- Submissions

Full Text

COJ Reviews & Research

Variability of Lime-Based Lateritic Soil Enhanced with Bitumen with Varying Proportions

Lucia Omolayo A1*, Samuel AO2, Olugbenga OA3 and Christopher EI3

1Department of Civil Engineering, Federal University of Technology Akure, Nigeria

2Department of Civil Engineering, Federal University Airforce Institute of Technology Kaduna,Nigeria

2Department of Civil Engineering, Federal University Oye-Ekiti, Nigeria

*Corresponding author: Lucia Omolayo A, Department of Civil Engineering,Federal University of Technology Akure,Nigeria

Submission: September 05, 2022; Published: September 16, 2022

ISSN 2639-0590Volum4 Issue2

Abstract

This research investigated the bituminous additive prerequisite of some lateritic soil samples as pavement materials. Both chemical and geotechnical experiment were carried out on untreated (raw) and improved laterite. Bituminous material was utilized in the present research as admixture. The California Bearing Ratio (CBR), Atterberg limit (Liquid and plastic limit), specific gravity, moisture content and compaction experiments of the samples were performed with varying percentages or proportions of bitumen; 3, 6, 9 and 12%. The soil categorization test reveals that the lateritic soil is between A-2-7 and A-2-4 which is Silty or clayed clayey gravel and sand based on AASHTO soil categorization. The C.B.R values are 9.87, 4.35% and 7.28% for samples A, B and C correspondently at 0% additive content, while for 12% additives, the result showed maximum C.B.R values for sample A and B as 41.21% and Sample C as 40.04%. Thus, bitumen has been verified to be a good admixture on the enhancement of the properties of lateritic soil as pavement materials.

Keywords: Strength characteristics; Bitumen; Lateritic soil; Pavement materials

Introduction

The necessity of enhancing the engineering properties of soil has been considered as old as construction work has existed. Numerous of the ancient Chinese, Romans and Incas buildings and roadways which exist till today utilized different techniques of soil stabilization [1,2]. The usage of lime as a building material dates back 5,000 years when lime and clay were mixed and compacted to form bricks used in the construction of the pyramids of Shensi in Tibet. About 2,000 years ago the Romans used lime to improve the quality of their roads [3,4]. The Romans also made mixtures of lime together with volcanic ash called “pozzolana” in which the principles of today’s cement can be seen. Similarly, bitumen is a genetic or chromosomal name for numerous mixtures of semisolid or solid [5-7], hydrocarbons gaseous, liquid in nature, as well as totally soluble in carbon desulphated. The most popular materials within genus of bitumen are asphalts, tars, and pitches. They have tendency to remain at solid surface and its adhesiveness is subject to the surface scenario and the state of the bitumen [8]. The road network provides the principal mode of freight and passenger transport in Ethiopia. Efficient transport plays a huge role in promoting development by lowering transport costs, cutting travel time and improving the quality of transport services [9,10]. Hence, the performance of the road sector plays a vital role in growing the economy of the country. When unsuitable materials are encountered measures like avoiding the route, redesigning the pavement with thicker sections or replacing the poor soil with good quality materials are viable but increasingly expensive options. With improved technological advances and concern for depletion of non-renewable resources, improving the properties of soil using chemical additives is gaining increased popularity [11,12]. The modern era of soil stabilization began in the United States during 1960’s and 1970’s when shortages of aggregates and petroleum resources forced engineers to consider alternatives of road construction instead of soil replacement [10-12]. Since 1930 tests have been carried out in the United States with lime stabilization but success was achieved only ten years thereafter. Soil stabilization is a process whereby increased strength and stability of the soil is attained mainly by mechanical or chemical means [13-15]. The most common improvements achieved through stabilization include better soil gradation, reduction of plasticity index or swelling potential, increase in durability and strength. In wet weather, stabilization may also be used to provide a working platform for construction operations. These types of soil quality improvement are referred to as soil modification. Soil stabilization decreases damage caused by settlement, washing and collapsing [16,17].

