- Submissions

Full Text

COJ Technical & Scientific Research

Emergency Oxygen Provision as a Mechanism of the Motion of an Aircraft through MIRCE Space

Knezevic J*

MIRCE Akademy, Woodbury Park, Exeter, UK

*Corresponding author: Knezevic J, MIRCE Akademy, Woodbury park, Exeter, UK

Submission: June 15, 2020; Published: July 22, 2020

Volume3 Issue1July, 2020

Abstract

The paper addresses the provisioning of emergency oxygen as a physical mechanism of the motion of an aircraft through MIRCE Space [1]. Although the malfunctioning of this process is not frequently observed event, their occurrences could cause significant consequences to airline and flying pubic, impacting the functionability performance of commercial aircraft in the air and on the ground [2]. A full understanding of the mechanisms of these actions is essential for the accurate predictions of the functionability performance of functionable system using MIRCE Functionability Equation. Thus, this paper focuses on the observed physical phenomena or human activities related to the aviation industry and some of them are briefly described and analyzed in the paper. Based on the evidence available recommendations for the reduction of the probability of occurrence of negative functionability events of the emergency oxygen provision are presented.

Preface

“Oh, we humans, never content to remain on the earth that holds us down with its gravity and sustains us with oxygen-laden atmosphere to breathe. No, as soon as we figured out how to ascend into that atmosphere, cheating gravity with hydrogen-filled balloons or artificial wings, we were compelled to claw our way ever higher into the thin, cold air of the stratosphere. But alas, fragile mammals that we are, we could not survive for long-let alone maintain consciousness to control our fabricated aerial conveyances. So, we learned to take containers of our precious gravity-thickened atmosphere aloft with us to inhale through rubber hoses or to encase our bodies in suits and helmets pumped full of that life-fortifying gas” David Esler [3].

Introduction

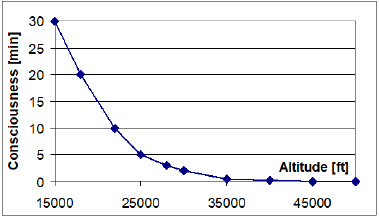

For thousands of years humans believed that air is an element1. Today we know that air is a composition of gases that include nitrogen, oxygen, argon, carbon dioxide and water vapor, together with solid particles such as dust, sand and carbon, with a traces of other gases such as helium, hydrogen and neon. Oxygen makes up approximately 21% of the dry atmosphere, by volume, and is essential for life. As any other tangible material substance, the universal force known as gravity influences air. Gravitational force of Earth shapes and influences all atmospheric processes and causes the density and pressure of air to decrease exponentially with a distance from its surface. As the altitude increases, the consequent decrease in pressure reduces the amount of oxygen the human body can absorb when breathing. At higher altitudes, flight crews and passengers would quickly be overcome by hypoxia, oxygen starvation, followed rapidly by unconsciousness and soon ending with a death. To enable flight at high altitudes, which significantly reduces fuel consumption, either the aircraft cabin has to be pressurized, to replicate the pressure at a lower altitude, or the occupants of the aircraft have to be given supplemental oxygen. A healthy person at sea level has a bodily oxygen saturation of 97%. Medical officials consider that an oxygen saturation of 93% is to be the lower limit of normal functioning. At an altitude of 10,000ft, saturation drops to almost 90%, at 15,000ft it is at 80% and at 25,000ft it is a mere 55% leading to incapacitation. The higher the altitude, the lower the time of useful consciousness, as shown by (Figure 1).

Figure 1: The relationship between the altitude and the time of useful consciousness.

Footnote

1“We live submerged at the bottom of an ocean of the element air, which by unquestioned experiments is known to have weight, and so much, indeed, that near the surface of the Earth where it is most dense, it weighs (volume for volume) about the four-hundredth part of the weight of water, whereas on the tops of high mountains it begins to be distinctly rare and of much less weight.” E. Torricelli (1608-47)

Consequently, commercial aircraft are pressurized to the cabin equivalent of 8,000ft, meaning that passengers sitting in an aircraft cruising at 35,00ft are experiencing the same concentration of oxygen that they would experience at an altitude of 8,000ft. The basics of pressurized aircraft date back to the mid-1930s. Nowadays, on most pressurized aircraft, in cases that the cabin pressurization is lost at the altitude above 14,000 feet, emergency oxygen is automatically provided. The supply of emergency oxygen typically provides enough air to last 12 to 20 minutes, which gives the flight crew sufficient time to descend at the safe altitude where masks are not needed anymore. The main objective of this paper is to examine the emergency oxygen provisioning process as a mechanism of the motion of an aircraft through MIRCE Space, which impacts the functionability work done by an aircraft and resources consumed during a given interval of calendar time. Although the malfunctioning of this process is not frequently observed phenomena, their occurrences could cause significant consequences to airline and flying pubic, impacting the functionability performance of commercial aircraft in the air and on the ground.

