- Submissions

Full Text

COJ Biomedical Science & Research

Effect of Different Dispersion Blade Designs on Processing Parameters and Properties of Solvent Borne Coating

Qureshi S. A.*

Department of Chemical Engineering, Pakistan

*Corresponding author: Dr. Engr. Sheraz Ahmed Qureshi, Institute of Chemical Engineering & Technology, PU, Pakistan, Email. sheraz7_2000@yahoo.com, Talk. 00923229001936

Submission: May 05, 2021; Published: June 10, 2021

Volume2 Issue1June 2021

Abstract

The effect of different dispersion blade designs on processing parameters and different properties of solvent borne white paint was observed. Three paint samples were produced having same formulation by replacing different agitator dispersion blades with same diameters. It was found that dispersion blade designs affect loading time, dispersion time and total processing time. Different blades also have an impact on power consumption and processing temperature. Solvent borne paint whiteness and opacity is also affected by blade design.

Keywords: Agitator; Amperes; Blade; Design; Dispersion; Opacity; Vortex; Whiteness

Introduction

Mixing is one of the most fundamental operations in industries like paper, food, cosmetic, paints, chemical, biochemical and pharmaceutical applications. Stirred vessels are widely used in the chemical industry for mixing very viscous liquids. Different types of rotating mixers are in use, in many cases simple propellers, turbines or anchor agitators. A helicalribbon agitator can be very effective [1,2].

Agitator is one of the important parts in the mixing process. Proper and uniform mixing gives improved quality of the product. The design of agitator effects on the mixing process as proper design can increase the mixing and uniform distributions of all additives, chemicals, raw material present in pulp. All operations involving blending, homogenization, emulsion preparation, extraction, dissolution, crystallization, liquid phase reactions, etc., need mixing in one form or the other [3].

Eccentric mixing is one of the traditional methods of promoting mixing in a vessel without baffles. An eccentrically located impeller generates a vertical flow, which contributes to mixing, without baffles. If a large impeller is used at an eccentric position, it is expected that the high performance of the large impeller can be combined with the advantages of eccentric mixer Separation damage and fracture rock movement reflect [4]. Agitators having a small blade area which rotate at high speed, for instance, propellers, flat or curved blade turbine are used to mix liquids having low viscosities [3]. Weetman et al. [5] developed a new type of mixer to provides axial flow in a non-uniformly flow field. The impeller will operate reliably in the environment which provides variable loads on the blades. Many methods are available for predicting solid distribution in agitated tank. These include optical method, sample withdrawal method, iso-kinetic sampling, two electrode conductivity probe method, four electrode conductivity probe method [6].

Researchers have been trying to find more efficient methods to improve the quality of mixing process. Many have studied the effects of geometry [7-9] operating condition [10] and rheological behavior of the fluid on quality of mixing [11,12] and also to predict the mixing time and to prepare the homogenization curves [13].

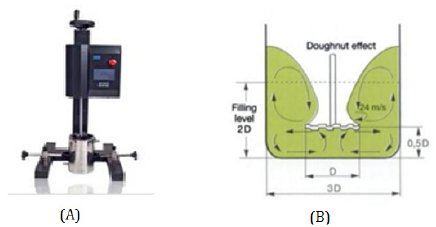

Paint manufacturing dispersers (agitators) are of two types, variable speed and fixed speed dispersers. Variable speed dispersers are always preferred due to low dust creation during raw material loading. After addition of additives and powders and complete wetting, revolution per minute is increased [14]. A benefit associated with high-speed dissolver is that they are less expensive, and they require low maintenance. Conventional agitator is shown in Figure 1a.

After proper dispersion of the mill base, solvent and binder are added. Binder helps to adhere the substrate and forms a durable film [15]. Scheme of flow of conventional agitator is shown in Figure 1b [16].

Figure 1:(a) Conventional agitator, (b) Scheme of flow of conventional agitator [16].

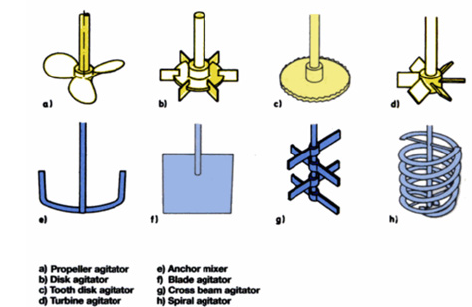

In an agitator, mixing, dispersion, grinding, finishing all steps can be done effectively. Different types of agitators are shown in Figure 2 [16].

Figure 2:Different agitator types [17].