Material and methods

Materials and preparation

The Lateritic soil was obtained from three distinct site located at KM 10 Osogbo-Ibadan Highway, Osun State, Nigeria. Ongoing highway construction works exposed the soil layers and the samples were taken at 2m depths from the natural ground surface via Trial Pit techniques. The sampling was air dried so as to tackle the aggregating capabilities of lateritic soils upon exposure to air as asserted by Abdullai [11]. The lime used for this experiment was purchased from the Osogbo market, whereas S 125 bitumen utilized was obtained from Dekit Construction Company in Osogbo, Osun State Nigeria (Coordinates 7.7827°N, 4.5418°E). Potable water was also used during mixture of materials to produce soil stabilizer. Experimental Engineering strength tests on treated and untreated samples were performed in the laboratory of Civil Engineering Department, Federal Polytechnic Ado-Ekiti, Ekiti State Nigeria in accordance with AASHTO (American Association of State and Transportation Officials), [6] recommendation for 0,3,6,9 and 12% additive.

Methods

Geotechnical scrutiny:Preliminary tests like particle size distribution and consistency or Atterberg limit (Plasticity Index) tests were carried out on the lateritic soil sampling to categorize the soil. The technique utilized for these tests agree with AASHTO [6], which endorse terminologies as well as the Unified Soil Classification System (USCS) to define and categorize lateritic soils for engineering reasons.

Compaction:Compaction test were performed on the natural samplings of soils obtained from Sheda-Abaji Highway after which 3,6,9 and 12 percent of hydrated lime and Portland cement, were introduced as soil admixtures. The soil samplings were broken up, 500grams of each sampling was measured with roughly four percent of water added, after thorough mixture the sapling was divided into three equal portions and compacted in three layers inside B.S mould with 25 uniformly blows via 5.5Kg rammer at height of 12 inches. The compacted sampling as well as mould was weighed, and rep sampling for dry density and moisture content determination was taken. The same approach was used for the entire admixture at different percentage. Dry density versus water content was plotted to form a curve, while the maximum dry density is referred to as Zero air voids. Likewise, the Optimum moisture content (OMC) determined is utilized during construction work for regulating the quantity of water to be added to earthworks.

California Bearing Ratio (C.B.R):For C.B.R test, roughly six kilograms of soil samplings that pass-through number four sieve was mixed with the OMC gotten from compaction test. This entails compaction of soil thrice with fifteen (15) blows and 2.5 kilograms rammer. Both compacted soil and the mould were positioned under C.B.R machine with application of penetrations at 25, 50, 15, 100, 125 and 750 inches, which was done for top and bottom layer. The C.B.R test is principally a penetration test with the function of assessing the soil resistance to penetration erstwhile to reading, while evaluation shearing value was carried out using equation below.

C.B.R %= (Test load ÷Standard load)x 100 (i)

Result and discussion

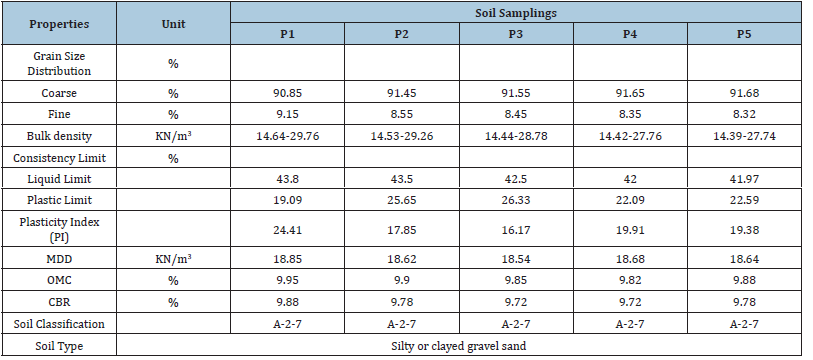

Outcomes of preliminary experiments

Results of preliminary experiments on the three lateritic soils are displayed in Table 1. It demonstrated that the soil is categorized as A-2-7 and A-2-4 based on AASHTO classification method. This infers that it below the suggested standard for pavement construction work, thus it requires enhancement.

Table 1: Outcomes of preliminary experiments.

