- Submissions

Full Text

COJ Robotics & Artificial Intelligence

Industry 4.0 Technologies in Logistics and Supply Chain Management

Asad Ullah*, Syed Arshad Hussain, Arif Deen and Shahid Imran

Department of Management Studies, Middle East College, Muscat, Oman

*Corresponding author: Asad Ullah, Assistant Professor, Middle East College, Muscat, Oman

Submission: February 15, 2024;Published: February 28, 2024

ISSN:2832-4463 Volume3 Issue4

Abstract

The Fourth Industrial Revolution (4IR) epitomizes the most advanced stages of technological innovation, guiding manufacturing and service providers towards achievable sustainability. While it has found diverse applications across various industries, businesses in both developed and developing nations have yet to fully embrace Industry 4.0 technologies. This research focuses on highlighting the importance and application of Industry 4.0 technology within Logistics and Supply Chain Management. We utilize qualitative research methodology to conduct a thorough analysis of the critical elements, challenges, and potential opportunities linked to the incorporation of advanced technologies in these domains. Through this approach, we aim to provide a comprehensive understanding of the implications and possibilities that arise with the implementation of Industry 4.0 in logistics and supply chain management processes.

The study also sheds light on the primary barriers hindering the adoption of Industry 4.0, revealing that many companies lack a comprehensive strategy to meet the technological demands. Merely relying on pilot initiatives is insufficient to achieve Industry 4.0 in the coming years. Existing employee skills do not entirely align with the required skill sets desired by companies for future technology integration. Furthermore, the current level of equipment digitization technology is at a medium level, suggesting room for improvement through a well-prepared strategy. The key barriers to Industry 4.0 adoption include the absence of a robust strategy, inadequacy of employee skills, future IT investment decisions, and challenges related to business data usage and analysis. Consequently, a framework is proposed to guide companies in developing a well-balanced technology strategy, facilitating the organization in meeting future technological needs.

Keywords:Logistics; Supply chain management; Industry 4.0; Technologies; Strategy

Introduction

Our goal in this work was to identify important research gaps and provide a summary of the existing knowledge by conducting a narrative literature review. Contemporary supply chains have evolved into intricate and highly sophisticated value networks, serving as pivotal contributors to gaining a competitive edge. However, ensuring product visibility throughout this complex value chain network and verifying the origins of raw materials pose growing challenges [1,2]. Enterprises stand to gain substantial advantages through the integration of Industry 4.0 technologies, notably the Internet of Things (IoT), enabling them to effectively observe, track, and monitor goods, activities, and processes within their intricate value chain networks. Businesses are turning to innovative technologies as supply chains become more complicated and heterogeneous due to the increasing requirement for intra- and interorganizational connectivity, which is being driven by tightly integrated business processes and modern technological breakthroughs [3,4]. These include notions like the physical Internet as well as the Internet of Things (IoT), cloud computing, business analytics, AI, ML, and Blockchain technology. The advent of several technologies at the same time and the widespread presence of linked devices, sometimes referred to as “smart” things or gadgets, enable value chain participants to reach new heights of efficiency and effectiveness [5].

The proliferation of smart devices and the ever-evolving technological landscape present a unique opportunity for supply chain partners to enhance both effectiveness and efficiency. These advancements, encompassing a diverse range of technologies frequently rolled out simultaneously, enable significant improvements in data collection, information exchange, and collaborative analysis between involved parties [6]. This not only paves the way for fundamental transformations in contemporary supply chain operations but also fosters greater transparency and trust among various stakeholders. Consequently, investigating the impact of these emerging technologies on supply chains remains a critical area of inquiry for both academics and practitioners alike [7].

The Internet of Things (IoT) and other Industry 4.0 technologies include sensors, active and passive RFID tags, and other electronics that are networked together. These devices are capable of processing, storing, and exchanging data in addition to detecting movement, activity, and temperature. For example, by monitoring environmental conditions during transportation and storage, Internet of Things (IoT)-enabled sensor devices connected to a wireless sensor network (WSN) can assist maintain product quality and safety in the food supply chain. WSNs notify supply chain partners in real-time and initiate actions based on predefined parameters by utilizing mobile networks to communicate with a base station [8,9]. The rapid use of Industry 4.0 technologies-particularly IoT-across industries attests to their expanding economic significance. The ubiquity of information and communication technologies (ICT) in supply chains and logistics can be attributed to the convergence of machine automation and ICT, as well as the declining costs of connected devices [10].

