- Submissions

Full Text

Aspects in Mining & Mineral Science

Determination of Suitable Explosives for Dolomitic Marble and Granodiorite Using Blastability Characteristics

Adebayo B1* and Bolarinwa HT2

1Department of Mining Engineering, Federal University of Technology, Akure, Nigeria

2Ministry Of Mines and Steel Development, Ilorin, Nigeria

*Corresponding author:Adebayo B, Department of Mining Engineering, Federal University of Technology, Akure, Nigeria

Submission: February 01, 2023; Published: March 20, 2023

ISSN 2578-0255Volume11 Issue1

Abstract

This paper evaluates blastability characteristics of dolomitic marble and granodiorite for explosive selection. The rock samples were tested in the laboratory for point load strength index, uniaxial compressive strength and specific gravity. Also, joint spacing and joint orientation were measured on the field. Blastability index was estimated for both rocks using empirical equation. The results of the various analyses revealed that point load strength index of dolomitic marble is 3.52MPa and that of granodiorite 4.37MPa. The uniaxial compressive strength of dolomitic marble and that of granodiorite are 93.57MPa and 116.40MPa. The specific gravity of dolomitic marble and granodiorite are 2.72 and 2.75. The porosity of dolomitic marble and granodiorite are 0.72% and 0.63%. The results of Blastability Index (BI) are 55.55 and 57.88 for dolomitic marble and granodiorite respectively. The joint orientation for dolomitic marble and granodiorite is 23.90°/142.83° and 26.83°/116.40°. Based on the results obtained for both rocks high explosives (ANFO) is selected for the rocks but where there is water problem emulsion is recommended.

Keywords:Explosive; Blastability; Rocks; Strength; Dolomite

Introduction

Blastability can be defined as the blasting characteristics of the rock mass subjected to a specified blast design, explosive characteristics and specified legislative constraints depending on the site specifics [1]. In other words, blastability indicates how easy or difficult to blast a rock mass under defined conditions. The parameters affecting rock fragmentation can be classified as blasting design parameters, explosive related parameters, physical and geomechanical properties of intact rock and rock mass [2,3]. Blastability represents the influence of rock mechanical parameters on the blasting result. In the work of Adebayo et al. [4] Ewekoro limestone was classified using rock mass classification system and blastability of limestone varied from high to low. Furthermore, model for prediction of rock fragmentation was developed using the concept of (RES) Rock Engineering System [5]. Distribution of explosive energy and multivariate analysis were used to predict fragmentation by blasting [6,7]. The selection of the type of explosive forms an important part of the blast design so that desirable fragment size can be obtained. The use of explosives is a routine process during fragmentation of rocks where the quantity of charge and firing sequence are designed for blasting rounds. The selection of suitable explosive is important for minimizing costs of breakage.

However, the following factors must be analyzed to achieve good fragmentation: cost of the explosive, charge diameter, rock characteristics, volume of rock to be blasted, presence of water, safety conditions, explosive, atmospheric condition and supply problems [8]. Selection of explosive for different types of rocks is largely dependent on the blastability index of the rock. If the blastability index of a rock is high the type of explosive that will be required will be different from that of a rock with low blastability index. Some researchers have related it with rock and blast design parameters. Also, others had tried to estimate blastability through approaches based on the drilling rates and blast performance. The objectives of this paper therefore are to determine the blastability characteristics and select suitable explosives for the selected rocks

Materials and Methods

Description of the study area and sample collection

The study areas are Ondo State and Oyo State, southwestern Nigeria. Ondo State lies between latitudes 05° 27′ and 08° 09′ N and longitudes 04° 00′ and 06° 00′ E. Oyo State which is the second study area, lies within the southwestern part of basement complex of Nigeria and is underlain by the lithological units of the crystalline basement complex [9]. Samples of granodiorite and dolomitic marble were taken along longitude N07°16’59.6’’, latitude E005°14’39.3’’ and longitude N08°37’41.6’’ and latitude E004°04’50.6’’ respectively.

Point load strength

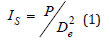

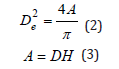

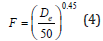

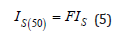

Point load strength for the rocks was determined using irregular rock samples. The irregular sample was prepared, and the test was conducted in accordance with [10]. The point load strength index was determined by employing Eqs. 1 to 5.

