- Submissions

Full Text

COJ Biomedical Science & Research

Mems Deterioration in Biomedical Industry of Mexicali

Badilla GL1, Robledo VA2, Reyes MIM2, andBernal OYV2*

1National Technological Institute of Mexico, Mexico

2Industrial Engineering Department, Mexico

*Corresponding author: BadillaGL, National Technological Institute of Mexico, Mexico

Submission: September 22, 2020; Published: November 24, 2020

Volume1 Issue3November 2020

Introduction

The biomedical industry is very relevant worldwide, where medicines, prostheses and support systems for the human body are developed with sophisticated equipment and industrial machinery and specialized methods with highly trained personnel [1]. This type of industry has very strict regulations and uses advanced technologies. One of the interesting aspects of companies in this industrial sector is the implementation of electronic micro devices, such as Micro Electromechanical Systems (MEMS) [2], which are currently widely used in any industrial plant in the world. Only that this type of micro devices are prone to variations in temperature and the presence of air pollutants, which normally occur in the city of Mexicali, which is located in the northwest of Mexico, and is a border area with the state of California, United States. In this region of the Mexican Republic, there are temperatures and relative humidity (RH) in the summer season greater than 45C and 50% in exteriors of companies and in interiors of industrial plants [3], the temperature can be increased by up to 10% of temperature and 50% RH, being agents promoting aggressive environments indoors in the biomedical industry of this city, in extreme conditions in the months of July and August. In addition, in the winter season, there are levels of temperature and relative humidity close to 5°C and 60% outdoors in the industries of this city and can be reduced to below 0°C and increase the RH up to 80% in interiors of industrial plants in the biomedical sector, in extreme conditions in the months of December and January. In addition to this, the Cerro Prieto Geothermal Power Plant, which generates electricity at high costs for the inhabitants of this area of Mexico, emits large amounts of sulfide oxides (SO2). This, in conjunction with the emission of cars that exists around 300,000 cars manufactured in this country or from the United States as a lag, together with carbon monoxide (CO) and nitrogen dioxide (NO2). These parameters accelerate the deterioration of metallic materials, which are used in MEMS connections used in electronic devices for equipment and industrial machinery of the biomedical industry [4].

Corrosion in the Biomedical Industries of Mexicali

This paper describes the importance of evaluating atmospheric corrosion in interiors of the biomedical industry of the city of Mexicali, because this has a negative effect on the deterioration of the metallic surfaces of MEMS connections, sometimes observed with the naked eye or sometimes with a microanalysis with specialized equipment such as the Scanning Electron Microscopy (SEM) technique [5]. When this situation arises, the MEMS used in equipment and industrial machinery used in the biomedical industry of the city of Mexicali do not operate efficiently and therefore these industrial systems. This generates that these industrial systems do not have an optimal operating performance and with it the productivity and quality indices decrease, generating concern in owners of these types of industries, the directive, managerial and supervisory personnel due to the presence of economic losses [6]. Due to this, these types of problematic situations occur that occur in most of the year in industrial plants of the biomedical sector of the city of Mexicali, if atmospheric corrosion is not controlled. In addition, there is the lack of confidence of the personnel of industries towards the corrosion specialists of educational institutions. This aggravated their problematic situations due to the presence of atmospheric corrosion in the interior of the biomedical industry, generating a large quantity of defective products and a large quantity of materials such as waste and causing great contamination in soils and water (especially in aquifers), mainly in areas attached to the industries of this sector located in Mexicali [2].

MEMS Used in the Biomedical Industry

This type of micro-devices are widely used in manufacturing areas due to their small size to be installed in equipment and industrial machinery of the biomedical industry and because of their great capacity to made various control activities at the same time in very short times [7] These microdevices and they have revolutionized the technology of industrial processes, being made up of semiconductor components such as transistors, resistors, coils, capacitors, relays, sensors and micro-scale actuators that together carry out support operations for control in manufacturing activities in equipment industrial machinery and for industrial support systems in manual operations of workers [8]. Unique wiring techniques such as wire bonding are also often used in microelectronics, due to the unusually microscopic size of the components. As microelectronic manufacturing techniques improve, the scale of microelectronic components continues to decrease. On a smaller scale, the relative impact of intrinsic circuit properties, such as interconnections, may be more significant. Due to this, sometimes, the so-called parasitic effects occur due to the presence of corrosion that deteriorates the micro-connections and micro-connectors, and the goal of the microelectronic design engineer is to find ways to compensate or minimize these effects at a low cost [9].

