- Submissions

Full Text

COJ Technical & Scientific Research

Novel Biodegradable Skin Tissue- Carrier for Advanced Cosmeceuticals and Nutraceuticals

Pierfrancesco Morganti1*, Maria BC2, Morganti G3, Natalia V4 and Hong DC5

1Dermatological Department, China Medical University, China

2Department of Civil and Industrial Engineering, University of Pisa, Italy

3ISCD Nanotechnology Center, Italy

4Ural Federal University, Russia

5Dermatology Department, The First Hospital of China Medical, China

*Corresponding author:Pierfrancesco Morganti, Dermatological Department, China Medical University, Shenyang, China

Submission: December 15, 2023:Published: January 24,2024

Volume4 Issue5January ,2024

Abstract

The vehicles to be applied on skin, hair or mucous membranes have the scope to load and carry selected active ingredients releasing them at the designed areas, dose and time. Regarding their use in the field of cosmetics (i.e, cosmeceuticals) and diet supplements (i.e., nutraceuticals),these carriers are generally made by emulsions and solutions containing not only active ingredients, but also preservatives emulsifiers and other chemicals necessary to maintain the product integrity and stability during their storage and use. Moreover, they are packed by containers 60% of which are made by non-biodegradable plastic material. The aim of the paper is to suggest the possibility to manufacture and use alternative novel smart and biodegradable carrier-tissues that made by natural polymers embedded by active micro nano block polymeric complexes are free of any kind of chemicals and globally biodegradable. The suggested carriertissues have been made by biopolymeric fibers bound to micro-nanocomplexes of chitin nanofibrilsnano chitin (CN-LG) encapsulating different active ingredients. The ingredients have been selected in advance to characterize effectiveness and safeness of the realized advanced medical devices, innovate cosmeceuticals and nutraceuticals, packed by biodegradable containers. This proposal could be useful to make innovative products that able to improve human health and beauty, may contribute to safeguard the environmental conditions reducing the food and agro-forestry waste and slowing down the global Green House Gas (GHG) emissions invading our planet. At this purpose and to better understand the great problems caused by this increasing pollution. The paper will start giving a look on the land and ocean waste that continuously invaded by plastic and microplastic became dangerous for the health of humans animals and the environment. Moreover, some considerations will be reported regarding production and use of biopolymers which including chitin nanofibrils and Nanolignin have been utilized from our research group for making the proposed innovative biodegradable cosmeceuticals and nutraceuticals. In conclusion its considered necessary to change the today way of producing and consuming not only reducing the actual food loss and waste, but also becoming to utilize innovative cosmeceuticals, nutraceuticals and clothes made by biodegradable polymers finally adopting the circular economy.

Keywords:Waste; Microplastics; Cosmeceuticals; Nutraceuticals; Polymers; Chitin nanofibril; Lignin Tissues; Carriers

