- Submissions

Full Text

COJ Technical & Scientific Research

Sensory Analysis of Olive Oil

Shaker MA1* and Basuny MA2

1Food Technology Research Institute, Agricultural center, Giza, Egypt

2Biochemistry Department, Faculty of Agriculture, Beni-Suef University, Egypt

*Corresponding author: Shaker MA, Oils & Fats Department, Food Technology Research Institute, Agricultural Center, Giza, Egypt

Submission: June 16, 2020; Published: August 18, 2020

Volume3 Issue1August, 2020

Abstract

Sensory analysis of oil, meaning the official organoleptic assessment of olive oil respectively the panel test (PT), relies on the standards of the International Olive Council (IOC), furthermore as on the Regulation (EC) 640/2008 of the European Commission (EC). These regulations lead to the classification of oil as extra virgin (EVOO), virgin (VOO) or Lampante, that but isn’t comfortable to obviously discriminate between totally different quality levels inside the grade EVOO. This chapter was meted out to the study sheet for sensory analysis; look at and methodology conditions, classification of olive oil. quality indices, polyphenols, tocopherols, volatile compounds, effects of selection, extraction system and storage conditions corresponding to packaging sort and temperature variation on the sensory analysis of virgin oil.

Keywords: Olive oil;Sensory attributes;Volatile compounds; Quality indices

Introduction

Sensory analysis is a necessary technique to characterize food and investigate shopper preferences. International cooperative studies, supported by the International oil Council (IOC) have provided a sensory written methodology for VOOs, known as the COI Panel test. Such an approach relies on the judgments of a panel of assessors, conducted by a panel leader, UN agency has comfortable information and skills to organize sessions of sensory analysis, encourage judgment, method information, interpret results and draft the report. The panel typically consists of a bunch of eight to twelve persons, elect and trained to spot and live the intensity of the various positive and negative sensations perceived. Sensory assessment is meted out in step with written rules, in a very specific tasting space, mistreatment controlled conditions to reduce external influences, employing a correct tasting glass and adopting each a selected vocabulary and a profile sheet that features positive and negative sensory attributes (Dec-23/98-V/2010). assortment of the results and applied mathematics elaboration should be standardized (EEC Reg. 2568/91, EC Reg. 640/08). the color of VOO, that isn’t considerably relating to its quality, could turn out expectations and interferences within the flavor’s perception part. so as to eliminate any prejudices which will have an effect on the smelling and tasting phases, panelists use a dark-colored (blue or ambercolored) tasting glass. normally oil is outlined on the idea of its sensory characteristics. world organization (EU) rules establish the organoleptic quality of virgin oil by suggests that of a panel take a look at, evaluating positive and negative descriptors (EU regulations). For the organoleptic assessment, many volatile compounds square measure thought-about because the main accountable for negative and positive attributes. Volatile compounds, either major or minor, square measure crucial to oil quality; even once gift below their locative threshold, they’ll still be vital to know their formation and degradation pathways and supply helpful quality marker data.

Definition and Classification of Oil

Virgin oil is that the oil obtained from the fruit of the fruit tree either by mechanical or different physical suggests that beneath conditions, significantly thermal conditions, that don’t cause alterations within the oil, and that has not undergone any treatment nevertheless laundry, decantation, activity and filtration. the assorted categories of oil as divided by European legislation square measure reported. The subdivisions in several categories square measure supported the degree of acidity furthermore as different analytical parameters and sensory analysis indices.

a) Extra virgin oil: is that the virgin olive oil that incorporates

a free acidity, expressed as oleic acid, of less than zero.8 gram per

one hundred grams, and therefore the sensory characteristics with

median defects is three.5 and therefore the median of fruitiness

bigger than zero.

b) Virgin oil: is that the virgin olive oil that incorporates a

free acidity, expressed as monounsaturated fatty acid, of less than

a pair of grams per one hundred grams and therefore the sensory

characteristics with median defects bigger than zero, however

lower than or capable a pair of.5 and therefore the median of

fruitiness bigger than zero.

c) Lampante oil: is that the virgin olive oil that incorporates

a free acidity, expressed as monounsaturated fatty acid, of over a

pair of grams per one hundred grams and therefore the sensory

characteristics with median defects bigger than three.5 or if the

median defects is a smaller amount than or capable three.5 and

therefore the median of fruitiness is zero. Such oil is meant for

processing functions.