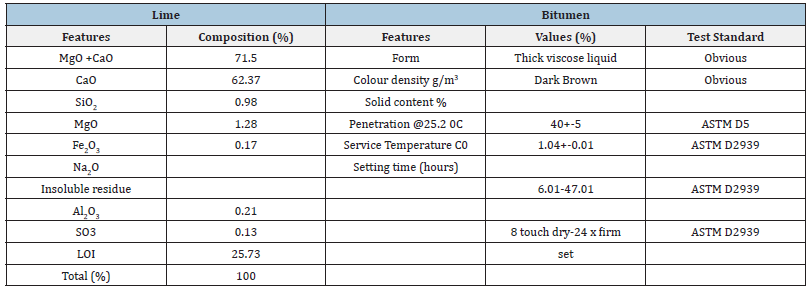

Outcomes of oxide composition of cement and bitumen

Results of the oxide composition of cement are demonstrated in Table 2. The result displays that cement has the main chemical constituents of cement which are CaO, SiO2, Al2O3, MgO etc. This shows that rice husk ash is a good pozzolana that could help further promote the formation of cementitious compounds with cement hydration reaction products.

Table 2: Results of oxide composition of hydrated lime and bitumen.

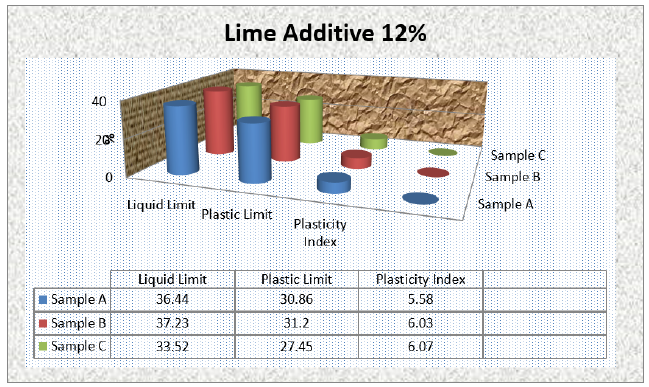

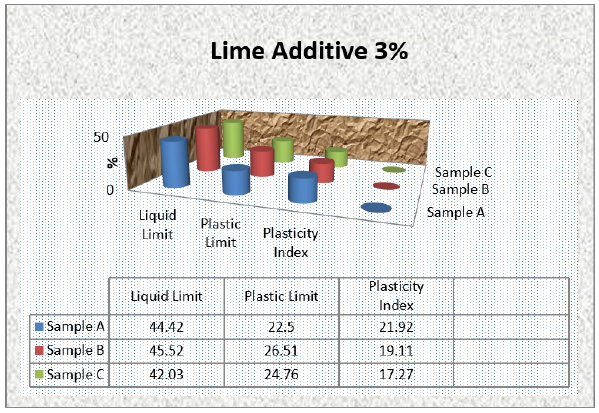

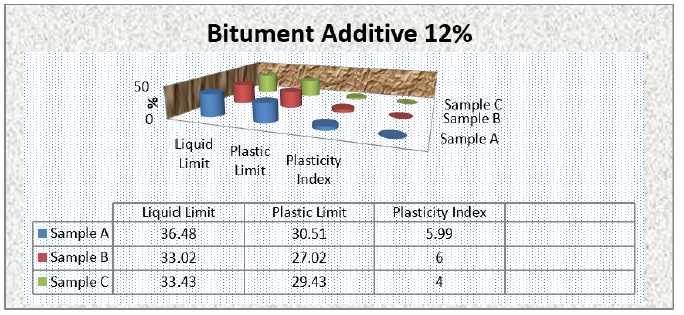

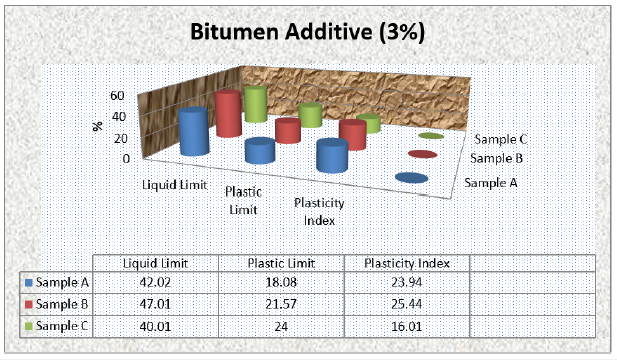

Outcomes of atterberg characteristics

Figure 1:Atterberg Limit test for lime additive at 12%.