MIRCE Science Fundamentals

According to MIRCE Science2, at any instant of calendar time,

a given functionable system3 could be in one of the following two

states [1]

a) Positive Functionability State (PFS), a generic name for

a state in which a functionable system is able to deliver the

expected measurable function(s),

b) Negative Functionability State (NFS), a generic name for

a state in which a functionable system is unable to deliver the

expected measurable function(s), resulting from any reason

whatsoever.

In MIRCE Science a life of a functionable system is defined by

the trajectory of its motion thorough MIRCE Space. Mathematically,

it is a three-dimensional space containing functionability points,

each representing functionability state that a functionable system

could be found in, probability of being in each of these states, at any

instant of the calendar time.

The motion of a functionable system through the MIRCE Space

is generated by functionability actions, which are classified as:

a) Positive Functionability Action (PFA), a generic name

for any human activity or physical phenomena that compels a

system to move to a PFS.

b) Negative Functionability Action (NFA), a generic name

for any physical phenomena or human activity that compels a

system to move to a NFS. Chemical reaction between oxygen

and a fuel is a negative functionability action that generates a

combustible process causing a flame and smoke. Consequently,

oxygen-generating equipment on aircraft presents a significant

fire hazard and has contributed to several aircraft fires, both on

the ground and in flight. For example:

c) On 11 May 1996, ValuJet Flight 592 carried expired

chemical oxygen generators that were improperly prepared

and labelled as company material. Without being designated

as HAZMAT4 they were placed in the cargo hold of a passenger

aircraft, where they caught fire in flight resulting in a crash in

Everglades, Florida, United States, which killed all 110 persons

onboard.

d) On 28 June 2008, ABX Air Flight 1611 a cockpit fire took

place in a B767-200 on the ground before engine start-up.

The National Transportation Safety Board determined that,

“the probable cause of this accident was the design of the

supplemental oxygen system hoses and the lack of positive

separation between electrical wiring and electrically conductive

oxygen system components. The lack of positive separation

allowed a short circuit to breach a combustible oxygen hose,

release oxygen, and initiate a fire in the supernumerary

compartment that rapidly spread to other areas. Contributing

to this accident was the Federal Aviation Administration’s

failure to require the installation of non-conductive oxygen

hoses after the safety issue concerning conductive hoses was

initially identified by Boeing5. “ Both pilots safely evacuated

through cockpit windows, but the aircraft was declared a total

loss.

Footnote

2MIRCE Science comprises of mathematical axioms, equations and methods that enable predictions of expected functionability performance of each feasible option of the future functionability system to be done, based on the time-dependent interactions between: physical properties of consisting components and applied functionability rules regarding operation, maintenance and support processes.

3According to Knezevic [1], functionable system is “a set of mutually related entities put together to do a functionability work in accordance with physical laws and given functionability rules.”

4HAZMAT is an abbreviation for “hazardous materials”, which are substances in quantities or forms that may pose a reasonable risk to health, property, or the environment, like: toxic chemicals, fuels, nuclear waste products, and biological, chemical, and radiological agents

e) On 30 July 2008, Qantas flight between Hong Kong

and Melbourne, carrying 369 passengers and crew, rapidly

depressurized following the forceful rupture of one of the

aircraft’s emergency oxygen cylinders in the forward cargo

hold6. At the time a Boeing 747-438 was cruising at 29,000ft.