d) Refined oil: is that the olive oil obtained from lampante

olive oils by processing ways that don’t cause alterations within

the initial glyceridic structure, that incorporates a free acidity,

expressed as monounsaturated fatty acid, of lower than or capable

zero.3 grams per one hundred grams.

e) Blended oil: is that the oil consisting of a mix of refined

oil and virgin olive oil that incorporates a free acidity, expressed as

monounsaturated fatty acid, of lower than or capable one gram per

one hundred grams. It is used for human consumption.

f) Crude olive-pomace oil: is that the oil obtained by

treating olive pomace with solvents, to the exclusion of oils obtained

by re-esterification processes and of any mixture with oils of other

forms. This oil is meant for processing with a read to its use in food

for human consumption.

g) Refined olive-pomace oil: is that the oil obtained

from crude olive-pomace oil by processing ways that don’t cause

alterations within the initial glyceridic structure, that incorporates

a free acidity, expressed as monounsaturated fatty acid, of lower

than or capable zero.3 grams per one hundred grams.

h) Olive-pomace oil: is that the oil comprising the mix

of refined olive-pomace oil and virgin oil that incorporates a

free acidity, expressed as monounsaturated fatty acid, of lower

than or capable one gram per one hundred grams. It is used for

consumption, but in no case should this blend be called olive oil.

One vital thought is that the primary 2 oils square measure the most effective for human consumption thanks to them being inside the set parameters, once obtained directly from the olive press. The third sort of oil can’t be consumed till it’s been corrected, which provides the fourth sort of oil. A small amount of extra-virgin olive oil or virgin olive oil is added to this rectified oil and is known as olive oil.

Olive oil tasting attributes

Olive oil as judged by consultants shows a mess of either positive or negative characteristics.

Positive attributes:

a. Almond: light-weight smell recalling that of contemporary or

dried almond.

b. Apple: A sensation recalling this fruit.

c. Artichoke: A smell recalling raw artichoke.

d. Astringent: A puckering sensation within the mouth created

by phenol.

e. Bitter: this is often a most popular characteristic style of olive

oils, if it’s not too extremely intense.

f. Fruity: vary of smells (dependent on variety) characteristic

of oil from healthy contemporary fruit, inexperienced or

ripe, perceived directly and/or retro nasally. Fruitiness is

qualified as inexperienced if the vary of smells is comparable

to inexperienced grass. Fruitiness is qualified as ripe if the vary

of smells is comparable to ripe fruit and is characteristic of oil

from inexperienced and ripe fruit.

g. Green grass: A sensation recalling that of freshly cut grass.

h. Hay: A smell recalling that of dried grass.

i. Spicy: A touch sensation kind of like that of a light-weight

capsicum pepper plant, particularly within the back of the

throat, which may force a cough.

Negative attributes:

a) Brine: Salty style of oil made up of brined olives.

b) Coarse: A touch sensation within the mouth thanks to texture

of oil.

c) Cucumber: Off flavor from prolonged storage, significantly in

tin.

d) Dreggiest: Odour of heat grease and is caused by the poor or

lack of the decanting method.

e) Earthy: This term is employed once oil has no inheritable a

musty wet odour as a result of it’s been ironed from unwashed,

muddy olives.

f) Esparto: Hemp-like smell no inheritable once olive paste has

been unfold on Esparto mats. Smells could dissent in step with

whether or not the mates square measure inexperienced or

dried.

g) Hemp: Caused by the utilization of filtering panels, those

aren’t absolutely clean, and recollect hemp.

h) Flat: Oils that have lost their characteristic aroma and have

neither style nor smell.

i) Frozen: Thanks to olives that are exposed to phase change

temperatures. Once soft-bo, this oil provides off terribly

unpleasant odours.

j) Fusty: thanks to olives chemical action in piles whereas in

storage waiting to be ironed.

k) Grubby: Smell imparted by grubs of the olive fly. The smell is

each rotten and putrid at an equivalent time.

l) Heated: Prolonged heating throughout extraction process.

m) Muddy: Typical odour of oil that has been keep to long on its

own sediment.

n) Musty: musty smell from olives being keep too long before

pressing.

o) Metallic: Oils processed or keep with extended contact to

metal surfaces.

p) Rancid: recent oils that have started oxidizing thanks to

exposure to light-weight or air.

q) Vegetable water: Oils that have absorbed the unpleasant

odours and flavours of the vegetable water once pressing that

they need remained up to date for too long.

r) Wine-vinegar: Typical odour of wine or vinegar thanks to

fermentation of olives.

