- Submissions

Full Text

Approaches in Poultry, Dairy & Veterinary Sciences

Analysis of Different Pre-Slaughter Management Systems of Broilers and Their Impact on Animal Welfare: Dead on Arrival, Injuries and Stress

Ricardo Lacava Bailone1*, Moira Harris2, Ricardo Borra3, Luis Kluwe de Aguiar4, Hirla Fukushima3 and Roberto de Oliveira Roça5

1São Paulo State University (UNESP)-Botucatu, Brazil/Brazilian Ministry of Agriculture, São Carlos, Brazil

2Department of Animal Production, Welfare and Veterinary Sciences, Harper Adams University, UK

3Department of Genetics and Evolution, Federal University of São Carlos (UFSCAR)-São Carlos, Brazil

4Department of Food Technology and Innovation, Harper Adams University, Shrophishire, UK

5Department of Animal Production, Sao Paulo State University (UNESP)-Botucatu, Brazil

*Corresponding author: Ricardo Lacava Bailone, São Paulo State University (UNESP)- Botucatu, Brazil/Brazilian Ministry of Agriculture, São Carlos, Brazil

Submission: March 11, 2021;Published: March 25, 2021

ISSN: 2576-9162 Volume8 Issue2

Abstract

Despite many advances in pre-slaughter handling procedures for broilers’ slaughterhouses, significant failures still occur which cause losses and affecting yield and final product quality, going in the opposite direction to sustainable production. The aim of the study was to test the impact of pre-slaughter procedures of broilers in two different establishments, one in the UK (mechanical catching and stunning by controlled atmosphere) and another in Brazil (manual catching and stunning by electronarcosis). Three parameters were measured: dead on Arrival (DOA), injuries and corticosterone levels (measured by ELISA test) considering three different distances (D1=0-50km; D2=51-150km; D3=151-300km) and two different seasons (summer and winter). Brazilian indices evaluated were overall higher than those in the United Kingdom (UK). DOA in Brazil was higher in the summer, while in the UK it was higher during the winter. While in Brazil, DOA was more influenced by the distance travelled from farm to slaughterhouse in the warmer months, in the UK the indices were higher over longer distance travelled during the colder months. Injury rates remained constant in England and were not affected by the farm-slaughterhouse distance travelled, yet during the winter period it was higher. Both the Brazilian and British corticosterone data showed that broilers transported for short distances were more stressed at the time of slaughter than those transported for long ones. Brazilian corticosterone levels were still significantly higher when compared to the British one. When considering all parameters, the overall welfare in the Brazilian slaughterhouse was considered poor. Yet, in the UK it was considered excellent. Concluding, there is a significant difference between animal welfare indices depending on the kind of management. The contribution of this study is to test and provide benchmark indexes for both establishments thus highlighting where producers and processors could improve by minimize economic losses by and enhancing animal welfare.

Keywords: Chicken; Corticosterone; Injury; Management; Mortality; Stress

Introduction

During pre-slaughter, the typical management interventions consist of catching, loading, transporting, unloading and stunning the birds. According to the European Food Safety Authority (EFSA), more broilers are transported than any other animal species yet, transportation represents a major threat to poultry welfare as it could affect a great number of birds [1]. Dead on Arrival (DOA), injuries as well as high level of physiological stress are attributed to poor welfare management during pre-slaughter management. Therefore, it is vital to improve the handling conditions to safeguard the welfare of the animals [2] as it represents one of the most stressful stage in poultry production.

In addition to DOA, other pre-slaughter-related problems can be attributed to injuries caused by a simple scratch in the skin, bruises, edemas, and fractures. These could lead to death prior to slaughter, or segregation in processing line where the carcass is only partially used. Thus, this can cause either total carcass loss or carcass quality depreciation during post-mortem examination [3] which affect yields. Grandin [4] suggests that during post-mortem inspection it is possible to detect old injuries attributable to poor welfare conditions at farm level as well as recent damage indicating incorrect pre-slaughter management. Nonetheless, according to Rocha et al. [5] 90% of the injuries observed by the meat inspection service occur during pre-slaughter. Moreover, failure to comply with animal welfare in pre-slaughter is understood to have an adverse impact on meat quality [6] contributing to higher stress levels in the birds and leading to a decrease in meat quality. The birds in close contact with human beings and experiencing increased noise levels release corticosterone, which is the most important hormonal indicator of stress. Furthermore, high levels of stress could cause increased susceptibility of animals to diseases and/or mortality [7].

The current literature shows a large discrepancy in the parameters related to animal welfare during pre-slaughter management, particularly, those used by different establishments. Therefore, the aim of the present study was to determine the level of animal welfare and losses during the pre-slaughter management of broilers. The hypothesis tested was based on the premise that the longer the distance travelled and the more extreme the climatic conditions, that would be adverse for the broilers.

Materials and Methods

Experimental design

For the purpose of this study, two slaughterhouses which typically used distinct management systems were analyzed, one in Brazil and the other one in the United Kingdom (UK). Samples were collected from birds arriving from production sites located at three distinct distances during two different seasons (summer and winter). Both slaughterhouses were characteristic of vertically integrated systems i.e., the companies owned the farms, transportation trucks, and directly employed all staff.

The sample size in Brazil consisted of 5,632,767 birds and the data was collected in 2013. In the United Kingdom, data was collected from 17,074,668 birds and it took place in 2015. The data was organized according to the total distance travelled from the farms to the slaughterhouses (D1=0-50km, D2=51-150km, D3=151-300km). For each truck that arrived at each of the slaughterhouses, the DOA figures were recorded in relation to the total load regarding their respective D1, D2 and D3 travelled. In both countries, whenever the DOA number was higher than 1%, ten birds were sampled to carry out a necropsy analysis to assess the presence of infectious-contagious diseases. The presence of injuries was recorded, and a percentage was calculated based on the number of live broilers arriving deducted from the number of DOA. The measurement of corticosterone levels was performed based on samples taken and also recorded against D1, D2 and D3.

a) The Brazilian case: The study was conducted in a large slaughterhouse located in the center-west region of the state of São Paulo. The facility worked based on two shifts, and slaughtered about 150,000 broilers per day, at an average speed of 10,000 broilers/hour. The local climate was typically semi humid tropical with rainy season (summer-November to February), and a dry season (winter May to August); the average annual rainfall as 1291.3mm. Local annual temperature averaged around 20.5 °C, and the coldest month being June at 17.3 °C, and a warmer one in December at 20.9 °C.