The test results are analyzed in Figures 1-4 reveal that the average Lime additive (3%) Liquid limit and plastic limit value is higher than cement additive, which is also higher than bitumen additive, while Bitumen additive (3%) average plasticity index greater than lime additive which also greater than cement additive. Bitumen additive (12%) average plasticity index greater than lime additive which also greater than cement additive. The mechanism of treatment with bituminous material consists of adding cohesive strength and reducing water penetration by the physical presence of bitumen. There is no chemical interaction in this process. Bitumen stabilization includes both water proofing and cementation actions. The results revealed that the addition of cutback bitumen with different soaking periods of (0,4,7 and 21) days would improve its strength and stiffness characteristics and enhance its waterproofing characteristics. This was due to the phenomenon of flocculation and agglomeration that obtained after the addition of stabilizing agents which leads to decrease in the thickness of the water layer (electric double layer). Therefore, the clay becomes less affected by the addition of water. Similar results were observed by Yoobanpot et al. [8]. As a result of differences between liquid limit and plastic limit, the reduction in plasticity index was 35.7%, 28.5%, and 21.4% for ideal mixing ratios of cement, hydrated lime, and bitumen (Figures 1-4), respectively.

Figure 2:Atterberg Limit test for cement additive at 3%.

Figure 3:Atterberg Limit test for bitumen additive at 12%.

Figure 4:Atterberg Limit test for bitumen additive at 3%.

