- Submissions

Full Text

Environmental Analysis & Ecology Studies

Environmental Implications of Abattoir Waste in Ethiopia

Meharu Kemal Yunus*

Ethiopian Meat and dairy Industry Development Institute (EMDIDI), Environmental Protection Safety and Energy Directorate, Bishoftu, Ethiopia

*Corresponding author: Meharu Kemal Yunus, Ethiopian Meat and Dairy Industry Development Institute, Ethiopia

Submission: August 22, 2019;Published: November 07, 2019

ISSN 2578-0336 Volume6 Issue3

Abstract

During abattoir operation numerous wastes obviously generated and pose a significant challenge to the effective environmental management practices. Rising of offensive odour and polluted water bodies and Residential areas are affected by abattoir activities where effective waste treatment and disposal systems are not practiced. This study aims to generate information on environmental implications of abattoir activities through scientific estimation of wastes generated, the corresponding slaughtered animals and waste management practices.

For this, an analytical survey approach, questionnaire, personal communication and secondary data were used and found out a total of 18,599 cattle, 301,332 sheep and 8,948,761 goats were slaughtered and from these, a total of 23,864.73ton solid waste and 76,977.65m3 liquid waste has been generated in between September 2014 -March 2018. 1 percent of the total solid waste was incinerated, 0.5% was open burned and the left over 98.5% was transported to landfill. In some cases, solid wastes are burred (put in the ground) but that was occurred on the odd occasions. Whereas, liquid waste management practices were highly improved from using primary and secondary treatment systems to reusing for greenery and cleaning purposes increased from 27% to 50%. Furthermore, waste management practices were found to be environmentally unfriend and need some improvement and so far, it seems no sufficient facilities as well legal enforcements that oblige abattoirs to treat and dispose their wastes in a way environmentally friendly. Therefore, developing strategies, monitoring and evaluation systems and providing successive environmental trainings parallel with legal enforcements are highly recommended.

Keywords: Abattoirs; Environment; Management practices; Waste generation

Introduction

Ethiopia is home to 59.5 million cattle, 30.7 million sheep and 30.2 goats [1]. Meat production is the most important function of these animals in the country. In addition to sheep and goat meat, there is an increasing demand for cattle meat (beef) by consumers in the Middle East countries. Slaughtering activities are one source of pollution since human activities such as animal production and meat processing have been reported to impact negatively on soil and natural water composition leading to pollution of the soil, natural water resources and the entire environment [2]. To achieve middle-income status by 2025, Ethiopia’s Climate Resilient Green Economy (CRGE) strategy has been developed to insure sustainable and environmentally friendly economic growth aiming to "climate-proof" i.e., without increasing its net greenhouse gas emissions and while protecting itself against the negative impacts of climate change.

The most common waste management practices of the Ethiopian export abattoirs are; letting the liquid effluents to undergo primary treatment and discharge to nearby rivers or drainages where as some of solid wastes are incinerated, some are transported to municipality landfill and in some of the abattoirs, very small portion of degradable solid waste generated are subjected to digesters for the production of biogas energy as a fuel. The international market for meat is becoming increasingly competitive and meat exporters must adopt improved abattoirs to maintain and grow market share. Hence, considerable environmental management system trainings will be essential to meet international market requirements and maximize the income generated from the sector.

Statement of the Problem

The main environmental problems arise from the meat industry which initiates this study to done are unavailability of quantified information regarding to the amount of solid wastes and the volume of liquid wastes that would generate from each export abattoirs. Knowing this, will help to manage the waste in a manner environmentally friendly. The other problem is that the blood, wastewater and intestinal contents generated from slaughterhouse in most abattoirs considered as waste and mixing them together and discharge to nearby rivers or drainage lines. But those blood wastes can be further utilized as blood meal, wastewater can be treated and reused for greenery, irrigation and cleaning purposes and intestinal contents can be used for biogas generation and the sludge derived from it also used for natural fertilizer. Generally, in the countries’ meat sector regarding to the aforementioned environmental point of views, there is no information even to brining in place any strategies developed aiming to reduce the global cross-cutting environmental issues.

Objectives of the Study

The general objective of this study is to generate information on environmental implications of Ethiopian export abattoirs through scientific estimations of the generated solid and liquid wastes, the corresponding number of slaughtered animals and the waste management practices with the following specific objectives to

- Estimate the percentage compositions of abattoirs effluent,

- Quantify the volume of abattoirs waste contribution to the environment and

- Design an intervention strategy.