Introduction

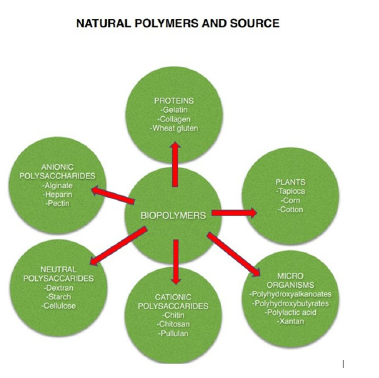

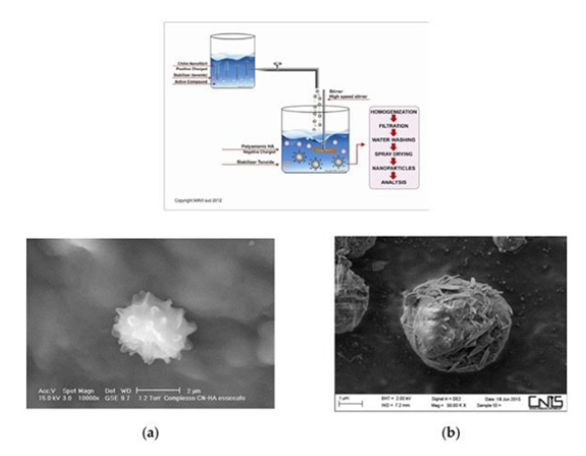

Pollution and waste, increasing and invading lands and oceans by macro and microplastic’ debris are entering into the food of marine animals and humans resulting dangerous for the global health [1]. Moreover, waste ranging 1.6 billion tones yearly represents the 8/10% cause of the global Green House Gas (GHG) emissions [2]. Plastic materials. In fact, are widely employed not only to make disposable medical equipments and textiles, but also to produce food and cosmetic packaging which, releasing 22 million tons of waste in 2019 is estimated to double the quantity by 2060, representing 3.4% of the today global GHG emissions [3]. Consequently, the worldwide people are starting to change the way of consuming and living, becoming more sensitive to their own health and the environment protection. Therefore, consumers are starting to purchase products made prevalently by biodegradable and sustainable technologies. They, wish to reduce or eliminate the actual great quantity of food and agro-forestry waste supposing that their rich content in active ingredients and natural polymers including polysaccharides could be utilized to make biodegradable and safe products. At this purpose and as discussed later biopolymers such as chitin and lignin might be useful to obtain biofibers utilized to make specialized carriers for manufacturing innovative tissues and films, necessary to produce. For example, textiles ,skin and environmentally disposable medical devices and equipments, smart cosmeceuticals, nutraceuticals and packaging [4]. Chitin and lignin are not only bio-eco-compatible, non-toxic and biodegradable polymers, but are also made by microstructure and morphology, easily modifiable in their mechanical properties [5]. At this purpose, the nitrogenous polysaccharide chitin and/ or the polyphenol-rich lignin found in crustacean /microbes and plant/algae respectively result particularly useful to make carriers for biomedical food and cosmetic applications, because easily obtainable at low cost from waste material also [6]. However, as for chitin and lignin the complex linear or branched structure of the majority of natural polymers are composed by monosaccharide units connected by glycosidic bonds, giving rise to neutral (i.e.dextran), cationic(i.e.chitin/chitosan) or anionic(i.e.Hyaluronic acid) compounds useful to make biodegradable fibers (Figure 1). Moreover, Chitin/chitosan and lignin/yaluronic acid obtainable in great quantity from natural and waste material may be easily bonded each other by the ionotropic gelation method to produce micro-nano particles, being polymers covered by electrical positive and negative charges respectively (Figure 2); [6-8]. For all these reasons, our research group are proposing to make micro-nano technological block polymeric complexes by the use of these biopolymers at their micro/nano size to make micronano nanoparticles (NPs) capable to encapsulate different active ingredients into their structure. Successively and according to our experience the “activated” NPs may be embedded into films or bound to fibers of non-woven tissues to make innovative advanced medications and/or novel cosmeceuticals and nutraceuticals. These innovative cosme-nutraceuticals might be used to obtain the so-called Beauty from within (i.e. the use of the same ingredients applied on the skin by cosmeceuticals and taken by oral route by nutraceuticals) [9,10]. This new beauty approach seems to represent the new way that consumers are becoming to consider at the basis of their appearance and health [9,10]. Therefore by this new patented carrier-tissues made by selected bioactive ingredients obtained from food and agro-forestry waste. It seems possible to make not only novel cosmeceutical/nutraceutical carriers and products but also biodegradable packaging. Therefore, it might be realized drugs, food, cosmetics and packaging of a new generation, by the use of the reported innovative film sand tissues [11-13]. Additionally, these novel products of great interest to reduce the actual no more sustainable organic waste could be useful for starting to create innovative goods for a better green economy also [14-16]. Finally, as soon after focused, it is to underline the possibility this technology could have for manufacturing water-soluble and water-insoluble tissues which being really free of water, preservatives, emulsifiers, fragrances and other chemicals might be useful to make innovative cosme-nutraceuticals in agreement with the EU rules for products “free from” [17-19].Therefore the aim of the paper is to range a better beauty with an healthy life and a more safe environment, according with the scientists and consumers request [6-8]. At this purpose it seems also useful to report some introductive news on the global pollution problems to better understand the consumers’ worry for the environmental disasters and the need to change the way of producing and consuming by the use of biodegradable goods as the proposed tissue-carriers.

Figure 1:Source and characteristics of natural polymers.

Figure 2:Micro nano particles of hyaluronan/chitin obtained by the gelation method up) between hyaluronic. acid a) Chitin b) Courtesy of Morganti et al. [6]

