- Submissions

Full Text

Aspects in Mining & Mineral Science

Self-Sustaining Smoldering to Construct Tailings-Based Tech Soil

Jie Li, Qun Zhao, Meiyan Si, Senlin Tian* and Jianhong Huang*

Faculty of Environmental Science and Engineering, Kunming University of Science and Technology, China

*Corresponding author:Senlin Tian and Jianhong Huang, Faculty of Environmental Science and Engineering, Kunming University of Science and Technology, Kunming, Yunnan, China

Submission: February 20, 2023; Published: March 10, 2023

ISSN 2578-0255Volume11 Issue1

Abstract

The worsening global climate change appeal of a low-carbon technology in tailing landscapes rehabilitation for the sustainable goal. This study explores smoldering to construct soil-like substrate in an eco-engineering tailings manner. The obtained tecnhsoil exhibit low metals bio-toxicity, elevated physiochemical properties and improved nutrients statue, which is significant for the subsequent revegetation of the mine tailings landscapes. Due to the self-sustaining characteristic of smoldering and the carbon-neutral nature of biomass energy, the article presents here are exactly a contribution to achieve carbon neutrality.

Keywords:Smoldering; Tailings; Tecnhsoil; Reclaim; Low-carbon footprint

Introduction

Due to the insatiable demands for commodity metals, from 5×109 to 14×109 tons of tailings are accumulated annually worldwide, which resulting significant damage to the environment around the tailings storage area once the mine was closed [1,2]. Covering these tailings landscapes with stable and functional ecosystems seemly a suitable strategy to decrease the environmental risks of mine tailings [3]. However, direct reclaiming of the abandoned tailings area is unsustainable and infeasible due to the high toxicity content of metals, harsh pH conditions, deficiency of nutrient contents and poor physical structure, which hindering the colonization of microbial and plant [3]. A common technique for tailings landscape restoration is covering these areas with topsoils to reconstruct root zones for plant establishment and growth [1]. Nevertheless, the further application of this conventional remediation approach has been hindered by the deficiencies of soil resources on site and enormous costs associated with offsite soil excavation and transportation [4]. Recently, a research hotpot, namely, in situ eco-engineering tailings into soils has been demonstrated as an efficient technique to convert the tailings into a soil-like substrate (or technosol) for mine site rehabilitation [5-8]. Yet, the methods used to construct tailing-based technosols by eco-engineering inputs of abiotic and biotic, such as organic matter, functional microorganisms, and pioneer plants are commonly time-consuming and costly. Herein, we provide an energy-efficient, cost-effective and low-carbon-footprint method, self-sustaining smoldering, to construct technosols for sustainable revegetation of the mine tailings area.

Experimental Procedure

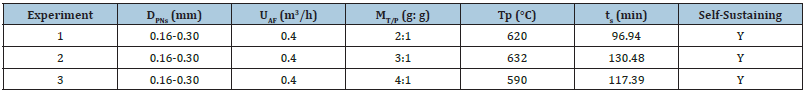

The tailing samples used in the experiments mainly consisted of quartz, apatite, olivine and pyrolusite. Naturally dried Pine Needles (PNs) act as surrogate fuel. After the sample mixed with mine tailings and biomass based on the required experimental condition was carefully prepared, the one-dimensional forward smoldering was conducted to construct the tailing-based technosol (Table 1).

Table 1:Summary of smoldering experiments based on a forward one-dimensional system. DPNs: the particle size of PNs; UAF: air flux, which is the flow of air in the smoldering reaction zone without a sample; MT/P: mine tailings to PNs ratio; TP: average peak temperature; tS: smoldering time.