For the purpose of analyzing the DOA and injuries, birds from 105 farms were tested corresponding to 929 truck arrivals and 444 flocks in total. As for the corticosterone analysis, 24 farms were randomly tested. All the broilers were manually caught and stunned by electronarcosis. The broilers slaughtered were typical of a commercial Cobb, Ross and Hubbard genetic line at about 40- 45 days old and around 2.2 and 2.5Kg in weight.

When arriving at the slaughterhouse, the birds were kept on hold under a shaded and ventilated environment (fans and water sprinklers were available) for one hour following the established resting time guideline prior to being slaughtered. After unloading the cages, all DOA were removed and recorded and the live birds were manually hung by their feet in the norea. When entering the stunning room the birds were subjected to electronarcosis by immersion in water with an electric current. Following that, they progressed towards to the mechanical bleeding.

b) British case: The study was conducted in a slaughterhouse also operating under two shifts (day and nighttime), which slaughtered about 300,000 broilers per day (in two lines), with an average speed of 10,000 broilers/hour. Near that site the climate in the UK was typically maritime temperate climate with a short summer and partly cloudy; contrasting with a long and very cold winter with strong winds and mostly overcast skies. The local annual temperature averaged around 9.3 °C, with the coldest period being in December (winter) at 4.0 °C and the mildest in June (summer) at 14.4 °C. For the purpose of analyzing the DOA and injuries, birds from 78 farms were tested corresponding to 3,041 trucks and 510 flocks. As for corticosterone analyses, 24 farms were sampled. Lines of broilers slaughtered in that establishment were commercial genetic lines of Cobb and Ross, at 40-45 days old and around 2.2 and 2.5kg in weight.

Differently from the Brazilian establishment, the catching of the birds at the farms was carried out mechanically and performed throughout the day and night to cater for the two processing shifts. When the trucks arrived at the slaughterhouse, they were parked within a sheltered area to protect the birds from the chill wind for about fifteen minutes before being taken to the slaughter. In that establishment, the birds were kept in the cages, because they were unloaded directly onto a conveyor belt and were stunned when exposed to a modified atmosphere containing CO2. After that, the dead animals were manually removed, and the live ones were hung by their feet on the shackle line to be bled.

Dead on arrival

Information on the rate of broilers DOA during transportation was measured daily from June and December. DOA was ascertained by touch (low body temperature and stiffness) after stunning.

Injuries

The UK Meat Inspection Service official checked for injuries (bruises, edemas and fractures) which were visually inspected from the carcass (chest, wings and legs) and through palpation, after evisceration during post-mortem examination.

Corticosterone levels

In both countries, samples were collected from 24 random farms which were separated into 3 groups of 8 farms each according to their location and consequently the distance travelled to the slaughterhouse i.e. D1, D2 and D3. During the study period, 13 blood samples were taken from each farm totaling 312 samples. The samples were collected and the analysis for corticosterone levels was carried out when the rate of DOA was high for the respective establishments studied and the different seasons i.e., summer in Brazil and winter in the UK. Blood collection was performed from the neck cut at post-mortem, following bleeding of broilers by cutting the carotids, and 5mL/broiler was collected. The collected blood was stored in vacutainer blood collection tubes, remaining refrigerated in a Styrofoam box, and then centrifuged under refrigeration (4500g/15 minutes and 4 ºC) to obtain serum, which was stored frozen until the moment of laboratorial analysis. Measurement of corticosterone levels was performed by ELISA (Enzyme-Lynked Immunosorbent Assay) using commercial kits (Enzo Life Science, Farmingdale, NY), according to the method described by Tachibana et al. [8].

Statistical analyzes

The statistical analyzes were performed using SPSS 16.0 [9] statistical package. For DOA and injuries, experimental units used were trucks. For the analyzes of the variables, two-way ANOVA statistical test was used, separately for each country. For post-hoc analyzes of the variables, the Bonferroni´s correction was used. The correlation of Spearman´s rho was used for the trend analysis of the significant variables in relation to DOA and injuries, and separately for each season. For the analysis of corticosterone levels, experimental units used were blood samples from each animal. Data were transformed to log at base 10 to obtain normality, and then submitted to one-way ANOVA followed by Dunnett’s T3 test. The correlation of Spearman´s rho was used for the trend analysis of the significant variables in relation to corticosterone levels. Values of p<0.05 were considered significant.

Result

Dead on arrival

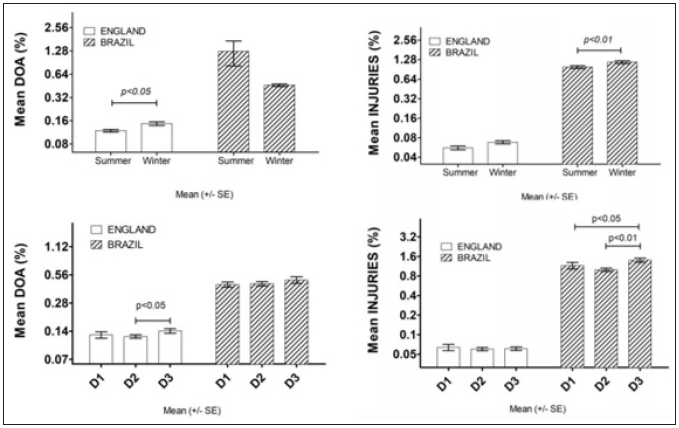

At the Brazilian abattoir, the overall mean (Standard Error) DOA percentage was 0.86% (±0.22) with minimum value being 0.077% and the maximum 43.18% per truck. It was observed that in the summer months, the mean DOAs were 0.50% (±0.16), 1.08% (±0.33) and 2.01% (±1.29) for D1, D2 and D3, respectively. In winter, DOA was constant with means (SE) of 0.44% (±0.03), 0.45% (±0.02) and 0.49% (±0.04) for D1, D2 and D3, respectively (Figure 1). Analyzing the results of factors and their interactions, there was no significant difference between summer and winter (p=0.111), with means (SE) of 1.26% (±0.44) and 0.46% (±0.17) respectively (Figure 2). When analyzing DOA in relation to the distances (summer and winter together) in Brazil, there were no significant differences between distances (p=0.407), the mean DOA percentages were (SE) 0.46% (±0.06), 0.80% (±0.18) and 1.27% (±0.66) for D1, D2 and D3, respectively (Figure 1). There is no difference in the interaction between distance and seasons factor (p=0.461).