Where P is the failure load (kN) and De is the equivalent diameter (mm).

where A is the area in mm2, D is the distance between load contact points (mm) and H is the width of the specimen (mm).

F is the correction factor and De is the equivalent diameter (mm).

Where IS(50) is the corrected point load strength index and Is is the uncorrected point load strength index.

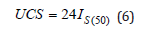

Uniaxial compressive strength

The mathematical model suggested by [11] relating Uniaxial Compressive Strength (UCS) and point load strength (IS(50)) was used to estimate the UCS.

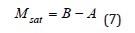

Porosity

The saturation and buoyancy technique for irregular rock samples was adopted and the procedures followed the standard suggested by [11] and also conform to [12]. The porosity of the sample was determined using Eqs. 7 to 9. Then, saturated-surface dry mass;

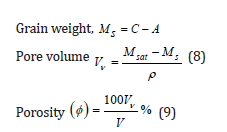

Specific gravity

Five samples of irregular form were prepared in the laboratory. The mass of each of the prepared samples Mγ was recorded. The sample was then immersed in water and the mass of water displaced by the sample Mwγ was recorded. The specific gravity is then calculated using Equation 10

where Gγ is the specific gravity, Mγ is the mass of the rock sample and Mwγ is the mass of water displaced.

Determination of discontinuity spacing

The discontinuity spacing of individual blocks of intact rock was measured in accordance with the suggested method by [11,12]. A measuring tape of 3m in length, calibrated in mm divisions and clinometer was held along the exposure such that the surface trace of the discontinuity set was approximately perpendicular to the tape.

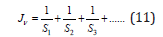

Determination of volumetric joint count

The volumetric joint count is a measure for the number of joints intersecting a volume of rock mass. It is defined as number of joints per m³. The volumetric joint count was determined using Eq. 11.

Joint orientation

The dip and dip direction of the selected rocks were measured with the aid of clinometers. The Discontinuities was measured in accordance with standard method suggested by [11].

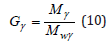

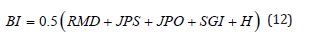

Blastability index

The blastability index was determined by adopting the Lilly [13] mathematical model written in Eq. 12.

Where, BI is Blasting Index, RMD is Rock mass Description, JPS is Joint Plane Spacing, JPO is Joint Plane Orientation.

SGI=Specific Gravity Influence, =25 X Specific Gravity of rock (t/

m3) – 50

H=Hardness in Mohr Scale (1–10).

Explosive selection criteria

The explosives were selected for the two rock types by considering blastability characteristics and joint spacing adopting criteria suggested by [14]. Jimeno et al. [8] suggested that explosive with high bubble energy to strain energy ratio should be selected for rock that is capable of absorbing 20%-40% strain energy as shown in Table 1.

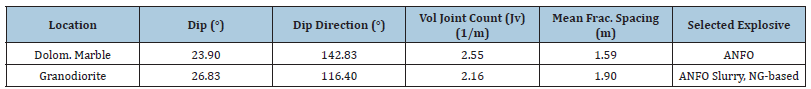

Table 1:Discontinuity and explosive selected for the rocks.

