- Submissions

Full Text

COJ Reviews & Research

Texture of Rapidly Solidified Foils of Tin, Indium, Bismuth, and Their Alloys

Shepelevich VG*

Doctor of Science in Physics and Mathematics, Belarus

*Corresponding author:Shepelevich VG, Doctor of Science in Physics and Mathematics, Minsk, 220030, Belarus

Submission: July 28, 2021; Published: September 13, 2021

ISSN 2639-0590Volum3 Issue3

Abstract

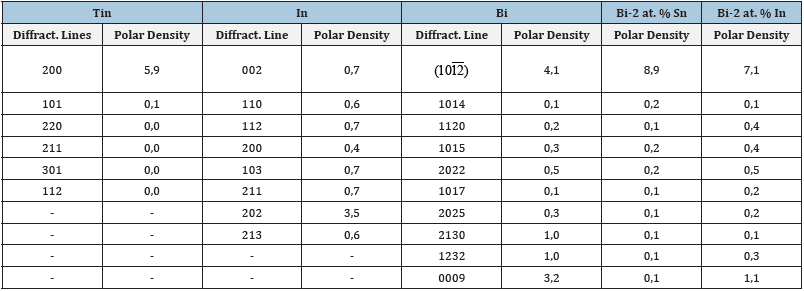

Tin, indium, bismuth, and their alloys are produced with rapidly solidified crystallization. Cooling rate

was in the order 105-106K/s. A thickness of foils was 30-80μm. Polar densities, phkl, of diffractional lines

hkl were calculated by Harris method. It was established, that tin, indium, and bismuth have texture

(100), (101) and texture  bismuth, correspondly. These textures are conserved in solid solution

and eutectic alloys. Textures of tin and indium are caused with most density packed planes. The texture

of bismuth is caused with orientation covalent bonds.

bismuth, correspondly. These textures are conserved in solid solution

and eutectic alloys. Textures of tin and indium are caused with most density packed planes. The texture

of bismuth is caused with orientation covalent bonds.

Keywords: Rapidly solidified foils; Tin; Indium; Bismuth; Polar density of diffractional line; Texture, Eutectic alloys

Introduction

Alloys of tin, indium and bismuth are considered as solders, contained lead and cadmium,

are dangerous for the Enviroment and Humen Health. These metals are anisotropic, and

their properties depend on texture (predominant orientation of grains) of material. Texture

must be taken into account when producing solders and other production. Despite on large

quantity of investigation of the alloys on base of light melt metals, forming of texture was

studied not enough. Because in this article was considered forming of textures of tin, indium,

bismuth, and their solid solutions, eutectic, and intermediate phases.

The foil textures were studied with roentgen methods, for example using the inverse pole

figures. The polar densities, phkl, of diffraction were calculated by Harris method [1]. A mass of

alloy ≈0.2g was cut off from ingot and melted into a quartz tube at 450-600K and then injected

on inner polish surface of rotary copper cylinder. Thickness of rapidly solidified foil (RSF) is

30-80μm. According to calculation [2-4], cooling rate were 105-106K/s, which corresponds

to the ultrarapid quenching rate range. Roentgen radiation fell on the foil surface, which

was contacted with crystallizer. PSF of tin and have texture (100) and (101) correspondly,

bismuth-binary texture  + (0001). Textures (100) of Sn, (101) of In and

+ (0001). Textures (100) of Sn, (101) of In and  of Bi are

increased and texture (0001) of Bi is disappeared with increase of the rotation frequency of

the cupper and the concentration of doping atoms.

of Bi are

increased and texture (0001) of Bi is disappeared with increase of the rotation frequency of

the cupper and the concentration of doping atoms.

The planes (100) of tin and (101) of indium and their solid solutions have the most

densities of atoms, what define growth of grains with such orientations and forming texture

[1,3-8]. Forming of texture  in bismuth and its alloys are caused crystal structure and

orientation of covalent bonds, which form angles 95, 5° to each other. Two covalent bonds

of every atom are located in same plane

in bismuth and its alloys are caused crystal structure and

orientation of covalent bonds, which form angles 95, 5° to each other. Two covalent bonds

of every atom are located in same plane  . The third bond binds two atom in adjacent

planes

. The third bond binds two atom in adjacent

planes  . Broken covalent bonds on planes

. Broken covalent bonds on planes  contribute to the additional atom from

the liquid to the crystal phase, which leads to a rapid growth of grains in which plane

contribute to the additional atom from

the liquid to the crystal phase, which leads to a rapid growth of grains in which plane  is

perpendicular to the direction of the heat flow [8]; (Table 1).

is

perpendicular to the direction of the heat flow [8]; (Table 1).

