- Submissions

Full Text

Environmental Analysis & Ecology Studies

Estimation of Potential Cassava Mill Effluents Discharged into Nigerian Environment

Sylvester Chibueze Izah*

Department of Biological Sciences, Niger Delta University, Nigeria

*Corresponding author:Sylvester Chibueze Izah, Department of Biological Sciences, Faculty of Science, Niger Delta University, Nigeria

Submission: May 09, 2018; Published: June 07, 2018

ISSN 2578-0336 Volume2 Issue5

Abstract

Most food processing effluents are discharged into the environment with little or no treatment. Nigeria is the largest cassava producing nation. Cassava processing is majorly carried out by smallholder processors especially in Southern Nigeria. The effluents generated in the dewatering zone are lethal to lives probably due to the acidic and/ or cyanide content. This study estimated the quantity of cassava mill effluents that is often discharged into the environment during gari production. Projections based on growth scenarios viz: current, low and high growth rates were made. Cassava production historical data (literature reviews/ secondary data) for Nigeria were used for the study. Results revealed that 57.134 million tons of cassava was produced in 2016 leading to release of about 5.142 million tonnes of cassava mill effluents. Projections showed that before 2035, Nigeria may likely produce at high, low and current status growth rate 79.544, 73.850 and 57.719 million tons of cassava leading to the release of 7.158, 6.646 and 5.194 million tonnes of cassava mill effluents, respectively. After considering the challenges of gathering cassava mill effluents in Nigeria, only 45-65% of total effluents generated could be gathered for large scale utilization. Cassava mill effluents has demonstrated positive effect for utilization through biotechnological advances including biogas, bio-ethanol, bioelectricity (energy), animal feed, enzymes, bio-surfactant, organic acids among other. Hence there is the need for more research into these areas for optimization and possibly commercialization to avoid the attendant environmental impacts associated with the effluents.

Keywords: Biotechnology advancement; Cassava processing; Environmental degradation; Food; Projections

Introduction

The impacts of environmental degradation have increased in the recent times [1-3]. Besides environmental components, it’s also having an impacts on biodiversity resources including mammals, fisheries, avian fauna, reptiles, amphibians, microbes and even plants [4-6]. Probably due to the effect of environmental degradation on resources, hence its sustainability is under intense threat [7]. Several emissions are released into the environment through human activities and to lesser extent natural effects. Some of the emissions associated with air quality include oxides of carbon, nitrogen and sulphur, volatile organic compounds, suspended particulate matters. Some heavy metals and microbes have been reported in air, and they can deposit in the different environment as aerosols. Some of the air pollutants including microbes are associated with air borne diseases. Heavy metals which are recalcitrant to degradation have the tendency to bio accumulate in living organisms such as animals and plants, and can persist in the environment [8,9]. Several other air pollutants such as methane, carbon dioxide, hydro fluorocarbons, per-fluorocarbons and sulphur hexafluoride have been implicated as greenhouse gases [7]. Oxides of sulphur and carbon in the atmosphere have the tendency to cause acid rain through the formation of weak acids when it comes in contact with water [10]. Solid wastes are another group of wastes stream that is poorly managed in most urban and rural areas in Nigeria. Solid wastes result from several human activities including market [11,12], abattoir [13], household activities [14], agricultural processing such as oil palm processing (viz: empty fruit bunch, chaff, palm press fibre, palm kernel shell) [15-18], cassava processing (viz: cassava peels) [1,2,19-26] among others. Solid wastes also include remain of scrap metals, plastics, woods, etc.

