- Submissions

Full Text

Aspects in Mining & Mineral Science

Developing Parameters of Well Construction Method in Terms of Thick Sediments

Yevhenii Koroviaka1*, Artem Pavlychenko2, Andrii Ihnatov1 and Valerii Rastsvietaiev1

1Oil-and-Gas Engineering and Drilling Department, Dnipro University of Technology, Ukraine

2Department of Ecology and Technologies Environmental Protection, Dnipro University of Technology, Ukraine

*Corresponding author: Yevhenii Koroviaka, Head of Oil-and-Gas Engineering and Drilling Department, Dnipro University of Technology, Dmytra Yavornytskoho 19, Dnipro, Ukraine

Submission: September 20, 2022;Published: October 18, 2022

ISSN 2578-0255Volume10 Issue1

Abstract

The purpose of the article is to establish the laws of physicochemical processes occurring in the wellbore, constructed in the sedimentary rocks, during the circulation of flushing fluids, and formulate on their basis adequate technological measures of the hydraulic well flushing program, the implementation of which will provide sufficient well construction, productivity, and economy. The novelty of the obtained results is in the methodological development of the regulations for drilling and related works in oil and gas wells, which implementation will ensure the avoidance of negative manifestations of the rock properties. The practical results of the article are to study a wide range of properties of various chemical compounds designed to increase the degree of stability of sedimentary rocks in the wellbore walls; use of test substances will significantly increase the drilling productivity, reduce the time for work related to elimination of complications and accidents in the well or complete exclusion of the latter; it will also provide the overall increase in efficiency and cost-effectiveness of the well construction process. Practical significance of article is as follows: increasing the efficiency of well work, based on the methods of integrated use of technological measures of the hydraulic program of well washing in preventing the manifestation of negative properties of sedimentary rocks.

The development and implementation of a progressive complex hydraulic washing programme for wells under construction are analyzed involving modern methods of analytical analysis and experimental studies. The drilling circulation processes in a well were modeled in terms of experimental wells involving a drill rig UKB-4P and corresponding auxiliary tools and equipment. Analytical studies was carried out with application of sequence of operations widely tested for the solution of scientific problems: formulation of a problem and drawing up of the settlement scheme of the investigated object; development of a physicochemical model that describes the nature of the processes; selection of the method to solve the specified tasks; solution of basic mathematical dependences of the process with maximum use of computational experiment; analysis of the obtained results; formulation of adequate conclusions and recommendations.

Keywords:Sedimentary rocks; Drilling; Rock breaking; Metal casings; Polymers

Introduction

The development of minerals that occur at great depths and in complicated mining and geological conditions requires the creation of energy- and resource-saving technologies that reduce energy consumption and increase the productivity of drilling wells [1]. The main process in the production cycle of well drilling is breaking the rock at the bottom. The effectiveness of this process largely depends on the breaking methods and rock-breaking tools as well as circulation mode and parameters of the washing liquids. Currently, the vast majority of wells are in the thickness of sedimentary rocks, and above all, a huge class of them are represented by clay rocks. The construction of a well in such rocks is almost always associated with a range of manifestations of negative nature: swelling and narrowing of the wellbore walls, talus, landslides, local expansions in the wellbore. At the same time, there are almost no comprehensive methods for designing the technology of wells in sedimentary rocks; the issues of physicochemical interaction of the active components of the washing liquid with rocks have not been studied sufficiently. The experience of drilling shows that the reserve for reducing the cost of time and resources to eliminate complications and accidents is to improve the technology of flushing wells by selecting the optimal formulations of flushing fluids. Therefore, one of the urgent tasks to reduce drilling costs is to develop a resource-saving hydraulic well cleaning program. Its perfect organization requires that the flow of fluid facilitates the separation of rock particles from the array and most effectively clean the bottomhole and wellbore from sludge. At the same time, the requirements for the stability of the well walls, the operation of the drill string and other factors must also be observed. Rational organization of well washing will increase the mechanical speed of drilling and drilling on the rock-destroying tool by reducing the specific energy consumption for rock breaking [2].

