation is a big problem. The wanted firms buy woodwaste @50/Kg and the community rate is 75/Kg. Therefore, match industries prefer to sell the wood-waste to the community. While match sticks with half and full chemical is also sold to community with low cost as these sticks are unable to be used in chipboard or paper manufacturing industries. Waste of cardboard/paper and plastic is given to workers for burning purposes (Table 3). Water containing chemicals is discharged into an industrial drain which on further joins river Kabul and pose negative effects on water quality [13-15].

Figure 1: Life Cycle assessment of match industry.

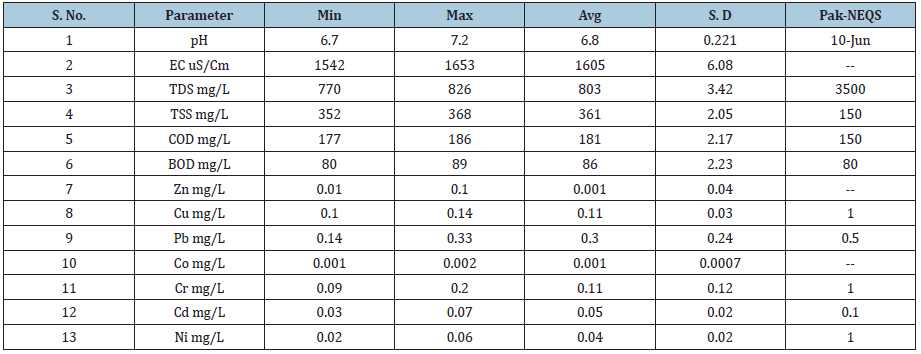

Water characteristics

Among physicochemical parameters in wastewater, pH and TDS were observed within the permissible limits, defined by Pak-NEQS. The electrical conductivity was 1605uS/cm. Suspended solids, COD and BOD5 were found above their permissible limits (Table 5). The presence of high contents of TSS, BOD5 and COD and its direct discharge into the aquatic body is harmful to aquatic organisms. Heavy metals were determined within Pak-NEQS limits (Table 5). The ANOVA test results showed insignificant results for physicochemical parameters in the wastewater of the match industry (Table 6). As the wastewater was observed contaminated therefore minor treatment is required before its discharge. Literature revealed that microbial treatment is effective for the wastewater of the match industry. This treatment can reduce the pollution load resulted in water become fit for reuse.

Table 5: Analytical results of the wastewater of match industry.

Table 6: ANOVA for the wastewater parameters of match industry.

Conclusion and Recommendations

There is no proper system for wood-waste recycling. Woodwaste of the match industry is an important raw material used in other industries such as the paper mill and chipboard industries. But its sharing is ineffective, and this resource is usually wasted. There is a need to find ways for treatment (recycling or reuse) and avoid the wastage of recyclable waste such as wood-waste and paper- waste. The wastewater of industries is not monitored properly and is discharged into nearby water channels. The industries cannot retain the effluents for a longer time, and it has to be discharged within a sensible time. These discharges contain toxic pollutants that show their significant responses to the aquatic ecosystem. High diversity of pollutants causes several disorders. Due to lacking treatment facilities for industrial effluents, mitigation of this problem is required to reduce pollution load.

Acknowledgement

The authors are thankful to Mr. Shujahat Khan the plant admin and other honorable staff of the match industry for their kind help in providing relevant data and briefing the manufacturing process.

References

- APHA (2005) Standard Methods for the Examination of Water and Wastewater. In: (23rd edn), Egypt, 21: 258-259.

- Azam M, Shah SIA, Khan AQ (2009) The study of industrial development: A case study of North West Frontier Province-Pakistan. Abasyn University J Social Sci 3(2): 49-52.

- Blengini GA, Garbarino E (2010) Resources and waste management in Turin (Italy): the role recycled aggregates in the sustainable supply mix. Journal of Cleaner Production 18(10-11): 1021-1030.

- Government of Pakistan (2005) Supply and demand of fuel wood and timber for household and industrial sectors and consumption pattern of wood and wood products in Pakistan. Ministry of Environment, Government of Pakistan.

- Government of Pakistan (1992) Forestry sector management plan. Ministry of Environment, Government of Pakistan.

- Khan MA (2015) A report on Potential Markets of Safety Match submitted to Trade Development Authority of Pakistan, Govt of Pakistan, Peshawar, Pakistan, pp. 6-9.

- Nazir N, Olabisi LS (2012) Forest area and land use change in Pakistan: A system dynamics approach. Pakistan J Bot 44(2): 511-514.

- Petersen AK, Solberg B (2005) Environmental and economic impacts of substitution between wood products and alternative materials: A review of micro-level analyses from Norway and Sweden. Forest Policy Eco 7(3): 249-259.

- Rebitzer G, Ekvall T, Frischknecht R, Hunkeler D, Norris G, et al. (2004) Life cycle assessment: part 1: framework, goal and scope definition, inventory analysis and applications. Environmental International 30(5): 701-720.

- Sarhad Development Authority (SDA), PIA Building, Arbab Road, Peshawar, Pakistan.

- Schenck R (2010) A roadmap to environmental product declarations in the United States. The Institute for Environmental Research and Education Vashon, USA, p. 22.

- Siddiqui KM, Khan S (1991) Wood use in the match industry of Pakistan. Forestry Planning and Development Project, Consultancy Report, pp. 1-22.

- Wisniak J (2005) Matches the manufacture of fire. Indian Journal of Chemical Technology 12: 369-380.

- Zaman SB, Ahmad S (2012) Wood supply and demand analysis in Pakistan-key issues. Managing natural resources for sustaining future agriculture. Research Briefings 4(22): 1-12.

- Hubbard SS, Bowe SA (2010) A gate-to-gate life-cycle inventory of solid hardwood flooring in the eastern US. Wood and Fiber Science 42: 79-89.

© 2020 Nazish Huma Khan. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)