Logistics and supply chains have been found to be critical areas for implementing Industry 4.0 technology, especially IoT. By facilitating better material flow tracking and resulting in increased efficiency in crucial processes, the use of IoT can boost supply chain competitiveness. IoT makes it easier for multi-party supply chains involved in production, quality control, distribution, and logistics to share accurate and timely information [11]. IoT applications also help to lower costs, increase productivity, enhance customer satisfaction, and increase visibility within manufacturing facilities and along the supply chain. There are still difficulties even with the anticipated advantages of using Industry 4.0 technologies, such as IoT, in supply chains [12,13]. When working at the ecosystem level, technical concerns including security, authenticity, secrecy, and privacy present difficulties. Security is emphasized as a crucial problem, and current solutions are limited in terms of processing overhead and energy use [14]. Concerns about data theft, hacking, manipulation, and counterfeiting make supply chain partners less trusting. Academics stress that in order to improve trust and maximize the benefits of connected IoT devices in supply chains, security measures must be developed [15,16]. These IoT security concerns are seen to have a potential remedy in blockchain technology, which provides particular assurances for permitted data access and change.

Review of Literature

This study delves into the impact of Industry 4.0 technologies on logistics and supply chain management, focusing on the Internet of Things (IoT) as a prominent example.

Understanding the Internet of Things (IoT) and its role in supply chains

Coined in 1999 by British businessman Kevin Ashton, the Internet of Things (IoT) essentially refers to a vast information network connecting diverse physical objects embedded with sensors - from industrial machinery and pallets to consumer goods, tools, and even household appliances [17]. By decentralizing processing, storage and communication through local devices, cloud computing, alongside the newer concept of fog computing, facilitates expansion and scalability for connecting, storing, and analyzing the immense data generated by the IoT, often referred to as “big data” [18]. Geographic information systems (GIS), wireless sensor networks (WSNs), global positioning systems (GPS) and general packet radio service (GPRS) are some of the key sources for acquiring this data. By analyzing this IoT data, real-time responses to situations become possible, potentially leading to automation and predictive analytics capabilities. Essentially, IoT devices, such as sensors, act as intelligent entities, sensing their surroundings, wirelessly connecting, and taking appropriate actions based on pre-defined parameters [19]. According to Barreto et al., the core characteristics of IoT - context, omnipresence, and optimization - enable real-time monitoring, engagement, and swift responses within regulated environments [20].

The anticipated emergence of 5G technology, with its accelerated data transfer rates, is poised to propel the rapid development and widespread integration of IoT into society. Cisco predicts 500billion IoT devices online by 2030, unlocking a plethora of new business opportunities [21]. The multifaceted applications of IoT have already permeated diverse industries, ranging from healthcare and automotive to smart homes, agriculture, and construction. As highlighted by Lee & Lee, within the realm of supply chains and logistics, five key IoT technologies have emerged as fundamental components: RFID, wireless sensor networks (WSNs), middleware, cloud computing, and IoT application software [22]. RFID, utilizing passive tags compliant with the GS1 Electronic Product Code (EPC) UHF Gen 2 standard, is extensively employed in supply chain operations. WSNs, consisting of node clusters, enhance real-time monitoring, leading to more efficient resource allocation [23]. Middleware acts as a central hub, collecting, storing, and organizing data for IoT applications. Cloud computing’s on-demand access to reconfigurable computing resources benefits data flow within the supply chain. Ultimately, cloud-based IoT applications ensure seamless data processing and prompt information transfer, enabling faster machine-to-machine and human-to-machine communication [24].