Plastic Pollution and Waste

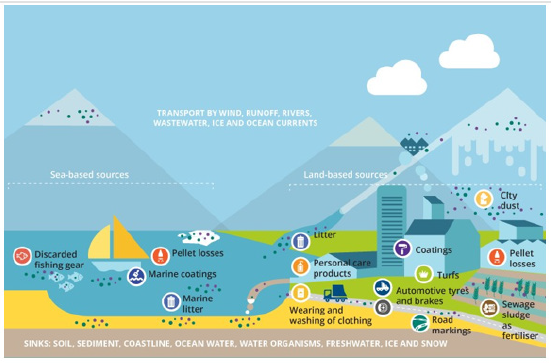

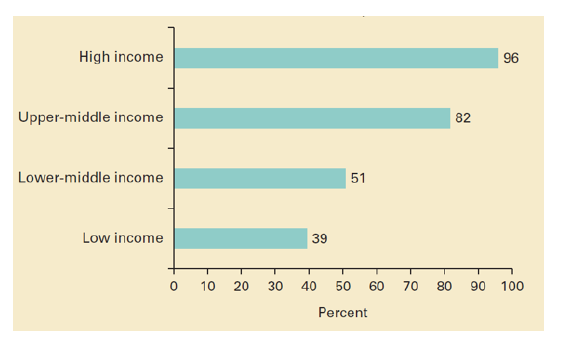

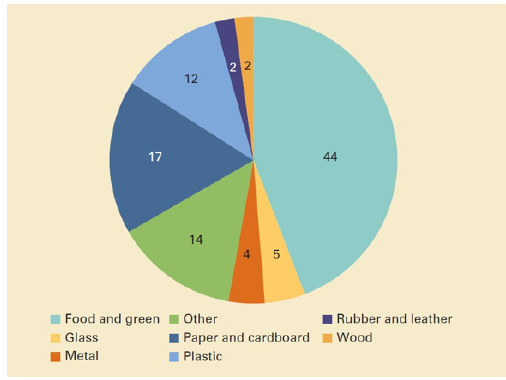

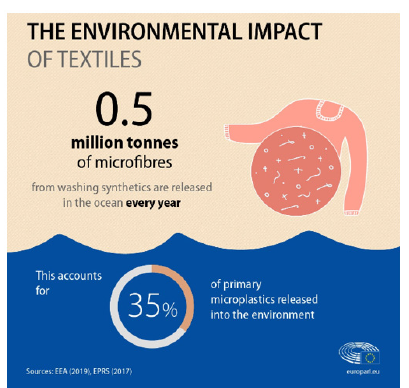

As previously reported the main plastic waste is due mainly to food and cosmetics packaging, cloth-textile-fibers)and disposable medical equipments released in landfill and oceans as microplastics [20] .At this purpose, it is to know that “each year in Europe about 3800 tons of Microplastics(i.e.over seven kilos every minute!)are released into the environment through the use of everyday cosmetics and personal care products while the beauty industry produces annually 120 billion units of packaging 60% of which made by non-biodegradable plastic material [21]. This waste is increasing day by day for the microfibers continually released into the oceans by the dressings treated by the washing-machines as well as the city dust road markings, fertilizers and other chemicals which end up every day in the environment’ land and air (Figure 3); [3,22,23]. In conclusion regarding the 2.01 billion tons of municipal waste generated worldwide each year and expected to grow to 3.40 billion tons by 2050 around 14 million tons are due to microplastics accumulated on the ocean floor while 1.5 million tons enter into the oceans annually also [22-25]. Unfortunately, in 2019 only 9% of all plastic waste ever produced has been recycled while about 12% has been incinerated and at least 79% was mismanaged ending up in landfills, oceans or the natural environment [26]. However, waste composition differs across income levels, reflecting different production and consumption [27]. Thus, high-income countries with an high income level of 96%, are generating 51% of dry waste (i.e. plastic, paper, cardboard, metal and glass) while middle- and low-income countries with an income level between 82 and 39% are generating 57% of food and green waste ,so that the recycled materials result different (Figure 4 & 5); [27]. At this purpose, its to remember that the daily per capita waste generation in high-income countries is projected to increase by 19% by 2050 compared to low- and middle-income countries where it is expected to increase more than three times [27]. Moreover, it has been estimated that in 2016 the 2.1 billion tons of carbon dioxide (CO2) equivalent GHG emissions generated as wastes is supposed to increase to 2.38 billion tons by 2050. Additionally, it has to be underlined that 26% of these emissions (i.e.52.3 billion tons of CO2 equivalent) are due to food production and consumption including supply chain (18%) livestock & fisheries (31%) crop production (27%) and land use (24%) [28]. At this purpose, it is to remember that the global food and textile systems, contributing to the use and consumption of plastics are among the main cause of the environmental economic and health problems affecting the society because of the release of gas emissions during their production and distribution processes [20-22]. It is not to be forgotten that clothes footwear and household textiles are responsible for many of the GHG emissions and landfills waste as well as for about 20% of water pollution [29]. It has been estimated that the European fashion industry in 2015 was responsible for 10% of global carbon emissions (i.e.654kg of CO2 per person) causing the release of 79 billion cubic meters of water. Moreover, due to the washing and laundering of clothes made by natural and synthetic polymers 0.5 million tons of micro fibres are released in the oceans every year accounting for 35% of primary microplastics released into the environment (Figure 6); [29]. Thus, the need to change the way of producing and consuming finding solutions that enable consumers to change their behaviours in terms of buying clothes cosmetics and food in the sufficient and right quantity for preventing incorrect storage and compact waste. Therefore, it should be necessary to drop across the linear economy based on the taking, making and producing waste adopting the circular economy based on redesigning, reducing, reusing and recycling goods [30]. In conclusion our proposed to use natural polymers for producing biodegradable t issue- carriers, innovative cosmeceuticals, nutraceuticals and packaging might be the best way to beat waste and save environment and human health from the plastics waste with its content of toxic chemicals [31]. Plastics on the one hand has transformed the everyday life bringing many social benefits while on the other hand their usage, disposal and durability caused accumulation of waste in the natural landfills and marine environment with the consequent ingestion by the human food chain of the content they have in toxic chemicals including phthalates polyvinyl chloride, bisphenol-A and other ingredients as previously reported. Therefore, the necessity to go on by more research studies deeply verifying the effects these compounds could have on animal and human population [31]. Consequently, the necessity to use more bioplastics and natural polymers such as the suggested chitin and lignin to make biodegradable, plasticfree nanocomposite complexes and non-woven tissues for realizing advanced medications cosmeceuticals and nutraceuticals as reported below [7-16,32-34].

