- Submissions

Full Text

Cohesive Journal of Microbiology & Infectious Disease

Study on Cell-Recycle Repeated-Batch Fermentation of Recombinant Flocculating Industrial Saccharomyces Cerevisiae Strain

Fuzhuan Wang*, Binyao Fang, Yue Li, Liyue Mao and Xiaoxue Yu

School of Bioengineering, China

*Corresponding author: Fuzhuan Wang, School of Bioengineering, China

Submission: May 10, 2021 Published: May 25, 2021

ISSN 2578-0190 Volume5 issues2

Abstract

In this report, the conditions for cell-recycle repeated-batch fermentation of recombinant flocculating industrial Saccharomyces cerevisiae strain ZWA46-F2 was studied. Upon the residual sugar decreased to 20 g/L, half amount of total yeast cells was directly recycled in the subsequent batch fermentation without prior washing. The following conclusions were obtained: (i) it was appropriate to conduct 22 cycles of cell-recycle repeated-batch fermentation; and (ii) in comparison with the first batch, the highest alcohol yield was increased by 18.4%, the fermentation time was decreased by 18 hours, and the productivity was increased by 78.7%.

Keywords: Saccharomyces Cerevisiae; Recombinant flocculating yeast strain; Alcohol fermentation; Cellrecycle repeated-batch fermentation

Introduction

Biomass energy is considered the fourth energy source, ranked behind other three fossil energies coal, petroleum and natural gas [1-4]. According to the International Energy Agency, about 9 percent of the total global energy consumption is biomass energy, and among which about 6 percent are fuels, i.e., biodiesel and bioethanol; such consumption is in a rapid growing trend [1]. The bioethanol research and the industrialization of bioethanol as a motor fuel, which is considered as one of the most important future renewable fuel, have received great attentions Li [3]. Due to an increasingly lower profit of alcohol production using fermentation technology, many researchers and manufacturing enterprises have conducted research attempting to decrease the production cost of alcohol. Recombinant flocculating yeast has been applied in the production of alcohol by cell-recycle repeated-batch fermentation, which belongs to the carrier-free immobilized cell-recycle technology [2,5-7]. In this study, the cell-recycle repeated-batch fermentation of recombinant flocculating industrial yeast Saccharomyces cerevisiae ZWA46-F2 was conducted Wang et al. [7]. The results indicated that 22 batches of cell-recycle repeated-batch fermentation could be conducted using the recombinant flocculating yeast strain. Compared with the first batch, the alcohol yield and productivity were greatly increased, while the fermentation time was significantly shortened. By this fermentation technology of alcohol, the production costs, e.g., equipment, raw materials, water and energy can be economized obviously.

Materials and Methods

Microorganism and media

Recombinant flocculating industrial Saccharomyces cerevisiae strain ZWA46-F2 was structed was constructed previously Wang et al. [7] and maintained in a frozen state at -70 ℃. The preculture contained yeast extract - 8.5g/L, glucose -30.0g/L, (NH4)2SO4 -0.5g/L, MgSO4 -0.1g/L and CaCl2 -0.06g/L. The fermentation medium consisted of yeast extract -5.0g/L, glucose -150.0g/L, (NH4)2SO4 -0.5g/L, MgSO4 -0.65g/L, CaCl2-2.0g/L and KH2PO4 -1.5g/L, and the initial pH of the medium was adjusted to 5.0.

Preparation of culture seed

The yeast was picked from fresh YEPD medium using an inoculating loop, and then inoculated into a Erlenmeyer flask containing seed medium (inoculation volume =50mL/250mL). After the flask was incubated at 30 ℃ for 10 hours on a rotating shaker running at 150 revolutions/min, the culture seed liquid was obtained.

Fed-batch fermentation

The culture seed liquid, at 5% inoculum size, was inoculated into a 250mL Erlenmeyer flask containing 150mL fermentation medium, and then fermentation was performed statically at 30 °C.

Cell-recycle repeated-batch fermentation

When glucose concentration in the previous batch fermentation was decreased to 20g/L, the recombinant yeast cells were flocculated and precipitated, and the supernatant was removed. After the cells were either washed with sterile deionized water or unwashed, all or half of the cells were inoculated into 150mL fresh fermentation medium, and then cultured at 30 °C.

Analysis Method

The determination of glucose was conducted using an SBA-40B type enzyme electrode analyzer with glucose oxidase-immobilized membrane. In the determination of cell biomass, the cells were centrifuged at 1500×g for 15 minutes, and subsequently washed twice with distilled water. After the cells were dried at 105 ℃ for 24 hours, the Dry Cell Weight (DCW) was determined. The determination of alcohol was carried out using Shimadzu GC-2010 gas chromatograph equipped with PEG20M capillary column. The operating conditions were as follows: temperature of 220 ℃; detector, FID; carrier gas, nitrogen; and flow rate, 3mL/min.