IoT in supply chains: levers and application scenarios

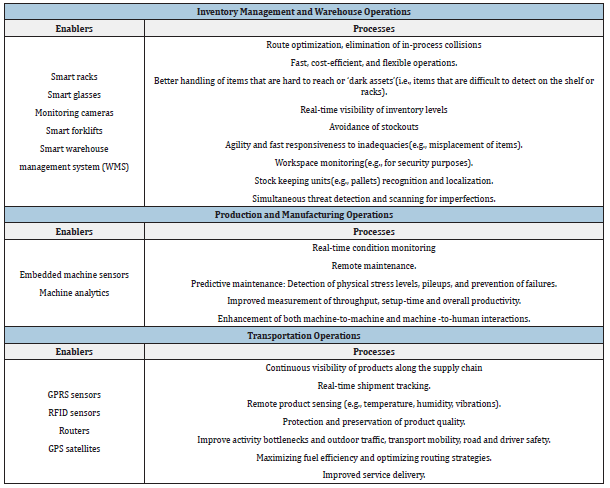

The deployment of IoT technology presents significant opportunities for improving supply chain effectiveness and operational efficiency. The main source of these benefits is the realtime information sharing, which can reduce the amount of time wasted due to the bullwhip effect [25,26]. Furthermore, IoT can significantly lower the dangers related to counterfeiting and illegal trading when paired with overt, covert, or forensic security features on tangible goods. As a result, IoT has the potential to completely alter supply chains, resulting in increased operational effectiveness and new business prospects [27]. Production and manufacturing activities, transportation operations, inventory management and warehousing operations are the three main areas that stand to gain from the implementation of IoT (Table 1).

Table 1:IoT levers in supply chains (Rajeb et al, 2019)

The Internet of Things (IoT) emerges as a cornerstone for revolutionizing various aspects of supply chain management, including inventory tracking, warehouse process optimization, reduced labor costs, and improved throughput times [28]. Smart forklifts, intelligent storage racks, “smart glasses” equipped with cameras and sensors for pinpointing inventory locations, monitoring cameras, and specialized warehousing software collectively spearhead this transformative wave. By attaching IoTenabled tags or devices to reusable warehouse assets like pallets and totes, pickers can effortlessly locate their designated storage areas. Furthermore, IoT fosters efficiency by minimizing manual efforts in product and material location, alongside automating tasks like picking and packing within the warehouse environment. Additionally, by automating the order dispatch and inventory receiving procedures at warehouses and distribution centers, IoT reduces costs and errors. The time spent on data collection, recording, and retrieval is decreased by using commercial RFID readers and antennas in receiving and shipping docks to recognize RFID tags on pallets, totes, or product cartons [29,30]. In certain industrial settings, RFID tags solve problems with barcode readability and provide greater read accuracy [29].

The second major benefit is the application of IoT in manufacturing and production. Intelligent sensors, microcomputers, microcontrollers, and microprocessors are examples of smart devices that can be used to monitor and control industrial machinery in real time. IoT-based solutions improve throughput, processing capacity, setup time, and operational control. This results in reduced production bottlenecks, increased machine efficiency, and improved production scheduling and planning. Furthermore, by enabling predictive maintenance and promptly detecting machine faults, IoT enablement offers increased agility and proactivity [30]. Improved machine-to-machine and machine-to-human interaction, as well as collaboration and value co-creation with suppliers, are all facilitated by this deeper understanding of production processes. IoT has the potential to be advantageous in the area of supply chain transportation activities. A well-defined and configured Transportation Management System (TMS), also referred to as a “smart” TMS, is facilitated by IoT-enabled solutions [19]. Certain IoT devices improve flexibility and efficiency by revolutionizing transportation procedures. As an illustration, GPS assists in positioning refrigerated vehicles from distant distribution centers, improving routing, cutting down on delivery times, and maintaining product quality [31]. In-transit visibility is improved by GPS, RFID, and other linked sensors that measure temperature, humidity, and accurately localize automobiles. Delivery time, fleet availability, and route efficiency predictions are all improved by the data gathered from these Internet of Things devices [30]. Furthermore, these gadgets make it easier for cars to share resources when parked or driving, which improves the effectiveness of transportation as a whole [19].

IoT in supply chains: weaknesses and threats

IoT has the potential to greatly improve supply chain operations by connecting previously disconnected elements [32]. It tackles several supply chain issues, such as the requirement to strengthen production data integrity and transparency as well as product identification (making sure the appropriate items are in the right quantities, conditions, and prices) [19]. But the enormous amounts of data that the Internet of Things generates throughout the supply chain frequently remain in idle silos, making it more difficult to extract business insights in real time. Because of businesses’ propensity to hoard data, Gartner refers to these data silos as “dark data” (https://www.gartner.com/smarterwithgartner/how-totackle- black-data/). The successful integration of IoT necessitates thorough mitigation of associated security risks [33]. These concerns encompass trust in the devices themselves, access control measures, data integrity, physical tampering prevention, and user privacy protection. A recent survey highlights the vulnerability of 70% of IoT devices, citing weak encryption, exposed interfaces, flawed permission structures, and inadequate software protection as key contributing factors [22].