Atmospheric Corrosion Analysis

This paper shows an experimental development of an investigation that was made in 2019 in a biomedical industry in the city of Mexicali, where climate and air pollution parameters were evaluated, as well as productivity and quality indices of manufactured products [10]. This was carried out, because in this company there was a low operating performance of industrial equipment and machinery that used MEMS devices, observing deterioration in the metal surfaces of connections of these micro-devices and other electronic components of the industrial equipment and machinery of this industry evaluated. This deterioration was due to the presence of uniform corrosion, especially in the winter season because all areas of the metal surfaces of the connections were covered in this period of analysis, and due to pitting corrosion in the summer season because the high temperature levels they caused that the areas of the metallic surfaces were not covered completely [11]. This caused overheating due to a stress on the metals used in the electrical connections of the MEMS and other electronic components of equipment and industrial machinery, either at the micro or macro level. As a first step, an analysis of electrical failures was developed, correlating them with levels of RH, temperature and levels of contamination of H2S, CO and NOX, for the summer and winter seasons of 2019. The Mat Lab program was used to develop a correlation of pollution and climatic factors with electrical failures [12]. Subsequently, MSEM micro connections and micro connectors used in the electronics industry of the evaluated company were evaluated, with the MBE technique and the micro photographs with the corrosion processes were shown. The third stage was an evaluation of copper and silver metal specimens, which are the most, used materials in MSEM, with which the corrosion rate was determined [13].

Corrosion Rate Evaluation

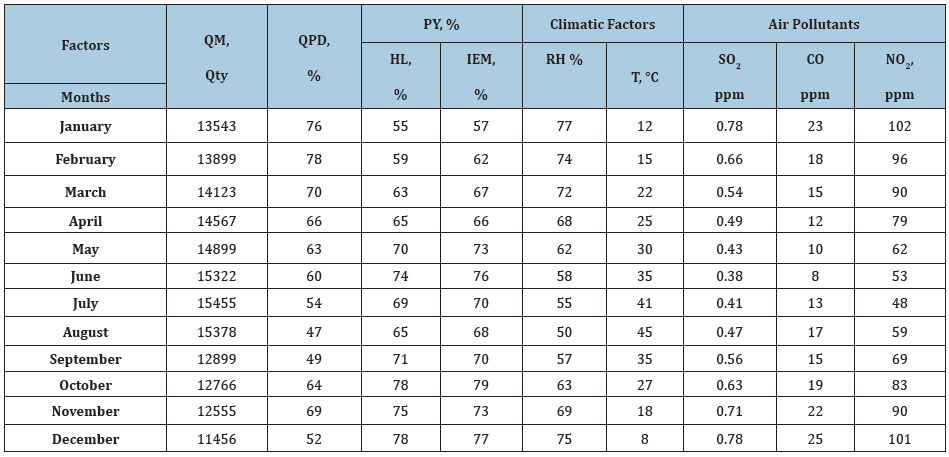

Most of the industries installed in the city of Mexicali, according to investigations by experts on corrosion, optimization of industrial processes and industrial manufacturing [14]; show that there is deterioration in the metallic surfaces of electrical connections of industrial equipment and machinery, in which they use micro components such as MEMS. Based on the above, an investigation was made analyzing the parameters of climate, air pollution and productivity and quality indices of manufactured products in a biomedical industry in this Mexicali. In this city, there are extreme atmospheric weather conditions in some periods of the year, which greatly affect both industrial materials and the health of workers and the population, where high costs are generated due to the aggressive pollution that occurs in this city. The evaluation of atmospheric corrosion and productivity levels in Table 1 as showed ISO standards [15].