Figure 1: Correlation between distance and seasonality in relation to DOA and injuries rates in both establishments.

Figure 2:DOA and injuries rates in relation to distance and seasonality in both establishments.

In the United Kingdom case, the overall mean (SE) DOA was 0.13% (±0.004), with minimum value being 0.04% and the maximum 0.48% pre truck. It was observed that during the winter, the longer the farm-to-abattoir distance, the higher the DOA, with means (SE) of 0.11% (±0.01), 0.14% (±0.01) and 0.17% (±0.01) (p=<0.05; Figure 1; D1, D2 and D3 respectively). Yet, in the summer, DOA was constant, with means (SE) of 0.14% (±0.02), 0.11% (±0.01) and 0.12% (±0.01) (D1, D2 and D3 respectively (Figure 1). When comparing the two seasons, there was a difference (p<0.05) between summer and winter with means (SE) of 0.12% (±0.01) and 0.15% (±0.01) respectively (Figure 2). The interaction between the distance and seasonal factors showed to be statistically significant (p<0.01), indicating that the influence of distance in the DOA also depends on the season. When analyzing the correlation of DOA in relation to the distances, and considering the seasons that country, it was possible to find a positive correlation (p<0.001; correlation coefficient = 0.553: Spearman´s rho test) between DOA and distance during the winter period. The same correlation was not found in the summer (Figure 1).

Injuries

In Brazil, the overall mean (SE) of injuries was 1.08% (±0.04), with the minimum value being 0.28% and the maximum 4.22% per truck. A difference (p<0.01) was observed between summer and winter with a mean value (SE) of 0.98% (±0.05) and 1.17% (±0.06) respectively (Figure 2). Mean (SE) values were 1.05% (± 0.09), 0.93% (±0.04) and 1.30% (±0.07), for D1, D2 and D3, respectively (Figure 2). Analyzing the relationship between mean percentage of injuries and seasons (p<0.01), and distances (p<0.01), it was possible to see that there were significant differences associated to both factors, but not with the interaction between then (p=0.704). At short distances (D1), mean (SE) of injuries in the summer was 0.87% (±0.10) and in the winter 1.16% (±0.13). At medium distances (D2), the mean value of injuries in the summer was 0.87% (±0.05) and in the winter 0.99% (±0.06). At long distances (D3), the mean value of injuries in summer was 1.20% (±0.10) and 1.41% (± 0.10) in winter (Figure 1). A significant difference in the mean value of injuries occurred between birds that travelled between a medium to long distance (p<0.05) during winter, and between a long and short (p<0.05) or medium (p<0.01) distances during summer (Figure 2). In Brazil, it was possible to show a positive correlation between DOA and distance during winter (p<0.001; correlation coefficient=0.258) or summer (p<0.001; correlation coefficient = 0.272) (Figure 1).

In the UK, the overall mean (SE) percentage values of injuries were 0.062% (±0.01), with the minimum 0.012% and the maximum 0.195% per truck. At short distances (D1) the mean percentage value of injuries in the summer were 0.063% (±0.01) and 0.065(±0.01) in the winter. Within distance D2, the mean injury values in the summer were 0.057(±0.01) and 0.063(±0.01) in the winter. Within distance D3, the mean injury value between summer and winter presented statistical differences (P<0.05), being 0.052% (±0.01) and 0.072% (±0.01), respectively (Figure 1). When analyzing the relationship between the mean percentage value of injuries and seasons (p=0.099) or distances (p=0.828) and their interaction (p=0.307), there were no significant differences associated with both factors, isolated and interactions (Figure 1).

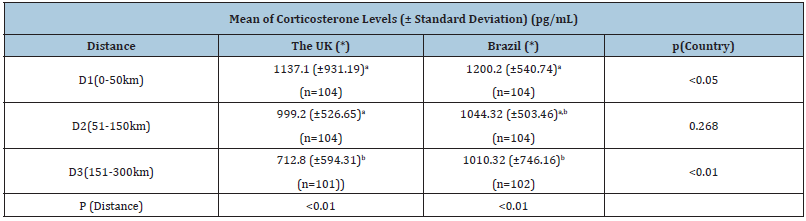

Corticosterone levels

The overall mean corticosterone level at the Brazilian slaughterhouse was 1085.4 (±34.6)pg/mL ranging from 1.00pg/ mL to 5241.4pg/mL. In the UK, it 952.0 (±41.3)pg/mL ranging from 128.9pg/mL to 6438.6/mL. When analyzing the relationship between the mean percentage corticosterone value and distances, it was possible to see that in Brazil and in the UK, there was a significant association between the factors (p<0.01). In both countries, the correlations between corticosterone levels and distances travelled were negatives and both significant (both p<0.01). In both countries, corticosterone levels were lower after long distance travelled. In Brazil, there were significant differences (p<0.01) for the long or medium distances travelled in relation to the short distance. In the UK, there were significant differences (p<0.01) amongst the long distance travelled in relation to short or medium distances (Table 1).

Table 1: Corticosterone levels in both establishments in different distances.

One-way ANOVA followed by Tukey test (data submitted to log transformation in base 10);

(a,b): Different letters within a column represent statistically different groups (p<0.05).