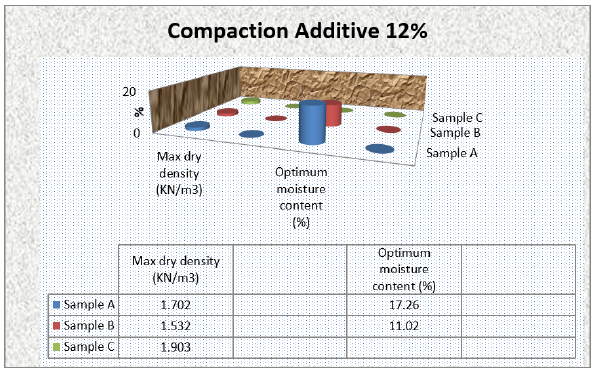

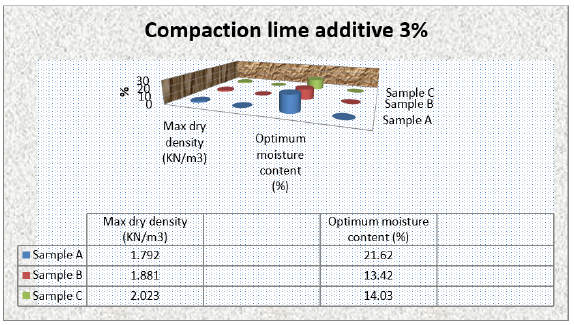

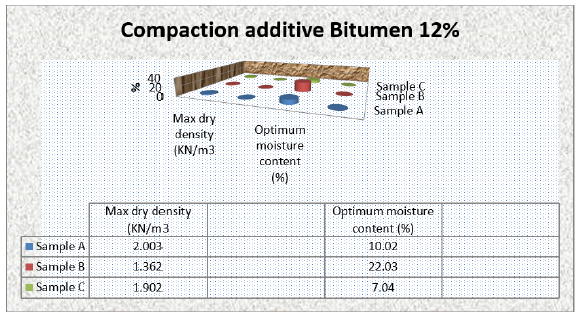

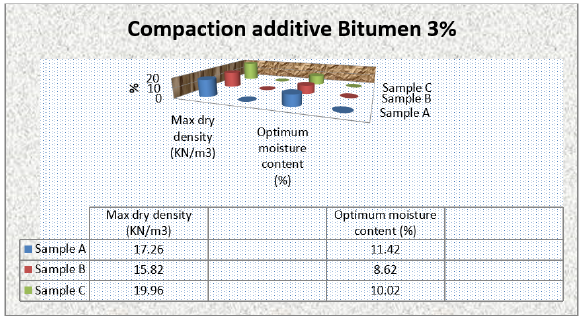

Outcomes of compaction characteristics

Figures 4-8 demonstrated the variations between OMC (Optimum Moisture Content), MDD (Maximum Dry Density) with lime and S125 bitumen addition. The MDD improved with increase in S125 bitumen content. The values range from 1.866mg/m3 at 0% to 2.003mg/m3 at 10% S125 bitumen content. Similarly, OMC diminishes from 9.91% at 0% to 7.04% at 12% S125 bitumen. Bitumen additive (3%) average Optimum dry density values greater than lime additive which also greater than cement additive. Also, Bitumen additive (12%) Maximum Dry density value is higher than Lime additive, which is also higher than cement additive, while cement additive (12%) average Optimum dry density values greater than bitumen additive which also greater than lime additive. The dry density of compacted soil increased within creased bitumen percentage by 1.1% for the ideal ratio was due to that the pore spaces were filled with bitumen that could move through the soil particles and link them together. The increasing in moisture content with bitumen was 11% for the ideal ratio. This was probably due to lubricating effect and fluid content of bitumen, as observed in Zu et al. [10]. The increasing of mixing ratios might cause by flocculation and accumulation of fine-grained soil particles which filled up the available larger space before improvement and consequently resulted to a corresponding falling dry density. Zhu et al. [15,17] reported similar results.

Figure 5:Compaction characteristic for lime additive at 12%.

Figure 6:Compaction characteristic for lime additive at 3%.

Figure 7:Compaction characteristic for bitumen additive at 12%.

Figure 8:Compaction characteristic for bitumen additive at 3%.

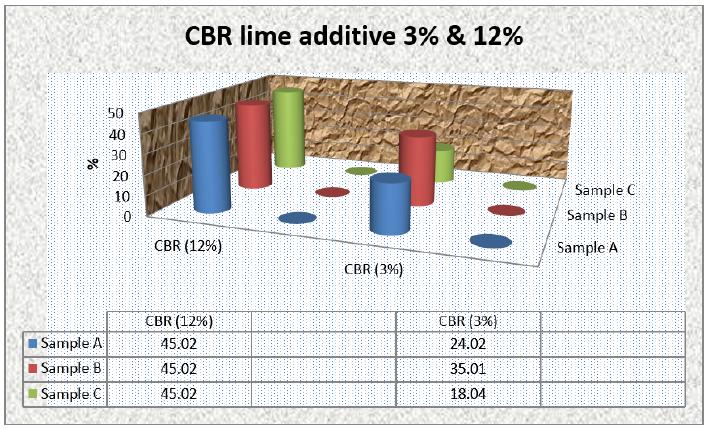

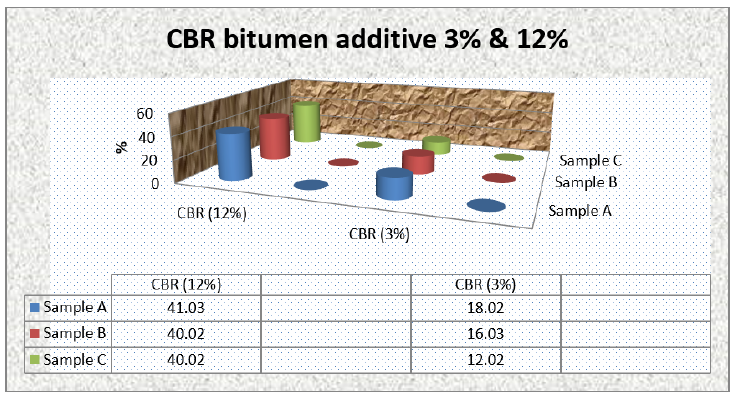

Outcomes of California Bearing Ratio (CBR)

Results of CBR test is shown in Figures 9 & 10. The results revealed that CBR values amplified from 9.89% at natural (raw) soil level to 41.02% at 12% bitumen content, which is below lime additive of 45.02% at 12%. Also, the average Lime additive (3%and12%) California bearing ratio value is higher than bitumen additive. Though, prior scrutiny through AASHTO categorization (Table 1) characterized the three samples as bad pavement materials due to their low dry densities and strength, thus improvement is required. With the outcome lower content of hydrated lime enhanced better than S125 bitumen contents. Though both are good enhancer for low strength and densities soil such as cut to spoil or unsuitable construction materials.

Figure 9:CBR characteristic for lime additive at 3% and 12%.

Figure 10:CBR characteristic for bitumen additive at 3% and 12%.