Following an emergency procedure, the fight crew descended to

10,000ft and diverted the aircraft to Ninoy Aquino International

Airport, Manila, Philippines, where it landed safely. None of the

passengers or crew sustained any physical injury. The aircraft

was repaired and returned to service in 2009.

f) On 29 July 2011 during the preparation for the EgyptAir

Flight 667 an electrical spark in the presence of the supplemental

oxygen system turned the flight deck of a Boeing 777-200

into a conflagration, at Cairo International Airport (CAI)7. The

captain unsuccessfully attempted to extinguish the fire with the

cockpit fire extinguisher. As the aircraft was on the ground at

the time, the captain ordered an emergency evacuation and all

of 307 passengers and crewmembers escaped without serious

injury. Due to the growing fire in the cockpit the first officer was

unable to use a radio to contact emergency services. Thus, after

exiting the Boeing he stopped a car on a service road to call the

fire department. Although there were no fatalities, the aircraft

was damaged beyond repair.

MIRCE Mechanics is a part of MIRCE Science that focuses on

the scientific understanding of the mechanisms that generate

functionability actions that govern the motion of functionable

systems though MIRCE Space [1]. A full understanding of these

mechanisms is essential for predicting the expected functionability

performance and the cost of resources consumed by a given

functionable system using MIRCE Science Equations.

Description and Certification of Aircraft Emergency Oxygen System

Brief description of the certification regulations related to the aircraft emergency oxygen system is presented here together with the description of their main parts.

Regulations

National regulations for the provision and use of supplemental

or emergency oxygen systems are based on the guidance provided

in Annex 6 of the International Civil Aviation Organization (ICAO)

Standards and Recommended Practices (SARPS)8. The most

significant items found in the guidance on oxygen are following:

1) All Aircraft

An operator shall ensure that passengers are made familiar

with the location and use of: oxygen dispensing equipment, if the

provision of oxygen for the use of passengers is prescribed.

2) Non-pressurized Aircraft

An aero plane intended to be operated at flight altitudes at

which the atmospheric pressure is less than 700hPa in personnel

compartments shall be equipped with oxygen storage and

dispensing apparatus.

A flight to be operated at flight altitudes at which the

atmospheric pressure in personnel compartments will be less than

700hPa shall not be commenced unless sufficient stored breathing

oxygen is carried to supply:

a) all crew members and 10 per cent of the passengers for

any period in excess of 30 minutes that the pressure in areas

occupied by them will be between 700hPa and 620hPa

b) the crew and passengers for any period that the

atmospheric pressure in areas occupied by them will be less

than 620hPa

Pressurized aircraft

a) An aero plane intended to be operated at flight altitudes at

which the atmospheric pressure is less than 376hPa or which, if

operated at flight altitudes at which the atmospheric pressure is

more than 376hPa, cannot descend safely within four minutes

to a flight altitude at which the atmospheric pressure is equal to

620hPa shall be provided with automatically deployable oxygen

equipment. The total number of oxygen dispensing units shall

exceed the number of passenger and cabin crew seats by at

least 10 per cent.

b) All flight crew members of pressurized aero planes

operating above an altitude where the atmospheric pressure is

less than 376hPa shall have available at the flight duty station

a quick-donning type of oxygen mask which will readily supply

oxygen upon demand.

Equipment

Due to the different requirements of the equipment used on the

flight deck and that used in the passenger cabin their design and

functionality methods differ.

Flight deck: Oxygen for the use of the flight deck occupants is

normally stored as pressurized gas in one or more tanks or cylinders. In certain aircraft types, oxygen is stored as a liquid. The total oxygen

capacity must be sufficient to supply all flight deck occupants with

adequate oxygen for a defined period of time at an altitude profile

specified in the applicable National Aviation Authority regulations.

Commonly, the altitude profile will incorporate an emergency

descent segment and followed by a period in level flight at a

defined altitude. A quantity gauge or other means of determining

the amount of available oxygen will be incorporated. A regulator

is installed to reduce storage cylinder pressure to a usable level.

Depending upon the aircraft type, regulators can be:

Footnote

5https://aviation-safety.net/database/record.php?id=20080628-0 (accessed 11 June 2018)

6http://news.bbc.co.uk/1/hi/world/asia-pacific/7532357.stm (accessed 7 May 2020)

7https://aviation-safety.net/database/record.php?id=20110729-0 (accessed 10 May 2020)

8https://www.skybrary.aero/index.php/Aircraft_Oxygen_Systems (accessed on 07.02.2019)

a) Constant flow type, that provides the same output pressure or flow regardless of altitude. The regulator is therefore optimized for a specific altitude. At altitudes lower than the designed optimum altitude, it will provide more oxygen than is actually required. This type of regulator is most often found in non-pressurized aircraft and on portable oxygen systems. A single constant flow regulator is able to control the oxygen flow to all users.

b) Diluter-demand type that provides oxygen at each crew position. Depending upon user selection, the diluter-demand regulator can provide 100% oxygen, 100% oxygen under positive pressure or a mixture of oxygen “diluted” with cabin air on a specific, altitude-based schedule.