Relevance of the Study

Since this study quantifies the wastes generated from slaughtering activities, export abattoirs are the one most benefited on knowing how to use/convert waste to wealth. The government is also benefited by the increased export income and Ethiopia is in signatory of carbon footprint, this study will have vital role in enabling to meet international agreements. Finally, the community living around the abattoirs are most benefited so as being created clean and safe environment.

Overview of the Sector

The Ethiopian livestock sub-sector

The agricultural sector of Ethiopia accounts for about 42% of growth and development plan (GDP) and between 80-85% of employment ministry of finance and economics development [3]. Within agriculture, the livestock subsector provides an opportunity for further development. The sheer size of the national livestock herd, one of the largest in Africa, makes it a resource with potential to contribute significantly to national development, including poverty reduction. The Central Statistical Agency (CSA) survey of 2016/2017 showed that the total cattle population of Ethiopia is about 59.5 million. Moreover, about 30.7 million sheep and 30.2 million goats are estimated to be found in the country. The government of Ethiopia intends to transform this sector and increase production and exports of meat in order to generate foreign exchange [4].

Emergence of the Ethiopian export abattoirs

Ethiopia’s export abattoirs are private, state of the art Halal-certified slaughterhouses with livestock reception pens, automatic and semiautomatic mechanical slaughter and processing equipment, chilling rooms, air-conditioned deboning facilities, packaging equipment, freezing facilities, and rendering and equipped with effluent treatment.

The report showed in [5] the volume of global meat exports was estimated at USD 105 billion, and Ethiopia accounted for less than one percent of this total (0.75 percent or USD 79 million), of which most is chilled sheep and goat carcasses. As the country has built markets in several African and Middle Eastern countries, including, United Arab Emirates, Saudi Arabia, Angola, Egypt, and Bahrain [5]. The country’s commercial red meat (beef, mutton and goat) industry has made remarkable progress to date and shows considerable growth potential for the future.

The government of Ethiopia encourages investments in meat processing, especially those that are focused on exporting value-added products abroad. According to [4], production would grow from 1.275 to 1.933 million tons between 2015 and 2020. This would not, however, meet expected consumption growth of 58% by 2020 (to 2.008 million tons), leaving a 7% deficit (187,000tons) in the 2015-2020 red meat production and consumption balance. Given the rapidly growing population and increasing incomes in Ethiopia, such projected deficits would put upward pressure on red meat prices and make it very difficult to meet the GTP II red-meat export goals.

Due to this, the export abattoirs are required to ensure a consistent and continuous supply of meat in order to meet the demand of the customers in the importing countries. Thus, there is an urgent need for export abattoirs to devise alternative strategies to ensure adequate market supply of quality live animals to meet their processing needs in order to improve their efficiency and competitiveness. The number of export standard abattoirs has increased in recent years to meet the export demand.

National environmental laws

Environmental policy of Ethiopia is aimed to improve and enhance the health and quality of life, to promote sustainable social and economic development through the sound management and use of natural, human-made and cultural resources and the environment as a whole to meet the needs of the present generation without compromising the ability of future generations to do so [6].

In the context of the Ethiopian legal system, National environmental law includes the provisions concerning the environment in the 1995 FDRE constitution; different environmental treaties ratified by the House of Representatives according to Art. 9(4) of our constitution and all laws (federal and regional) concerned with the environment [7]. Taking this into consideration, whenever we speak about development and economic growth the concept of green economy and sustainability have become a great concern. In the Growth and Transformation Plan (GTP) the issue of sustainable development has been given much emphasis.

Moreover, Ethiopia launched the Ethiopia’s Climate Resilient Green Economy (CRGE) Facility to insure sustainable and environmentally friendly economic growth aiming to "climate-proof" manner, to achieve middle-income status by 2025, without increasing its net greenhouse gas emissions and while protecting itself against the negative impacts of climate change.

Abattoirs waste and environmental implications

Abattoir activities are one source of pollution since human activities such as animal production and meat processing have been reported to impact negatively on soil and natural water composition leading to pollution of the soil, natural water resources and the entire environment [2].