Discussion

Dead on arrival

Grandin [10] defines the rates for DOA at 0.5% as “acceptable” and 0.25% as “excellent”. Following this, and regarding the mean values obtained, during the winter period DOA (%) the mean values would be considered as “acceptable” for the Brazilian case. However, in all other circumstances i.e., season and distances travelled the DOA rate failed to be classed as “excellent”. On the other hand, in the UK, the DOA mean value would be considered “excellent” during both winter and summer and for all distances travelled. Regarding the experimental unit, trucks, the DOA Brazilian data indicated 28.73% as “excellent”, 43.09% as “acceptable” and 28.18% as “unacceptable”. Conversely, in the UK, it was 93.66% as “excellent”, 5.88% as “acceptable” and only 0.46% as “unacceptable”, thus showing a poorer animal welfare regarding the Brazilian case.

As for “ideal” rates of DOA Branco [11] recommended it to be 0.3% in the summer and 0.2% in the winter. Yet, Genswein et al. [12] recommended that the sector to consider a DOA rate below 0.20%. Based on that recommendation, considering all three distances and seasons analyzed for both countries the present study found higher levels in the Brazilian data, unlike the British one. A great discrepancy of values was observed between the two cases since they tended to be influenced by many other factors such as the climate and travelled distance, not to mention the differences in the pre-slaughter management systems, such as catching, handling and stunning. Such a discrepancy occurred between countries (Table 2), therefore each establishment as a unit of study must be treated separately, reflecting its particularities.

Table 2: Benchmark of DOA in different articles and countries from the last 10 years.

In Brazil, a higher mortality rate happened in the summer, which is similar to other studies carried out under the same climatic condition [13,14]; (Table 2). There was no difference in the DOA of the broilers in relation to the distance travelled during winter, however, significant differences were observed during the summer, since the longer the distance, the higher the number of DOA. The same occurred in a study by Silva et al. [14], who found higher mortality rate in longer distances travelled in the summer, while in winter no differences were found. It is clear that depending on the duration and climatic conditions, the broilers tend to find it difficult to thermoregulate their bodies thus contributing to the increase of mortality during transit [15,16]. Thermal stress challenges are likely to be the main threat to broilers’ welfare and survival, which tend to increase by prolonged withdrawal of food and water not to mention exposure to noise, vibration and change in acceleration during in transportation [17]. Of the total mortality caused during transportation, about 40% of the losses are due to thermal stress [18].

According to Warriss et al. [19], in pre-slaughter, temperatures of up to 17 °C, close to Brazilian temperatures in the winter and the UK in the summer months, have a few or no effect in DOA broilers caused by transport. Nijdam et al. [20] showed that DOA in temperatures below 5 °C and above 15 °C increased the DOA, indicating that during warmer and colder weather extremes transportation should be managed carefully. In tropical conditions such as in Brazil, transport should be carried out during the cooler hours of the day such as dawn to reduce the afore mentioned problems. Therefore, providing the birds with sun protection should be considered to decrease exposure. Moreover, boxes and vehicle design could also contribute to minimize these losses [21]. Diseases already present on farm can also contribute to transport mortalities [22-24] therefore, changes in flock management, specifically those aimed at reducing disease incidence of the flock cycle need to be considered [25].

In the UK case, the slaughterhouse showed to have an excellent mortality rate, demonstrating a good level of animal welfare during the pre-slaughter management (Table 2). Warriss et al. [26] reported a mean DOA average rate of 0.19% in the UK, which increased to 0.28% when travel lasted more than 4 hours and decreased to 0.16% for shorter journeys. In the present study, the mean DOA average in the UK was 0.13%, demonstrating an improvement in the index over the years. It has to be also emphasized that the findings of the mean DOA for this study indicate that the UK has a lower DOA when compared to other European studies [16,20,25,27-33]. Thus, it is evident that transportation routes must be planned, and transportation schedules adhered to in accordance with local climatic conditions. Long distance transportation should not take place during hot periods in summer in tropical countries and necessary measures to mitigate heat stress should be in place. On the other hand, in temperate countries, during the winter months, long distances transportation should also be avoided during colder periods, and the trucks should be covered to minimize the birds being exposed to cold stress.

As seen, for all the studied situations, DOA rate was significantly higher in the Brazilian case (generally, over 600% when compared to the UK), which demonstrates the urgent need to reduce these losses through changes in management. In addition to climatic differences, manual harvesting in the Brazilian case might also contribute to higher mortality rates. Absence of legislation or industry standards (in case of distances) and inadequate enforcement or supervision to provide proper transportation conditions can contribute to increased mortality rates. Animal welfare guidelines and audit checklists have been developed by the US National Chicken Council for broilers, and state that when DOA rates are higher than 0.5%, corrective action is required. If some broilers are sufficiently stressed leading to death, is an indication that many other birds will be equally stressed and close to their capacity to survive which jeopardize the birds’ general welfare [34].

Injuries

A high incidence of injuries during transport are also associated with low animal welfare and represents a considerable loss for broiler industry, especially in the tropics [14]. Ferreira et al. [35] studied the main causes of condemnation of broilers’ carcasses and found contamination and injuries that led to partial condemnation were the most significant ones. Significant losses through partial condemnations were also found by Costa et al. [36] who analyzed two abattoirs in Brazil and found a mean incidence of injuries of 38.22% and 20.07%, respectively, which were by far much higher than those found in the current study for the Brazilian abattoir. When comparing the UK slaughterhouse to other European countries’ establishments, these values were shown to be inferior when compared to countries such as Italy, Germany/Netherlands, and Slovakia, which presented averages of 10.0, 2.2 and 0.52% of injuries, respectively [20,33,37]. The DOA % reported in most studies in Europe was about 0.2% [38]. Some of the variability between studies in which factors were identified as significantly affecting injury and mortality were usually due to differences between methodologies used regarding the range of some variables used, for example type of catching, loading, climatic conditions, journey duration, transport procedures, stunning, not to mention the robustness of the multivariable analyses [38].