Factors Moving Sensory Properties of Oil

Processing of healthy olives

When the common olive fly (Bactrocera oleae) attacks olives

(from the start of summer to the beginning of harvesting), harm

happens as a results of larval growth: oils from broken fruits

show changes in each volatile and phenolic resin compounds that

influence negatively the sensory properties and aerobic stability

of the merchandise, particularly throughout oil storage (polar

phenols have a basic role as antioxidants throughout storage).

The dangerous style thanks to these changes caused by the olive

fly is accepted as a grubby defect [1,2]. so as to get a top-quality

oil, it’s necessary to method olives that aren’t ripe. the utilization

of fruits that have part degraded tissues cause a rise in catalyst and

microorganism activities and aerobic reactions; so, the made oil

most likely are characterized by a higher free acidity and perceivable

sensory defects. once olives square measure accumulated in piles

for several days, the warm temperature and humidness within

the mass promotes proliferation of bacterium, yeasts and moulds,

manufacturing undesirable fermentation and degradation that

create to specific volatile molecules accountable for unpleasant

odours (i.e. winey, fusty and mouldy). Winey, the standard pungent

sensory note perceptible in oils made by olives keep in piles or

in jute sacks for many days, arises from alcoholic fermentation:

eubacteria and Acetobacter are detected in olives causation

fermentative processes. the most organism found in olives depends

on the length of storage: at the start the Enterobacteriaceae genera

bacteria genus and enteric bacteria prevail, whereas Pseudomonas,

true bacteria and genus Serratia square measure predominant once

longer periods of your time. The activity of those microorganisms

ends up in the presence of low concentrations of synthesis

volatiles and enormous amounts of compounds corresponding

to the branched alcohols thanks to degradation of amino acids

that cause the standard undesirable sensory note called fusty

[3,4]. the foremost bumper class Deuteromycetes found in olives

keep at high humidness square measure many species of the

fungus genus in conjunction with ascomycetes Penicillium; these

organisms oxidize free fatty acids manufacturing primarily alkyl

radical ketones, in distinction to yeasts of the genera fungus, fungus

genus and Pichia that square measure ready to scale back radical

compounds. Enzymes from these microorganisms interfere with

the LOX pathway to provide volatile C8 molecules characterised by

terribly low odour thresholds and scale back some C6 compounds.

This volatile profile is accountable for the musty defect of EVOO.

Variety: The various varieties represent a very important part for

the assembly of additional virgin olive oils, characterized by totally

different organoleptic characteristics.

Cultivation: Techniques (irrigation, fertilization, treatment of

plants, diseases etc.). Among the environmental factors that

influence the standard of the olives and so the oil, each the

temperature and therefore the quantity of water offered have a very

important role, with the primary moving the acidic composition

of the olives, whereas the latter the number of phenolic resin

substances.

Maturity index of the olive fruits: The early harvest typically

provides an additional bitter and spicy oil thanks to the high phenol

content.

Harvest time and storage of the olive fruits: The quality of

the oil is very conditioned by the state of integrity of the olive.

ancient manual gathering techniques avoid damaging the fruit

compared to mechanical ways. Storage of the olives in not terribly

huge crates, avoids AN excessive mass of olives that might either

become crushed or hot, facilitating attacks from micro-organisms

furthermore as chemical reaction and fermentation.

De-leafing and laundry of the olive fruits: Before being processed,

the olives should be cleansed of any superfluous material, together

with leaves, and branches. These square measures all parts which

will negatively influence the standard of the oil.

Pressing extraction of olive oil: The olives square measure

broken throughout the pressing part with the skin and therefore

the pulp being torn furthermore because the stone crushed. The

press can be a traditional pan-mill one, either discontinuous system

or combined with an extraction system so as to hold out continual

activity. These presses will either be hammers or disks. Metal

presses have an additional violent pressing of the olive (above all beat ones) furthermore as a bigger laceration of the skin, giving

a better extraction of the phenolic resin composites and so an

additional bitter and spicy oil that lasts longer.