Table 1:Polar densities of diffraction lines of tin, indium, bismuth, and its alloys.

Forming of texture  in bismuth and its alloys are caused

crystal structure and orientation of covalent bonds, which form

angles 95, 5˚ to each other. Two covalent bonds of every atom are

located in same plane

in bismuth and its alloys are caused

crystal structure and orientation of covalent bonds, which form

angles 95, 5˚ to each other. Two covalent bonds of every atom are

located in same plane  . The third bond binds two atom in

adjacent planes

. The third bond binds two atom in

adjacent planes  . Broken covalent bonds on planes

. Broken covalent bonds on planes  contribute to the additional atom from the liquid to the crystal

phase, which leads to a rapid growth of grains in which plane

contribute to the additional atom from the liquid to the crystal

phase, which leads to a rapid growth of grains in which plane  is perpendicular to the direction of the heat flow [8].

is perpendicular to the direction of the heat flow [8].

Indium and tin form β-phase (In3Bi) and γ -phase (InSn4). RSF

of β-phase has texture (101) and γ-phase – texture (0001). Forming

textures in these phases are caused the most densities of atoms on

planes, what define growth of grains with such orientations [5,6].

Texturies of RSF of the eutectic in + 47 at. % Sn are (101) of β-phase

and  of γ-phase [5-7]. RSF of the eutectic alloy In-56 at. %

Bi consist of solid solution bismuth (texsture

of γ-phase [5-7]. RSF of the eutectic alloy In-56 at. %

Bi consist of solid solution bismuth (texsture  and ε-phase

(InBi) with light texture (101) +(111). RSF of the eutectic alloy

In-21 at. % Bi are mixture of In and In2Bi with weak texture (001)

+(110) and

and ε-phase

(InBi) with light texture (101) +(111). RSF of the eutectic alloy

In-21 at. % Bi are mixture of In and In2Bi with weak texture (001)

+(110) and  +(1011), correspondily [9].

+(1011), correspondily [9].

Study of PSF of ternary alloy showed that texture formation

occurs in their phases. For example, the foils consist of the solid

solution of bismuth and tin and ε-phase (InBi), which have textures

+(0001), (100) and (102) +(101), correspondly. Thus, the

formation of the texture of pure components and phases formed

in binary and ternary alloys based on tin, indium and bismuth

is determined by density of atoms on the crystal planes and

orientation of covalent bonds.

+(0001), (100) and (102) +(101), correspondly. Thus, the

formation of the texture of pure components and phases formed

in binary and ternary alloys based on tin, indium and bismuth

is determined by density of atoms on the crystal planes and

orientation of covalent bonds.

References

- Waccehvann G, Greven J (1962) Texturen metallischer Wekstoffe, Verlagberlin, Gottingen, Heiddberg, Springer, Germany.

- Miroshnichenko IS (1982) Hardening from the liquid state. Metallurgy, Moscow, Russia.

- Gusakova OV, VG, Husakova SV (2010) Grain structure and texture rapidly solidified tin foils. Materiails, Technjlagy, Tool 19 (2): 54-57.

- Shepelevich V. Hight speed solidification of bismuth, tin, and indium alloys. LAP LAMBEERT Academic Publishing, CA, USA.

- Van Tzintzte, Shepelevich VG (2010) Grain structure of rapidly quenched foils of indium. Vestnic BSU Ser 12: 28-30.

- Shepelevich VG, Van Tzintzte, Shcerbachenko LP (2017) Phase composition, microstructure and microhardness. News of Science and Technology 1: 48-53.

- Shepelevich VG, Gusakova OV, Koucharenko EL, Husakova SV (2019) Microstrural studies of ultrarapidly quenched foils of zinc - doped indium - tin eutectic alloys. Journal of Materials Science 54: 2577-2584.

- Shepelevich VG (1991) Texture of rapidly solidified foils of bismuth, antimony and it’s alloys. Crystallography 36(1): 231-239.

- Koukharenko E, Frety N, Nabias G, Shepelevich V, Tedenac J (2000) Microstructural study of Bi2Te3 material obtained by the ultrarapid quenching process route. Journal of Crystal Growth 209(4): 773- 778.

© 2021 Shepelevich VG. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)