The case of Ethiopian, the main driving factor in the livestock sector was the cattle population is expected to increase from close to 50 million today to more than 90 million in 2030. This will increase emissions from 65Mt CO2 today to almost 125Mt in 2030 [8]. Accordingly, this study tries to identify the main sources of Greenhouse gasses and generates information by estimating the volume of the wastes based on which, either adaptive or mitigation approaches would be used to meet the goals of the CRGE strategy. During the operations of the slaughterhouse the waste generated is of liquid and solid nature. The solid waste can be broadly classified into two categories i.e. vegetable matter such as rumen, stomach and intestine contents, dung, agriculture residues, etc., and animal matter like inedible offal’s, tissues, meat trimmings, waste and condemned meat, bones etc. These waste streams can be segregated and treated separately.

Whereas, the liquid waste in a slaughterhouse mainly consists of blood from the animals, urine, and other such internal fluids along with the water that is used to wash and contains mostly biodegradable matter. This study mainly focus on the estimatin of solid and liquid wastes generated from the 12 selected potential export abattoirs between 2014/15-2017/18 [2007-7 months of 2010 E.C]. In fact, some abattoirs are poor in waste management practices, particularly solid wastes and in contrary to this, there are some abators which are state-of-the art in the management practices of various types wastes generated from theresloughtering activities.

Animal blood and trimmed parts

Animal blood is known to possess high oxygen demand. Blood from beef cattle has a biochemical oxygen demand (BOD5) of 156,500mg/l and a chemical oxygen demand (COD) of 218,300mg/l. The implication of this fact is that discharge of animal blood into streams would deplete the dissolved oxygen (DO) of the aquatic environment. But as depicted in the second photograph, if the blood and trimmed parts are separately managed, the severity of environmental pollution can be well managed. Beyond the reduction of environmental pollution, it is even possible to further processing into blood meal (Figure 1 & 2).

Figure 1: Best collection of blood in separate line

Figure 2: Poor collection of blood.

Odour: Degeneration of any tissue material remaining as a waste in the premises of the slaughterhouses. Always give a particular stink. In order to avoid this stinking odour proper ventilation of slaughtering halls, washing of the floors with non-poisonous disinfectants and if need be use of aerobic deodorants must be provided at each slaughterhouse [9]. Similarly, the export abattoirs visited for this study use nearby river and municipality drainages for the disposal of wastes generated from slaughtering activities and this give rise offensive odour which found to be unhygienic and endanger the entire human environment.

Intestinal content (punch manure): In ruminants, the first stomach or paunch contains undigested materials or paunch manure. The solid portion of the intestinal content contains the greatest pollution load of the COD and BOD of the effluent. Improper disposal of paunch manure can therefore exert oxygen demand on the receiving environment or breed large population of micro-organisms which may be pathogenic and some of the abattoirs convert these wastes to biogas energy (Figure 3).

Figure 3: Degradable solids to biogas energy.

Abattoir effluent: Abattoir effluents whether it reaches the water body through a point source or nonpoint source reduce oxygen in water and endanger aquatic life and can leads to life threatening effect. The organic nutrients added to ground water produce excessive microbial growth causing unpleasant taste and odours of water from this source [2]. Fresh Abattoir effluent is mainly composed of diluted blood, fat and suspended solids. It may also contain some coarse solids e.g. manure, pieces of meat etc. This study also strongly agrees with Ojekunle and the pictures shown below are just to give highlight on the other hand, aged and decomposing abattoir effluent is often malodorous (Figure 4a & 4b).

Figure 4: a. No treatment b. Treatment Practice.

Research Methodology

Study area

The study was conducted in three regions of Ethiopia from January 2014 to March 2018 by selecting a total of 12 potential export abattoirs. 10 of the 12 abattoirs are located in a radius of 100 kilometers from Addis Ababa situating at 8º58'50.17" N, 38º45'27.9" E and at an Altitude of 2,355 meters, one is located in Tigray region at Mekele in the northern part of the country at a coordinate of 13°29'52.12" N, 39°32'38.08" E and an Altitude of 2,084 meters. and the other one is located at eastern part of Ethiopia called Ethio-Somali region situating in Jigjiga also spelt as (Jijiga) at 9º21'24.42" N, 42º47'43.87" E and at an Altitude of 1,646 meters above sea level.

Data collection

The major animals slaughtered in all abattoirs were cattle, goat and sheep. Their operational activities are usually on demand by the buying countries abroad. An investigative survey was carried out. A total of 10 abattoirs located approximately within 100 kilometers radius to Addis Ababa were selected based on their export potential for interview using structured questionnaire and visual observation was also made to investigate the waste management practices. Data was collected using a structured questionnaire, personal communication with abattoirs’ managers and responsible workers, collecting through investigative survey and also related literatures where reviewed for utilization of secondary data to estimate the generated wastes.