Passenger compartment: In non-pressurized aircraft that

routinely fly above 10,000ft, passenger oxygen is typically provided

by:

a) Fixed systems that draw their oxygen supply from a

pressurized cylinder of gaseous oxygen. This can be a dedicated

cylinder, or it might be the same cylinder that is used to supply

the flight deck occupants. An oxygen manifold runs from the

cylinder into the passenger compartment via a single regulator.

Attachment ports allow passenger oxygen masks to be

connected to the manifold. A shutoff valve capable of isolating

the passenger compartment is normally incorporated.

b) Portable systems that consist of a storage tank, a regulator

and one or more passenger masks. These will be distributed

to the passengers when required. Pressurized aircraft which

have a certified maximum altitude of 25,000ft or less do not

require passenger oxygen systems subject to the aircraft being

able to descend to 13,000ft or below within 4 minutes of loss

of pressurization. If the aircraft is not capable of achieving the

descent profile or the route structure does not allow the descent

due to terrain, an oxygen system must be fitted in the aircraft as

per the provisions which apply to aircraft which are certified to

fly at higher altitudes (above 25,000ft). For pressurized aircraft

which are certified to operate above 25,000ft, emergency

oxygen equipment must be available. Some aircraft utilize

cylinders of pressurized oxygen to meet this requirement, but

most types are fitted with chemical oxygen generators. The

emergency oxygen supply must last a minimum of 10 minutes.

Provisions must be provided in the system to automatically

deploy the emergency oxygen masks when the cabin altitude

exceeds a pre-determined level (typically 14,000ft). Sufficient

masks must be provided for at least 10% more passengers than

there are seats in the passenger compartment.

Oxygen mask

Oxygen masks used in the flight deck are different from those

that are available in passenger cabin.

Flight deck: An oxygen mask is provided at each flight deck

station. The mask could be of the “full face” variety incorporating

smoke goggles or a “mouth and nose” type mask with smoke goggles

available separately. The masks at the pilot stations will incorporate

microphones to allow internal and external communications.

Masks are fitted to the face utilizing various suspension harnesses.

For aircraft which routinely fly above 25,000ft, masks are generally

of the “quick-donning” variety, which allow them to be put on

in 5 seconds or less using only one hand. For diluter-demand

systems, selectors for normal, 100% and positive pressure may

be incorporated into the mask itself. If not, they will be found on

the associated regulator. Diluter-demand oxygen masks are stowed

with the selector in the 100% oxygen position and should be

reelected to the normal (or diluting) position when mask utilization

is required for other than a smoke or fume event.

Passenger compartment: The most typical passenger oxygen

masks consist of a soft, yellow, silicone cup fitted with elastic

bands for securing the mask to the face. The bands are adjustable

to accommodate passengers of different sizes. The mask may also

have a clear concentrator or re-breather bag. Depending upon the

cabin altitude, the concentrator bag may or may not inflate. Airlines

make a point during their safety presentation of pointing out that

the bag may not inflate as, in the past, lack of bag inflation has led

some passengers to believe that their mask was not working and

to remove it resulting in hypoxia [2]. The bag is attached to a tube,

connected to the oxygen source in the compartment, allowing for it

to drop down and hang in front of the passengers. To operate on all

aircraft except the L-1011 and B787, they must be pulled sharply

toward the passenger who needs it to un-clip the flow pin and start

the process of transporting the oxygen to the passenger. Passenger

oxygen masks cannot deliver enough oxygen for sustained periods

at high altitudes. Therefore the flight crew needs to place the aircraft

in a controlled emergency descent to a lower altitude where it is

possible to breathe without emergency oxygen. While the masks

are being used, passengers are not allowed to leave their seat for

any reason until it is safe to breathe without the emergency oxygen.