Figure 3:Microplastic debris recovered into land, air and ocean (By courtesy of OECD [3]).

Figure 4:Per cent of global waste collection level of high, middle and low income Countries (by courtesy of the World Bank Group [27]).

Figure 5:Per cent of different waste material by courtesy of the World Bank Group [27]).

Figure 6:Synthetic microfibers from textiles released every year in oceans (Courtesy of EEA. [22,29]).

Biopolymers, Block Polymeric Complexes and Tissue-Carriers

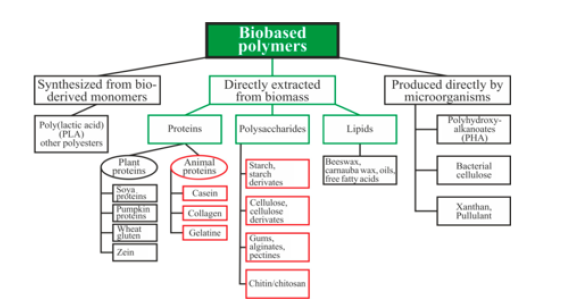

A major use of natural polymers and natural-based polymers

is the request of the majority of scientists and consumers looking

for a greater production and use of bio-plastics and biodegradable

products which obtainable by these ingredients extracted from

food and agro-forestry waste result necessary for safeguarding

the natural raw materials. Therefore, the so called green products

are considered skin- and environmentally-friendly because safe

for humans may reduce the negative environmental impact of the

traditional plastics also [35]. By the biopolymers, its possible to

obtain monomers and composite polymeric compounds necessary

to make biodegradable micro/nanoparticles and tissue-carriers

useful for marking sustainable clothes, agricultural films and

innovative medical devices, smart cosmeceuticals, nutraceuticals

and different biodegradable packaging materials. In conclusion,

the biopolymers obtainable by the valorization of agro-food waste

result useful to reduce the use of petrochemical resources with the

many derived-made compounds [35]. But how Biopolymers may

be classified and produced? They are polymeric macromolecules

that produced by living organisms may be directly extracted from

organic biomass-waste and renewable resources or synthesized

from chemical polymerization of monomers produced by

genetically modified microorganisms (Figure 7); [35]. Biopolymers

obtainable in different shapes (linear, branched and cross-linked)

and sizes (micro, nano) and from different sources, may have

different functions (Figure 1 & 7). However, naturally occurring or

man-made all the polymers are based on differing monomeric units

covalently bonded to form larger structures made by repeating

building blocks. Generally, they are classified in three main classes

as reported in Figure 7; [35]. Thus, while synthetic polymers contain

a random molecular mass (polydispersity), the natural ones are all

alike with the mass containing similar sequence and number of

monomers (mono dispersity). Regarding their production, these

macromolecules may be obtained from different sources (i.e.

agricultural, forest and marine) and by different routes such as:

1. Direct extraction of biopolymers from plants and fishery

waste (i.e. polysaccharides and macromolecules (starch. lignin,

chitin etc)

2. Chemical processes: hydrolysis of biomass to obtain

monomers (sugars) transformed in turn in building blocks such

as polylactate and polyesters.

3. Direct polymerization of monomers into a finished

product by microorganisms, including bacterial cellulose and

polyhydroxyalkanoates.

Figure 7:Biobased polymers (courtesy of Balart et al. [35]).

However, natural polymers such as chitin and lignin have attracted much attention because for their easy availability from waste, low cost, unique properties such as bio-degradability, bio-activity, bio-compatibility, film-coating ability, non-toxicity are considered skin- and environmentally friendly [35,36]. Moreover they result of great utility because, avoiding the use of non-biodegradable petrol-derived products and reducing the consumption of natural resources may increase the sustainable production of biobased polymers and goods [37]. For all these reasons biopolymers have a wide range of use by many industries including, clothing, food, cosmetics and medical products also because useful to make specialized scaffolds which easily interfacing with biological systems may act as support of human cell to build up different biomatrices [36]. Unfortunately, biopolymeric materials for textiles are not competitive for industrial applications because of their limited production-volumes with high cost. However, it seems possible to create innovative fashion combining biopolymers with other synthesized hydrocarbon-polymers by the use of the socalled green chemistry [37].