Storage of oil beneath appropriate conditions: In unfiltered oil,

the low amounts of sugars or proteins that stay for extended times

in oil is hard or degraded by specific anaerobic microorganisms

of the true bacteria genus, fermentation. The filtration of newly

produced oil will avoid this development. it’s far-famed [5-7] that

EVOO incorporates a low quantity of water, and for this reason it

is thought-about as a water-in-oil emulsion [2]. The orientation of

phenolic resin compounds within the interface and therefore the

active surface of water droplets will shield against the chemical

reaction of oil. in step with some researchers [8,9], the steadiness

of unfiltered samples is considerably over that of the corresponding

filtered oils. This coincides with a better total phenolic resin

content in unfiltered oils thanks to a bigger quantity of blended

water. On the opposite hand, higher water levels square measure

expected to favour catalyst chemical action, together with enzyme,

lipoxygenase and polyphenol enzyme activities. Thus, a additional

speedy chemical reaction of unfiltered oil is predicted. Some

authors [10] ascertained that hydrolytic processes occur in parallel

with chemical reaction throughout long run storage.

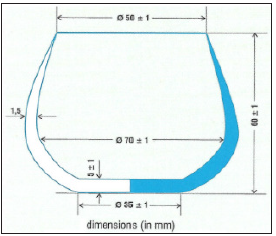

Methodology of Sensory Evaluation

A sensory written methodology for virgin olive oils, known as the COI Panel test, represents the foremost valuable approach to gauge the sensory characteristics of VOO. The use of statistical procedures to analyze data from assessor’s evaluation provides results that can be trusted as well as methods usually adopted in scientific fields. the aim of this international technique is to standardize procedures for assessing the organoleptic characteristics of VOO, and to ascertain the methodology for its classification. this technique, incorporated into rules of the EC Union since 1991, uses, as AN analysis tool, a bunch of 8-12 persons elect in a very controlled manner, UN agency fitly trained to spot and measure the intensity of positive and negative sensations (EEC Reg. 2568/91). a set of ways and standards has been adopted by the International oil Council (IOC or COI) for sensory analysis of olive oils. These documents (IOC/T.20/ Doc. 4/rev.1 and IOC/T.20/Doc.15/rev.2) describe the overall and specific terms that tasters use. a part of the vocabulary is common to sensory analysis of all foods (general vocabulary), whereas a selected vocabulary has been developed unplanned and established by sensory IOC/T.20/Doc.14/rev.2) includes precise recording of the right tasting temperature, furthermore because the dimensions and color of the tasting glass (Figure 1) and characteristics of the room.

Figure 1: Tasting glass.

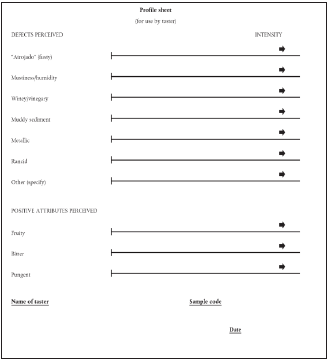

The panel leader is that the person behind for choosing, coaching and observance tasters to determine their level of power in step with (IOC/T.20/Doc.14/rev.2). the quantity of candidates is usually bigger than that required so as to pick out people who have a bigger sensitivity and discrimination capability. Screening criteria of candidate’s square measure based on sensory capability, however additionally on some personal characteristics of candidates. Given this, the panel leader can in person interview an outsized variety of candidates to become accustomed to their temperament and perceive habits, hobbies, and interest within the food field. He uses this data to screen candidates and rejects those that show very little interest, aren’t without delay offered or UN agency square measure incapable of expressing themselves clearly. The determination of the detection threshold of the group of candidates for characteristic attributes is necessary because the “threshold concentration” is a point of reference common to a normal group and may be used to form homogeneous panels on the basis of olfactory-gustatory sensitivity. a range of tasters is created by the intensity rating technique, as described by [11]. A series of twelve samples is ready by diluting a VOO characterized by a really high intensity of a given attribute in AN odorless and tasteless medium (refined oil or paraffin). The panel leader sends out the candidate, removes one in every of the twelve tasting glasses from the series, and places the remaining together; the candidate is named back within the space and is asked to properly replace the testing glass withdrawn from the series by comparison the intensity of this last therewith of the others. The take a look at is meted out for fusty, rancid, tasteful and bitter attributes to verify the discriminating capability of the candidate on the complete scale of intensities. The stage coaching of assessors is important to familiarize tasters with the particular sensory methodology, to heighten individual talent in recognizing, characteristic and quantifying the sensory attributes and to enhance sensitivity and retention with regards to the assorted attributes thought-about, so the top result’s precise and consistent. additionally, they learn to use a profile sheet (Figure 2).