Data analysis

Data entry and analysis was done by using Microsoft Excel, 2016 version and for the sake of company’s privacy, the abattoirs are codified as shown below in Table 1

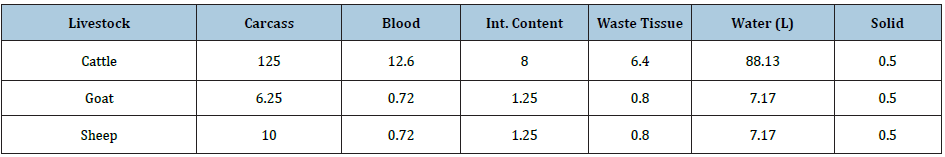

Table 1: Calculation basis per livestock head.

Source: Data from survey, 2017 [10,11]. Note: all the unmentioned figures in the above table are in kilogram

Result and Discussion

As a general introduction, in this section the average yearly slaughtered number and type of livestock animals in each selected export abattoirs are estimated. An attempt has been made to rank abattoirs in comparison with one another by their export contribution. The amount and type of wastes generated in each export abattoirs per year and their waste management practices as well as what the waste comprises of and finally, some intervention strategies have been suggested.

Yearly aggregated slaughtered heads by the selected abattoirs

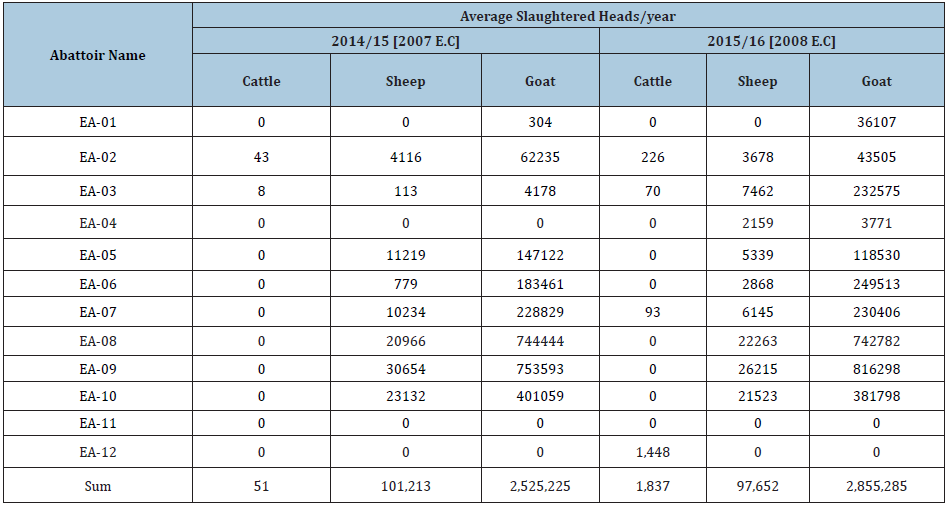

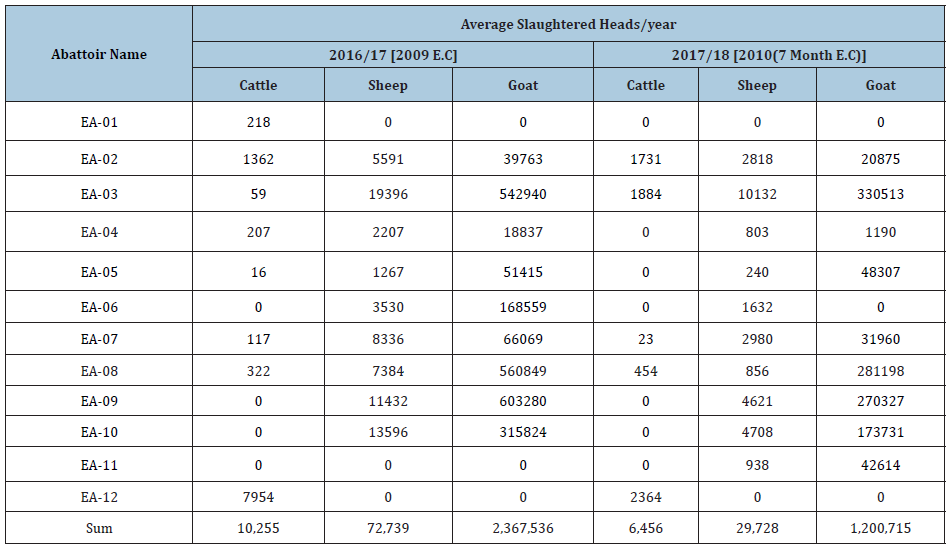

The following table presents, the number of slaughtered livestock animals were obtained/ calculated from the carcass weight as recorded by the Ethiopian revenue and custom data, by using the conversion rates of each livestock type as stated in the Table 2a & 2b. From the above tables, one can understand that, the demand for cattle meat export is getting increased from 51 to 10,255 without decreasing or giving up the demand for small ruminant’s meat. While the number of slaughtered livestock heads were calculated from the export data extracted from Ethiopian Revenue and Custom Authority by using carcass conversion rate of 125kg/head for cattle, 6.25kg/head for sheep and 10kg/goat. These conversion factors were taken by considering the needs of buying countries.