Material and Method

The following chemicals were used in the preparation of paint samples.

a) Long oil alkyd resin, oil length 70%

b) Titanium dioxide, crystal 128

c) Zinc oxide, grade 100

d) Kerosene oil

e) Long oil alkyd resin, oil length 60%

f) Cobalt octoate

g) Calcium octoate

h) Lead octoate

i) Methyl ethyl ketoxime

j) Dipentene, hydrocarbon

Procedure for preparation of sample

Three solvent borne paint samples were prepared having same formulation and with different dispersion blade designs (Figure 3) using high speed agitator (Figure 1a). RPM of high-speed agitator shaft was set at 1400.

Figure 3:(a) Conventional ‘F’ Style high shear dispersion blade, Brighto Paints Pakistan (b) HSXP dispersion blade, (c) ITT dispersion blade, both HSXP and ITT blades manufactured by DisperseTech LLC the dispersion Blades Company USA.

The same procedure and processing sequence were followed with three different blade designs independently having same diameters 4 inches. Long oil alkyd 70% resin (259.8gm) along with titanium dioxide (606gm) and Zinc Oxide (5.4gm) was mixed in agitator tank. The agitation was carried out at 1400 rpm. After the required dispersion of 10 microns is achieved, long oil alkyd 60% resin (1740gm), kerosene oil (264.45gm), cobalt octoate (7.86gm), calcium octoate (28.14gm), lead octoate (18.75gm), methyl ethyl ketoxime (3gm) and dipentene (37.8gm) were added. The agitation was continued for 5 minutes at 1000rpm.

Loading time for ITT blade was 6min, while 5min for both HSXP and conventional blades. Dispersion time for conventional blade was 15min, while 5min for both HSXP and ITT blades. Maximum temperature achieved during dispersion process was observed to be 80 Celsius for conventional blade, 65 Celsius for HSXP blade and 60 Celsius for ITT blade. Amperes measured during processing were found to be 1.6 for conventional blade and 1.5 for both HSXP and ITT blades. It was also observed that the total processing time with conventional blade was 25min, 15min with HSXP and 16min with ITT blade for producing the sample of solvent borne paint with the same composition.

Determination of physical properties of paint samples

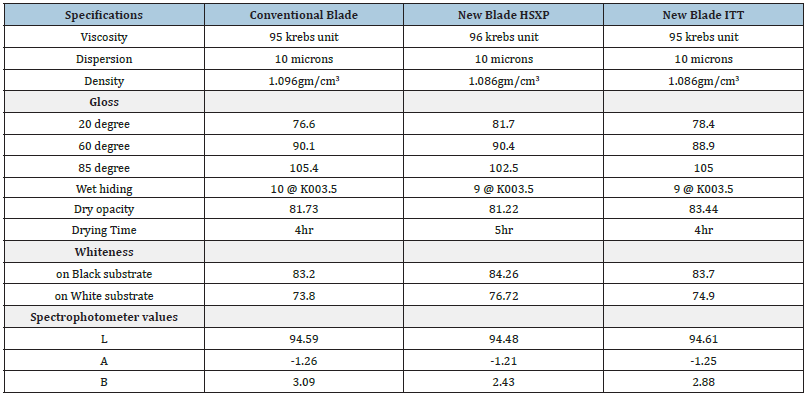

Solvent borne paint samples so prepared were applied on hiding power charts (sheen UK, Coated, 255 × 140mm) with the help of Automatic Film Applicator (manufactured by BEVS Industrial Co. Ltd., China. Model Number: BEVS1811/2) following the standard ASTM D 823-95. An instrument crypto meter (with glass plates No. 3.5 with Wedge Constant K = 0.0035 and No. 7 with Wedge Constant K = 0.007, sheen UK) was used to check the wet hiding of paint samples. Crypto meters offer a quick method to determine the wet opacity, hiding power and coverage in square meters per liter of liquid coating materials [17]. Top Plates (No. 3.5 with Wedge Constant K = 0.0035 and No. 7 with Wedge Constant K = 0.007) were offered with each of the crypto meter products to cover a range of film thickness. ASTM D2457 test was followed to test the gloss or sheen of paint samples with the help of Tri- Glossmaster equipment (sheen UK, angles 20-60-85°). Samples dry hiding, whiteness and CIE L,A,B values were determined with the help of spectrophotometer (data color 110). In order to find out drying time of latex paint samples, drying time recorder (Sheen, UK) was used. Standard test ASTM D1084 was followed to measure viscosities of samples by using Brookfield KU-1+ viscometer. Densities of the paint samples were determined using Pyknometer (sheen, UK) following the standard ASTM D1475. Dispersion of paint samples were determined by using Grind/Dispersion Gauge, (sheen, UK, range 0-100μm). The results so obtained are summarized in Table 1.