If there is a fire on board the aircraft, masks are not deployed, as the

production of oxygen may further fuel the fire.

Types of oxygen generating systems

There are two systems that are typically found on commercial

aircraft, namely:

a) A chemical oxygen generator system that is connected

to all masks in the compartment. Pulling down on one oxygen

mask removes the firing pin of the generator igniting a mixture

of sodium chlorate and iron powder, opening the oxygen supply

for all the masks in the compartment. During the short period of oxygen production, the generator becomes extremely hot

and should not be touched. A burning smell may be noted

and cause alarm among passengers, but this smell is a normal

part of the chemical reaction. For any aircraft which carries

more than a very few passengers, the weight, complexity and

maintenance issues associated with a compressed gas system

would be prohibitive. Hence, the commercial aviation industry

relies on chemical oxygen generators.

b) A gaseous manifold system that connects all oxygen masks

to a central oxygen supply usually is in the cargo hold area.

Pulling down on one oxygen mask starts the oxygen supply for

that mask only. The entire system can usually be reset in the

cockpit or in some other location in the aircraft.

Malfunctions of Emergency Oxygen Provisioning System

Veillette [4] conducted a search of 100 recent NASA Aviation Safety Reporting System (ASRS)9 records regarding involving incidents, in which oxygen masks were employed, submitted in 2016 and 2017. Out of the records analyzed 71 are related to a loss of pressurization or suspected smoke or fumes. In all of these cases emergency oxygen systems operated as designed, enabling the flight crews to breathe and they safely got the aircraft and their passengers on the ground. However, the remaining 29 reports draw attention to the serious risk posed for a flight crew being without supplemental oxygen as well as other serious problems with masks used when needed. The following few examples are extracted from Veillette [4].

Case 1

NASA ASRS Report 1498858, published in November 2017, contains the following statement by flight crew whose oxygen masks and hoses physically failed: “In cruise flight, I went to put on quick-donning mask as first officer was going to leave the flight deck for physiological needs. I pulled the mask out of the box and it came apart in my hands. It was useless had there been an emergency. Where the hose attaches with the microphone to the main rubber face area was broken and dangling. The full mask section was intact, but the hose/microphone area was detached and hanging by a wire, no ability to breathe oxygen from the mask.”

Case 2

NASA ASRS Report 1462284, published in July 2017, contains the following statement “While out on the lavatory break a copilot heard a loud whoosh noise from up in the flight deck. So, he immediately returned to the flight deck to request entry back in. When arrived at his seat he saw the captain holding the oxygen hose and mask together in his hands, accomplished with a hissing sound. The captain explained that the oxygen hose for his crew mask would not stay attached to the mask. The captain made several attempts to re-secure the oxygen hose to the mask but did not succeed. Due to the positive pressure of oxygen coming from the hose, neither of them was successful at securing the oxygen hose. After several minutes they became unable to even hold the oxygen hose to the mask. At this point there was nothing to even slow the flow of the crew oxygen and they began to lose crew oxygen at an extremely fast rate.”

Case 3

On 3 September 2010, a UPS Boeing 747 departed Dubai International Airport (DXB) on a cargo flight to Cologne, Germany (CGN). Twenty minutes into the flight, at approximately 32,000ft., the crew advised ATC that there was an indication of an onboard fire and declared an emergency. Both pilots had donned their oxygen masks approximately 90 sec. after the fire bell sounded. Less than 90 sec. later, the fire caused severe damage to the flight control system and filled the cockpit with continuous smoke. During the emergency descent the cabin reached a pressure altitude of 21,000 ft., followed almost immediately by the rapid failure of the captain’s oxygen supply without any indication of trouble. Unknown to the flight crew, the fire had severely damaged many significant systems on the aircraft, including the crew supplementary oxygen system supply. The damage caused a cessation of oxygen flow to the captain’s mask and reduced capacity for the remainder of the flight to the F/O’s mask.

To obtain the portable oxygen bottle, the captain left his seat, but did not return due to incapacitation from toxic gases. As the F/O could not view outside the cockpit, or see the primary flight displays, the aircraft subsequently entered an uncontrolled descent into terrain, killing both pilots in the crash. During the investigation, several UPS line pilots commented on the use of the oxygen mask and goggle sets during their training. They reported receiving little hands-on instruction for the actual use of the set and smoke vent, and what they did receive occurred during initial training for the aircraft in the form of computer-based text and images. They also stated that they were never taught about the relationship between the emergency selector on the regulator and the need to simultaneously open the smoke vent to clear contaminants from inside the goggles or how to locate the switches on the oxygen regulator after the oxygen mask was donned. Furthermore, they were never required to practice these actions in the presence of an instructor or check airman.