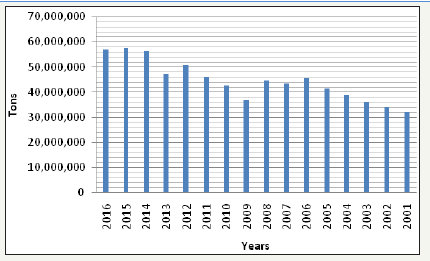

Like solid wastes, liquid wastes which are generated as effluents are typically discharged into the environment with little or no treatment depending on the source and constituents. Besides effluents resulting from oil and gas activities, most waste effluents produced in Nigeria is rarely treated before being discharge into the environment. For instance, in the food processing sector, oil palm processing in which Nigeria is the 5th largest producing nation produces large volume of effluents probably due to the water used for the processing processes [27]. Nigeria is also the largest producer of cassava in the world accounting for about 20.6% of the global output [1,2,19-26]. The effluents produced during cassava processing are injurious to the environment. The effluents are discharged into the soil which may drain into canals, nearby surface water and even percolates in the receiving soil. It has the tendency to make the environment becomes bare and devoid of vegetation [1]. In addition, cassava mill effluent in the soil has the tendency to reduce the microbial density in the receiving soil [27]. Instances of cassava mill effluents leading to death of domestic animals and inhibiting germination of plants and reducing productivity have been reported in literature [1,28-31]. Furthermore, it could cause several alterations in haematology, behavioural response, histology, mortality rate in fisheries exposed to the effluents in the aquatic ecosystem [1,32,33]. This could be due to its toxicity level. Several toxicant have been reported in cassava mill effluents including cyanides [23], heavy metals [24], acidic pH [34-36], high concentration of chemical oxygen demand, anions (sulphate, nitrate, phosphate), salinity, total dissolved solid, conductivity, turbidity, etc [25]. The toxicity of the effluents may be highly influenced by the cyanide content, acidic pH and heavy metals content. Cyanide in effluents can be reduced by activities of heat, fermentation using Saccharomyces cerevisiae and additives such as palm oil [23]. Nigerian cassava production industry has not been steady with regard to production rate (Figure 1). For instance, there was a decline in production rate between 2015 and 2016, 2012 and 2013, 2008 and 2009. The fluctuation could be due to several developmental projects encouraging the cultivation of cassava as well as change in political regime. Thus change in regime tends to favour some area of the economy to the neglect of the others. Like oil palm processing, Nigeria cassava industry is dominated by smallholders that accounts for over 80% of total production [37,38] and use manual/ rudimentary equipment for processing. Nearly 90% of total cassava produced are locally consumed with about 10% are used for industrial processes [37]. Some of the notable applications of cassava include kpokpo gari (commonly produced in Delta State), gari, fufu/akpu, edible starch, abacha and raw materials some industries including food processing (bread production), textile, pharmaceuticals, breweries, etc [37]. High quality cassava flour, native starch and modified starches (viz: production of dextrin and glucose), and animal feed (chips or pellet) are the major industrial uses of cassava in Nigeria [37].

Figure 1: Cassava tuber production in Nigeria between 2001 – 2016. Modified from [36].

Cassava processing and marketing of the associated products is a major business, and main source of livelihood to several families especially in southern Nigeria. Cassava processing tends to vary according to locality. Dewatering processing usually take about 6 hours to 1 week depending on the type of gari the producer intended to produce. In addition, several local varieties of cassava exist in Nigeria depending on locations. Each variety is characterized by varying level of water contents, cyanide level among other chemical constituents. The amount of waste water generated during cassava processing is usually large. But information about the quantity of effluents generated from the processing of cassava in Nigeria appears scanty hence the need for the study. The study concludes by suggesting potential biotechnological advances for the management of cassava mill effluents. This finding of this study will be valuable to environmentalists, government and policy makers towards sustainable management of cassava mill effluents.

Methodology

Secondary (historical) data were used for this study. Data obtained were used to estimate the quantity of effluents from cassava processing in Nigeria for a period of 15years (2001-2016) and projection were made to 2034 based on 3years interval under 3 scenario viz: current status, low and high scenarios.

