- Submissions

Full Text

Environmental Analysis & Ecology Studies

Distillery Wastewater: it's Impact on Environment and Remedies

Pankaj Chowdhary, Nawaz Khan and Ram Naresh Bharagava*

Department of Environmental Microbiology, Babasaheb Bhimrao Ambedkar University, India

*Corresponding author: Ram Naresh Bharagava, Department of Environmental Microbiology, Babasaheb Bhimrao Ambedkar University, Vidya Vihar, Raebareli Road, Lucknow 226 025, Uttar Pradesh, India

Submission: January 13, 2017; Published: February 16, 2018

ISSN: 2578-0336 Volume1 Issue2

Abstract

Distillery wastewater and its toxicity is a serious concern worldwide. Unfortunately, if discharged into the environment without proper treatment, it causes serious environmental problems and health hazards in human and animals. Due to very high chemical oxygen demand (COD), biological oxygen demand (BOD), it causes inhibition of seed germination and depletion of vegetation by reducing the soil alkalinity and manganese availability in agricultural land whereas in aquatic environments, it reduces sunlight penetration and decreases photosynthetic activity and dissolved oxygen content damaging the aquatic fauna and flora both. Various physico-chemical and biological approaches employing membranes, coagulant, bacteria, fungi, microalgae etc. used for the treatment of distillery wastewater.

Keywords: Distillery wastewater; Toxicity; Health problem; Treatment

Distillery Wastewater and Its Toxicity

Distillery wastewater causes serious concern to living organisms resulting in a greater environmental stress. There are >325 distilleries in India, producing approximately 3 billion liters of alcohol and 45 billion liters of spent wash annually [1] Distillery units are generating huge amount of wastewater during the alcohol production process, which an average of 10-15L of wastewater is released with the production of 1L of alcohol [2,3] In distillery wastewater, the presence of many types of organic and inorganic pollutants such as melanoidin, polysaccharides, reduced sugar, proteins, waxes, N, K, Ca, SO4-, PO4- etc. are reported by various researchers [4,5].

Melanoidins are one of the major pollutants causing serious environmental and health problems [6]. Distillery wastewater contains various types of recalcitrant organic pollutants including endocrine disrupting chemicals like phthalates are reported and it causes the hormonal imbalance and disturb the reproductive fitness of living organism and ultimately leading to the carcinogenesis [7-9]. Melanoidin is formed by the reaction between amino acid and carbohydrate called "Maillard reactions" [10,11]. Melanoidins are dark brown to black coloured recalcitrant compounds of sugar and amino acids, which are produced during the processing of sugar cane juice in sugar industries and molasses in fermentation industries [5].

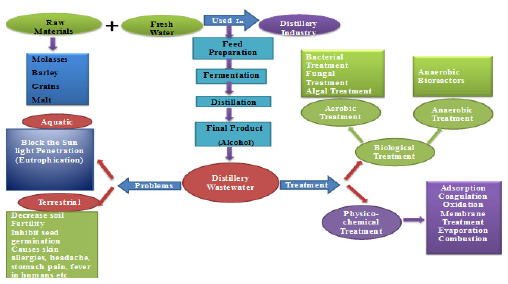

Distillery wastewater mainly affects soil and aquatic region due to the presence of water-soluble recalcitrant colouring organic and inorganic compounds [4]. In aquatic region, distillery wastewater can block out sunlight from rivers and streams, thus reducing oxygenation of the water by photosynthesis and hence, become detrimental to aquatic life. Secondly, it has a high pollution load, which would result in eutrophication of contaminated water sources [2] (Figure 1).

Distillery wastewater also causes soil pollution and acidification in the cases of inappropriate land discharge [2]. It is reported to inhibit seed germination, reduce soil alkalinity, cause soil manganese deficiency, and damage agricultural crops [2]. It also affects the farm animals. They drink it and resulted in increased livestock mortality, poor health, and reduced milk yield. Even the human beings lived in distillery wastewater polluted area is affected by skin allergies, headache, vomiting sensation, irritating eyes, fever, and stomach pain [12]. It is analyzed that distillery wastewater, highly polluted and having very high COD and BOD, and dark brown reddish colour. Some of the contaminants, such as certain level of minerals or compounds are not only harmful to health, but also create a long term effects such as cytototoxic and genotoxic effect [4].