Table 2a: Yearly aggregated slaughtered head from (2014-2016).

Table 2b: Yearly aggregated slaughtered head from (2016-2018).

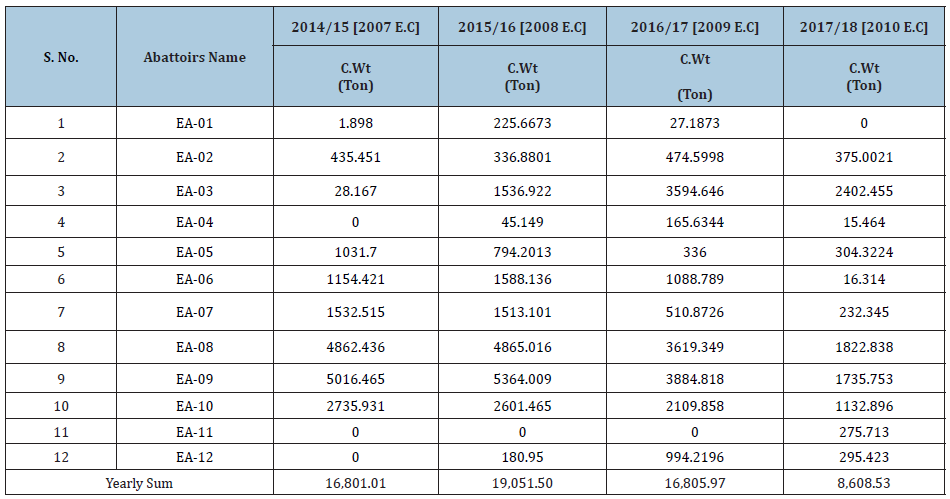

Export contribution

Here below, an attempt was made to rank the percentage export contributions of the selected abattoirs in each year (Table 3). Between the years 2014/15-2016/17 the first largest export was done by the abattoir coded with EA-09, EA-08 is the second largest export was performed and abattoir coded with EA-03 takes the 3rd rank in 2016/17 by displacing EA-10 which was the 3rd in 2014/15-2015/16 wherein, EA-10 is at the 4th place in their contribution to the total export.

Table 3: Percentage export contribution of each abattoir.

Between the years 2014/15-2016/17 the first largest export was done by the abattoir coded with EA-09, EA-08 is the second largest export was performed and abattoir coded with EA-03 takes the 3rd rank in 2016/17 by displacing EA- 10 which was the 3rd in 2014/15-2015/16 wherein, EA-10 is at the 4th place in their contribution to the total export.

Abattoirs waste estimation

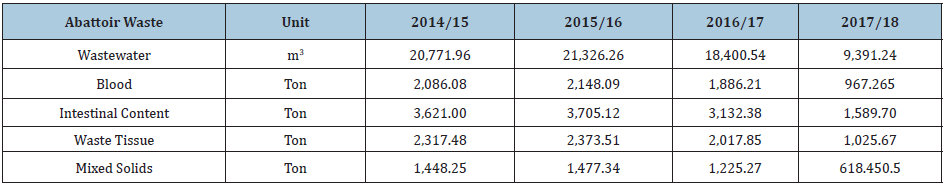

The main sources of solid waste in abattoirs include animal holding areas, slaughterhouse and processing areas, waste treatment plant, unwanted skin pieces and condemned carcasses and carcass parts. Wherein this study tries to estimate the blood, intestinal content, waste tissue and wastewater and trimmed parts in general. The amount/volume of wastes generated by each selected export abattoirs are shown in the Table 4.