Estimation of cassava mill effluents

The cassava production statistics is often expressed in tons. The production of 1 tonne of cassava tuber produces 2.4-27.3% (mean 16.7%) as liquid wastes [39]. The effluents now translate to 0.167 tonnes per 1tonne of cassava tubers. After considering, the different varieties of cassava processed under Nigerian environment, which has varying water content. Therefore, 0.15tonnes per 1tonne (or 15%) was estimated as the quantity of water produced from cassava tuber. Nigerian cassava production statistics was used to compute the total cassava production in Nigeria during the period of study (Figure 1) [36]. The cassava production statistics did not specific whether is a short ton (where 1ton=0.907185 tonnes) or long ton (where 1ton=1.0160469088tonnes). Since both values is less than ±0.1 to be approximated as 1, hence, 1ton were assumed to be equal to 1tonne in the cause of the computation.

Estimation of future scenario

The cassava production in Nigeria was 57,035,410 tons at as 2016 economic year [36], which translates to about 20.6% of global production [1,36]. Projection rates were made in 3 scenarios at 3 years interval from 2019-2034 (Table 1). The scenarios were considered as current status (which was calculated from average production of 2014-2016) with growth rate of 0.17%, low scenario (which was calculated from average production of 2013-2016) with growth rate of 4.37%, and high scenario (which was calculated from average production of 2012-2016) with growth rate of 5.67%. The values produced were used to estimate the volume of cassava mill effluents that have been generated under Nigeria environment if all the cassava produced is used for gari production. Furthermore, cassava is used to produce several products in Nigeria including gari, akpu/ fufu, tapioca, starch, chips and flour [37]. Of these applications of cassava tuber, gari production accounts for over 70% of total cassava production [37]. Nigeria has entered bioethanol production and cassava is one of the major feedstock for production. Though till date, the projects appears moribund compare to policies and framework released when the country entered the bio-fuel projects over 10 years ago. In addition, Nigeria now has certain percent of cassava that is incorporated into bread [40]. After considering these application of cassava about 60% of total produced cassava were estimated for gari production alone, and it was used for the computation of cassava mill effluents generated and discharged into the environment.

Result and Discussion

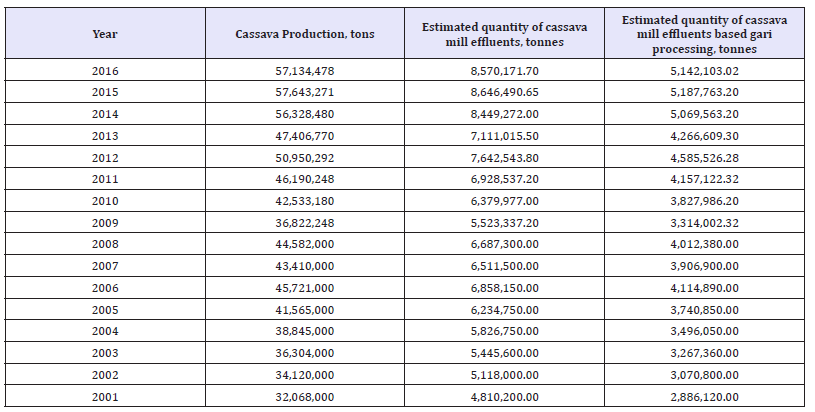

Table 1 presents cassava yield and estimated effluents generated in processing mills in Nigeria between 2001-2016 economic years. The result shows that Nigeria produced 32.068 to 57.134 million tons of cassava tuber and generating 4.810 to 8.570 million tonnes of cassava mill effluents assuming that all cassava tubers produced within the historical study period was used to produce gari. But, if 60% of the total cassava produced was processed into gari, Nigeria could have produced 2.886 to 5.143 million tonnes of cassava mill effluents between 2001-2016.