According to Cam-Winget et al. [33], the dynamic nature of IoT networks and scalability challenges render standard security solutions inadequate. The server-based infrastructure of the current Internet architecture could not be able to manage multiple devices and enormous volumes of data, creating a single point of failure for physical and cyberattacks. IoT devices run the risk of being remotely hijacked, targeted by DDoS attacks, and stolen data. Furthermore, certain Internet of Things (IoT) systems may lack robust service level agreements, potentially jeopardizing the protection of personally identifiable information (PII) and raising concerns about data integrity, security, and privacy [34]. While the Internet of Things (IoT) boasts the capability to authenticate and verify item authenticity, concerns regarding the physical security and privacy of product information persist among supply chain partners. These anxieties stem from potential vulnerabilities surrounding content manipulation, tampering, cloning, and counterfeiting, especially if Radio Frequency Identification (RFID) tags are compromised and exploited to bypass security protocols [35]. Additionally, the manual retrieval and storage of unique tag IDs within centralized databases create avenues for information replication and forgery, further complicating the detection of counterfeit goods with fabricated provenance histories [31].

In IoT implementations for supply chain traceability, centralized systems could present vulnerabilities. The presence of centralized organizations might breed mistrust and impede supply chains’ ability to get even better [36]. Risks to data integrity, security, and privacy associated with centralized data hosting and control include the potential for cloud-based monitoring solutions to be manipulated and privacy laws to be violated when sending private data to outside providers. Furthermore, opacity brought on by centralized systems may exacerbate information asymmetry amongst supply chain participants. One possible way to lessen these difficulties is by the application of blockchain technology [37].

Research Methodology

Conducting an extensive narrative review, this study meticulously examined the available literature to amalgamate insights and pinpoint crucial gaps in contemporary knowledge. This approach aimed to distill collective wisdom, presenting a comprehensive overview of the subject matter. Employing this method, essential themes, challenges, and opportunities pertaining to Industry 4.0 in Logistics and Supply Chain Management were methodically extracted. The study contributes nuanced perspectives to the dynamic intersection of technology and logistics.

To ensure a comprehensive understanding, the review incorporates “grey” literature alongside academic publications, capturing recent developments across all relevant sources. Primary information sources include renowned databases like EBSCO Business Source Premier, Scopus, IEEE Xplore, ScienceDirect, and Google Scholar. Additionally, conference proceedings and cited references from relevant papers are meticulously examined through a snowballing approach to uncover supplementary and overlooked materials. The search strategy utilizes a combination of keywords: (“Industry 4.0” OR “4th Industrial revolution technologies”) AND (“Internet of Things” OR “IoT”) AND (“supply chain*” OR “logistics”).

Data collection and analysis were conducted between February and April 2023. Each identified paper underwent rigorous screening for relevance, and core topics were meticulously summarized. Subsequently, these topics were synthesized and leveraged to formulate research questions guiding further investigation. This resulted in a comprehensive map delineating the potential impacts of Industry 4.0 technologies on various aspects of LSCM.

Discussion

Industry 4.0, often hailed as the fourth industrial revolution, signifies a profound transformation in industrial processes through the pervasive integration of digital technologies. In the context of logistics and supply chain management, these Industry 4.0 innovations serve as dynamic catalysts, reshaping operational norms to enhance efficiency, amplify visibility, and fortify responsiveness across the expansive tapestry of the supply chain. This monumental shift is conspicuously manifested in the harmonious amalgamation of cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics, woven seamlessly into the fabric of supply chain operations. The synergies thus forged by these technologies empower organizations to navigate the intricate web of supply chain intricacies with unparalleled precision, cultivating a supply chain ecosystem that is not only dynamic but also highly responsive.

The infusion of advanced technologies within the supply chain landscape, as brought forth by Industry 4.0, signifies more than a mere technological evolution; it marks a paradigm shift in the operational ethos of businesses. The IoT, AI, and data analytics converge to create a symbiotic relationship that revolutionizes how businesses perceive and engage with their supply chain processes. This transformation culminates in a supply chain ecosystem characterized by its adaptability and precision, where businesses possess the tools to optimize resource allocation, streamline processes, and proactively navigate challenges. The result is a heightened state of operational excellence that positions businesses on the cutting edge of supply chain management.