Case 4

On 20 July 2009 United Airlines Flight 949 was on route from London Heathrow Airport (LHR) to Chicago O’Hare International Airport (KORD). At 37,000ft. the flight crew encountered smoke in the cockpit and diverted to Keflavik International Airport (KEF) in Iceland. During the event, the flight crew donned their oxygen sets and attempted, with difficulty, to establish and maintain their communications. The following statement the pilot provided to the Icelandic Aircraft Accident Investigation Board, “We struggled with the audio panels to communicate with the masks on.” Thus, he removed the oxygen mask to communicate with the Flight officer (F/O) and relief pilot in the cockpit. The F/O said, “The entire process of donning goggles, the use of the oxygen mask, pushing all the different buttons and toggles to communicate with all the people involved was very frustrating at times. Between the goggles scratching my glasses and the smoke film in front of them too, it was hard to see at times. Too many items have to come together for this setup to work.” Also, the pilot added that “Crew communications with oxygen masks on was non-effective and increased crew workload significantly. It was made worse with three crewmembers plus ATC all trying to communicate10.”

Footnote

9https://asrs.arc.nasa.gov/#:~:text=ASRS%20%2D%20Aviation%20Safety%20Reporting%20System,information%20to%20the%20aviation%20 community. (accessed 3 July 2019)

Case 5

Retired FedEx pilot Bob Bostick Jr. commented on the Veillette’s article [4] with a following words11, “Years ago I was the right seater in the 727. My habit pattern for checking the oxygen mask was to pull the mask off the spring-loaded strap it was hanging from, test for flow without putting it on, and reinstall the mask on the strap. Yup, I was not doing a full check and that was my habit pattern until I got an education. Just by chance, during one pre-flight I decided to take the mask off the strap, put it on, and give it a full test, along with taking out the smoke goggles and seeing how well it all worked with my glasses on. Had a simulator ride the next day and knew using the mask would be part of the drill. Donned the mask, flipped the switch on, took a breath…and something came out of the mask and lodged in my throat. That something was moving. After ripping off the mask and doing some very dramatic coughing and heaving, while the Captain and Flight Engineer were watching and wondering what the heck was wrong, I finally spit out a fairly good-sized live moth! Wow. How did that happen? Didn’t take long to figure it out, the mask hangs from the top left corner of the Flight Engineer panel, and just above the attach point is one of the flood lights for the panel. Hmmm. Light attracts bug, bug gets tired, bug falls into mask. A good lesson, from that point on in my flying career I made it my habit to pull the mask out of wherever it was, clean it with a mask wipe, put some pressure to it, check it, then put it on and check for function and communication. And yes, on several occasions there was another moth in the mask. Can imagine how bad things could go with smoke/fumes/loss of pressurization and inhaling a moth with that first deep breath.”

Case 6

On 25 October 1999, a chartered Learjet 35 was scheduled to fly from Orlando, Florida, to Dallas, Texas. Early in the flight, the aircraft, which was climbing to its assigned altitude on autopilot, quickly lost cabin pressure and all six on board were incapacitated due to hypoxia (a lack of oxygen). The aircraft continued climbing past its assigned altitude, then failed to make the westward turn toward Dallas over north Florida and continued on its northwestern course, flying for almost four hours (1,500 miles). The plane ran out of fuel over South Dakota and crashed into a field near Aberdeen after an uncontrolled descent. The NTSB has several levels of investigation, but the final conclusion was; “The probable cause of this accident was incapacitation of the flight crew members as a result of their failure to receive supplemental oxygen following a loss of cabin pressurization, for undetermined reasons12. ” However, the crash investigation has highlighted that in Learjet model 35/36, the oxygen bottle regulator/shutoff valve is located in the nose cone of the airplane and therefore inaccessible to flight crewmembers during flight. It was further discovered that pilots may have difficulty visually verifying the position of this valve during a pre-flight inspection because of the way it is installed in the airplane. The Safety Board noted that it is critical that the valve position indicators are clearly visible and easily understandable during pre-flight check. Oxygen bottle supply pressure is indicated on a gauge in the cockpit of the Learjet 35/36. Since a visual check of the oxygen bottle supply may not provide information about the position of the oxygen bottle regulator/shutoff valve, the pilots’ only sure indication in the cockpit that the oxygen bottle regulator/ shutoff valve is in the OFF position would be the failure of the oxygen mask to deliver oxygen.