The figures in the above table are calculated by using the volume of exported meat from each export abattoir in accordance with slaughtered animal type as per the data obtained from survey and as referred in [10,11]. The figures in the table are the main waste types generated by the 12 potential export abattoirs. As the estimation done, the volume of wastewater is extremely huge and need to be minimized. The blood generated from all abattoirs whereby this study was conducted used directly discharged by considering it as waste, but it can be.

Table 4: Yearly average estimated wastes.

Waste categorization

The wastes generated by the selected abattoirs were categorized under two broad categories; namely, solid and liquid waste. Moreover, efforts have been made to classify the solid waste into intestinal content, waste tissue, and mixed solids which comprises of trimmed parts, office paper waste, condemned meat and waste packaging materials. Horn, hooves and legs are excluded in this study because of unavailability of full information. Wherein bone also excluded in solid waste estimation because in all export abattoirs deboning is not there.

Here-below, wastes generated between 2014/2015-2017/18 [2007-7 Months of 2010 E.C] are estimated and discussed in line with the corresponding tons of exported meat as follows.

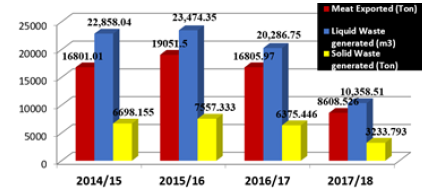

As shown on the figure above between 2014/15-2017/18 years, from the production of 61,267.01 tons of carcass weight, 76,977.65m3 liquid wastes and 23,864.727 tons of solid waste has been generated. Year to year both liquid and solid wastes are getting increased as the export volume increases and from this result one can understand that the abattoirs need to construct waste treatment plant which can undertake the maximum waste that might be generate by operating in their full production capacity (Figure 5).

Figure 5: Yearly average generated solid and liquid wastes.

Existing Abattoirs Waste Management Practice

Solid waste management practices

There are about four mechanisms of solid waste management practices are being used in the abattoirs by which this study was conducted, and these are:

- Incineration: Mostly used for dead (condemned) and/or sick animals.

- Open burning: This mechanism is not for wastes from slaughterhouses but for solid wastes generated from offices, like paper waste.

- Burying: in some cases, companies are obliged to bury (put in the ground) solid waste like gut content, in their compound.

- Landfill: It can be almost all export abattoirs frequently used to discharge or transport their solid wastes to the municipality landfill.

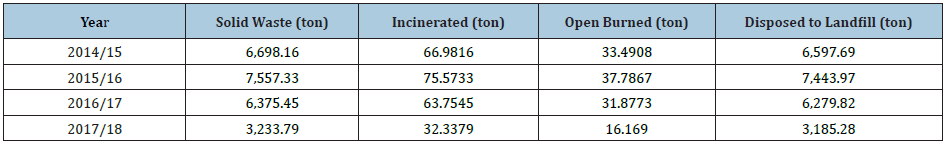

Table 5: Existing solid waste management practices.

During the analysis of the management practices or fate of generated solid wastes, the following result has been achieved (Table 5). The analysis of exiting solid waste management practices reviled that, 1% of the total solid waste was subject to incineration, 0.5% goes to open burning and the left over which is to about 98.5% was transported to municipality landfill. In some cases, insignificant amount of solid waste was observed to be buried (put in the ground) but which occurs on the odd occasion [10].

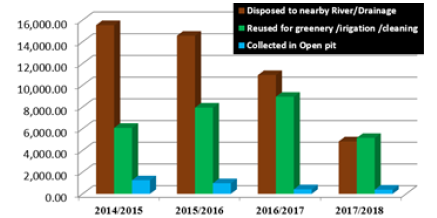

Liquid waste management practices

In this study the liquid waste management practices of the selected abattoirs were identified and fall under three common management approaches.

Discharging to nearby river/drainage lines: in some abattoirs the general liquid waste was observed as directly flow into nearby river and municipality drainage lines with only primary treatment technique which in place just only to separate larger solids [11].

- Reuse: some abattoirs have the experience of treating the liquid waste and then reused for greenery and

- Use of pit: some abattoirs were observed that, they simply allow liquid waste generated from slaughterhouses to flow out through channels to be collected in large open pits and letting it for evaporation. As a result, high

- offensive odor, many rodents and scavengers were observed around the premises. Hence, numeric values are shown below in (Figure 6).