Analysis of Recent Studies and Publications and Singling out of Previously Unsolved Parts of a General Problem

Drilling wells in modern conditions, namely, depths that can reach ten or more kilometers, penetration during drilling into rocks with abnormally high or low pressures require improvements in drilling technology and techniques [1]. Most often, drillers encounter complications such as falling and collapsing well walls and tightening and gripping drilling tools. Captures are unforeseen accidents in the well, characterized by partial or complete cessation of movement of drilling tools, metal casings or geophysical (hydrogeological) devices and devices. Captures are the most common, complex and labor-intensive drilling accidents. There are three main types of captures: 1) drill strings; 2) casing; 3) rockbreaking tools and column sets [3]. Accidents due to unsuccessful cementation include the capture of a hardened cement mortar of a column of drill pipes, on which a section of casing or shank is descended; failure and damage to the suspension units of the casing section, which disrupt the fastening process and subsequent wiring of the well; bare shoes or insufficient lifting of cement [2]. Accidents with casings and their equipment elements include accidents with metal casings or their parts, which are lowered and cemented, and which are caused by: disconnection by threaded connections; weld break; crumpling or rupture of the body of the pipe; damage to the casing when drilling the cement cup, stop ring, check valve and guide plug. Accidents with downhole engines include leaving a turbodrill, electric drill, screw engine, or their components in the well due to breakage or disconnection from the drill string [4]. The fall of foreign objects into the well includes the fall of the rotor tabs, rotor wedges, wrenches, sledgehammers and other hand tools and devices used to work on the wellhead.

Elimination of the possibility of an emergency situation in specific mining and geological conditions is solved as follows: choose the design of the well on the basis of the allocation of zones with incompatible drilling conditions; determine the intervals dangerous for captures and establish possible types of captures that may occur during drilling; choose the type of washing liquid that corresponds to the rocks of the geological section; calculate the density of the drilling fluid to open the oil and gas-saturated formations included in one interval of compatible conditions, and select the formation with the maximum gradient of formation pressure etc. [5].

Modern requirements for flushing fluid are its ability to prevent entrapment of pipes, namely, to ensure the insolubility of the shaft and maintain the strength of the well walls. The fluid must have good lubricity and low solids content. The choice of the minimum excess of the hydrostatic pressure of the drilling fluid column over the formation (repression) [6]. Much attention is paid to the development of rational technologies for well construction. However, this problem is still very far from its solution, which is confirmed by the presence of a large number of works on this topic and the existence of significant contradictions in the conclusions of the authors. Therefore, consideration of possible ways for further improvement of drilling technology and in particular in sedimentary rocks is of great interest. First of all, it should be noted that the problem of deeper knowledge of the role of various factors in the efficiency of washing liquids as the main factor in ensuring safety in the excavation of sedimentary rocks is on the way to solve this problem. The most universal influence of flushing fluids on the processes of drilling wells in sedimentary rocks is the effect of maintaining the well walls in a stable state while observing all the technological functions inherent in the circulating processes in the wellbore [4].

The provision of certain properties to washing liquids can be carried out by complex methods, and in particular the use of physical fields for pre-treatment of the dispersion medium, followed by the use of active additives belonging to a known class of surfactants [7]. At the same time, in such an important matter as the selection of effective chemicals for various technological processes, there is still an empirical approach; there is no theoretical tool that could be used to elect confidently the type and composition of dispersion systems (bright representatives of which are drilling liquids) for certain purposes. It is necessary to develop new approaches to a more in-depth study of the problem of preparation and use of washing liquids and in terms of understanding the essence of the processes occurring in the interaction of dispersion systems (such as washing liquids) with the newly formed surface. interactions. The causes of sludge aggregation and wall packer formation also remain unexplored. Improving flushing is also associated with the possibility of solving the problem of reducing the pressure of the flushing fluid at the bottom of the well while maintaining the required pressure in the annulus of its wellbore.

Statement of the Main Research Material

Flushing fluids, as working media in the well, must perform the following functions during drilling [8]: clean the bottom of the well from the fragments of drilled rocks and bring them to the surface; keep the particles of the drilled rock in a suspended state and the wellbore at drilling stops; clay unstable walls and prevent landslides and debris in the wellbore; prevent manifestations and emissions of gas, oil and water; transfer energy to the downhole engine); influence rocks in a physicochemical way to facilitate their breaking; provide normal conditions of opening and developme of productive layers; cool the bit in the process of rock breaking and perform some other functions. Timely and technologically justified removal of the rock fragments from the well bottom drilled with a bit or a crown is the most important condition for obtaining the maximum possible mechanical drilling speeds [9]. The presence of a foreign environment (drilling mud) on contact with the rock causes physicochemical processes at the interface: osmotic phenomena, surface hydration, dissolution, capillary penetration and the like. In some rocks, they can cause a marked change in their physical state, the forces of internal adhesion and as a result can change significantly the properties of rocks in the shaft space of the well in comparison with the primary in the natural occurrence. Especially dangerous is the increase in the tendency to plastic flow of clay and hemogenic rocks [8].

