- Submissions

Full Text

Cohesive Journal of Microbiology & Infectious Disease

Microalgae Fuels under the Integrated Research Perspective

Leonardo Brantes Bacellar Mendes1* and Carolina Vieira Viegas2

1 Petrobras Research & Development Center, Brazil

2 Federal University of Rio de Janeiro School of Chemistry, Brazil

*Corresponding author:Leonardo Brantes Bacellar Mendes, Petrobras Research & Development Center, Brazil

Submission: November 11, 2019; Published: February 20, 2019

ISSN 2578-0190 Volume2 Issue3

Introduction

Interest in alternative fuel sources to oil has fluctuated throughout contemporary history according to the availability of this resource. The biggest impact of the reduction in the supply of oil is the increase in the price of the barrel practiced in the international market.

The first oil shock in 1973 showed that the price of the barrel rose rapidly, from US $ 2.90 /barrel to US $ 11.65/barrel in three months, causing enormous losses in the economy of countries that do not have strategic oil and gas reserves (e.g.: Germany, France and Italy).

In the late 1970s amid the second oil shock, when the price of a barrel of oil exceeded US$ 80.00, renowned German and Italian scientists began research to obtain microalgae fuels - notably from Tetraselmis sp - in southern Italy.

Throughout the 1980s, with the normalization of oil prices in the international market, the interest for fuels from microalgae was very low and the activities of microalgae cultivation were directed to aquaculture, nutraceutical production and fine chemical compounds, highlighting the genera Chlorella and Dunaliella, as well as the cyanobacterium of the genus Arthrospira.

It is important to note that even during this period with less demand for microalgae fuels the US government did not cease its investments and promoted research and development activities to obtain products such as ethanol and biodiesel over 15 years through the Aquatic Species Program. A new moment arose between 2008 and 2009 when the price of oil surpassed US $ 120/barrel, making the interest in research and development focused on microalgae fuels resurface once more on the international scene.

Since then, new governmental incentives have been allocated in several countries, A. Mainly in the USA through the National Renewable Energy Laboratory. It has given a considerable boost to many universities and small companies with expertise in micro-algal biotechnology.

Several projects aimed at obtaining microalgae biomass were developed using photobioreactors, open ponds or heterotrophic culture technologies in bioreactors in the absence of light. Among the main scientific problems presented during the upstream projects were the high cost of investment for photobioreactors and the difficulty in achieving stability and high productivity in open ponds.

As regards the processing of microalgae biomass, there were also several research and development projects aimed at improving the efficiency and cost-effectiveness of the steps of harvesting, cell disruption, extraction and conversion of the target compounds into biofuels (e.g.: ethanol, biodiesel and jet fuel).

The relevance of an integrated approach to obtaining microalgae fuels

Although some scientific and technological advances achieved for specific stages of microalgae biomass production and processing are of utmost importance for obtaining advanced fuels, only the set consisting of strains selection, crop management, biomass collection, extraction and final conversion to fuel can add economicity to all the activities carried out.Each operation used in the production of microalgae biomass has singular importance and complexity. An excellent growth and efficient harvesting depends on a well-prepared inoculum that is active and healthy (Figure 1).

Figure 1:Successful inoculation in 100 m2 open ponds in Northeast of Brazil. Project carried out by Petrobras in partnership with Rio Grande do Norte Federal University.

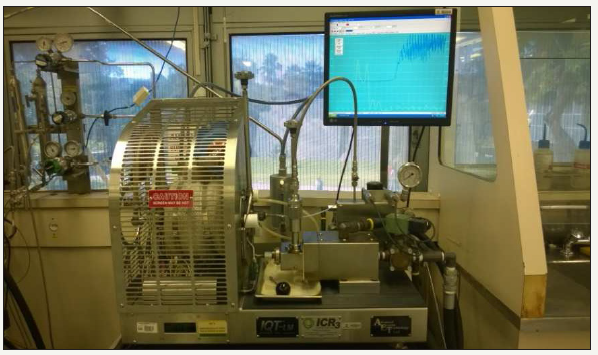

Figure 1:Determination of cetan number at Petrobras Research and Development Center attested excelent quality of microalgae biodiesel.

All operations involved in the biomass production processes appropriate to achieve an end product are somewhat similar to those of a mathematical model that will only provide reliable output if the input data are also reliable.

There is no way to generalize statements for the particular behavior of a microalgae strain. The whole process of growth with stability and resistance to biological contaminations to increase productivity will not be very successful if there is no enrichment of the biomass in target molecules. This makes the information obtained by the analysis and processing of the biomass an essential feedback for directing and improving crop management in outdoor environments.

The qualitative and quantitative composition of the culture medium to be used is another example of an interactive and integrated result since its adjustments depend not only on the results related to microalgae productivity but also on the quantity and quality of target compounds obtained from the strain of interest (Figure 2).

The same arguments can be applied to the strain selected for biomass generation since each strain of a given species has a differentiated gene pool and is capable of producing greater or lesser amount of the compounds of interest under certain environmental conditions.

Chemical, thermal or mechanical processes of cell rupture are highly dependent on the biochemical characteristics of the cell wall present in each strain and have a direct impact on the viability of the extraction and conversion to obtain target compounds. In this way, the choice of the target strain to obtain fuels again relies on the integration of the information obtained along the downstream. Each biofuel obtained must pass through the quality control according to the specific legislation of each country and the final product depends heavily on the scientific interactions caused during the upstream and downstream processes (Figure 3).

In this way, the particular nature of everything that surrounds the production of microalgae fuels along the way, from the small volumes in the laboratory to the scale of millions of liters to be required by the commercial scale is evidenced.

As can be seen in Figure 3, there are several scientific issues that have been studied worldwide trying to produce fuels from microalgae economically. The increase of the lipid content in the biomass without loss of productivity is one of the most important and difficult to achieve along the scale up process.

The main conclusion is that the generation of technical indices for assessments of realistic economic scenarios depends on an integrated scientific evolution which in order to be achieved requires continued investments in research and development activities.

In this way an integrated approach without previously established barriers that separate the microalgae cultivation from the biomass processing knowledge can generate realistic and attractive economic projections linked to advanced fuels.

© 2019 Leonardo Brantes Bacellar Mendes. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)