Result and Discussion

The effects of recycling time of recombinant ZWA46-F2 cells

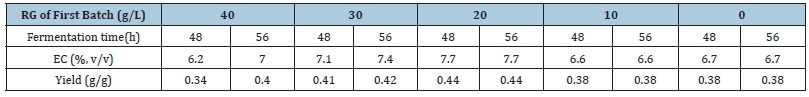

During the cell-recycle repeated-batch fermentation experiments, residual sugar concentration in fermentation medium was used as an indicator determining the recycling time. The cells were recycled when the residual sugar concentrations (RG) were dropped to 30,20,10, and 0g/L, and their effects on ethanol yield (EC) in the subsequent batch fermentation were investigated. The results shown in Table 1 indicated that when the cells were recycled at residual sugar concentration of 20g/L (at 48 hours), ethanol concentration and sugar conversion rate were 7.7% and 0.44g/g, respectively, while all other fermentation indexes were optimal. Therefore, the cell-recycle repeated-batch fermentation experiments using recombinant yeast ZWA46-F2 showed that when residual sugar in fermentation medium was decreased to 20 g/L, the cells should be recycled in the subsequent batch fermentation.

Table 1: Recycling time of recombinant ZWA46-F2 strain fermentation.

The effects of recycled amount of recombinant yeast cells on cell-recycle repeated-batch fermentation

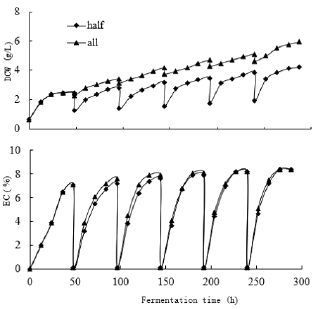

To investigate the effects of recycle number of cells on alcohol production through fermentation of recombinant yeast ZWA46-F2, half or total amount of yeast cells were continuously recycled in 6 repeated-batch fermentations. During the fermentation, samples were taken at 12,24,36 and 49 hours, and their Dry Cell Weight (DCW) and Ethanol Concentration (EC) were determined. The results shown in Figure 1 indicated that cell quantity increased with increasing cycles of batch fermentation, and the increase of cell quantity resulted from recycling half number of cells was significantly higher than that resulted from recycling the entire amount of cells. Moreover, the effects of recycled cell quantity on cell biomass were more significant than those on alcohol concentration. In the fifth batch fermentation, the final alcohol concentrations as a result of two different cell quantities reached equilibrium at 8.2% and 8.4%. The repeated-batch fermentation using half amount of recycled cells not only was able to guarantee initial high cell quantity, shorten the fermentation time, and increase the alcohol yield, but also provided the cell density suitable for division and proliferation; thus keeping the exuberant growth and metabolic activities, and delaying the cell aging process. Therefore, following the prior round of batch fermentation, only half amount of yeast cells was recycled and used in subsequent cycle.

Figure 1: Time courses of biomass and ethanol concentration in repeated batch fermentation with all and half recycled cells.

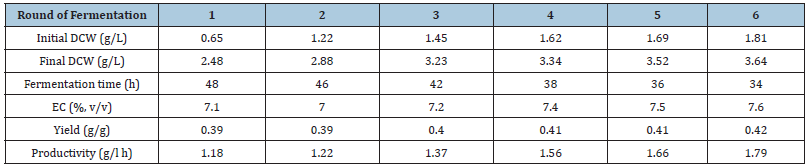

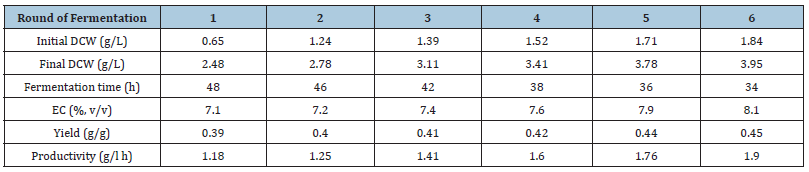

The effects of washing recombinant yeast cells on cell-recycle repeated-batch fermentation. Previous studies Liu et al. [6] have considered that the accumulated metabolic by-products produced during the repeated-batch fermentation can have inhibitory effects on both cell growth and product yield, and the performances of repeated-batch and batch fermentations using un-washed recycled cells were not different. Therefore, in this study, the effects of cell wash on alcohol yield from the repeated-batch fermentation using recycled half yeast cells were studied. According to the results shown in Tables 2 & 3, alcohol yield was affected by cell wash-un-washed cells had slightly higher fermentation indexes, including alcohol yield, sugar conversion rate and productivity. It is possible that the un-washed yeast cells are relatively stable to external growth and metabolism environment in the prior batch of fermentation, and in turn, more beneficial. In addition, the yeast strain used in this study is a recombinant strain, which was genetically modified engineering to have enhanced flocculating ability. The process of washing cells maybe prolongs the flocculating time, while cause the decreases of productivity and production efficiency.