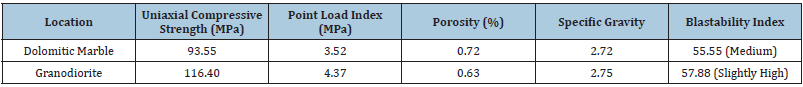

Results and Discussion

Table 2 shows the summary of blastability characteristics of selected rocks. The values of point load strength index for dolomitic marble and granodiorite 3.52 and 4.37MPa respectively. Uniaxial compressive strength estimated from the point load strength index for dolomitic marble and granodiorite are 93.55 and 116.40MPa respectively. These rocks are classified as very high strength rocks according to ISRM [11] but compressive strength of granodiorite is greater than the strength of dolomitic marble. The specific gravity of dolomitic marble and granodiorite are 2.72 and 2.75. The porosity of dolomitic marble and granodiorite are 0.72 and 0.63. It can therefore be deduced that dolomitic marble is more porous than granodiorite. The blastability index of dolomitic marble is 55.55 while that of granodiorite is 57.88 as presented in Table 2. This shows that dolomitic marble is easier to blast than granodiorite. Hence, this means that blasting of granodiorite requires more explosive than dolomitic marble. Table 1 presents summary of discontinuity and the explosive selected. The dip and dip direction for dolomitic marble are 23.900 and 142.830 while dip and dip direction for granodiorite are 26.830 and 116.400 respectively. The average values of volumetric joint count are 2.55 and 2.16 (1/m) as presented in Table 1. The results revealed that granodiorite has low joint count as compared to that of dolomitic marble. ANFO is selected for dolomitic marble while Slurry, NG-Based explosive and ANFO are selected for the granodiorite based on [8] and [14] suggested criteria.

Table 2:Blastability characteristics of selected rocks.

Conclusion

The results of the research revealed that: uniaxial compressive strength of dolomitic marble and granodiorite are 93.55 and 116.40MPa. The average specific gravity of the dolomitic marble and granodiorite are 2.72 and 2.75 respectively. The average volumetric joint count of marble is 2.55 while that of granodiorite is 2.16 1/m. The Blastability Index of dolomitic marble is 55.55 and that of granodiorite is 57.88. ANFO is selected for the rocks based on [8] suggestion that explosive that has high bubble energy to strain ratio for rocks having joint range of 1.50 to 2.5 where about 20% to 40% strain wave energy may be absorbed. In addition, where there is water problem water gel or emulsion explosive is selected for the rocks.

References

- Kaushik D, Phalguni S (2003) Concept of blastability. Department of Mining Engineering, Indian School of Mines, Dhandad, Indian Mining and Engineering Journal 42: 24-31.

- Ghosh A, Daemen JJK, Van Zyl D (1990) Fractal based approach to determine the effect of discontinuities on blast fragmentation. Proceeding of 31st USA Symposium on Rock Mechanics, Golden, Colorado, pp. 905-912.

- Kulatilake PHSW, Hudaverdi T, Kuzu C (2010) Mean particle size prediction in rock fragmentation using neural networks. Engineering Geology 114(3-4): 298-311.

- Adebayo B, Adeniyi PR, Agbalajobi SA (2015) Blastability of Ewekoro limestone using rock mass classification. Proceeding of the 24th International Mining Congress and Exhibition of Turkey-IMCET 15, Turkey, pp. 867-873.

- Faramarzi F, Mansouri H, Ebrahimi FMA (2013) A rock engineering systems-based model to predict rock fragmentation by blasting. International Journal of Rock Mechanics and Mining Science 60: 82-94.

- Lownd CM (1995) Prediction of fragmentation based on distribution of explosives energy. In: Proceeding of the 11th Annual Conference of Explosives and Blasting Research, Orlando Florida, USA, pp. 286-296.

- Aler J, Du Mouza J, Arnould M (1996) Measurement of the fragmentation efficiency of rock mass blasting and its mining application. International Journal of Rock Mechanics and Mining Science, Geomechanics Abstr 33(2): 189-196.

- Jimeno CL, Jimeno EL, Francisco JAC (1995) Drilling and blasting of rock. In: Balkema Rotterdam AA, De Ramiro, Visser Y, pp. 30-190.

- Rahman MA (1976) Review of the basement geology of Southwestern Nigeria. In: Kogbe CA (Ed.), Geology of Nigerian. Elizabethan Publishing Company, Lagos, Nigeria, pp. 41-58.

- (1981) ISRM, suggested methods Point Load Strength. International Journal of Rock Mechanics, Mineral Science Geo-mechanics, 22(2): 51-60.

- (1981) ISRM, Rock characterization, testing and monitoring. In: Brown ET (Ed.), ISRM suggested methods. Pergamon Press, Oxford, UK, p. 211.

- (1994) ASTM, Annual book of ASTM standards-construction: Soil and rocks. ASTM publication, pp. 1-975.

- Lilly PA (1986) An empirical method of assessing rock mass blast ability. In: Davidson JR (Ed.), Proceedings, Large Open Pit Mining, The Aus IMM, Parkville Victoria, pp. 89-92.

- Brady EH, Brown ET (1985) Rock mechanics for underground mining. George Allen and Co., London.

© 2023 Adebayo B. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)