- Submissions

Full Text

Approaches in Poultry, Dairy & Veterinary Sciences

Effects of Lighting Length on Isa Brown Layer Performance and Egg Characteristics in Poultry Production in Madagascar

Hantanirina Herisoa Isabelle*, Rabearimisa Rivo Nirina, Ratsarasataharitera Aina Tiana Erick and Rakotozandriny Jean de Neupomuscène

Ecole Supérieure des Sciences Agronomiques, Université d’Antananarivo, Madagascar

*Corresponding author: Hantanirina Herisoa Isabelle, Ecole Supérieure des Sciences Agronomiques, Université d’Antananarivo, B.P. 175 -Antananarivo -Madagascar

Submission: June 13, 2018; Published: July 31, 2018

ISSN: 2576-9162 Volume4 Issue3

Abstract

A total of 357 Isa Brown layers were used in this study in order to assess the effects of lighting length on laying performance and on some egg characteristics in a family farm of Antananarivo suburb, Madagascar. The birds, in their egg producing phase (37 week old), were distributed at random into one of 3 lots, each allocated to one of 3 lighting treatments: 12 hour natural daylight, used as control; 14 hour lighting length (natural daylight + artificial light) and 16 hour lighting length (natural + artificial light). The artificial lighting was supplied by 60 Watt incandescent lamps placed within the treated lots. Eggs, numbering 840, were taken at random in order to assess their physical and chemical characteristics. Thus, lighting length affects significantly layer weight and production performance (p< 0.05). Layer weights tend to be lower with increasing lighting, but egg production increase with lighting length. Lighting length has no effect neither on egg weight nor on egg volume, but it affects significantly the shell index (p=0.0018) and egg internal qualities (p< 0.05), except for yolk pH.

keywords: Poultry; Layers; Lighting length; Performance; Egg characteristics; Madagascar

Introduction

Appreciated for its meat and its egg productions, poultry operation has become a major farming activity since 80% of all farmers are poultry producers in Madagascar. Furthermore, poultry production is an income generating activity integrated into the Malagasy population customs [1]. It, also, is classified among the activities accessible to the poorest and population most vulnerable part [2]. However, overall egg production remains low in Madagascar in spite of the increasing number of semi-industrial or industrial poultry operators within the suburban areas of Antananarivo, the Capital. In fact, raising layers requires following some technical management rules in order to get a good production level, especially, among others, getting a good control over lighting length during the laying phase [3-5]. The present study is initiated in order to identify some good practices in term of lighting length in relation with Madagascar environmental conditions.

Material and Methods

This study has been undertaken in a laying hen family farm located within the District of Atsimondrano, Antananarivo, in the Analamanga Region, Madagascar (18°57’57 ‘’ latitude South, 47°32’17 ‘’ longitude East and 1,269m altitude) during 2 months, from February to April 2016 (8 weeks). A total of 357 layers in their production phase (37 weeks of age), belonging to the strain Isa Brown, have been used. The animals have been raised in the same building before being allocated at random to three lots including a control for which the lighting length was 12 hours per day of natural daylight (Lot 1); the second lot has been exposed to a lighting length of 14 hours per day (Lot 2) and the last lot received a 16 hours per day lighting length treatment (Lot 3). Each lot has been equipped with feed troughs, water troughs, laying spaces and a litter made up of wood shavings that were replaced twice a week. The birds were all fed a ration containing 2,796.24Kcal ME per day, distributed in 2 times, at a fixed hour and access to water was on an ad libitum basis. For artificial lighting, 60watt incandescent lamps have been used in Lot 2 and 3. The ignition and the extinction of the artificial light were performed at fixed hour depending on the lighting length for each lot.

In order to appreciate production, 840 eggs were taken at random (from the week production) and have been individually weighed (in order to get egg weight, yolk weight, white weight, shell weight), measured (for egg volume, egg diameter, egg length) and tested (yolk pH, white pH) at the Animal Nutrition laboratory of the Animal Science Department, Ecole Supérieure des Sciences Agronomiques, University of Antananarivo, Madagascar. Furthermore, individual weighing was performed on each layer at the beginning and at the end of the experiment. Besides, other indices permitting to assess production quality have been calculated such as egg shape index, shell index, laying rate and the food conversion ratio.

In all cases, data were analyzed using the JMP/SAS 5.0.1.2 software. Statistical tests included Tukey multiple comparison tests on every studied variables and the Spearman correlation test for egg caliber appreciation

Results and Discussion

Hen performance -lighting length relationships

Table 1: Laying hen performance.

Layer characteristics and performance are synthesized in Table 1. Comparative analysis shows that lighting length affects significantly layer performance (p < 0.05) (Table 1). In fact, this study results do not agree with those found by Lacassagne & Jacquet [6] who showed that birds raised in buildings provided with an artificial light surplus are heavier than those raised in buildings exposed only to natural light. Besides, weights at the end of the experiment during this study are very close (lot 2 and lot 3) to the Isa Brown strain hen experimental weight at the 44th week of age [7]. However, at the end of this experiment, hens from lot 1 (control) are heavier than those of the two other lots. Indeed, considering the laying rate or the feed conversion ratio range of variation between lots, birds treated with a surplus of artificial light converted more their rations into eggs while individuals from control converted theirs into body weight [8]; the latter is a result not very sought-after in raising laying hens. In this case, the use of artificial light is beneficial for the success of a laying farm [9].