When comparing losses caused by injuries in both countries, it was observed that, in Brazil, injuries rates were much higher than those in the UK. The contributing factors being likely to be the catching and stunning systems [31,39] which still employ manual methods which is the case of Brazil as proposed by Lund et al. [31]. Moreover, manual catching heightens the intensity of humananimal interaction which is stress-inducing [40]. Conversely, in mechanical harvesting the actions are more standardized and less stressful. In addition, since stunning in Brazil was performed by electronarcosis, while in the UK by modified atmosphere, the latter is part of the requirements as set out by the European Union for the humane treatment of slaughter animals which also caters for a greater awareness of carcass quality [41]. In electronarcosis by immersion in water, the birds are hung by the feet before having their heads submerged in the water, thus raising the stress level of the animals. Yet, stunning by controlled atmosphere tend to be a smoother system during which the birds remain in the cages and are only removed after they have been stunned.

The findings in the present study indicate that in the Brazilian case, the highest rate of injuries was found at distances longer than 150km. Therefore, the ideal location should be for poultry farms to be located as close to the slaughterhouses as possible. Costa et al. [36] also observed a significant correlation between distances and broilers injured when trucks travelled long distances (250 km). This are likely to be because the birds are more exposed to longer acceleration, vibration, breaks and microclimate instances which could contribute to as being harmful factors to their welfare. Thus, in Brazil, too long a journey should be avoided. Furthermore, truck drivers should be aware of the implications of driving conditions and it is proposed that the industry invest more on driving staff to achieve fewer injuries [42], thus the need of the implementation of a different managerial mindset.

As for the injury rate in the UK, these did not vary among the distances travelled. However, they tended to be significantly higher in the winter, thus in line with the number of DOA for the same period. According to Elrom [43], 35% of mortalities during catching and transportation of broilers were due to injuries, and due to events during pre-slaughter handling [31]. The majority of transport mortality might be attributed to factors related to the transport process, indicated by the pathological findings such as lung congestion and trauma [44]. In Brazil, injuries rates were also higher in the winter. This could be probably attributed to the high mortality rate in summer, which led to a lower number of broilers diagnosed with injuries. As a result, since many of the injured broilers already arrived dead at the abattoir, the causes could not be segregated.

Despite the large variation found in the Brazilian data regarding both DOA and injuries rates, the same did not occur in the UK case. The Brazilian data made it clear there are deficiencies in preslaughter managerial methods regarding of the control of systems and logistics in face of adverse conditions that may occur, not to mention the heterogeneity of the conditions of farms and trucks during the transportation of live animals.

Corticosterone levels

In the UK, the collection of blood samples for experimental purposes required approval by the British Home Office. Taking blood samples at arrival and prior to stunning implied a change to the usual handling procedure used by the slaughterhouse, which could potentially introduce an experimentally induced stressor. Therefore, to avoid adding to stress, it was decided to collect all blood post-mortem in both countries. Doktor & Poɫtowicz [45] reported differences in blood corticosterone immediately postmortem between broilers that had and had not been transported, thus, for the purpose of this study it was expected that differences between countries, seasons and transportation differences even after death could also be detected.

Broilers exposed to acute or short-term heat stress, immediately prior to slaughter, presented changes in meat quality [46]. Bianchi et al. [47] demonstrated that the incidence of pale meats with impaired functional properties was higher in summer, thus demonstrating the influence of heat stress on the occurrence of low-quality chicken meat. Langer et al. [48], found a relationship between pre-slaughter stress and PSE (Pale, Soft, Exudative) meat, but no corticosterone levels were measured in their study. Those authors showed that water bathing just before the beginning of the journey from the farm to the slaughterhouse promoted unfavorable conditions for the broilers’ welfare in short distance travelled; however, for relatively longer distances, such a management was beneficial and reduced the amount of PSE meat in the summer season [48].

Further studies are needed to elucidate the physiological corticosterone metabolism of the broilers during pre-slaughtering, one of the most stressful phases for the animal, to obtain consistent data on the relationship between management, stress and meat quality. At the present study, regarding corticosterone mean level in Brazil, it was found a significant difference in D1, D2 and D3. The longer the farm-slaughter distance travelled, the lower the corticosterone at the time of slaughter. In the UK case, it was found that animals transported for short and medium distances had higher corticosterone levels at the point of than those transported over longer distances.

A study by Thaxton et al. [49] found no cases of stressed broilers which tended to present a normal mean corticosterone levels of 624pg/mL. They also demonstrated that the maximum corticosterone concentration in stressed broilers exceeded 15,000pg/mL, and that at the onset of stress in chickens, blood concentrations of corticosterone rose to levels between 1,500 to 3,000pg/mL [50]. In the present study, the Brazilian data showed that all samples presented a range from 223,12pg/mL to 5241,41pg/mL, very similar to the UK data, that ranged from 128,92pg/mL to 6438,57pg/mL.

Vosmerová et al. [51] in the Czech Republic, analyzing temperature and distances travelled linked to corticosterone, found values from 2,450pg/mL (70km/10 to 20 °C) to 9,220pg/ mL (0km/-5 to +5 °C) which were higher than those found in this study. The same authors showed that after catching, loading into transport boxes but before transport taking place corticosterone levels were higher in broilers at a distance of 0km during all seasons. In contrast, after largest distances travelled, as demonstrated here for both the Brazilian and the UK cases, pre-transport catching tended to be an incredibly stressful event for broilers. These results indicate that longer transportation periods provided sufficient time for broilers to partially recover from the stress associated with pre-transport catching. Therefore, it is recommended that broilers transported for short distances should be allowed to rest in a ventilated environment longer before being slaughtered so that corticosterone levels to return to normal.

The Brazilian average of corticosterone was significantly higher than that in the UK, showing again the discrepancy in management systems between both establishments. Corticosterone levels in D1 and D3 were also higher in Brazil, but no significant difference was found in D2. It was possible that the higher stress levels of Brazilian broilers were due to the different methods of catching and/or stunning. Thus, the kind of catching and stunning method used may have been possible factors those caused higher serum corticosterone levels in the Brazilian case as well as regarding DOA and injuries.