Oxygen Masks Related Negative Functionability Actions

Although emergency oxygen masks and connecting lines are used very infrequently, they are not protected from negative functionability actions, like “wear out” process. The most common components that fail are around valves, fittings, and connections involving rubber seals, tubing and hoses. Other possible negative functionability action that affects oxygen system components is a “dry rot”, which occurs when rubber or plastic surfaces are exposed for long periods to alternative heating and cooling temperature swings in dry air (which is an apt description of an aircraft cockpit.) Moisture within the rubber or plastic is wicked away, degrading its flexibility and elasticity over time. Cracking, tearing, and breakage are common indications of dry rot. The Australian Civil Aviation Safety Authority (CASA) issued Airworthiness Bulletin 35-004 (Nov. 29, 2012) noting service difficulty trends with oxygen systems service during maintenance identified by their Service Difficult Report database.

The observed negative functionability actions that caused the transition of emergency oxygen provisioning system from PFS to NFS include [5]:

1. Lines and fittings disconnected or blanked during inspections.

Footnote

10In response to these events the NTSB issued Safety Recommendation A-11-089, to require airline, charter and fractional operators “to include, during initial and recurrent training, aircraft-specific training on establishing and maintaining internal cockpit communications when the oxygen masks are donned.”

11a300bob (accessed 28 January 2019)

12https://en.wikipedia.org/wiki/1999_South_Dakota_Learjet_crash (accessed 11 February 2019)

2. Missing information on part number identification labels.

3. Contaminated oxygen masks.

4. Contaminated oxygen fittings.

5. Passenger service unit doors glued at hinges.

6. Unserviceable oxygen masks.

7. Incorrectly packed oxygen masks.

8. Discharged oxygen generators.

9. Worn or damaged components and fittings.

10. Kinked oxygen lines and hoses.

11. Passenger service unit doors not closed properly.

12. Overstrained oxygen hoses.

13. Oxygen fill line nuts cracked.

14. Cracked in-line oxygen flow indicators.

15. Incorrect oxygen cylinder configuration.

16. Bent oxygen generator firing pins.

17. Leaking pilot oxygen regulators.

Functionability Improving Actions for Emergency Oxygen Provisioning

The analysis of ASRS reports performed by Veillette [4]

lead to the deduction of the following recommendations for the

reduction of the probability of malfunctioning of emergency oxygen

provisioning process, thus:

a) The pressure-demand masks must be properly stowed in

their containers to qualify as quick-donning equipment. Each

mask has two red harness inflation levers that, when squeezed,

allowing the mask to be removed from the storage box.

Releasing the levers after placing the mask over the head fits it

securely to the head and face. Although, it can be” challenging”

stowing the oxygen mask after completing pre-flight checks, it

is imperative to do so correctly as it could help safely resolve a

dangerous in-service situation!

b) The frequent pre-flight inspections could cause

undetected wear and tear on the mask and hose connections.

The pilots expressed concern that some mask designs are not

sturdy enough for repeated extraction and re-stowing. These

reports were submitted by regional airline crews whose aircraft

can be operated by a dozen different pilots within a handful of

days, each necessitating a full inspection of the oxygen system

during an aircraft acceptance check. In addition, the ASRS

submitters were concerned that many of the facemasks are

getting scratched to the point that they would be difficult to see

through in a real event.

c) Aircraft cabin that has become cold-soaked, it may

require the cabin to be warm sufficiently to ensure the proper

deployment and operation of passenger oxygen masks. For

example, the Cessna Encore manual, stipulates that cabin

temperature must be held at or above 32° F for a minimum of

15 minutes prior to takeoff after a prolonged ground cold soak.

d) It is vital that all flight crewmembers to personally

make sure that during the pre-flight checks that their oxygen

equipment is: functioning, fitted properly and connected to

appropriate supply terminals, the oxygen supply and pressure

are adequate, and the oxygen buttons are selected for optimum

performance in case of emergency.

e) All pilots of high-performance aircraft should receive

appropriate, hands-on instruction regarding the use of oxygen

mask/goggle sets, including the regulator’s emergency selector

and smoke goggle venting, and practice communications using

the mask microphones during initial and recurrent training.