Figure 6: Liquid waste management practices.

From yearly total liquid waste generated between 2014/15-2017/18 [2007-7 months of 2010 E.C] 68%, 62%, 54% and 47% respectively, were undergo primary treatment and discharged to nearby rivers and/or municipality drainage lines. Whereas, 27%, 34%, 44% and 50% were subject to primary and secondary treatment plants and then reused for greenery and cleaning purpose. Lastly 5%, 4%, 2% and 3% of the yearly total liquid waste where simply collected in open pit.

The percentage decrease of discharging liquid waste from abattoirs to nearby rivers and municipality drainage lines only using primary treatment or with no treatment at all, from 68% to 47% by the respective years between 2014/15-2017/18 [2007-7 months of 2010 E.C]. Whereas, using primary and secondary treatment systems and then reusing for greenery and cleaning purpose has been increased from 27% to 50% in 2014/15-2017/18 [2007- 7 months of 2010 E.C]. The finding implies the increase in understanding economic, social and, environmental impacts of wastes generated from slaughtering activities and companies start giving attention towards its management practice.

Suggested Intervention Strategies

The government of Ethiopia endeavors for the country to achieve lower middle-income status by following a green economic development pathway. Accordingly, a climate-resilient green economy (CRGE) strategy has been formulated. To realize this vision as a stakeholder, Ethiopian Meat and Dairy Industry Development Institute (EMDIDI) has been prepared a series of five-year strategic plan in the form of Growth and Transformation Plans (GTPs) that aim to increase productivity and fostering the sectors’ export growth. Hence, to address environmental issues as it kept in the strategic plan of the institute, this study tries to generate target information which will help to identify the bottle necks and to combat these, intervention strategies are suggested below.

- The EMDIDI need to give emphasis on delivering short term trainings for personnel in export abattoirs and sector stakeholders to rise up limited understanding and concern for the environment.

- The EMDIDI in line with regulatory bodies should enforce to implement environmental protection tools and practices such as environmental impact assessment (EIA), cleaner production (CP), good manufacturing practice (GMP) and environmental management system (EMS) widely by the export abattoirs.

- Increase institutional capacity and capability to support companies in implementing environmental and social protection tools.

- The government will better to provide incentives to export abattoirs with regards to improving environmental performance.

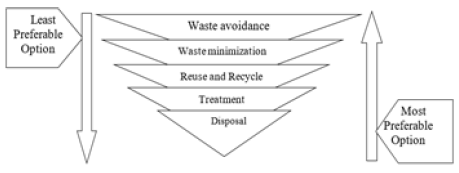

- Waste Management hierarchy should be considered before disposal by landfill and would require innovations within the abattoir and slaughter process itself to avoid production of waste as far as possible [12-16] (Figure 7).

Figure 7: Abattoirs waste management hierarchy.

Conclusion

The total number slaughtered livestock animals by the selected abattoirs were estimated to about 2,896,489, 2,954,681 and 2,450,530 in the respective years between 2014/15- 2017/18 [2007- 7 months of 2010 E.C] with the corresponding yearly average effluent of 22,858.04m3, 23,474.35m3 and 20,286.75m3 liquid wastes and 6,698.155 ton, 7,557.333 ton and 6,375.446 tons of solid waste have been generated respectively.

In further conclusion, the exiting solid waste management practices of the Ethiopian abattoirs is that, 1 percent of the total solid waste particularly, condemned carcasses are incinerated, 0.5% were open burned and the left over, to about 98.5% was transported to municipality land fill. In some cases, insignificant amount of solid wastes was used to bury (put in the ground) but that was occurred on the odd occasions.

Generally, using primary and secondary treatment systems and then reusing for greenery and cleaning purpose has been increased from 27% to 50% and discharging untreated or somehow treated liquid waste to nearby rivers and/or municipality drainage lines become decreased from 68% to 47% in the year 2014/15-2017/18 [2007-7 months of 2010 E.C].

Furthermore, it can further be concluded as, 75-78% of any encountered problems, either it be environmental, Social, and /or export concern, can be solved by working with the top four ranked export abattoirs. In toting up, export abattoirs are on their ways of understanding and giving due considerations for economic, social and environmental impacts of wastes generated from slaughtering activities and to make this effective in collaboration with regulatory bodies, developing strategies as well legal enforcement of environmental tools as to implement in their premises and environmental trainings are the most crucial points.