Figure 2: Profile sheet for VOO assessment currently adopted by the EU (EC Reg. 796/02).

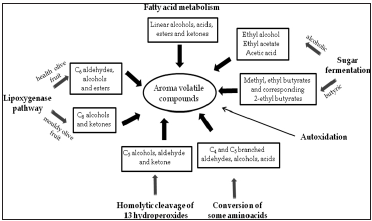

Biosynthesis of the Volatile Compounds of Olive Oil

The wide range of volatile compounds found in top quality virgin

oil square measure made through biogenic pathways of the olive

fruit, specifically the lipoxygenase (LOX) pathways , and carboxylic

acid or amino alkanoic acid metabolism, as pictured in (Figure

3) [12]. Besides the contribution of many volatile compounds,

connected with the mentioned pathways, the role of different

compounds, particularly aldehydes derived from auto-oxidation

processes, ought to even be thought-about to the ultimate aroma

of the olive oils [3]. different metabolized product, originated from

potential fermentations, conversion of some amino acids, catalyst

activities of moulds or aerobic processes, square measure closely

connected with off-flavour of virgin oil. As illustrated in Figure

1, many compounds specifically carbonyl compounds, alcohols,

esters and hydrocarbons contribute to the aroma profile of oil [12].

The volatile compounds, accountable for virgin oil aroma, square

measure usually: low relative molecular mass (<300 Da); high

volatility, comfortable hydrosolubility, honest liposolubility and

chemical options to bond with specific proteins [3].

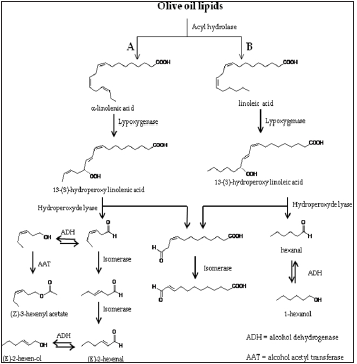

During crushing and malaxation steps, considerable changes, in

oil chemical composition happens accomplished by the activation

of olive fruit enzymes thanks to the inherent disruption of cellular

tissues. Consequently, the LOX pathway is initiated by the reaction

of triglycerides and phospholipids, mediate by acyl group hydrolase

(AH), resulting in the discharge of fatty acids. Lypoxygenases, once

their unleash, become right away active and rework the unsaturated

fatty acids, made by the action of AH, linolenic (LnA) and linoleic

(LA) acids, into their corresponding 9- and 13-hydroperoxides,.

The subsequent cleavage of fatty acids 13-hydroperoxides is

catalyzed by specific hydroperoxide lyases (HPL) resulting in

the formation of C6 aldehydes (Z)-hex-3-enal and hexanal from

linolenic and linoleic acids, respectively) and oxoacids (Figure 4).

The unsaturated sort of C6 organic compound (Z)-hex-3-enal) bear

speedy isomerization to the additional stable (E)-hex-2-enal. The

action of alcohol dehydrogenase (ADH), catalyses the reversible

reduction of open-chain C6 aldehydes to the corresponding volatile

alcohols [13]. Alcohol species square measure any reworked into

esters thanks to the chemical action activity of alcohol acyl group

enzyme (AAT), manufacturing acetates [14]. Many factors, for

example cultivar and extraction method, together with in operation

temperature, seem to play a relevant role on the advance of AAT

activity [15]. once the substrate is LnA, LOX catalyses, besides the

hydroperoxide formation, additionally its cleavage, via AN alkoxy

radical, increasing the formation of stable pent-1,3-diene radicals.