In relation with laying rates and feed conversion ratios, it can be noted that the use of artificial light to increase the lighting length shows some positive effects on the former variables. These results are similar to those of Sauveur [9,10] as well as to those of Galéa et al. [11], Thiele [12], Chemineau et al. [13] and of Fellah Trade [14]. The likely reason of this variation could be bound to the more active and persistent neurohormonal mechanisms among animals treated with a longer lighting length. Indeed, the longer the day is the more intense hormonal activities coming into play within egg formation would be [9,10,15].

Indeed, the use of natural daylight is a good practice, but creating an environment where light management is completely under control proves to be interesting and advantageous since light intensity in semi-open buildings might be difficult to master. On the other hand, light intensity in a poultry building for laying hens affects significantly the laying rate and the birds feed conversion ratio [15,16]; but beside light intensity effect might be added that of light source that mostly affects laying rate [17-20].

Egg characteristics -lighting length relationships

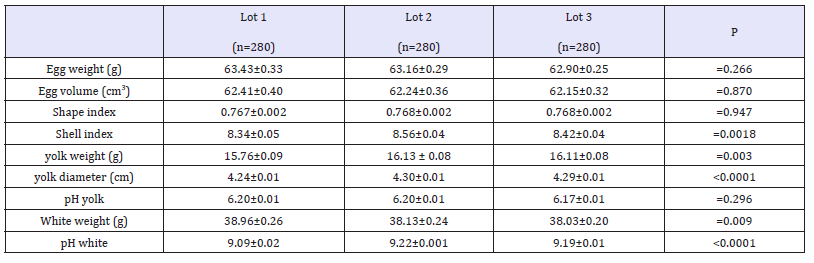

From a practical standpoint, egg external characteristics are not affected at all by the lighting length during production phase (p>0.05). On the other hand, some significant differences are observed for the egg internal qualities, except for the pH of the yolk (p< 0.05) (Table 2).

Table 2: Egg qualities.

Beside, egg weight and volume are influenced by the lighting length [6,11]. This divergence is probably the result due to an insufficiency of photo-sexual reflex stimulation during egg production phase in order to get good caliber eggs, meaning heavier and more voluminous [12]. However, the results of this study through these two variables, weight and volume, agree with those found by Narushin [21] and those of Soltani et al. [22].

Considering their shape indices, eggs found in this study are close to those of Er et al. [17], Rabenirina [23], Moula et al. [24] and of Shi et al. [25]. On the other hand, their characteristics lie outside the range of the values proposed by Sauveur [9]. According to Sauveur [9], egg shape index varies between 0.70 and 0.75; 0.65 is the index for much stretched out eggs versus 0.82 for the very rounded eggs. In this study, eggs tend to be rounded in shape (Table 2). This result is related to the age of the animals since younger hens tend to lay more rounded eggs [26]. In any case, lighting length doesn’t affect egg shape. Yet, shell toughness appreciated through the shell index is affected by the lighting length [27,28].

On one hand, egg yolk physical characteristics (weight and diameter) are influenced by lighting length [9,18,23] while chemical quality (pH) seems to be steady [23,29]. On the other hand, egg white physical and chemical qualities (weight and pH) are affected by the lighting length within the hen housing [9,18,23,29,30]. However, it should be noted that egg storage duration could lead to an albumen deterioration thus changing its acidity [31].

Conclusion

In poultry, light is an important factor in egg production cycle. This study allows showing lighting efficiency to a determined length for laying hens during production phase within a family poultry farm in Madagascar. Through the results obtained during this study, relationships between egg productions - lighting length are significant making it necessary to use artificial light in poultry farm building in order to increase daylight length over 16 hours while the relationship between egg qualities -lighting length is apparently concealed. The good control over lighting length in raising laying hens on family farm is full of promise in Madagascar.

Acknowledgement

Authors are thanking family farm for providing the facilities to carry out the present study.

References

- Philippison A (2005) Etude de l’approvisionnement en viandes de volailles et ovo produits de la zone urbaine et périurbaine de Morondava. Mémoire de fin d’étude. Département Elevage. Ecole Supérieure des Sciences Agronomiques-Université d’Antananarivo, Madagascar.

- Ministère de l’Elevage (2013) L’élevage, un secteur à redynamiser. Madagascar, p. 10.

- Henquin G (1963a) Cours théorique et pratique d’aviculture professionnelle à l’usage des élèves d’Aviculture et de Petit élevage de l’Etat de Liège. Ministère de l’Agriculture, Bruxelle, Belgium.

- Henquin G (1963b) Cours théorique et pratique d’aviculture professionnelle à l’usage des élèves d’Aviculture et de Petit élevage de l’Etat de Liège. Ministère de l’Agriculture, Bruxelle, Belgium.