Further studies should be conducted with the purpose of establishing standards of broiler welfare related to corticosterone levels, as they already exist for other parameters, such as for standardized DOA by Grandin [10]. Poultry processing plant managers must realise that animal welfare problems during the transportation of broilers not only cause direct losses such as DOA and injuries [52,53], but also regarding the overall loss of meat quality due to the deterioration of the physical appearance and its functional characteristics [54-60]. In addition, it could also contribute to raising the levels of pathogens in chicken carcasses, such as Campylobacter spp. and Salmonella spp. [61-63], not to mention affecting the overall carcass yields.

Animal welfare implications

This study brought to light novel information about management pre-slaughter of broilers and their relationship to welfare to avoid losses during this phase. There might have been other external factors that could have affected the results. However, animal welfare in the UK case can be considered acceptable, while in Brazil, that is not the case. The Brazilian establishment studied would require major improvement in terms of animal management and logistics planning during pre-slaughter. In addition to parameters such as climate and distance, different management methods in the pre-slaughter also contribute to the final results and measures to reduce the level of stress to the animals should be implemented. It is concluded that there is a need for better planning of the journeys from the farm to the slaughterhouse in relation to distance and according to the seasonal conditions in both countries. In the Brazilian case, higher losses were observed in the warmer season, as well as in the longer distances, caused by both DOA and injuries. This thus suggests that for long distances travelled and hot days, protection against the sun and high temperatures such as covers, and shadow curtains should be used. Conversely, in the UK case, higher losses due DOA were observed in the colder season, as well as in the longer distances. While the injuries remained constant, it could be also suggested that for the purpose of long distances travelled during cold days, the use of curtains against rain and wind should be also recommended [64-68].

Regarding the levels of corticosterone, both the Brazilian and the British data showed that animals transported at shorter distances were more stressed at the time of slaughter than those transported at long ones. Some suggestions presented in this article, together with optimal logistical arrangements to avoid delays during each pre-slaughter stage, should result in continued improvement.

Conclusion

Different pre-slaughter management systems can cause distinct economic losses and levels of animal welfare. This article can serve as a basis for managers to implement changes and set targets to reduce economic losses by increasing the well-being of the birds during the pre-slaughter. The literature cited consist of recent publication (Table 2) and the benchmark figures that would serve as basis for managers to analyze their performance against them. Savings generated by reducing the losses during transportation could cover the cost of the changes necessary to improve animal welfare of the poultry chain at pre-slaughter. Moreover, staff training, better design and quality of transport boxes, the modernization of trucks, logistic planning and coordination, and the improvement of facilities and equipment for the reception of birds are recommended. In so doing not only economic loss could be avoided but also product quality could be improved, and more value would be aggregated to the poultry product. As a result, the profitability for the companies would improve too. Since this study investigated only two large slaughterhouses further research in other establishments would be needed to confirm the extent to which the findings, we have reported are generalizable.

Despite short, travelled distances tend to be less advantageous for the purpose of hormonal level, yet, as for injuries, the impact on meat quality it can be beneficial. Nonetheless, for both extreme climatic conditions i.e., too warm or too cold distance travelled they could also be detrimental for the broilers. When better planning and optimization of operations are implemented, it is clear that economic losses could be mitigated and consequently the welfare of the animals is improved.

Acknowledgment

This study was supported by the CNPq (National Counsel of Technological and Scientific Development, Ministry of Science, Technology, Innovations and Communications, Brazil) and CAPES (Coordination of Improvement of Higher-Level Personnel, Ministry of Education, Brazil) Research Project No. 233310/2014-2. We thank both poultry processors (in Brazil and in England) for their assistance and co-operation.

References

- EFSA (2004) Opinion of the scientific panel on animal health and welfare on a request from the commission related to the welfare of animals during transport. European Food Safety Authority 44: 1-36.

- Mitchell MA, Kettlewell PJ (2008) From farm to processing plant: are there still problems? In: Proceedings of XXIII World’s Poultry Congress Brisbane. Australia.

- Rosa OS, Albino JJ, Bassi LJ, Grah RA, Niendicker T (2013) Manejo pré-abate em frangos de corte. Embrapa Suínos e Aves.

- Grandin T (2011) Animal welfare audits for cattle. pigs, and chickens that use the haccp principles of critical control points with animal-based outcome measures.

- Rocha JSR, Lara LJC, Baião NC (2008) Produção e bem-estar animal: Aspectos éticos e técnicos da produção intensiva de aves. Ciência Veterinária nos Trópicos 11(1):49-55.

- Grandin T (2013) The effect of economics on the welfare of cattle, pigs, sheep, and poultry. Department of Animal Sciences.

- Filho WMQ, Ribeiro A, Paula V, Pinheiro ML, Ferreira AJP, et al. (2009) Efeito do estresse por calor sobre os índices zootécnicos, a integridade intestinal e a atividade de macrófagos em frangos de corte. Anais do Prêmio Lamas.

- Tachibana T, Oikawa D, Takahashi H, Boswell T, Furuse M (2007) The anorexic effect of alpha-melanocyte-stimulating hormone is mediated by corticotrophin-releasing factor in chicks. Comparative Biochemistry and Physiology Part A: Molecular and Integrative Physiology 147(1):173-178.

- (2007) SPSS for Windows, Version 16.0. SPSS Inc, Chicago, USA.

- Grandin T (2021) Poultry slaughter plant and farm audit: critical control points for bird welfare. 2009.

- Branco JAD (2004) Manejo pré-abate e perdas decorrentes do processamento de frango de corte. In: Conferência Apinco de ciência e tecnologia avícolas, Santos, SP, Brazil 2: 129-142.

- Genswein KS, Faucitano L, Dadgar S, Shand P, González LA, et al. (2012) Road transport of cattle, swine and poultry in North America and its impact on animal welfare, carcass and meat quality: A review. Meat Science 92: 227-243.

- Silva JAAO, Simões GS, Rossa A, Oba A, Ida EI, et al. (2011) Preslaughter transportation and shower management on broiler chicken Dead on Arrival (DOA) incidence. Semina: Ciências Agrárias 32(2): 795-800.