The implications of this paradigm shift extend beyond mere operational enhancements. Industry 4.0’s impact resonates throughout the organizational framework, providing businesses with a strategic advantage in resource optimization and operational fluidity. It is within this transformed landscape that businesses find themselves equipped not only to meet current challenges but also to pre-emptively address emerging issues. The holistic integration of technologies within supply chain operations, fostered by Industry 4.0, serves as a testament to the adaptability and resilience that businesses can harness in a rapidly evolving marketplace.

The adoption of Industry 4.0 technologies is not merely a technological upgrade; it is an organizational metamorphosis that propels businesses into an era of heightened operational prowess. Through the intricate fusion of IoT, AI, and data analytics, Industry 4.0 reshapes supply chain dynamics, fostering an ecosystem that is not only responsive but also anticipatory. This discussion lays the groundwork for understanding the transformative power of Industry 4.0 in reshaping the logistics and supply chain management landscape. The key aspects and implications of Industry 4.0 in logistics and supply chain management:

Real-time visibility

Industry 4.0 technologies enable real-time monitoring and tracking of goods throughout the supply chain. RFID (Radio- Frequency Identification), GPS and IoT (Internet of Things) devices provide accurate and instant information on the location and condition of shipments. This real-time visibility allows stakeholders to make data-driven decisions, reduce lead times and optimize inventory levels.

Automation and robotics

Automation and robotics are integral components of Industry 4.0. Autonomous vehicles, drones, and robotic systems streamline warehouse processes, minimizing errors, and accelerating order fulfillment. Automated guided vehicles (AGVs) and autonomous drones are increasingly used for tasks such as inventory counting, picking, and packing, leading to improved operational efficiency.

Predictive analytics and machine learning

Industry 4.0 leverages predictive analytics and machine learning to analyze historical data, forecast demand, and optimize inventory. This proactive approach helps in minimizing stockouts, reducing excess inventory, and improving overall supply chain resilience. Machine learning algorithms can also optimize routing and scheduling, considering factors like traffic conditions, weather, and transportation costs, leading to more efficient and cost-effective logistics operations.

Blockchain technology

Blockchain emerges as a pivotal technology augmenting transparency, traceability, and security within supply chain operations. Its immutable ledger meticulously captures each transaction and movement of goods, substantially mitigating fraud risks and guaranteeing product authenticity. Particularly noteworthy is the role of smart contracts, a facet empowered by blockchain. These contracts not only automate but also enforce contractual agreements, fostering expeditious and secure transactions among supply chain participants.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies find application in training, maintenance, and quality control. Warehouse workers benefit from hands-free picking and packing guided by visual instructions through AR devices. VR simulations are utilized for training drivers, reducing the learning curve and enhancing safety in transportation operations.

Cyber-physical systems

Cyber-physical systems integrate digital technologies with physical processes, creating intelligent and responsive supply chain ecosystems. This integration allows for seamless communication between machines, sensors, and humans, fostering a more interconnected and efficient supply chain. For example, smart factories leverage cyber-physical systems to enable real-time communication and coordination between machines on the factory floor, leading to enhanced production efficiency.

Data security and interoperability

As Industry 4.0 relies heavily on data exchange between various devices and systems, ensuring robust cybersecurity measures and interoperability standards is crucial. This safeguards sensitive information and ensures that different components of the supply chain can seamlessly communicate with each other.

Environmental sustainability

Industry 4.0 technologies play a crucial role in advancing environmental sustainability within logistics and supply chain operations. By optimizing transportation routes, minimizing energy consumption, and reducing waste through data-driven insights, these technologies align with sustainability goals. This eco-conscious approach contributes to the broader commitment to reducing the ecological footprint of supply chain activities. In conclusion, Industry 4.0 technologies are revolutionizing logistics and supply chain management by providing unprecedented levels of connectivity, visibility, and efficiency. Embracing these technologies is not just about adopting the latest tools; it’s a strategic shift toward a more intelligent and responsive supply chain that can adapt to the dynamic challenges of the modern business landscape.

Conclusion, Limitations and Further Research

While Industry 4.0 technologies undoubtedly usher in a new era of connected, intelligent, and agile supply chains, their transformative journey is far from complete. This study has illuminated the immense potential of these technologies, particularly the Internet of Things (IoT), in bolstering supply chain integrity and efficiency. However, as with any transformative journey, challenges and uncertainties emerge alongside opportunities.