These compounds will suffer dimerization resulting in the assembly

of C10 hydrocarbons (pentene dimmers) or react with a chemical

group gift within the medium, resulting in C5 carbonyl compounds

[16]. the foremost vital fraction of volatile compounds, of topquality

virgin olive oils, contains C6 and C5 compounds, particularly

C6 linear unsaturated and saturated aldehydes. The presence of

different volatile compounds, specifically C7-C11 monounsaturated

aldehydes, C6-C10 dienals, C5 branched aldehydes and alcohols

and a few C8 ketones, in comparatively high concentrations, within

the aroma of virgin oil, is related to unpleasant notes. The presence,

or lack of defects, within the aroma of olive oils is said with the

contribution of the assorted pathways concerned on volatiles

formation.

Figure 3: The main pathways involved in the formation of the volatile compounds.

Figure 4: Lypoxygenase pathway for the formation of major volatile compounds.

References

- Angerosa F, Di Giacinto L, Solinas M (1992) Influence of Dacus oleae infestation on flavor of oils, extracted from attacked olive fruits, by HPLC and HRGC analyses of volatile compounds. Grasas y Aceites 43(3): 134-142.

- Gómez Caravaca AM, Cerretani L, Bendini A, Segura CA, Fernandez GA, et al. (2008) Effects of fly attack (Bactrocera oleae) on the phenolic profile and selected chemical parameters of olive oil. Journal of Agriculture and Food Chemistry 56(12): 4577-4583.

- Angerosa F (2002) Influence of volatile compounds on virgin olive oil quality evaluated by analytical approaches and sensor panels. European Journal of Lipid Science and Technology 104(9-10): 639-660.

- Morales MT, Luna G, Aparicio R (2005) Comparative study of virgin olive oil sensory defects. Food Chemistry 91(2): 293-301.

- Fregapane G, Lavelli V, Leon S, Kapuralin J, Salvador MD (2006) Effect of filtration on virgin olive oil stability during storage. European Journal of Lipid Science and Technology 108(2): 134-142.

- Mendez AI, Falque E (2007) Effect of storage time and container type on the quality of extra-virgin olive oil. Food Control 18(5): 521-529.

- Lozano SJ, Cerretani L, Bendini A, Segura CA, Fernandez GA (2010) Filtration process of extra virgin olive oil: effect on minor components, oxidative stability and sensorial and physicochemical characteristics. Trends in Food Science & Technology 21(4): 201-211.

- Tsimidou MZ, Georgiou A, Koidis A, Boskou D (2004) Loss of stability of ‘‘veiled’’ (cloudy) virgin olive oils in storage. Food Chemistry 93(3): 377-383.

- Gómez Caravaca AM, Cerretani L, Bendini A, Carretero AS, Lercker G, et al. (2007) Effect of filtration systems on the phenolic content in virgin olive oil by HPLC DAD-MSD. American Journal of Food Technology 2(7): 671-678.

- Montedoro GF, Servili M, Baldioli M, Selvaggini R, Miniati E, et al. (1993) Simple and hydrolysable phenolic compounds in olive oils: Note 3 Spectroscopic characterization of the secoiridoid derivates. Journal of Agriculture and Food Chemistry 41(11): 2228-2234.

- Gutiérrez RF, Risco MA, Gutiérrez GQR (1984). Selección de catadores mediante el método de clasificación por intensidad. Grasas y Aceites 35: 310-314.

- Angerosa F, Servilli M, Selvaggini R, Taticchi A, Espoto S, et al. (2004) Volatile compounds in virgin olive oil: occurrence and their relationship with the quality. J Chromatogr A 1054(1-2): 17-31.

- Benicasa C, De Nino A, Lombardo N, Perri E, Sindona G (2003) Assay of aroma active components of virgin olive oils from southern Italian regions by SPME-GC/Ion trap mass spectrometry. Journal of Agricultural and Food Chemistry 51(3): 733-741.

- Kalua CM, Allen S, Bedgood DR, Bishop AG, Robards K et al. (2007) Olive oil volatile compounds, flavour development and quality: a critical review. Food Chemistry 100(1): 273-286.

- Salas J (2004) Characterization of alcohol acyltransferase from olive fruit. Journal of Agricultural and Food Chemistry 52(10): 3155-3158.

- Pizarro C, Tecedor SR, Pérez D Notario, Sáiz JMG (2011) Recognition of volatile compounds as markers in geographical discrimination of spanish extra virgin olive oils by chemometric analysis of non-specific chromatography volatile profiles. Journal of Chromatography A 1218(3): 518-523.

© 2020 Shaker MA. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)