- Vieira FMC, Silva IJO, Filho JAD, Vieira AMC, Broom DM (2011) Pre-slaughter mortality of broilers in relation to lairage and season in a subtropical climate. Poultry Science 90(10): 2127-2133.

- Caffrey NP, Dohoo IR, Cockram MS (2017) Factors affecting mortality risk during transportation of broiler chickens for slaughter in Atlantic Canada. Preventive Veterinary Medicine 147: 199-208.

- Villarroel M, Pomares F, Ibáñez MA, Lage A, Guijarro P, et al. (2018) Rearing, bird type and pre-slaughter transport conditions I. Effect on dead on arrival. Spanish Journal of Agricultural Research 16(2): 0503.

- Mitchell MA, Kettlewell PJ (2009) Welfare of poultry during transport a review. Poultry Welfare Symposium, Cervia, Italy.

- Ritz CW (2003) Reducing caching and livehaul DOA’s. Poultry Digest Online 4(1): 1-14.

- Warriss PD, Pagazaurtundua A, Brown SN (2005) Relationship between maximum daily temperature and mortality of broiler chickens during transport and lairage. Poultry Science 46(6): 647-651.

- Nijdam E, Arens P, Lambooij E, Decuypere E, Stegeman JA (2004) Factors influencing bruises and mortality of broilers during catching, transport, and lairage. Poultry Science 83(9): 1610-1615.

- Ramakrishnan C, Babu RN, Rao VA, Abraham RJ, Gnanaraj PT, et al. (2019) Economic loss due to live weight shrinkage and mortality during broiler transport in summer and winter season in Chennai city. IJCS 6(1): 816-819.

- Kittelsen KE, Moe RO, Hoel K, Kolbjørnsen Ø, Nafstad O, et al. (2017) Comparison of flock characteristics, journey duration and pathology between flocks with a normal and a high percentage of broilers ‘dead-on-arrival’at abattoirs. Animal 11(12): 2301-2308.

- Jacobs L, Delezie E, Duchateau L, Goethals K, Tuyttens FA (2017) Impact of the separate pre-slaughter stages on broiler chicken welfare. Poultry Science 96(2): 266-273.

- Jacobs L, Delezie E, Duchateau L, Goethals K, Tuyttens FA (2016) Broiler chickens dead on arrival: associated risk factors and welfare indicators. Poultry Science 96(2): 259-265.

- Haslam SM, Knowles TG, Brown SN, Wilkins LJ, Kestin SC, et al. (2009) Prevalence and factors associated with it, of bird’s dead-on arrival at the slaughterhouse and other rejection conditions in broiler chickens. British Poultry Science 50(1): 150.

- Warriss PD, Bevis EA, Brown SN, Edwards JE (1992) Longer journeys to processing plants are associated with higher mortality in broiler chickens British Poultry Science 33(1): 201-206.

- Petracci M, Bianchi M, Cavani C, Gaspari P, Lavazza A (2006) Preslaughter mortality in broiler chickens, turkeys, and spent hens under commercial slaughtering. Poultry Science 85(9): 1660-1664.

- Vecerek V, Grbalova S, Voslarova E, Janackova B, Malena M (2006) Effects of travel distance and the season of the year on death rates of broilers transported to poultry processing plants. Poultry Science 85(11): 1881-1884.

- Chauvin C, Hillion S, Balaine L, Michel V, Peraste J, et al. (2011) Factors associated with mortality of broilers during transport to slaughterhouse. Animal 5(2): 287-293.

- Weeks CA, Brown SN, Richards GJ, Wilkins LJ, Knowles TG (2012) Levels of mortality in hens by end of lay on farm and in transit to slaughter in Great Britain. Veterinary Record 170(25): 647.

- Lund VP, Kyvsgaard NC, Christensen JP, Bisgaard M (2013) Pathological manifestations observed in dead-on-arrival broilers at a Danish abattoir. British Poultry Science 54(4): 430-440.

- Visser EK, Ouweltjes W, Neijenhuis F, Lourens A, Werf JVD, et al. (2014) Jaarrapportage onderzoek animal welfare check points 2013. Lelystad, Wageningen UR (University and Research centre) Livestock Research, Livestock Research Report, p. 753.

- Grilli C, Loschi AR, Rea S, Stocchi R, Leoni L, et al. (2015) Welfare indicators during broiler slaughtering. British Poultry Science 56(1): 1-5.

- Weeks CA (2014) Poultry handling and transport. Livestock Handling, Transport, Cabi Publishing, Wallingford, England, pp. 378-398.

- Ferreira TZ, Sesterhenn R, Kindlein L (2012) Perdas econômicas das principais causas de condenações de carcaças de frangos de corte em Matadouros-Frigoríficos sob Inspeção Federal no Rio Grande do Sul, Brasil. Acta Scientiae Veterinariae 40(1):1-6.

- Costa FMR, Prata LF, Pereira GT (2007) Influência das condições de pré-abate na incidência de contusões em frangos de corte. Veterinária e Zootecnia 14(2): 234-245.

- Luptáková O, Nagy J, Popelka P, Turek P, Nagyová A (2012) Trend analysis of the dead-on arrival and condemnation causes of broiler chickens from farm livestock (the Slovak Rrepublic) in the years 2006-2010. Folia 56: 37-38.

- Cockram MS, Dulal KJ, Mohamed RA, Revie CW (2018) Risk factors for bruising and mortality of broilers during manual handling, module loading, transport, and lairage. Canadian Journal of Animal Science 99(1): 50-65.

- Nijdam E, Delezie E, Lambooij E, Nabuurs MJ, Decuypere E, et al. (2005) Feed withdrawal of broilers before transport changes plasma hormone and metabolite concentrations. Poultry Science 84(7): 1146-1152.

- Machado ST, Reis JGM, Vendrametto O, Nääs IA (2014) Logística aplicada à produção de aves de corte: desafios no manejo pré-abate. Enciclopédia Biosfera 10(18): 2108-2122.