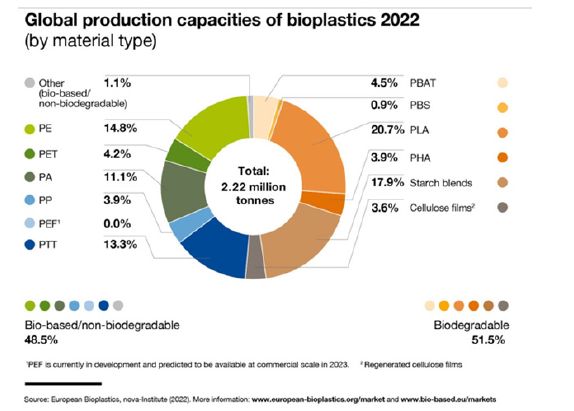

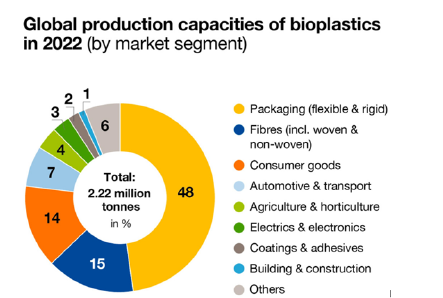

Tissue-Carriers

Regarding films and non-woven tissues to be used as carriers and packaging for medical devices,food, nutraceuticals and cosmeceuticals. Our research group realized micro nanoparticles (NPs) and innovative matrices utilizing chitin nanofibrils and nano lignin [7-16]. Thus as previously reported the biopolymers chitin nanofibrils (CN)and nano lignin (LG) have been mixed by the ionotropic gelation method in water solution to obtain the CNLG block polymeric micro/nanoparticle complexes which bound successively to the biodegradable tissues fibers have been utilized as novel active carriers (Figure 2); [6-8]. These smart innovative carriers applied on the skin and easily hydrolyzed by the human enzymes to their natural active polymers (chitin and lignin) have shown to possess interesting antioxidants, anti-inflammatory, immune modulates and skin-repairing activities [6-16,32-34]. Moreover, it’s to underline that both the polymers have been used at their micro/nano dimension because for their higher surfacearea- to-volume ratios, compared to the bulk materials. This size has shown to improve the effectiveness of the final product [6- 26,32-34]. It has been shown that the topical administration of micro/ nano scaled delivery systems has the possibility to combine the advantage of a deeper penetration with a better local targeting being also cause of an increased effectiveness, differentiating the relative activities [37]. Thus on the one hand it has been used chitin nanofibrils, because the polymer at less than 40 milli microns size has shown to have an anti-inflammatory response by the production of the anti-inflammatory Interleukine-10 (IL-10),while its intermediate at 40-70millimicron size induced production of proinflammatory cytokines including IL-17 and IL-23 [38]. On the other hand, it has been used the active ingredient glycyrrhizin acid that encapsulated into the innovative carrier CN-LG complex has show to increase its solubility, greatly ameliorating bioavailability and the pharmacological effectiveness, according to the activity shown when carried by micro emulsions [39]. At this purpose the different active ingredients, encapsulated into the CN-LG complexes have been selected and used to characterize activity, effectiveness and safeness of the realized tissues [9-14]. Therefore in our opinion, it might be possible to partially solve the many problems created by the excessive production and use of non-biodegradable plastics fossil-made products also, becoming to utilize the proposed tissuecarriers and increasing the utilization of the so-called biodegradable bioplastics to produce biodegradable packaging. Fortunately, it has been reported from different research companies that the new natural- derived polymers ranged in 2022 a global production of 2.2 million tones, should increase significantly to 6.3 million tons by 2027 by an estimated compound annual growth rate (CARG) between 10 and 23%. However, just to better understand this market it is necessary to know that bioplastics are represented by two groups of different composites polymers: biodegradable plastics including polylactic acid (PLA), polyhydroxyalcanoates (PHA) starch blends and others that account for more than 51% and non-biodegradable plastics such as biobased PE (polyethylene) PET (polyethyleneterephtalate) and others accounting for 48.5% of the global bioplastics as reported in Figure 8; [40]. With a view of the regional capacity development 25% of the bioplastics global production is actually located in Europe while Asia-Pacific, representing today more than 41%, has been predicted to increase its productive capacity to almost 63% by 2027, becoming the major worldwide production hub [40,41]. Regarding the market production by segment, bioplastics are used prevalently to make, catering, consumer goods, electronics, agriculture/horticulture products and coatings, as well as textiles, automotive& transport or building & construction all materials and packaging that represent the more increasing segments (Figure 9); [40]. Fortunately, for maintaining an environmental equilibrium with an healthy life, it is useful to know that land, used to produce bioplastics will remain at very low levels (0.8 million ha in 2022 and 2.9 million ha in prevision by 2027) showing no competition with the necessity for the global agricultural area including feedstock for pasture (3.3 billion ha) food & feed (1.4 billion ha) biofuels (200 million ha) and relative produced materials (106 million ha). Unfortunately on other hand, the global plastics production valuated in 2021 to be more than 390 million tons has been projected to grow by a CAGR of 3.7% during the forecast period 2022-2030 while on the other hand bioplastics represent today less than 1% only. For all these reasons and in our opinion the proposed final cosmeceutical-tissues could represent an interesting approach for utilizing biodegradable products being made by natural biopolymers and packed by the same biodegradable specialized paper used for the medical gauze. Therefore, these smart tissue-carriers are not only 100%made by biodegradable polymers but also embedded by natural and different active ingredients selected to realize the innovative skinand environmentally-friendly cosmeceuticals and nutraceuticals. They have been conceived to make the same products requested from consumers who are dreaming to range beauty and health by the so called Beauty from within [10,14.42]. They are made of biopolymeric carriers and natural active ingredients free of water preservatives, emulsifiers, fragrances and chemicals, having shown high effectiveness and safeness also [10,32-34,42].