Table 2: Repeated batch fermentation with recycled cells washed.

Table 3:Repeated batch fermentation with recycled cells not washed.

The cell-recycle repeated-batch fermentation of recombinant flocculating yeast ZWA46-F2

In this study, recombinant flocculating yeast ZWA46-F2 cells were recycled in 26 batches using the repeated-batch fermentation; the results were shown in Figure 2. During the first 18 batch fermentations, the cell quantity had an increasing trend, and reached a maximum quantity of 11.08g/L, which was 2.3 times higher than that of the 1st batch (4.82g/L). The final alcohol concentrations, as a result of the 6th to the 19th batches, were fluctuated between 8.5% and 9.0%, while reached a maximum value of 9.0% (v/v) - an increase by 18.4% compared to the 1st batch -with alcohol yield of 0.50 g/g in the 11th and 12th batches. The fermentation time was shortened to between 30 and 40 hours from the 3rd to the 12th batches, which was reduced by 8-18 hours compared with the 1st batch (48 hours). The productivity after 30 hours of the 6th batch reached a maximum value of 2.27g/L·h, an increase by 78.7% compared with the 1st batch (1.27g/L·h). The productivity of the 22nd batch was reduced to 1.26g/L·h, which was equal to that of the 1st batch; whereby the repeated-batch fermentation was terminated. To sum up, it was appropriate to conduct 22 cell-recycle repeated-batch fermentations using the recombinant flocculating yeast ZWA46-F2.

Figure 2:Time courses of repeated fermentation with recycled cells of recombinant yeast ZWA46-F2.

Conclusion

In summary, the cell-recycle repeated-batch fermentation of recombinant flocculating yeast was studied. It was appropriate to conduct 22 batches of the cell-recycle repeated-batch fermentation using recombinant flocculating yeast ZWA46-F2. Observably, the alcohol yield and productivity were increased while the fermentation time was decreased during the 22 repeated batches. Despite a number of reports on the use of flocculating yeast in alcohol fermentation [4,8,9], a few reports studied the alcohol production using cell-recycle repeated-batch fermentation by transformant industrial yeast.

Acknowledgement

This work was supported by the National Natural Science Youth Foundation of China (No. 31201409); Henan Science and Technology Department production and research projects No. 142107000017 and No. 132107000005; and Open Program for National Engineering Laboratory of Wheat & Corn Further Processing, Henan University of Technology (No. NL2017006).

References

- Agency IE (2011) IEA technology roadmaps: biofuels for transport. Source OECD Energy, pp. 1-56.

- Bai F (2000) Application of self-immobilization cell technology for biochemical engineering. Progress in Biotechnology 20: 431-435.

- Li Z, Li D, Huang G, Wei H (2013) Insight on current development of fuel ethanol. Chemical Industry and Engineering Process 32: 1457-1467.

- Liu C, Bai F, Shao M, Xie J, Li N (2001) High concentration ethanol continuous fermentation using yeast flocs. Acta Microbiologica Sinica 41(3): 367-371.

- Liu H, Feng Y (2015) The development status and future trend of biomass energy in the world. World Agriculture 433: 117-120.

- Liu Y, Liu D, Ma Z, Su Q (2002) Main factors affecting preparation of glycerol in repeated batch fermentation. Journal of Chemical Industry and Engineering 53: 1139-1142.

- Wang FZ, Shen W, Rao ZM, Fang HY, Zhan XB, et al. (2008) Construction of a flocculating yeast for fuel ethanol production. Biotechnol Lett 30: 97-102.

- Yu J, Zhang X, Tan TW (2007) An novel immobilization method of Saccharomyces cerevisiae to sorghum bagasse for ethanol production. J Biotechnol 129(3): 415-420.

- Zhou G, Lu M, Yun X (1997) Alcohol continuous fermention of agglomerative Saccharomycete. J of Dalian Institute of Light Industry 16: 32-35.

© 2021, Fuzhuan Wang. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)