Conclusion

The study on lateritic soil samplings from a construction site situated at KM 10 Osogbo-Ibadan Highway, Osun State, revealed that constructive impacts are achieved by the addition of hydrated lime and bitumen, to enhance the strength of weak soil. Categorization test shown that the lateritic soil was grouped as A-2- 7 and A-2-4 soil, that is Silty or clayed clayey gravel and sand. As percentage of hydrated lime additive increases, both LL and Pl also decrease, this shows that slight percentage of both hydrated lime and bitumen will augment the soil strength. Lower percentage of hydrated lime and bitumen gave maximum values of MDD and OMC respectively. At 3% Hydraulic Lime Content (HLC), the experiment displayed a general improvement in MDD with 3% S125 bitumen content. Whereas OMC also diminished with increase in S125 bitumen content. It was seen that CBR increased with 3% bitumen content for the 3% lime content. With slight quantities of hydrated lime additive and bitumen, soil enhancement will be great. Thus, bitumen is confirmed or inveterate to be a beneficial admixture in lateritic soil enhancement using 6%cement and 3% bitumen.

Acknowledgment

The authors wish to express profound gratitude to Dekit Construction Company in Osogbo, Osun State Nigeria, and management of Civil Engineering Department Soil Laboratory, Federal Polytechnic Ado-Ekiti, for their kind cooperation on data collection and experiments that made this study a success.

References

- Akinje I (2015) Comparison characterization of A-6(10) laterite soil stabilized with powermax cement and hydrated lime separately. International Journal of Engineering and Technology (7): 392- 401.

- Akinwumi I (2014) Plasticity, strength and permeability of reclaimed asphalt and lateritic soil blends. International Journal of Scientific and Engineering Research 5(6): 631-636.

- Ali F (2012) Stabilization of residual soils using liquid chemical. The Electronic Journal of Geotechnical Engineering Science and Technology 1(2): 102-110.

- Amu OO, Bamisaye OF, Komolafe IA (2011) The suitability and lime stabilization requirement of some lateritic soil samples as pavement. International Journal of Pure and Applied Sciences Technology 2(1): 29-46.

- Latifi N, Marto A, A Eisazadeh (2014) Structural characteristics of lateritic soil treated but SH 85 and TX-85/ nontraditional stabilizers. The Electronic Journal of Geotechnical Engineering 1(3): 1707-1718.

- AASHTO (2007) Standard specification for classification of soils and soil-aggregate mixtures for highway construction purposes. AASHTOM, p. 145.

- Ghazi M Mutter, Abdul-Sahib T, Raghad R Rashed (2017) Influence of soil stabilizing materials on lead polluted soils using Jet Erosion tests. International Journal of Integrated Engineering 9(1): 28-38.

- Yoobanpot N, Jamsawang P, Horpibulsuk S (2017) Strength behavior and microstructural characteristics of soft clay stabilized with cement kiln dust and fly ash residue. Appl Clay Sci 141: 146-156.

- Pooria G, Mostafa Z, Nazanin M, Mohammad S, Jie L, et al. (2021) Shear strength and life cycle assessment of volcanic ash-based geopolymer and cement stabilized soil: A comparative study. Transportation Geotechnics 31: 100639.

- Xu Z, Ye D, Dai T, Dai Y (2021) Research on preparation of coal waste-based geopolymer and its stabilization/ solidification of heavy metals. Integrated Ferroelectrics 217(1): 214-224.

- Abdullah H (2021) Cyclic behaviour of clay stabilized with fly-ash based geopolymer incorporating ground granulated slag. Transp Geotech 26: 100430.

- Suksiripattanapong C (2021) Evaluation of polyvinyl alcohol and high calcium fly ash based geopolymer for the improvement of soft Bangkok clay. Transp Geotech 27: 100476.

- Wattez T (2021) Interactions between alkali-activated ground granulated blast furnace slag and organic matter in soil stabilization/solidification. Transp Geotech 26: 100412.

- Venkatesh N, Mallikarjuna R, Sudheer R, Rama C (2021) Strength and durability characteristics of GGBS geopolymer stabilized black cotton soil. Materials Today: Proceedings 43(4).

- Zhu Y, Chen R, Lai H (2020) Stabilizing soft ground using geopolymer: an experimental study. American Society of Civil Engineers (ASCE), Chain, pp. 1144-1155.

- Dheyab W, Ismael ZT, Hussein MA, Huat BBK (2019) Soil stabilization with geopolymers for low cost and environmentally friendly construction. Int J Geomate17(63): 271-280.

- Adeyanju EA, Okeke CA (2019) Clay soil stabilization using cement kiln dust. IOP Conf Ser Mater Sci Eng 640: 1-10.

© 2022 Lucia Omolayo A. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)