Figure 8:Global production capacity of bioplastics 2022 by material type (Courtesy of European Bioplastics [40]).

Figure 9:Global bioplastic production by market segment by 2022(Courtesy of Europea Bioplastics [40]).

Conclusive Remarks

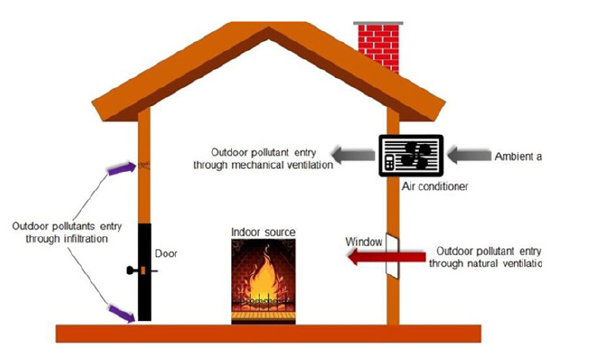

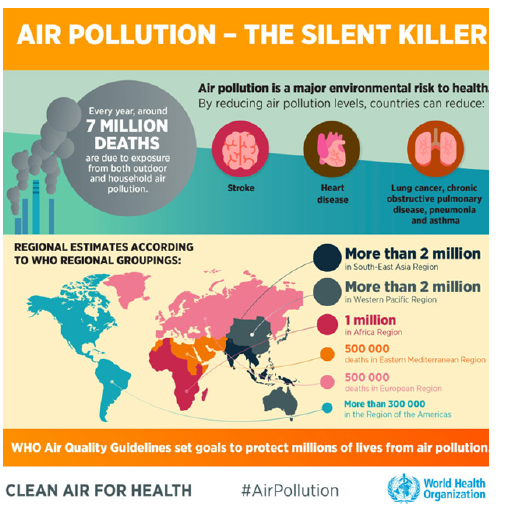

Consumers, especially after the COVID-19 pandemic and the more intensive use of skin care want to know how they’re spending their money in the right way. Consequently, they are increasingly prioritizing and purchasing products characterized for effectiveness and safeness and first of all recommended from either dermatologist plastic surgeons and all the doctors working in the aesthetic-healthy field [42,43]. People are looking and willing to pay more for natural skin- and eco-friendly products rich not only of active ingredients and known for effectiveness and safeness, but because promoted and tested by scientific studies [42,43]. According to these requests, we are proposing the use of innovative cosmeceutical-tissues which may be applied on the skin and/or taken by oral route as functional food or diet supplements (nutraceuticals) being able to enhance the skin wellbeing and the global-healthy appearance [33,34]. Consumers desire that these innovative products should have the possibility to protect themselves against the global ageing effects respecting and maintaining the skin integrity by a combined immune boosting-activity balanced by the micro bioma activity also [10-16]. Additionally, people are demanding for an integrated wellness where they may work and play in peace. Thus, living in an healthy environment. Therefore, the necessity to realize the circular green economy slowing down or possibly eliminating the actual air and water pollution for going versus production and consumption at a zero waste, characterized by a clean and healthy environment. Air pollution is associated worldwide with about 3.3 million premature deaths per year with the indoor ones causing nearly 4 million deaths while the water pollution is the cause of 80% of diseases and 50% of children’s deaths [44-46]. At this purpose it isn’t to be forgotten that indoor air pollutants representing around 50-80%of human exposure to nano particles (NP)(10,000 to 240,000 NP/mL air) compared to outdoor air pollutants(estimated 10,000 to 50,000 NP/mL air) (Figure 10); [44-48] are provoking every year around 7 million of global deaths (Figure 11); [49].Thus the necessity to produce goods according to the circular economy rules utilizing skinand eco-friendly products as the proposed cosmeceuticals- and nutraceuticals-tissues at zero waste and plastic free [8,32,33,50,51]. These cosme-nutraceutical products, made by smart biodegradable polymers used to manufacture innovative carrier-tissues seem to provide nutritional and protective benefits to skin and mucous membranes, because of the similarity of their scaffolds with the natural ECM components. Consequently, they may be used to revitalize and rejuvenate the skin and body’ structures, combining the topic effectiveness to the and systemic ones. Therefore these specialized and well-studied tissue-carriers, made by human and eco-friendly biopolymers alternative to petrol-derived ones, result useful for manufacturing the reported active cosmeceuticals and nutraceuticals [9-11,32-34].At this purpose the selected natural polymers [51,52] including chitin and lignin complexed each other at their nano size to form micro/nano particles bound to the fiber-tissues seem to represent the best option to produce biodegradable and eco-compatible carriers alternative to the actual emulsions for producing cosme-nutraceuticals [11-14].Therefore these innovative skin- and environmentally-friendly products result in line with the request of consumers, who are looking for nature- derived innovative and advanced products considered necessary to obtain the so-called “Beauty from Within “[11-14,53- 59]. As previously reported the realized tissue-carriers embedded by the right “actives” may be useful to “encapsulate” antioxidant and immunomodulant ingredients useful to help the skin to restore and balance some of its structures altered by the aggression of the environmental xenobiotic chemicals and UV radiations. On the one hand, the many -OH groups present on chitin-lignin block polymeric micro/nano particles establishing hydrogen bonds with molecules of water could contribute to maintain the skin hydration and the rebalancement of the immune system stimulating the pro- collagen synthesis. On the other hand, the nano-sized active ingredients, such as glycyrrhyzic acid or lutein, embedded into the polymeric tissues may improve bioavailability, stability and protection of the target tissues, acting as antioxidant and anti-inflammatory ingredients [6-16,60-63].They, easily released from the carrier because of their nano dimension may penetrate throughout the skin layers having the possibility to modulate and regenerate the cells functions [13,14,60-63].In conclusion, the use of the reported innovative carrier-tissues, embedded by selected biopolymers and made by a novel safe and patented technology open the possibility to manufacture biodegradable clothes, cosmetics, food and other goods. They avoiding the production of waste and toxic compounds can help to maintain the earth’ natural raw materials and biodiversity for the future generations. Moreover, the realized nutri-cosmeceuticals result skin- and environmentally-friendly having shown to possess sustainability, effectiveness, safeness and transparency having also the capacity to connect appearance and beauty with a body global health. In conclusion, the aim of our future research group is and will be focused on the use of selected biopolymers and active ingredients obtained by the food and agroforestry waste to make innovative smart carriers.