Firstly, the inherent dynamism of IoT environments, coupled with ever-evolving security regulations and interoperability requirements necessitates ongoing research efforts as highlighted by [38,39]. Future scholarly investigations should delve deeper into diverse application scenarios, leveraging established theoretical frameworks while remaining agile to adapt to emerging phenomena [40]. This will require cross-disciplinary collaboration, drawing from expertise in fields such as logistics, information technology, and law to tackle complex issues like data security and regulatory compliance.

Secondly, unlocking the full potential of Industry 4.0 demands a nuanced understanding of its human impact. While automation offers efficiency gains, potential job displacement and the need for re-skilling must be addressed. Research should explore strategies for mitigating negative human consequences while maximizing the benefits of human-machine collaboration within these evolving ecosystems. Finally, the proposed research propositions serve as steppingstones for further exploration. Their operationalization and refinement across diverse research settings will yield deeper insights into the intricate interplay between Blockchain, IoT, and supply chain management. This requires robust collaboration between academia, industry, and policymakers to ensure impactful research translates into tangible solutions for real-world challenges.

In conclusion, while Industry 4.0 represents a significant leap forward, the path towards its full realization demands continued research efforts. By addressing the complexities of a dynamic technological landscape, fostering responsible human integration, and actively collaborating across disciplines, we can unlock the true potential of Industry 4.0 to transform supply chains into engines of sustainable and resilient global commerce.

References

- Sahin F, Robinson EP (2005) Information sharing and coordination in make-to-order supply chains. J Oper Manag 23(6): 579-598.

- Fayezi S, Zomorrodi M (2015) Supply chain management: Developments, theories and models. In: Handbook of Research on Global Supply Chain Management IGI Global, Hershey, Pennsylvania, USA, pp. 313-340.

- Zantalis F, Koulouras G, Karabetsos S, Kandris D (2019) A review of machine learning and IoT in smart transportation. Future Internet 11(4): 94.

- Li Y (2018) An integrated platform for the internet of things based on an open-source ecosystem. Future Internet 10(11): 105.

- Treiblmaier H (2019) Combining blockchain technology and the physical internet to achieve triple bottom line sustainability: A comprehensive research agenda for modern logistics and supply chain management. Logistics 3(1): 10.

- Kharlamov AA, Parry GC (2018) Advanced supply chains: Visibility, blockchain and human behaviour. In: Moreira AC, Ferreira LMDF, Zimmerman RA, (Eds.), Innovation and Supply Chain Management Springer International Publishing: Cham, Switzerland, pp. 321-343.

- Rejeb A, Sule E, Keogh JG (2018) Exploring new technologies in procurement. Transport & Logistics: The International Journal 18(45): 76-86.

- Hofstede GJ (2007) Trust and transparency in net chains: A contradiction? In: Wang William YC, Michael SHH, Patrick YKC, (Eds.), Supply Chain Management: Issues in the New Era of Collaboration and Competition, Idea Group Inc: Hershey, Pennsylvania, USA, pp. 105-126.

- New S (2010) The transparent supply chain. Harvard Business Review, Brighton, Massachusetts, USA.

- Hsiao HI, Huang KL (2016) Time-temperature transparency in the cold chain. Food Control 64: 181-188.

- Óskarsdóttir K, Oddsson GV (2019) Towards a decision support framework for technologies used in cold supply chain traceability. Journal of Food Engineering 240: 153-159.

- Atzori L, Iera A, Morabito G (2010) The internet of things: A survey. Computer Networks 54(15): 2787-2805.

- Gubbi J, Buyya R, Marusic S, Palaniswami M (2013) Internet of Things (IoT): A vision, architectural elements, and future directions. Future Generation Computer Systems 29: 1645-1660.

- Shrouf F, Ordieres J, Miragliotta G (2014) Smart factories in industry 4.0: a review of the concept and of energy management approached in production based on the internet of things paradigm. In: IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, pp. 697-701.

- Chen IR, Guo J, Bao F (2014) Trust management for service composition in SOA-based IoT systems. 2014 IEEE Wireless Communications and Networking Conference (WCNC), Istanbul, Turkey, pp. 3486-3491.

- Yane D (2011) Design of intelligent agriculture management information system based on IoT. In: 2011 Fourth International Conference on Intelligent Computation Technology and Automation, Shenzhen, China.

- Pérez L, Paulino Santos VD, Cambra Fierro JJ (2017) Taking advantage of disruptive innovation through changes in value networks: Insights from the space industry. Supply Chain Management An International Journal 22(2).