Table 1:Slope of the Layers

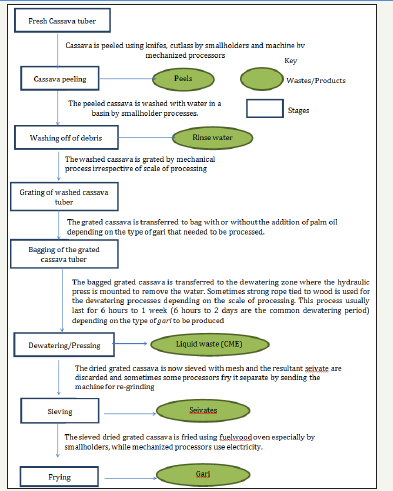

The cassava mill effluents generations showed similar trend with Figure 1. This trend is in accordance with the work of Ohimain & Izah [7] that estimated the quantity of palm oil mill effluents produced from fresh fruit bunch of oil palm between 2004-2013. Basically the smallholders are predominantly involved in the processing of cassava tuber into gari and to lesser extent other products such as akpu/ fufu, tapioca, starch, chips and flour Pind et al. [37] etc. The processing of cassava tuber to gari involves several processes (Figure 2). Table 2 presents the predicted cassava output and estimated cassava mill effluents (2019-2034) under different projection scenario. Under high scenario, Nigeria would likely to produce 79,544,210.69 tons of cassava leading to the release of 11,931,631.60 tonnes of cassava mill effluents by 2034 if all the cassava tubers produced are used for gari production (Figure 2). In the low consideration scenario, Nigeria could produce 73,850,328.43 tons of cassava tubers while generating 11,077,549.27 tonnes of cassava mill effluents by 2034 on full scale utilization for gari production alone. Under current growth rate of 0.17% in the last 3 economic year, Nigeria is likely going to produce 57,719,610.52 tons of cassava tuber, while releasing 8,657,941.58 tonnes of cassava mill effluents before 2035. Specifically, if 60% of the total cassava produced was processed into gari, Nigeria could produce 5,194,764.92; 6,646,529.56 and 7,158,978.96 tonnes of cassava mill effluents before 2035. In a similar study using oil palm as feedstock, Ohimain & Izah [7] reported that several factors including prices, policy, and stakeholders and government participation could influence the production rate. Typically, based on historical data available, between 1997-2001, 1980-1982, 1976-1977 and 1971-1974 there was not major growth on the cultivation of cassava in Nigeria. But between 2002-2015, there was a major boost in cassava production, though a slight decline existed between 2007-2009 which later increased. The massive growth could be due to several developmental projects that require cassava as a raw materials including bio-ethanol and cassava bread production. Probably due to change in direction of government due to regime change, it appears it has led to decline in total cassava production between 2015 and 2016 economic year. Furthermore, due to massive involvement of Nigerian government in agriculture, cassava production may likely rise again

Figure 2: Generation of cassava mill effluents during gari production by smallholder processors in Nigeria (CME: Cassava Mill Effluents) [35,39,40].

Table 2:Predicted cassava output and estimated cassava mill effluents (2019–2034) under different projection scenario.

Furthermore, the effluents resulting from production of cassava is still high, having impacts on the ecosystem [1]. There is the need for utilization in several other fields through biotechnological advances. Some of the area that cassava based products have demonstrated positive effect for sustainable management practices including energy production viz: bioethanol [35,41-43], biogas [44- 48], bio-electricity using microbial fuel cells technology[49-53]; animal feed production [22,26,54], bio-surfactants [55], raw materials for production of amino acids [26], enzymes [56,57], organic acids etc. The conversion of the potential cassava mill effluents to bio-valued products could create employment for several families especially in region of high cassava production. It could also reduce the attendant environmental impacts associated with unsustainable management approach of cassava mill effluents in many processing mills. Owing to the fact that the smallholder processors dominate the enterprise, it will be challenging to gather all the effluents. Considering inaccessibility of some cassava production areas, it become nearly impossible to achieve the theoretical values. Hence in practice, only 45-65% of total effluents generated can be gathered for large scale production of bio-valued products.

Conclusion

The processing of cassava tuber into gari could lead generation of large volume of effluents. In many cassava processing communities in Nigeria, the effluents are discharged into the environment with little or no treatment. This study estimated the quantity of cassava mill effluents that was generated between 2001- 2016, and projected were also made on potential effluents that could be generated between 2019-2034 under 3 scenarios based on estimated growth rate. With increased level of effluents, its impacts on the receiving environment could also increase. Hence, there is the need to manage the effluents through biotechnological advancement.