Figure 10:Outdoor and indoor pollutants (Courtesy Leung [46]).

Figure 11:Air pollution’ Deaths (Courtesy of WHO [49]).

References

- Barboza LGA, Vethaak D, Lavorante B, Lundebye RBO, Guilhermino AK (2018) Marine microplastics debris: An emerging issue fir food security. Marine Pollution Bulletin 133: 336-348.

- FAO (2023) Food wastage footprint, impacts on natural resources 2023. UN.

- OECD (2023) Plastic leakage and greenhouse gas emissions are increasing.

- Priya S, Batra U, Samshritha RN, Sharma S, Chaurasiya A, et al. (2022) Polysaccharide-based nanofibers for pharmaceutical and biomedical applications: A review. Int J Biol Macromol 218: 209-224.

- Cumpstey I (2013) Chemical modification of polysaccharides. ISRN Org Chem 417672.

- Morganti P, Morganti G and Coltelli MB (2023) Natural polymers and cosmeceuticals for a healthy and circular life: The examples of chitin, chitosan and lignin. Cosmetics 10: 42.

- Morganti P (2022) Biopolymers to save human health and environment Chitin and lignin. Biomedical Research & Sciences 3(12): 1507-1510.

- Morganti P, Chen HD, Morganti G (2020) Nano cosmetics: Future perspective. pp: 455-481.

- Morganti P, Morganti G, Danti S, Coltelli MB, Donnarumma G (2021) Biodegradable nano materials for cosmetic and medical use. pp 62-73.

- Morganti P (2009) Natural products work in multiple ways. pp: 95-111.

- Morganti P, Morganti G, Yudin VE, Chen HD (2021) Chitin and lignin: Old polymers and new bio-tissue-carriers. J Dermatology and Dermatitis 6(3).

- Morganti P, Morganti G, Coltelli MB, Yudin VE, Chen HD, et al. (2022) Non-woven tissues as novel cosmetic carriers for a green beauty. Adv Environ Eng Res 3(2).

- Tishchenko G, Morganti P, Stoller M, Kelnar I, Mikesova J, et al. (2019) Chitin nanofibrils-chitosan composite films: Characterization and properties. pp: 191-226.

- Morganti P, Morganti G, Memic A, Coltelli MB, Chen HD (2021) The new renaissance LG beauty and wellness through the green economy. Latest Trends in Textike & Fashion Design 4(2).

- Morganti P, Morganti G (2021) Circular and Green Economy: Which is the Difference. pp: 17-40.

- Morganti P, Tishchenko G (2021) Circular Economy for a Healthy Environment. pp: 97-112.

- EC (2019) Cosmetic products regulation no 1223/2009 and EU regulation no 665/2013.

- WG (2017) Technical document on cosmetic claims.

- EC (2019) Guidelines for cosmetic product claim substantiation, revising and expanding the colioa guidelines on efficacy (2001/rev.2008).

- Pironti C, Ricciardi M, Motta O, Miele Y, Proto A, et al. (2021) Microplastics in the Environment: Intake through the Food Web, Human Exposure and Toxicological Effects. Toxics 9(9): 224.

- PSF (2023) Plastic the Hidden Beauty Ingredients 2022.

- EU (2023) Microplastics from textiles: towards a circular economy for textiles in Europe 2021.

- Haap J, Classen E, Berlinger J, Micheels S and Gutmann JS (2019) Microplastics fibers released by textile Laudry: A new analytical approach for the determination of fibers in effluents. Water 11: 2088.

- Boucher J, Friot D (2023) Primary microplastics in the oceans, Union for the Conservation of Nature.