Recommendation

- Solid waste should be kept separate from wastewater streams via the use of traps and this can decrease the volumetric and organic load on the wastewater treatment stream. For this, the solid waste should not be carted away here and there, rather specific and regular place, so as to avoid the presence of rodents and scavenger around.

- It is highly recommended that hides and skins should be immediately transported out of the slaughtering area using a closed device and, in any case, the hides and skins should not be spread on the floor of the slaughtering area for inspection. If this is done, nuisance odour emissions can be minimized and enables to create attractive as well as safe working environment.

- Anaerobic digestion technology is highly recommended to produce biogas as fuel for heating and lighting, which will be a great extent to help alleviate shortage fluctuation of electrical energy and conserve environment so as it is practicable and fully competitive with other treatment options for the wastes generated from abattoirs.

- It is obvious that blood and bone are ingredients with high protein content and are highly needed in the manufacturing of poultry and pig feed. Therefore, it is recommended to abattoirs to produce blood and bone meal that will assist promoting poultry industry.

- It is also recommended that utilization of by-products will increase returns and can cover some of the costs that will go for environmental protection activates of the abattoirs premises by twining or integrating factories producing glue, combs, buttons, gelatin, brushes, lubricants, grease and this will create employment as a result contribute to the national economy.

- For environmental and sanitation reasons, biodegradable solid wastes and sludge from wastewater treatment systems are recommended to composting which can be done in pits.

- The liquid waste should be washed away by fresh water with adequate pressure throughout the slaughtering premises and the wastewater from slaughter house is heavy in pollution and, therefore, it should not be allowed to drain in to nearby river or mix with the municipal drain system without pre-treatment meeting discharge standards as per the provisional standards set by the Ethiopian Environmental Protection Authority (EEPA).

- Insufficient skills and knowledge and waste management practices are identified as a key constrain to ensuring environmental protection activities. So that providing successive environmental training for personnel who are working on sanitary, hygiene and technical operations is highly recommended.

References

- CSA (Central Statistical Authority) (2017) Agricultural sample survey. Volume II of 2009 EFY report on the Livestock and Livestock Characteristics. Addis Ababa, Ethiopia.

- Ojekunle OZ, Lateef ST (2017) Environmental impact of abattoir waste discharge on the quality of surface water and ground water in abeokuta. J Environ Anal Toxicol 7(5): 509.

- MOFED (Ministry of Finance and Economic Development) (2012) Growth and Transformation Plan (GTP) 2010/11-2014/15. Working paper. Addis Ababa, Ethiopia.

- Barry IS, Getachew G, Solomon D, Asfaw N, Kidus N, et al. (2015) LMP (Ethiopian Livestock Master Plan). Roadmaps for growth and transformation.

- UN Comtrade United Nations.

- EPE (Environmental Policy of FDRE) April (1997) Addis Ababa, Ethiopia.

- A proclamation for the Environmental Protection Organs Establishment (EPOE) (2002) Proclamation No. 295/2002. Negarit Gazeta of the FDRE Addis Ababa.

- CRGE Ethiopia’s Climate-Resilient Green Economy (2011) Green economy strategy. Addis Ababa, Ethiopia.

- Aswin V, Prasanth S, Jiju J (2012) Slaughterhouse: Polluting the Environment.

- Aniebo AO, Wekhe SN, Okoli IC (2011) Abattoir blood waste generation in river state and its environmental implications in the Niger delta. Toxicol Environ Chem 91(4): 619-625.

- Amha S (2008) Sheep and goat meat characteristics and quality, FAO: International Information System for the Agricultural Science and Technology.

- EMPEA (Ethiopian Meat Producer-Exporters Association) (2013) Meat Producer-Exporters profile.

- ERCA (Ethiopian Revenue and Custom Authority) 2007-1010 E.C. statistical data.

- Fearon, S. B. Mensah V. Boateng (2014) Abattoir operations, waste generation and management in the tamale metropolis: case study of the tamale slaughterhouse. Journal of Public Health and Epidemiology 6(1): 14-19.

- (2015) Mini guide to the Management of Abattoir Waste, Western Cape.

- YD Twumasi (2016) Abattoir waste contribution to municipal waste generation. International Journal of scientific research and management (IJSRM) 4: 4812-4848.

© 2019 Meharu Kemal Yunus. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)