There are several different methods for treatment of distillery wastewater such as:

Coagulation

Reduction of repulsive forces through addition of coagulant, there are many coagulant used in distillery wastewater treatment such as aluminium sulfate (AlSO4), ferric chloride (FeCl3), ferrous sulfate (FeSO4), alum, iron aluminum; calcium salts, polyaluminium chloride (PACl) etc. [13,14].

Flocculation

Physical process by which particle contact and agglomeration occurs.

Ion exchange

To separate ionized molecules (organic as well as inorganic) from aqueous solution as well as contaminants in organic streams.

Membrane technology

The effluent collected from the distillery industry is highly alkaline with pH range of around 8.5. Hence, it is neutralized using sodium hydroxide. The neutralized solution has a lot of suspended solids, so the filtration is carried out to remove the suspended solids with fine-pore thin cloth or by using some membranes [15,16].

Figure 1: Schematic representation of alcohol production and its impact on environment.

Biological Approaches of Treating Distillery Wastewater

Anaerobic treatment processes have higher nutrient requirements and cause operational difficulties in treating high organic strength wastewaters. These methods in primary treatment of still age would result in lower cost-efficiency and eco-friendly in nature [17]. A mesophilic two-stage system consisting of an anaerobic filter (AF) and an UASB reactor was found suitable for anaerobic digestion of distillery wastewater [2,3]. Aerobic treatment stage still has high organic loading and is high dark brown in colour, hence it is generally followed by a secondary, aerobic treatment.

Bacterial treatment has been reported frequently in past and recent years. Bacterial degradation/decolourization of industrial wastes is an eco-friendly and cost effective alternative to chemical decomposition process of wastes minimization [1]. Fungal treatment which are used in the treatment of distillery wastewater such as basidiomycetes and ascomycetes as well as used in the decolourization of natural and synthetic melanoidins in connection with colour reduction of wastewater from distilleries. Fungal treatment is use to purify the wastewater by consumption of organic compound, thus, reducing its COD and BOD, and at the same time to obtain some valuable products, such as fungal biomass for protein rich animal feed or some specific fungal metabolites [2,18].

Algal treatment attracts researchers not only by treating but also by its products/byproducts, which are in demands for social welfare. Microalgae have the ability to take up its nutrients (majority inorganic compounds) requirement from biomethanated spent wash and energy requirement from the sun [19]. Constructed wetland (CW) is an artificial wetland created for the purpose of treating anthropogenic discharge such as municipal or industrial wastewater, or storm water runoff [20]. It may also be created for land reclamation after mining, refineries, or other ecological disturbances such as required mitigation for natural areas lost to land development [21]. Constructed wetlands are engineered systems that use natural functions of vegetation, soil, and organisms to treat different water streams [4].

Biocomposting is an aerobic, thermophilic process resulting in a product rich in humus, which is thus used as a fertilizer (Torres- Climent et al. 2015). In this process, press mud generated from sugar mills is utilized to produce compost by mixing distillery wastewater. Both anaerobic and aerobic composting systems are practiced. There are several enzymes (e.g., Peroxidases, Oxidoreductases, Cellulolytic enzymes, Cyanidase, Proteases, Amylases, etc.) reported from different sources to play an important role in waste treatment process [22,23].

There are many problems facing by distillery industries, which are described below:

a) Distillery industry release 91-93% as wastewater causes serve environmental problems.

b) Lack of advance processing techniques and waste treatment technologies in developing countries.

c) Total dissolved solid (TDS) value of distillery wastewater is more problematic.

Thus there is an urgent need to adequate treatment of distillery wastewater and also social awareness for sustainable development.

Conclusion

Environmental sustainability with rapid industrialization is one of the major challenges of the current scenario worldwide. This review article concluded that distillery industries use in huge amount of water, various types of chemicals and raw materials in the production of alcohol, which generate high strength of wastewater. Due to very high BOD and COD, this wastewater is considered as an environmental hazard. Thus, there is an urgent need to address the limitations in the existing methods and to develop integrated treatment processes that provide a complete solution to the treatment of distillery wastewater.

Acknowledgement

The Rajiv Gandhi National Fellowship (Letter No. RGNF 2015-17SC-UTT-20334) awarded to Mr. Pankaj Chowdhary for Ph.D. work from University Grant Commission (UGC), Government of India (GOI), New Delhi is duly acknowledged.

References

- Bharagava RN, Chandra R, Rai V (2009) Isolation and characterization of aerobic bacteria capable of the degradation of synthetic and natural melanoidins from distillery effluent. World Journal of Microbiology and Biotechnology 25: 737-744.