- Barret J, Chase Z, Zhang J Banaszak Holl MM, Willis K, et al. (2020) Microplastic pollution in deep-sea sediments from the Great Australian Bight. Front Mar Sci 7: 576170.

- OECD (2023) Global plastics outlook database.

- WB (2023) Trends in solid waste management.

- Ritchie H (2019) Food production is responsible for one-quarter of the world’s greenhouse gas emissions. UK.

- EU (2023) The impact of textile production and waste on the environment (infographics).

- EMAF (2023) From linear to circular economy: A global learning program.

- Thompson RC, Moore CJ, Saal FS, Swan SH (2009) Plastics, the environment and human health: Current consensus and future trends. Phil Trans R Soc B 364: 2153-2166.

- Morganti P, Coltelli MB (2021) A new carrier for advanced cosmeceuticals. Cosmetics 6: 10.

- Morganti P, Morganti G, Colao C (2019) Bio-functional textiles for aging skin. Biomedicines 7(3): 51.

- Morganti P, Morganti G, Coltelli MB (2019) Chitin nano materials and nanocomposites for tissue repair. pp: 523-544.

- Balart R, Garcia GD, Fombuena V, Quiles CL, Arrieta MP (2021) Biopolymers from natural resources. Polymers 13(15): 2532.

- Sun Y, Bai Y, Yang W, Bu K, Tanveer DK, et al. (2022) Global trends in natural biopolymers in the 21st Century: A sciento metric review. Front Chem 10: 915648.

- Ahmad MZ, Mohammed AA, Algahtani MS, Mishra A, Ahmad J (2022) Nanoscale topical pharmacotherapy in management of psoriasis: Contemporary research and scope. J Funct Biomaterial 14(1): 19.

- Lee CH, Da Silva CA, Lee JY, Hartl D, Elias L (2008) Chitin regulation of Immune responses: An old molecule with new roles. Curr Opinion Immunol 20(6): 684-689.

- Pashkina E, Evseenko V, Dumchenko N, Zelikman M, Aktanova A, et al. (2022) Preparation and characterization of a glycyrrhizinc acid- asked drug delivery system for allergen-specific immunotherapy. Nanomaterials 12(1): 148.

- EU (2023) Bioplastics market data.

- Morganti P, Morganti G, Gagliardini A and Lohani A (2021) From Cosmetics to Innovative Cosmeceuticals- non-woven tissues as new biodegradable carriers. Cosmetics 8(3): 65.

- Jindel S (2023) Beauty trends. UK.

- Douglad A (2023) Connecting Immune Health with Beauty & Wellbeing. UK.

- Aravijskaia E, Berardesca E, Bieber T, Gontijo G, Sanchez VM, et al. (2019) The impact of airborne pollution on skin. J Eur Acad Dermatol Venereol 33(8): 1496-1505.

- Lin L, Yang H, Xiaocang X (2022) Effects of water pollution or human health and disease heterogeneity: A review. Front Environ Sci 10: 880246.

- Leung DYC (2015) Indoor-outdoor air pollution in urban environment: Challenges and opportunity. Front Environ Sci 2: 69.

- Nohynek G (2011) Nanotechnology and the skin: A risk to human health.

- Morganti P, Morganti G and Palombo M (2021) Research & innovation for sustainable products: Polysaccharides for a smart circular economy at zero waste. Clin Res Clin Truals 3(3): 037.

- WHO (2023) Household air pollution.

- Morganti P (2019) Bio nano technology to save the environment.

- Morganti P (2022) Bio functional textiles for an ageing skin.

- Baranwal J, Barse B, Fais A, Delogu GL, Kumar A (2022) Bio polymer: A sustainable material for food and medical applications. Polymers 14(5): 983.

- Lanteri S (2023) The new consumer mindset. UK.

- Anderson K, Gleason AJ (2023) Special Report: 5 Well Beauty Trends.

- Pickford A (2018) Wellness is the nexus of health, food and beauty.

- Morris T (2021) New looks for personal care.

- Gerstel E (2022) Fostering inclusive beauty.

- Alexander G (2022) A year of innovation in facial skin-care. UK.

- Nahal L, Sarker SD (2017) Importance of nanotechnology in drug delivery. J Pharm Res 1(5): 000130.

- Coltelli MB, Dabti S, Trombi L, Morganti P, Donnarumma G, et al. (2018) Preparation of Innovative skin compatible films to release polysaccharides for biobased beauty masks. Cosmetics 5(4): 70.

- Danti S, Trombi L, Fusco A, Azimi B, Lazzari A, et al. (2019) Chitin nanofibrils and nano lignin as functional agents in skin regeneration. Int J Mol Sci 20(11): 2669.

- Morganti P, Morganti G, Coltelli MB (2019) Chitin nanomaterials and nanocomposites for tissue repair. pp: 523-544.

- Morganti P, Morganti G, Coltelli MB (2020) Skin and pollution: The smart nano-based cosmeceutical-tissues to save the planet ecosystem. Nano cosmetics, pp: 287-304

© 2024 Pierfrancesco Morganti. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)