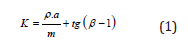

The development of fatigue phenomena that occur under the influence of hydrodynamic shocks and variable pressure in the shaft during lowering operations also contributes to the weakening of rocks in the well walls [2]. During the circulation of the washing agent along the shaft, the temperature regime of the rocks in the walls of the well is disturbed, which also causes the appearance of additional stress. Finally, long-term or short-term disturbances of hydrodynamic equilibrium can be observed at the contact of formation fluids with the washing agent, and in such cases the mobile medium (liquid or gas) under the action of the pressure difference will easily flow into the region of reduced pressure. There may be an overflow of the washing agent in the surrounding rock shaft or, conversely, formation fluids in the wellbore. All these violations of the equilibrium state in the wellbore and on its walls adversely affect the process of deepening and complicate it. The main role in interpackage swelling and in the formation of solvate (hydrate) layers on the outer surfaces of clay minerals is played by adsorption forces [10]. The amount of liquid that binds to the clay and the increase in the volume of its particles can be characterized by the swelling coefficient K, which is equal to the ratio of the volume of the swelling fluid Vp to the volume of dry clay particles Vo

Where ρ is the density of dry clay; m is the mass of the suspended sample; β is the coefficient indicating what proportion of the volume of the pore space is stored in the swollen sample; a is the coefficient depending on the properties of the clay and the value of β.

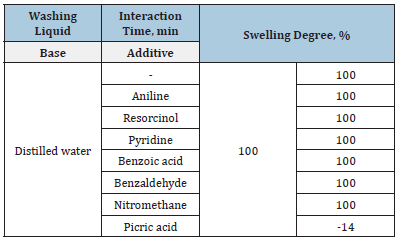

In studies of the effect of washing liquids on the swelling of clays, which were conducted at the Department of Oil and Gas Engineering and Drilling of Dnipro University of Technology, to characterize this process used the degree of swelling K, equal to the sum of volumes Vp + VoK, which shows how many times increased volume dry particles. Because the swelling of the clays was investigated in washing liquids containing various substances, distilled water was taken as the reference liquid. The study of the swelling process was performed on the most active sedimentary clay rock – montmorillonite, with the interpretation of the results for other clay rocks. Tables 1-3 shows the results of these laboratory tests. The data in Table 1 indicate the absence of influence of organic substances (except picric acid) on the process of minimizing the negative effect of the filtrate of washing liquids on the swelling of montmorillonite. The organic compounds listed in the table are components of substances used in the treatment of washing liquids to give them a lubricating effect, approximation of properties close to those for formation fluids (so-called oil-based solutions). Therefore, in order to prevent the manifestation of swelling in the first place, drilling fluids must be subjected to chemical treatment with surfactants that will prevent the penetration of the filtrate of washing liquids into the inter-package space of clays [11].

Table 1:Influence of organic substances on swelling of montmorillonite.

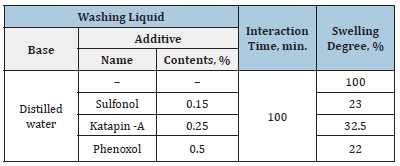

Table 2:Influence of organic surfactants on swelling of montmorillonite.

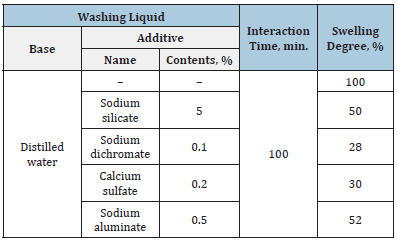

Table 3:Influence of inorganic surfactants on swelling of montmorillonite.