- Gerritzen MA, Reimert HGM, Hindle VA, Verhoeven MTW, Veerkamp WB (2013) Multistage carbon dioxide gas stunning of broilers. Poultry Science 92(1): 41-50.

- Bailone RL, Roça RO (2016) Tendências no transporte de frangos de corte no Brasil: do bem-estar animal às perdas econô Revista Avicultura Industrial 108(10): 44-49.

- Elrom K (2001) Handling and transportation of broilers-welfare, stress, fear and meat quality. Israel Journal of Veterinary Medicine 55(1): 1-4.

- Kittelsen KE, Granquist EG, Kolbjørnsen Ø, Nafstad O, Moe RO (2015) A comparison of post-mortem findings in broilers dead-on-farm and broilers dead-on-arrival at the abattoir. Poultry Science 94(11): 2622-2629.

- Doktor J, Poɫtowicz K (2009) Effect of transport to the slaughterhouse on stress indicators and meat quality of broiler chickens. Annals of Animal Science 9(3): 307-317.

- Sandercock DA, Hunter RR, Nute GR, Mitchell MA, Hocking PM (2001) Acute heat stress-induced alterations in blood acid-base status and skeletal muscle membrane integrity in broiler chickens at two ages: Implications for meat quality. Poultry Science 80(4): 418-425.

- Bianchi M, Fletcher DL, Smith DP (2005) Physical and functional properties of whole and ground pale broiler breast meat. Poultry Science 84: 803-808.

- Langer RODS, Simões GS, Soares AL, Oba A, Rossa A, et al. (2010) Broiler transportation conditions in a Brazilian commercial line and the occurrence of breast PSE (Pale, Soft, Exudative) meat and DFD-like (Dark, Firm, Dry) meat. Brazilian Archives of Biology and Technology 53(5): 1161-1167.

- Thaxton JP, Stayer P, Ewing M, Rice J (2005) Corticosterone in commercial broilers. Journal of Applied Poultry Research 14(4): 745-749.

- Puvadolpirod S, Thaxton JP (2000) Model of physiological stress in chickens 3. Temporal patterns of response. Poultry Science 79(3): 377-382.

- Vosmerová P, Chloupek J, Bedánová I, Chloupek P, Kruzikova K, et al. (2010) Changes in selected biochemical indices related to transport of broilers toand slaughterhouse under different ambient temperatures. Poultry Science 89(12): 2719-2725.

- Carlyle WWH, Guise HJ, Cook P (1997) Effect of time between farm loading and processing on carcass quality of broiler chickens. Veterinary Record 41(14): 364.

- Tabba’A MJ, Alshawabkeh K (2000) Some factors affecting preslaughtering mortality and damage to broilers and interaction during transportation to processing plants. Dirasat Agricultural Science 27(3): 375-384.

- Zaboli G, Huang X, Feng X, Ahn DU (2019) How can heat stress affect chicken meat quality? -a review. Poultry Science 98(3): 1551-1556.

- Hussnain F, Mahmud A, Mehmood S, Jaspal MH (2019) Influence of long-distance transportation under various crating densities on broiler meat quality during hot and humid weather. The Journal of Poultry Science 57(3): 246-252.

- Hussnain F, Mahmud A, Mehmood S, Jaspal MH (2019) Meat quality and cooking characteristics in broilers influenced by winter transportation distance and crate density. The Journal of Poultry Science 57(2):175-182.

- Utomo MCC, Sarjana TA, Suprijatna E, Kismiati S, Nasoetion MH, et al. (2019) The influence of transportation distance during the dry season on broiler chickens’ carcass traits. In: IOP Conference Series: Earth and Environmental Science. IOP Publishing, UK.

- Teke B, Akin PD, Akdag F, Ugurlu M, Ekiz B (2019) The effect of season on dead on arrival rate and meat quality characteristics of broiler chicken transported in commercial slaughter conditions. Large Animal Review 25(4): 147-152.

- Urayama PM, Padilha JB, Pia J, Takahashi SE (2018) PSE meat formation in broiler chickens: a pre-slaughter management case. Veterinaria y Zootecnia 12(2): 33-48.

- Spurio RS, Soares AL, Carvalho RH, Silveira V, Grespan M, et al. (2016) Improving transport container design to reduce broiler chicken PSE (pale, soft, exudative) meat in Brazil. Animal Science Journal 87(2): 277-283.

- Verbrugghe E, Boyen F, Gaastra W, Bekhuis L, Leyman B, et al. (2012) The complex interplay between stress and bacterial infections in animals. Veterinary Microbiology 155(2-4): 115-127.

- Freestone PP, Sandrini SM, Haigh RD, Lyte M (2008) Microbial endocrinology: how stress influences susceptibility to infection. Trends in Microbiology 16(2): 55-64.

- Lyte M (2004) Microbial endocrinology and infectious disease in the 21st Trends in Microbiology 12(1): 14-20.

- Grilli C, Stocchi R, Loschi AR (2018) Survey on broiler pre-slaughter mortality in a commercial abattoir of central Italy. Italian Journal of Food Safety 7(3): 5878.

- Vecerek V, Voslarova E, Conte F, Vecerkova L, Bedanova I (2016) Negative trends in transport-related mortality rates in broiler chickens. Asian-Australasian Journal of Animal Sciences 29(12): 1796-1804.

- Bulent T (2019) Survey on dead on arrival of broiler chickens under commercial transport conditions. Large Animal Review 25(6): 237-241.

- Freitas AS, Carvalho LM, Soares AL, Neto ACDS, Madruga MS, et al. (2016) Simultaneous occurrence of broiler chicken hyper and hypothermia in-transit and lairage and dead-On Arrival (DOA) index under tropical climate. International Journal of Poultry Science 15(11): 459-466.

- Filho JÁB, Queiroz ML, Brasil DDF, Vieira F, Silva IJ (2014) Transport of broilers: load microclimate during Brazilian summer. Engenharia Agrícola 34(3): 405-412.

© 2021 Ricardo Lacava Bailone. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)