- Tzounis A, Katsoulas N, Bartzanas T, Kittas C (2017) Internet of things in agriculture, recent advances and future challenges. Biosysems Engineering 164: 31-48.

- Keertikumar M, Shubham M, Banakar RM (2015) Evolution of IoT in smart vehicles: An overview. In: 2015 International Conference on Green Computing and Internet of Things (ICGCIoT), Noida, India, pp. 805-810.

- Barreto L, Amaral A, Pereira T (2017) Industry 4.0 implications in logistics: An overview. Procedia Manufacturing 13: 1245-1252.

- Witkowski K (2017) Internet of Things, big data, industry 4.0-Innovative solutions in logistics and supply chains management. Procedia Engineering 182: 763-769.

- Celestine A, Peter JD (2020) An IoT based modified graph cut segmentation with optimized adaptive connectivity and shape priors. Sustainable Computing: Informatics and Systems 28: 100249.

- Lee I, Lee K (2015) The Internet of Things (IoT): Applications, investments and challenges for enterprises. Business Horizons 58(4): 431-440.

- Lu W, Huang GQ, Li H (2011) Scenarios for applying RFID technology in construction project management. Automation Construction 20(2): 101-106.

- Saragih LR, Dachyar M, Zagloel TYM, Satar M (2018) The industrial IoT for Nusantara. In: 2018 IEEE International Conference on Internet of Things and Intelligence System (IOTAIS), Bali, Indonesia, pp. 73-79.

- Wang SJ, Liu SF, Wang WL (2008) The simulated impact of RFID-enabled supply chain on pull-based inventory replenishment in TFT-LCD industry. International Journal of Production Economics 112(2): 570-586.

- Zhou Z (2012) Applying RFID to reduce bullwhip effect in a FMCG supply chain. Advances in Computational Environment Science, Berlin, Heidelberg, Germany, pp. 193-199.

- Newman D (2018) How IoT will impact the supply chain.

- Jedermann R, Ruiz Garcia L, Lang W (2009) Spatial temperature profiling by semi-passive RFID loggers for perishable food transportation. Computers and Electronics Agriculture 65(2): 145-154.

- Goyal S, Hardgrave B, Aloysius JA, DeHoratius N (2016) The effectiveness of RFID in backroom and sales floor inventory management. The International Journal of Logistics Management 27(3): 795-815.

- Obitko M, Jirkovský V, Bezdícˇek J (2013) Big data challenges in industrial automation. In: Proceedings of the International Conference on Industrial Applications of Holonic and Multi-Agent Systems, Berlin, Heidelberg, Germany, pp. 305-316.

- Rejeb A (2018) Blockchain Potential in Tilapia Supply Chain in Ghana. Acta Technica Jaurinensis 11(2): 104-118.

- Cam Winget N, Sadeghi AR, Jin Y (2016) Invited: Can IoT be secured: Emerging challenges in connecting the unconnected. 53rd Annual Design Automation Conference (DAC), Austin, Texas, USA.

- Yang K, Forte D, Tehranipoor MM (2015) Protecting endpoint devices in IoT supply chain. IEEE/ACM International Conference on Computer-Aided Design, Austin, Texas, USA.

- Suresh P, Daniel JV, Parthasarathy V, Aswathy RH (2014) A state of the art review on the Internet of Things (IoT) history, technology and fields of deployment. International Conference on Science Engineering and Management Research (ICSEMR), Chennai, India, pp. 1-8.

- Biswas K, Muthukkumarasamy V, Tan WL (2017) Blockchain based wine supply chain traceability system. Future Technologies Conference (FTC), Vancouver, Canada, pp. 1-7.

- Cekerevac Z, Prigoda L, Maletic J (2018) Blockchain technology and industrial internet of things in the supply chains. Mest Journal 6(20): 39-47.

- Vermesan O, Friess P (2015) Building the hyperconnected society: Internet of Things research and innovation value chains, ecosystems and markets. River Publishers Series in Communications 43: 1-332.

- Wu D, Arkhipov DI, Asmare E, Qin Z, McCann JA (2015) UbiFlow: Mobility management in urban-scale software defined IoT. 2015 IEEE Conference on Computer Communications (INFOCOM), pp. 208-216.

- De Filippi P, Wright A (2018) Blockchain and the law: The rule of code. Harvard University Press, Cambridge, Massachusetts, USA, p. 300.

© 2024 Asad Ullah. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)