Table 1: Specifications of paint samples processed through different blade designs.

Results and Discussion

Loading time, dispersion time and total processing times

It could be observed that loading time with ITT blade is slight high as compared to ‘F style and HSXP blades. Dispersion time with conventional blade is three times more than HSXP and ITT blades. Total processing time for solvent borne paint produced using HSXP and ITT blades is lesser than observed in case of conventional blade as given in Table 1 above and shown in Figure 4. This lesser time could be due to particular blade designs.

Figure 4:Comparison of processing, loading and dispersion times with different blades.

Ampere

The amperes of the agitator motor during solvent borne paint processing are same with HSXP and ITT blades but slight high with conventional blade as given in Table 1 above and shown in Figure 5. Less amperes with HSXP and ITT blades might be due to particular holes/gaps on these blades so that power consumption is less.

Figure 5:Comparison of ampere (current) of agitators with different blades.

Maximum process temperature

The maximum process temperature of solvent borne paint is highest with conventional blade and lower with HSXP blade and least with ITT blade as given in Table 1 above and shown in Figure 6. This high processing temperature could be due to more time taken to achieve 10-micron dispersion.

Figure 6:Comparison of maximum temperature of solvent borne paint with different blades.

Dry hiding

It could be found that dry hiding of the paint is better with ITT blade, lesser with ‘F’ style blade and least with HSXP blade. More dry hiding/opacity with ITT blade could be attributed to better dispersion as given in Table 1 above and shown in Figure 7.

Figure 7:Comparison of dry hiding with different blades.

Conclusion

On the basis of observations, it could be suggested that solvent borne paint samples processed with HSXP and ITT blades showed better results in terms of reducing amperes, process temperature, dispersion time and processing times as compared to conventional ‘F’ style blade. HSXP and ITT blades are also energy efficient blades as compared to conventional ‘F’ style blade. Operating parameters of solvent borne paint could be changed by changing the blade design used in processing.

Acknowledgement

The support from Brighto Paints Private Limited, Pakistan, UAE to conduct this research work is gratefully acknowledged.

References

- Nagata S, Yokgama T, Yaragimoto M (1957) A study on the mixing of high-viscosity liquid. Chem Engg Japan 21: 278-286.

- Gray JB (1963) Batch mixing of viscous liquids. Chem J Zngng Prog 59: 55.

- Rajasekaran E, Kumar B (2014) Agitator and wiper design modification for milk khoa machine. International Journal of Innovative Research in Science, Engineering and Technology 3(1): 1262-1267.

- Nishi K, Enya N (2013) Potential of an asymmetrical agitation in industrial mixing. International Journal of Science and Engineering 5(2): 73-80.

- Ronald W, Richad H (1988) Mixer for axial flow on a non-uniform flow field.

- Dickey DS, Fasano JB (2004) Mechanical design of mixing equipment. Wiley Online Library, New Jersey, USA.

- Montante G, Micale G, Brucato A, Magelli F (2000) CFD simulation of particle distribution in a multiple impeller high aspect ratio stirred vessel. 10th European Conference on Mixing, Delft, Netherlands.

- Syrjänen J, Manninen M (2000) Detailed CFD prediction of flow around a 45° pitched blade turbine. 10th European Conference on Mixing, Delft, Netherlands.

- Musgrove M, Ruszkowski S (2000) Influence of impeller type and agitation conditions on the drop size of immiscible liquid dispersions. Proceedings of the 10th European Conference on Mixing, Delft, Netherlands.

- Taşkin G, Wei H (2003) The effect of impeller-to-tank diameter ratio on draw down of solids. Chemical Engineering Science 58(10): 2011-2022.

- Ulbrecht J (1998) Mixing of viscous non-Newtonian liquids. State University of New York, New York, USA.

- White S (2001) Polymer Mixing. (1st edn), Hanser Publishers, Germany.

- Giuseppina M, Moštěk M, Jahoda M, Mangell F (2004) CFD simulations and experimental validation of homogenization curves and mixing time in stirred Newtonian and pseudoplastic liquids. Chemical Engineering Science 60(8-9): 2427-2437.

- US Environmental Protection Agency (1988) Summary of state VOC regulations. Group III CTG and greater than 100 ton per year Non-CTG VOC regulations, EPA-450/2-88-004, Office of air quality planning and standards. Research Triangle Park, USA.

- Chemical E (1991) Guide to state volatile organic compound control regulations. Modern Paint and Coatings.

- Goldschmidt A, Streitberger HJ (2003) BASF handbook on basics of coating technology.

- Pfund AH (1930) Hiding power measurements in theory and practice. Proceedings American society for testing and materials 30: 882.

© 2021 Qureshi S. A. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)