- Submissions

Full Text

Aspects in Mining & Mineral Science

Obtaining High Quality Concentrate of Precious Metals by Flotation Method of Enrichment

Mamuka Bagnashvili, Asmat Shekiladze* and Nukri Samkharadze

LEPL Grigol Tsulukidze Mining Institute of Georgia, Tbilisi

*Corresponding author: Asmat Shekiladze, LEPL Grigol Tsulukidze Mining Institute of Georgia, 0186, Tbilisi

Submission: February 02, 2023;Published: February 16, 2023

ISSN 2578-0255Volume11 Issue1

Opinion

Gold and silver are the subject of international trade, the demand for them and the price increase are directly proportional, and the resource is inexhaustible. According to https://www.mining.com/ data in 2022 the American company Newmont was the leader in terms of gold mining in the world 5.88 million ounces of gold, and according to https://www.kitco.com/ data in 2021 in terms of silver mining - Mexican company Fresnillo-53.1 ounces of silver. RMG Holding is the largest producer of precious metals in Georgia. Both mechanical and hydrometallurgical methods of enrichment are used in the process of processing precious metals. The environmentally safe gravitational method is not used independently in most cases, it is applied in the combined technology at the initial stage, and for the re-enrichment of tails and intermediates - hydrometallurgy or flotation. One of the most common methods of enriching precious metals is hydrometallurgy, where the risks of environmental pollution are higher since they mostly use a chemical such as cyanidation. Environmental safety must be maximized during the extraction and enrichment of minerals. In world practice, cases of its spillage have also been reported, which has had a devastating impact on rivers. The flotation method of enrichment is also often used, it does not always provide the maximum extraction of gold and silver in concentrate, which is replaced by the above-mentioned ecologically hazardous hydrometallurgical process in production. Therefore, obtaining high quality concentration and reducing the loss of useful components during flotation enrichment is very important

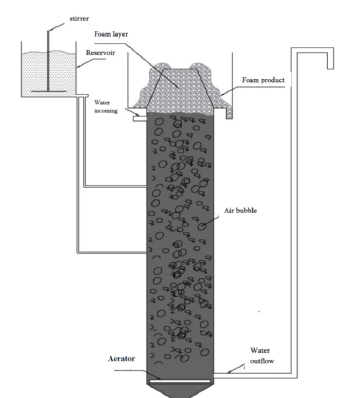

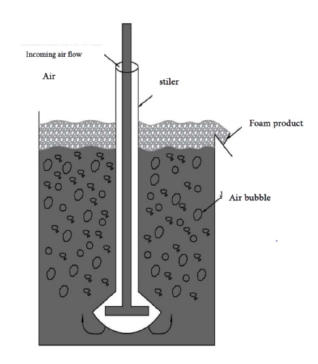

The novelty of the research is a column-type flotation chamber (Figure 1) will be created in which the air supply system in which is improved through aerators attached to the lower bottom of the chamber. The presence of an ascending flow of air in the chamber ensures the distribution of bubbles in the pulp, maintaining the velocity of their motifs, which will prevent the useful component from settling to the bottom and sticking to the walls of the flotation chamber. The suspension will be homogeneous, multiple touches of air bubbles and hydrophobic minerals will cause fixation of the foam pellicle to the mineral and get them into the foam product, so-called concentrate. Improved air supply will be effective at both main and clean as well as control flotation. In a standard type of mechanical flotation chamber (Figure 2), pulp aeration is carried out by suction of atmospheric air as a result of impeller rotation. The degree of pulp aeration is characterized by the thickness, quantity, and even distribution of the vesicles in the pulp. The accumulation of bubbles causes the velocity of their emersion to decrease, hence the suspension is no longer homogeneous, in some cases a useful component is attached to the walls of the flotation chamber and precipitated to the bottom. In the reseach of the study, grinding was carried out in order to avoid grinding into fractions within the project to avoid overgrinding. Proper calculation of the degree of crushing and grinding in the process of mineral enrichment has a double effect, first, almost 50% of the economic cost is spent on crushing/grinding, second, if the sample is overgrinding, the silt is an obstacle to the efficient management of the process. The initial sample will be crushed to 1 then divided into fractions -1+3.15mm -0.315+0.074 and -0.074+0mm. The first two fractions will be ground separately to -0.074 which avoids the reception of crushed waste rock and contamination of the concentrate with silt. In this way it is possible to reduce the number of multiple clearing operations which is also associated with additional economic costs. The effect of simultaneous application of two aggregate reagents used in the flotation process to obtain a highquality concentrate. In flotation of precious metals two collecting reagents will be used as a collector to obtain a highquality concentrate and to reduce the loss of a useful component. Which is explained by the fact that the stability of the collector or collecting reagent to the mineral is determined by the hydrocarbon chain in it, the longer the hydrocarbon radical in the reagent the greater the stability of its attachment to the mineral and vice versa. The disadvantage of such reagents is that they take relatively longer to give the mineral hydrophobicity than the short hydrocarbon reagent, so the short hydrocarbon reagent instantly imparts the hydrophobicity to the gold and silver ores, while the long-term carbonate does not. In the flotation of precious Air stiler Foam product Air bubble Incoming air flow metals within the project the simultaneous use of two aggregate reagents experienced ensuring the production of highquality concentrate and the reduction of the loss of the useful component.

Figure 1:Column-type flotation chamber.

Figure 2:Mechanical flotation chamber.

Acknowledgement

This work was supported by the Shota Rustaveli National Science Foundation (SRNSF) [Grant YS-22-221], Title: “Obtaining high quality concentrate of precious metals by flotation method of enrichment.

© 2022 Asmat Shekiladze. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)