- Sauveur B, Picard M (1990) Effet de la température et de l’éclairement appliqués à la poule pondeuse. Inra, l’Aviculture en méditerranée. Série A 7: 211-226.

- Lacassagne L, Jacquet J (1963) Elevage de poulettes en lumière constante de six heures. Son action sur la croissance, la maturitè sexuelle, le poids de l’oeuf et le pourcentage d’oeufs à double jaune en début de ponte. Annales de zootechnie, INRA/EDP Sciences 12(3): 159-172.

- www.isapoultry.com (2014) Guide d’élevage -Systèmes de production alternatifs.

- Hocquette J, Ortigues Marty I, Damon M, Herpin P, Geay Y (2000) Métabolisme énergétique des muscles squelettiques chez les animaux producteurs de viande. INRA Productions Animales 13(3): 185-200.

- Sauveur B (1988) Reproduction des volailles et production d’oeufs. Paris, p. 449.

- Sauveur B (1996) Photopériodisme et reproduction des oiseaux domestiques femelles. INRA Prod Anim 9(1): 25-34.

- Galea F, Ferchal E, Rouilliere H (2003) Effet d’un changement de programme lumineux sur les performances de ponte de deux souches de pondeuses, Tours, pp. 1-3.

- Thiele H (2009) Programmes d’éclairage pour les poules pondeuses: La lumière fait la différence. Lohmann Information 44: 39-48.

- Chemineau P, Malpaux B, Brillard JP, Fostier A (2009) Saisonnalité de la reproduction et de la production chez les poissons, oiseaux et mammifères d’élevage. Inra Prod Anim 22(2): 77-90.

- www.fellah-trade.com (2010) Technique de conduite des élevages de poules pondeuses d’oeufs de consommation.

- Jacome I, Rossi L, Borille R (2014) Influence of artificial lighting on the performance and egg quality of commercial layers: a review. Brazilian Journal of Poultry Science 16(6): 337-344.

- Chang S, Lin M, Fan Y, Lee T (2016) Effects of lighting intensity on growth and reproductive performance of breeder geese. The Journal of Applied Poultry Research 25(3): 315-321.

- Er D, Wang Z, Cao J, Chen Y (2007) Effect of monochromatic light on the egg quality of laying hens. Poultry Science 16(4): 605-612.

- Li D, Zhang L, Yang M, Yin H, Xu H, et al. (2014) The effect of monochromatic light-emitting diode light on reproductive traits of laying hens. The Journal of Applied Poultry Research 23(3): 367-375.

- Long H, Zhao Y, Wang T, Ning Z, Xin H (2015) Effect of light-emitting diode vs. fluorescent lighting on laying hens in aviary hen houses: Part 1 - Operational characteristics of lights and production traits of hens. Poultry Science 95(1): 1-11.

- Olanrewaju H, Miller W, Maslin R, Collier S, Purswell J, et al. (2016) Effects of light sources and intensity on broilers grown to heavy weights. Part 1: Growth performance, carcass characteristics, and welfare indices. Poultry Science 95(4): 727-735.

- Narushin V (2005) Production, modeling and education -Egg geometry calculation using the measuements of length and breadth. Poultry Science84(3): 482-484.

- Soltani M, Omid M, Alimardani R (2014) Egg volume prédiction using machine vision technique based on pappus theorem and artificial neural network. J Food Sci Technol 52(5): 3065-3071.

- Rabenirina Z (2006) Effets de l’incorporation de graine de Ceiba pentandra et de Heritiera littoralis dans l’alimentation des poules pondeuses sur les performances de ponte et la qualité de l’oeuf. Mémoire de fin d’étude. Département Elevage. Ecole Supérieure des Sciences Agronomiques-Université d’Antananarivo, Madagascar, p. 68.

- Moula N, Antoin Moussiaux N, Do Duc L, Pham kim D, Nguyen Chi T, et al. (2011) Comparaison de la qualité des oeufs de deux race de poules Vietnamiennes (Ri et Mia). Journal of Agriculture and Rural Development in The Tropics and Subtropics 112(1): 57-69.

- Shi S, Lu J, Tong H, Zou J, Wang K (2012) Effects of graded replacement of soybean meal by sunflower seed meal in laying hen diets on hen performance, egg quality, egg fatty acid composition, and cholesterol content. Journal of Applied Poultry Research 21(2): 367-374.

- www.inra.fr (2014) L’oeuf au trésor.

- www.isapoultry.com (2011a) Guide d’élevage général des pondeuses commerciales.

- www.isapoultry.com (2011b) Principes généraux des programmes lumineux pendant la période de production.www.food-info.net (2015) Quel est le pH des aliments ?

- www.food-info.net (2015) Quel est le pH des aliments ?

- www.isapoultry.com (2016) Qualité des oeufs.

- Roberts J (2004) Factors affecting egg internal quality and egg shell quality in laying hens. Journal of Poultry Science 41(3)161-177.

© 2018 Hantanirina Herisoa Isabelle. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)