Results and Discussion

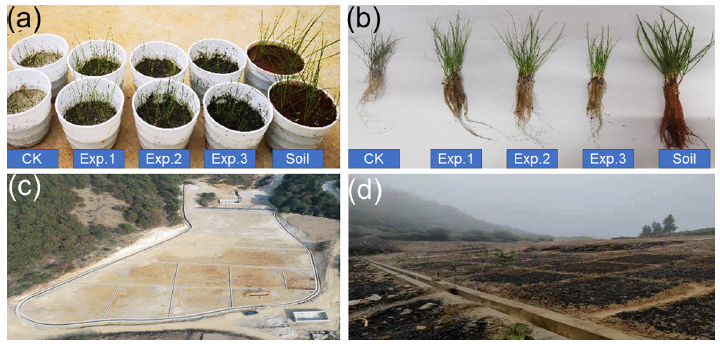

In order to assess the influence of smoldering on the toxicity of heavy metals, the Cu, Zn and Pb bioavailable concentration was monitored. Compared with control group, the amount of bioavailable Cu, Zn and Pb in the treated soils decreased by 33.22- 81.49%, 40.78-92.80% and 32.44-50.27%, respectively, depending on the experiments condition. The result indicated that smoldering as a novel thermal treatment technology, could decline the potential bioavailable risk of heavy metals in tailings. The regreening potential of the tailings treated by smoldering has been examined by the potexperiments tests. As shown in Figure 1a, it can be observed that the higher growth in smoldered soils compared to the untreated soils, which might be attributed to the change of soil properties caused by smoldering. Basically, smoldering is a combustion problem, in which pyrolysis and oxidation are the main steps involved to convert carbonaceous fuel to solid “char”, water and heat as well as volatile carbon dioxide [9]. In the present study, since the formed biochar and biomass ash after smoldering treatment, the technosol showed improved physiochemical properties and the contents in nutrients, such as pH, EC, SOM, AN, AP and AK. Concomitantly, as the cultivation time increased, the elevated soil nutrients in the treated soils increased shot length and average plant yield were observed after 31 days (Figure 1b). Furthermore, findings of the present investigation direction a pilot field test located in a historical tin mining site (E98°15′22″ E, N24°55′34″) in Lianghe County, Dehong Prefecture, Yunnan Province, China (see Figures 1c & 1d). Notice that when the application of the technique to a real scenario, it is necessary to take into account the weather information, since water is the biggest heat sink of smoldering [10]. Meanwhile, smoldering temperature and velocity were found to depend on the fuel concentration and injected air flux, respectively, which is a valuable indicator for smoldering operator to control the magnitude and speed of smoldering [11]. Furthermore, the estimated cost of implementation the technique on a larger scale range of $ 5×103–10×103/hectare based on our pilot field test, which highlight the great applied potential of smoldering to recover tailing landscapes for rehabilitation purposes.

Figure 1:Growth of ryegrass in tailing-based technosol under different smoldering treatments after 31 days growth period (a, b); A pilot field test based on the smoldering treatment (c, d).

Conclusion

This work presents a contribution to achieving carbon neutrality from the perspective of energy consumption, carbon footprint and carbon sink. Firstly, smoldering uses no external energy after ignition, which helps in achieving energy saving in comparison with pyrolysis. Secondly, smoldering conversion of biomass into biochar brings benefits to reduce the technology carbon footprint during application. Thirdly, the restoration of tailing landscapes ecosystem advantageous to carbon capture, utilization, and storage.

Acknowledgement

This work was supported by the National Natural Science Foundation of China (52060011) and the Analysis and Testing Foundation of Kunming University of Science and Technology (2020P20191107004).

References

- Wu S, Nguyen TAH, Liu Y, Southam G, Wang S, et al. (2019) Deficiencies of secondary Fe(oxy)hydroxides associated with phyllosilicates and organic carbon limit the formation of water-stable aggregates in Fe-ore tailings. Chem Geol 523: 73-87.

- Lazorenko G, Kasprzhitskii A, Shaikh F, Krishna RS, Mishra J (2021) Utilization potential of mine tailings in geopolymers: physicochemical and environmental aspects. Process Saf Environ Protect 147: 559-577.

- Morugán Coronado A, Soriano Disla M, Moreno Barriga F, Linares C, Faz Á, et al. (2021) Use of Piptatherum miliaceum to enable the establishment success of salvia rosmarinus in technosols developed from pyritic tailings. Chemosphere 267: 129281.

- Huang L, Baumgartl T, Zhou L, Mulligan D (2014) The new paradigm for phytostabilising mine wastes–ecologically engineered pedogenesis and functional root zones, Life-of-Mine 2014. AUSIMM pp. 663-674.

- Wu S, Liu Y, Bougoure JJ, Southam G, Chan TS, et al. (2019) Organic matter amendment and plant colonization drive mineral weathering, organic carbon sequestration, and water-stable aggregation in magnetite Fe ore tailings. Environ Sci Technol 53(23): 13720-13731.

- Yi Q, Wu S, Southam G, Robertson L, You F, et al. (2021) Acidophilic iron- and sulfur-oxidizing bacteria, Acidithiobacillus ferrooxidans, drives alkaline pH neutralization and mineral weathering in Fe ore tailings. Environ Sci Technol 55(12): 8020-8034.

- Wu S, Liu Y, Southam G, Robertson LM, Wykes J, et al. (2021) Rhizosphere drives biotite-like mineral weathering and secondary Fe-Si mineral formation in Fe ore tailings. ACS Earth Space Chem 5(3): 618-631.

- Yi Q, Wu S, Liu Y, Chan TS, Lu YR, Saha N, et al. (2023) Mineral weathering of iron ore tailings primed by Acidithiobacillus ferrooxidans and elemental sulfur under contrasting pH conditions. Sci Total Environ 856(1): 159078.

- Grant GP, Major D, Scholes GC, Horst J, Hill S, et al. (2016) Smoldering combustion (STAR) for the treatment of contaminated soils: examining limitations and defining success. Remediat J 26(3): 27-51.

- Yermán L, Wall H, Torero J, Gerhard JI, Cheng YL (2016) Smoldering combustion as a treatment technology for faces: Sensitivity to key parameters. Combust. Sci. Technol 188(6): 968-981.

- Duchesne AL, Brown JK, Patch DJ, Major D, Weber KP, et al. (2020) Remediation of PFAS-contaminated soil and granular activated carbon by smoldering combustion. Environ. Sci. Technol 54(19): 12631-12640.

© 2023 Senlin Tian and Jianhong Huang. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)