- Bharagava RN, Chandra R (2010) Effect of bacteria treated and untreated post- methanated distillery effluent (PMDE) on seed germination, seedling growth and amylase activity in Phaseolusmungo L. J Hazard Mater 180: 730-734.

- Chowdhary P, Yadav A, Kaithwas G, Bharagava RN (2017b) Distillery Wastewater: A Major Source of Environmental Pollution and Its Biological Treatment for Environmental Safety. In: Replace with: Singh R, Kumar S (Eds.), Green Technologies and Environmental Sustainability.

- Chowdhary P, Raj A, Bharagava RN (2018) Environmental pollution and health hazards from distillery wastewater and treatment approaches to combat the environmental. Chemosphere 194: 229-246.

- Arimi MM, Zhang Y, Sven-Uwe G (2015) Color removal of melanoidin- rich industrial effluent by natural manganese oxides. Separation and Purification Technology 150: 286-291.

- Chandra R, Chowdhary P (2015) Properties of bacterial laccases and their application in bioremediation of industrial wastes. Environ Sci Processes Impacts 17(2): 326-342.

- Dixit S, Yadav A, Dwivedi PD, Das M (2015) Toxic hazards of leather industry and technologies to combat threat: A review. Journal of Cleaner Production 87: 39-49.

- Chowdhary P, More N, Raj A, Bharagava RN (2017a) Characterization and identification of bacterial pathogens from treated tannery wastewater Microbiol Res Int 5: 30-36.

- Alam MZ, Ahmad S, Malik A, Ahmad M (2010) Mutagenicity and genotoxicity of tannery effluents used for irrigation at Kanpur, India. Ecotoxicol Environ Saf 73(5): 1620-1628.

- Tamanna N, Mahmood N (2015) Food processing and maillard reaction products: effect on human health and nutrition. Hindawi Publishing Corporation International Journal of Food Science p. 6.

- Saranraj P, stella D (2014) Impact of Sugar Mill Effluent to Environment and Bioremediation: A Review. World Appl Sci 30(3): 299-316.

- Chaudhary R, Arora M (2011) Study on distillery effluent: chemical Analysis and impact on environment. International Journal of Advanced Engineering Technology 2(2): 352-356.

- Wagh MP, Nemade PD (2015) Treatment of distillery spent wash by using chemical coagulation (CC) and electro-coagulation [EC]. American Journal of Environmental Protection 3(5): 159-163.

- Prajapati AK, Chaudhari PK (2015) Physicochemical treatment of distillery wastewater-a review. Chemical Engineering Communications 202: 1098-1117.

- Nataraj SK, Hosamani KM, Aminabhavi TM (2006) Distillery wastewater treatment by the membrane-based nanofiltration and reverse osmosis processes. Water Research 40(12): 2349-2356.

- Prodanovic JM, Vasic VM (2013) Application of membrane processes for distillery wastewater purification-a review. Desalination and Water Treatment 51(1-18): 3325-3334.

- Pant D, Adholeya A (2007) Biological approaches for treatment of distillery wastewater: a review. Bioresource Technology 98(12): 23212334.

- Pant D, Adholeya A (2009) Concentration of fungal ligninolytic enzymes by ultrafiltration and their use in distillery effluent decolorization. World Journal of Microbiol and Biotechnology 25(10): 1793-1800.

- Sankaran K, Premalatha M, Vijayasekaran M, Somasundaram VT (2014) DEPHY project: Distillery wastewater treatment through anaerobic digestion and phycoremediation-A green industrial approach. Renewable and Sustainable Energy Reviews 37: 634-643.

- Mulidzi AR (2010) Winery and distillery wastewater treatment by constructed wetland with shorter retention time. Water Sci Technol 61(10): 2611-2615.

- Sayadi MH, Kargar R, Doosti MR, Salehi H (2012) Hybrid constructed wetlands for wastewater treatment: A worldwide review. Proceedings of the Int Acad of Ecol and Environ Sci 2(4): 204-222.

- Chandra R, Chowdhary P (2015) Properties of bacterial laccases and their application in bioremediation of industrial wastes. Environ Sci Process Impacts 17(2): 326-342.

- Dec J, Bollag JM (1994) Use of plant material for the decontamination of water polluted with phenols. Biotechnol Bioeng 44: 1132-1139.

© 2018 Pankaj Chowdhary, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)