References

- Izah SC, Bassey SE, Ohimain EI (2018) Impacts of cassava mill effleunts in Nigeria. Journal of Plant and Animal Ecology 1(1): 14-42.

- Izah SC, Bassey SE, Ohimain EI (2018) Ecological risk assessment of heavy metals in cassava mill effluents contaminated soil in a rural community in the Niger delta region of Nigeria. Molecular Soil Biology 9(1): 1-11.

- Aghoghovwia OA, Miri FA, Izah SC (2018) Impacts of anthropogenic activities on heavy metal levels in surface water of nun river around gbarantoru and tombia towns, bayelsa state, Nigeria. Annals of Ecology and Environmental Science 2(2): 1-8.

- Izah SC, Aigberua AO, Nduka JO (2018) Factors affecting the population trend of biodiversity in the Niger delta region of Nigeria. International Journal of Avian and Wildlife Biology 3(3): 206-214.

- Izah SC, Angaye CN, Aigberua AO, Nduka JO (2017) Uncontrolled bush burning in the Niger delta region of Nigeria: potential causes and impacts on biodiversity. International Journal of Molecular Ecology and Conservation 7(1): 1-15.

- Izah SC, Seiyaboh EI (2018) Changes in the protected areas of bayelsa state, Nigeria. International Journal of Molecular Evolution and Biodiversity 8(1): 1-10.

- Ohimain EI, Izah SC (2014) Possible contributions of palm oil mill effluents to green house gas emissions in Nigeria. British Journal of Applied Science and Technology 4(33): 4705-4720.

- Izah, SC, Angaye TCN (2016) Heavy metal concentration in fishes from surface water in Nigeria: potential sources of pollutants and mitigation measures. Sky Journal of Biochemistry Research 5(4): 31-47.

- Izah SC, Chakrabarty N, Srivastav AL (2016a) A review on heavy metal concentration in potable water sources in Nigeria: human health effects and mitigating measures. Exposure and Health 8(2): 285-304.

- Seiyaboh EI, Izah SC (2017) A review of impacts of gas flaring on vegetation and water resources in the Niger delta region of Nigeria. International Journal of Economy Energy and Environment 2(4): 48-55.

- Ben Eledo VN, Kigigha LT, Izah SC, Eledo BO (2017) Water quality assessment of epie creek in yenagoa metropolis, bayelsa state, Nigeria. Archives of Current Research International 8(2): 1-24.

- Ben Eledo VN, Kigigha LT, Izah SC, Eledo BO (2017) Bacteriological quality assessment of epie creek, Niger delta region of Nigeria. International Journal of Ecotoxicology and Ecobiology 2(3): 102-108.

- Seiyaboh EI, Izah SC (2017) Bacteriological assessment of a tidal creek receiving slaughter house wastes in bayelsa state, Nigeria. Journal of Advances in Biology and Biotechnology 14(1): 1-7.

- Angaye TCN, Zige DV, Izah SC (2015) Microbial load and heavy metals properties of leachates from solid wastes dumpsites in the Niger Delta, Nigeria. Journal of Environmental Treatment Techniques 3(3): 175-180.

- Ohimain EI, Izah SC (2014) Energy self-sufficiency of smallholder oil palm processing in Nigeria. Renewable Energy 63: 426-431.

- Izah, SC, Angaye TCN, Ohimain EI (2016) Environmental impacts of oil palm processing in Nigeria. Biotechnological Research 2(3): 132-141.

- Ohimain EI, Izah SC, Abah SO (2013) Air quality impacts of smallholder oil palm processing in Nigeria. Journal of Environmental Protection 4: 83-98.

- Ohimain EI, Izah SC, Obieze FAU (2013) Material mass balance of small holder oil palm processing in the Niger delta, Nigeria. Advance Journal of Food Science and Technology 5(3): 289-294.

- Izah SC, Bassey SE, Ohimain EI (2017) Assessment of pollution load indices of heavy metals in cassava mill effluents contaminated soil: a case study of small-scale cassava processing mills in a rural community of the Niger delta region of Nigeria, Bioscience Methods 8(1): 1-17.