Impact of the Descent on Human Body

After addressing the emergency oxygen provision systems to complete the study it is necessary to address the impact of the emergency descent on human body. In the case of an uncontrolled depressurization, the crew would try to descend immediately to an altitude at which they and the passengers can breathe without supplementary oxygen. When a cabin depressurizes, the percentage of oxygen in the air stays about the same, but the molecules get further and further apart. It is usually given as 10,000 feet amsl13 subject to adequate terrain clearance. If it happens quickly, there is little time to react, although pilots are trained to keep an eye on cabin pressure and adjust the plane’s oxygen levels accordingly. Once pressure dips below acceptable levels, oxygen masks drop down and people put them on to breathe in pure oxygen for as long as it lasts. Protocol dictates that the pilot fly to a lower cruising altitude, usually below 10,000 feet, so that breathing would no longer be a problem for a healthy person [4]. The oxygen, or lack of it, is the underlying issues concerning rapid emergency descents. While a reasonably healthy person may be able to endure a cabin depressurization and the subsequent rapid descent, the experience may not be the same for someone who is ‘pneumatically challenged’ with a condition like COPD14, asthma or the effects of heavy smoking. Other factors can include obesity, advanced age, and lack of fitness. Bad depressurization can cause additional medical problems like gastronomic, dental, anxiety, the bends15. It is necessary to stress that if depressurization happened slowly, passengers might not notice right away.

Footnote

13AMSL is an abbreviation for the Above Mean Sea Level, and it refers to the elevation or altitude used in aviation (for recording and reporting most heights) and in the atmospheric sciences.

14Chronic Obstructive Pulmonary Diseases (COPD) defines a group of lung conditions that make it difficult to empty air out of the lungs because the airways have become narrowed.

Conclusion

The main objective of this paper was to address the emergency oxygen provisioning as a physical mechanism of the motion of an aircraft through MIRCE Space [1]. Although the malfunctioning of this process is not frequently observed negative functionability event, their occurrences could cause significant consequences to airline and flying pubic, impacting the functionability performance of commercial aircraft in the air and on the ground [4]. Emergency oxygen provisioning systems have been briefly described in the paper considering their main characteristics and potential negative impact on crew and flying passengers. Timely response by a flight crew to a loss of cabin pressurization or to smoke or fumes is critical for the safe operation of an aircraft and certainly not the time to discover that emergency oxygen provisioning system is in a negative functionability state (NFS). It has been pointed out in the paper that in many instances the accident report concluded that the deterioration of the condition of emergency oxygen provisioning systems were intensified by inadequately maintained oxygen masks, their attachments to the rest of the system and frequent inspections by flight deck crew. This paper clearly confirms that malfunctions of emergency oxygen provisioning system have caused considerable contributions to the transition of an aircraft from positive to negative functionability state, resulting in the reduction of the functionability work done and occasional destruction of the aircraft or human fatalities. Recommendations provided in the paper, based on the observed in-service functionability events, should be used for the design of the future emergency oxygen provisioning systems as well as the planning of their maintenance programs and a corresponding cabin crew training.

Footnote

15A condition experienced by divers when the dissolved nitrogen in the blood begins bubbling out of the circulatory system. At the higher altitudes that some aero planes fly today, without cabin pressurization, the pilots ‘s blood can actually boil.

References

- Knezevic J (2017) The origin of MIRCE science. MIRCE Science Limited, UK, p. 231.

- Knezevic J (2016) Aerotoxic syndrome as a MIRCE mechanics phenomenon. International Journal of Applied Engineering Science 14(4): 451-456.

- Elser D (2020) Under pressure: what to do when you lose it. Aviation Weekly New York, USA.

- Veillette PR (2019) An emergency is not when to discover your oxygen masks don’t work. Business & Commercial Aviation New York, USA.

- Weak points on oxygen masks that are failing (2019) “Oxygen Mask Failures” Business & Commercial Aviation New York, USA.

© 2020 Knezevic J. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)