Table 1 shows maximum levels of manufactured products and average values in the other parameters, observing that in manufactured products it starts with a lower quantity, as 2019 passed, production increased and subsequently decreased at the end of the year. Regarding the number of defects, it was higher at the beginning of the year, and after applying continuous improvement by specialists in this study due to failures due to the presence of atmospheric corrosion, they decreased. In the analysis of operating performance of workers and industrial equipment and machinery, a low operating performance was observed at the beginning of the year in both parameters, but when applying continuous improvement, it increased at the end of the year in both. The relative humidity indices were higher at the beginning of the year, which was when the investigation began with high levels due to the winter season, uniform corrosion, and in the middle of the year in the winter season, it diminished, generating pitting corrosion. The temperature indices were low at the beginning of the year in the winter season and high in the summer season and in both it was combined with the relative humidity for the presence of both types of corrosion mentioned in each period of the year evaluated. The same happened in the evaluation of the three air pollutants, generating high levels in all three in the winter season at the beginning of the study in 2019, and low levels in the summer season, being a fundamental part in the generation of both types of corrosion mentioned.

Table 1:Analysis of atmospheric corrosion and productivity levels (2019).

QM Quantity manufactured, QDP Quantity of defective products, PY Production yielding, HL Human workforce, IEM Industrial Equipment and Machinery, RH Relative humidity (%), T Temperature (°C), SO2 Sulfide oxides (ppm), CO. Carbon monoxide (ppm), NOX. Nitrogen oxides (ppm).

References

- Badilla GL, Samaniego ER, Perea SLT, Gómez MMA (2013) Characterization of copper sulfides formed in MEMS connections by atmospheric corrosion in indoor of electronics industry of arid and marine environments. IFAC Proceedings 46: 24-30.

- López G, Tiznado H, Soto G, Cruz WDL, Zlatev R (2010) Corrosion of electronic devices due to atmospheric pollution indoors in arid and marine environments. Revista Nova Scientia 3: 11-28.

- Gustavo LB (2008) Characterization of corrosion in metallic materials of the electronic industry in Mexicali.

- Moncmanova A (2007) Environmental deterioration of materials. WIT Press Publishing, UK.

- Caggiano MF, Barkley E, Sun M, Kleban JT (2000) Electrical modeling of the chip scale ball grid array package at radio frequencies original research microelectronics. Journal of Industrial Manufacturing 31: 701-709.

- López G, Valdez B, Schorra M (2012) Microscopy and spectroscopy analysis of MEMS corrosion used in the electronics industry of the Baja California region, INTECH, Mexico.

- Oxtoby DW, Gillis HP, Butler LJ (2015) Principles of modern chemistry. Brooks Cole, USA.

- Robaina RR, Alvarado HT, Plaza JA (2010) Planar coil-based differential electromagnetic sensor with null-offset. Sensors and Actuators 64: 15-21.

- Tkatchenko A, Scheffler M (2009) Accurate molecular Van Der Waals interactions from ground-state electron density and free-atom reference data. Physical Review Letters 102(7): 073005.

- Villa JL, Sallán J, Llombart A, Sanz JF (2009) Design of a high frequency inductively coupled power transfer system for electric vehicle battery charge. Applied Energy 86(3): 355-363.

- George R, Ellison F (2013) The FMEA method in the industry related with the economy. Elsevier, Amsterdam, Netherlands.

- Gregory G, Fontanent H (2011) The evaluations of manufacturing processes with the FMEA method. Science Applied to Industry Journal 3: 79-92.

- Romero E, Toledo S, Cervantes M, López G, Acosta M, et al. (2018) Use of novel FMEA method in the manufacturing processes of electronics industry in arid environment. International Educational Applied Research Journal 2(2): 54-68.

- Thompson H, Redick Y, McDowell P, Quentani R (2014) The FMEA methods applied to the electronic industry. Journal of Industrial operations 5: 68-79.

- ISO 11844-2 (2005) Corrosion of metals and alloys-classification of low corrosivity of indoor atmospheres-determination and estimation attack in indoor atmospheres. ISO, Geneva.

© 2020 BadillaGL. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)