- Izah SC, Bassey SE, Ohimain EI (2017) Assessment of heavy metal in cassava mill effluent contaminated soil in a rural community in the Niger delta region of Nigeria. EC Pharmacology and Toxicology 4(5): 186-201.

- Izah SC, Bassey SE, Ohimain EI (2017) Geo-accumulation index, enrichment factor and quantification of contamination of heavy metals in soil receiving cassava mill effluents in a rural community in the Niger delta region of Nigeria. Molecular Soil Biology 8(2): 7-20.

- Izah SC, Bassey SE, Ohimain EI (2017) Assessment of some selected heavy metals in Saccharomyces cerevisiae biomass produced from cassava mill effluents. EC Microbiology 12(5): 213-223.

- Izah SC, Bassey SE, Ohimain EI (2017) Cyanide and macro-nutrients content of saccharomyces cerevisiae biomass cultured in cassava mill effluents. International Journal of Microbiology and Biotechnology 2(4): 176-180.

- Izah SC, Bassey SE, Ohimain EI (2017) Removal of heavy metals in cassava mill effluents with saccharomyces cerevisiae isolated from palm wine. MOJ Toxicology 3(4): 1-57.

- Izah SC, Bassey SE, Ohimain EI (2017) Changes in the treatment of some physico-chemical properties of cassava mill effluents using Saccharomyces cerevisiae. Toxic 5(4): 1-28.

- Izah SC, Bassey SE, Ohimain EI (2017) Amino acid and proximate composition of saccharomyces cerevisiae biomass cultivated in Cassava mill effluents. Molecular Microbiology Research 7(3): 20-29.

- Ohimain EI, Izah SC (2017) A review of biogas production from palm oil mill effluents using different configurations of bio reactors. Renewable and Sustainable Energy Reviews 70: 242-253.

- Izah SC, Aigberua AO (2017) Assessment of microbial quality of cassava mill effluents contaminated soil in a rural community in the Niger delta, Nigeria. EC Microbiology 13(4): 132-140.

- Orhue ER, Imasuen EE, Okunima DE (2014) Effect of Cassava mill effluent on some soil chemical properties and the growth of fluted pumpkin (Telfairia occidentalis Hook F.). Journal of Applied and Natural Science 6(2): 320-325.

- Ehiagbonare JE, Enabulele SA, Babatunde BB, Adjarhore R (2009) Effect of cassava effluents on Okada denizens. Scientific Research Essay 4(4): 310-313.

- Ero NR, Okponmwense M. The effect of cassava waste on the environment and its implication on the national economy

- Asogwa CN, Ezenwajiaku FO, Okolo CA, Ekeh FN, Nwibo DD, et al. (2015) Behavioural and biochemical responses of juvenile catfish (Clarias gariepinus) exposed to graded concentrations of cassava waste water. Animal Research International 12(1): 2136-2142.

- Adeyemo OK (2005) Haematological and histo pathological effects of cassava mill effluent in Clarias gariepinus. African Journal of Biomedical Research 8(3): 179-183.

- Izah SC, Ohimain EI (2015) Bioethanol production from cassava mill effluents supplemented with solid agricultural residues using bakers’ yeast Saccharomyces cerevisiae. Journal of Environmental Treatment Techniques 3(1): 47-54.

- Izah SC (2016) Bioethanol production from cassava mill effluents supplemented with oil palm chaff, empty fruit bunch and cassava peels using Saccharomyces cerevisiae, Niger Delta University, Wilberforce Island, Nigeria, pp. 1-113

- Fact fish (2016) Nigeria: Cassava, production quantity (tonnes).

- Pind (2011) Foundation for partnership initiatives in the Niger delta. A report on cassava value chain analysis in the Niger delta, Abuja, Nigeria.

- Oyebanji OO, Akwashiki HK (2003) Infrastructure development for enhanced cassava marketing. Paper presented at the workshop on cassava processing/post harvest and marketing, Port Harcourt, pp. 23- 25.

- Ohimain EI, Silas-Olu DI, Zipamoh JT (2013) Bio-wastes generation by small scale cassava processing centres in Wilberforce Island, Bayelsa State, Nigeria. Greener Journal of Environmental Management and Public Safety 2(1): 51-59.

- Ohimain EI (2014) The prospects and challenges of cassava inclusion in wheat bread policy in Nigeria. International Journal of Science Technology and Society 2(1): 6-17.

- Akponah E, Akpomie OO (2012) Optimization of bio-ethanol production from cassava effluent using Saccharomyces cerevisiae. African Journal of Biotechnology 11(32): 8110-8116.

- Akponah E, Akpomie OO, Ubogu M (2013) Bio-ethanol production from cassava effluent using Zymomonas mobilis and Saccharomyces cerevisiae isolated from rafia palm (Elaesis guineesis) SAP. European Journal of Experimental Biology 3(4): 247-253.

- Aisien F, Aguye MD (2010) Blending of ethanol produced from cassava waste water with gasoline as source of automobile fuel. Electronic Journal of Environment, Agriculture and Food Chemistry 9(5): 946-950.

- Eze JI (2010) Converting cassava (Manihot spp.) waste from gari processing industry to energy and bio-fertilizer. Global Journal Researches Eng 10(4): 113-117.

- Budiyono, Kusworo TD (2011) Biogas production from cassava starch effluent using microalgae as bio stabilisator. International Journal of Science and Engineering 2(1): 4-8.

- James PS, Regina FM, Bovas JJL, Kamaraj S (2013) Development of a hybrid anaerobic bioreactor for treatment and energy conversion of organic effluents. Journal Root Crops 39(2): 183-188.

- Kullavanijaya P, Thongduang P (2012) Enhanced biogas production in anaerobic digestion of cassava waste water though supplementation of biodiesel waste as co-substrate. International Journal of Renewable Energy Research 2(3): 510-515

- Jijai S, Srisuwana G, Othong S, Ismail N, Siripatana C (2014) Specific methanogenic activities (sma) and biogas production of different granules size and substrates. The 1st environment and natural resources. The Sukosol hotel, Bangkok, Thailand.

- Kaewkannetra P, Chiwes W, Chiu TY (2011) Treatment of cassava mill waste water and production of electricity through microbial fuel cell technology. Fuel 90(8): 2746-2750.

- Quan X, Tao K, Mei Y, Jiang X (2014) Power generation from cassava alcohol wastewater: effects of pre-treatment and anode aeration. Bioprocess Biosystems Eng 37(11): 2325-2332.

- Leano EP, Babel S (2011) Electricity generation from anaerobic sludge and cassava wastewater subjected to pre-treatment methods using microbial fuel cell. University in Khlong Nueng, Thailand

- Prasertsung N, Reungsang A, Ratanatamskul C (2012) Alkalinity of cassava wastewater feed in anodic enhance electricity generation by a single chamber microbial fuel cells. Engineering Journal 16(5): 17-28.

- Edem DE, Opara CC, Evbuomwan BO, Oforkansi BC (2015) Effects of novel substrates in electricity generation in a mediator-less microbial fuel cell. Greener Journal of Science and Engineering Technology Research 5 (1): 11-19.

- Balogun TF, Bawa GS (1997) Cassava peels in the diet of young pigs in Nigeria. Trop Anim Health Prod 29(4): 209-215

- Barros FFC, Ponezi AN, Pastore GM (2008) Production of biosurfactants by Bacillus subtilis LB5a on a pilot scale using cassava waste water as substrate. J Ind Microbial Biotechnol 35(9): 1071-1078.

- Arotupin DJ (2007) Evaluation of microorganisms from cassava waste water for production of amylase and cellulase. Research Journal of Microbiology 2(5): 475-480.

- Santhi R (2014) Microbial production of protease by Bacillus cerus using cassava waste water. European Journal of Experimental Biology 4(2): 19-24.

© 2018 Sylvester Chibueze Izah. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)