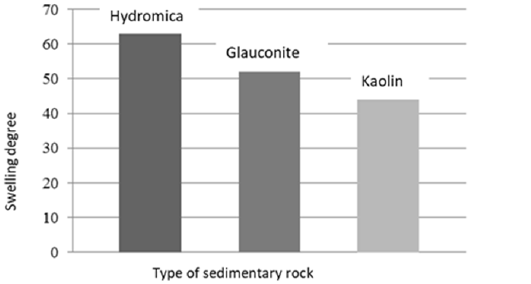

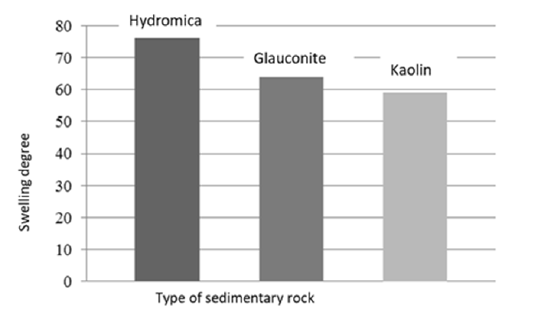

Analysis of the data given in Tables 2 & 3 show the following: surfactants (surfactants) significantly reduce the degree of swelling of the clay under the action of the filtrate of the washing liquids. Qualitatively organic surfactants are more suitable for the use in the treatment of washing liquids, because they are much more effective in reducing the degree of swelling of the investigated clay than inorganic. The given values of surfactant concentration in washing liquids are limiting, their excess will not lead to qualitative changes in the processes of interaction of washing liquids with sedimentary clays. Figures 1 & 2 show the qualitative dependences that give an idea of the degree of influence of surfactants of organic and inorganic nature on the degree of swelling of the main types of clay rocks. For comparative studies, the most effective surfactants were used, which was determined in studies of the degree of swelling of montmorillonite, namely phenoxol and sodium dichromate. These dependences (Figures 1 & 2) indicate the preservation of qualitative patterns established for montmorillonite clays, in relation to the degree of swelling under the action of the filtrate of washing liquids and, in addition, further confirm the much higher efficiency of organic surfactants compared to inorganic. Recently, there has been a steady trend of increasing the use of polymeric substances (macromolecular compounds) for the preparation of drilling fluids [12]. Macromolecular substances include substances consisting of large molecules (macromolecules) with a molecular weight of at least 10000-15000. Often the molecular weight of natural macromolecular compounds reaches several million. The size of macromolecules is very large compared to the size of ordinary molecules. For example, if the length of the ethane molecule is only a few angstroms, the length of the linear molecules of rubber and cellulose reaches 4000-8000 angstroms (with a transverse size of 3-7.5 angstroms).

Figure 1:Dependence of the swelling degree of the main types of clay rocks for the conditions of use as a surfactant of the organic substance phenoxol.

Figure 2:Dependence of the swelling degree of the main types of clay rocks for the conditions of use as a surfactant of the inorganic substance sodium dichromate.

Table 4:Effect of polymer compounds on the montmorillonite swelling.

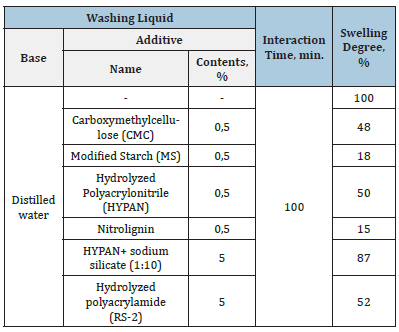

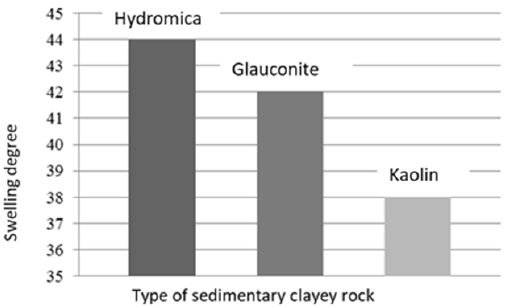

In addition to natural macromolecular substances, a number of synthetic macromolecular products are currently used. These include synthetic rubbers and various synthetic polymers. These products, extremely diverse in chemical structure and properties, are not only full-fledged substitutes for natural macromolecular substances, but also often receive a completely new application. Molecules of macromolecular substances can be linear and branched, and the length of molecular chains can be relatively large - more than 1μm. It is the linear form of macromolecules that determines the typical properties of polymers: rubbery elasticity, the ability to form strong films and threads, swell, give viscous solutions when dissolved, etc. Solutions of macromolecular substances, if they are in a thermodynamically equilibrium state, are aggregatively stable, as well as real solutions [10]. With the introduction of large amounts of electrolytes, the release of macromolecular substances from the solution. However, this phenomenon should not be equated with coagulation of typical colloidal systems. Coagulation of sols occurs with the introduction of relatively small amounts of electrolyte and is usually an irreversible phenomenon. Isolation from a solution of a macromolecular substance occurs when adding relatively large amounts of electrolyte is usually a reversible process - after removal of the electrolyte from the precipitate, the macromolecular substance is again able to dissolve. Table 4 shows the data of research aimed at elucidating the mechanism of interaction of polymeric compounds introduced into the composition of drilling fluids, with sedimentary clays (in terms of of montmorillonite). The use of water-soluble polymers, most of which combine the properties of anionic surfactants and polyelectrolytes, helps to reduce the swelling of clays (Table 4). In general, the obtained data can serve as a starting point for the selection of recipes for the preparation of drilling fluids when re-drilling the layers of clay deposits. Figure 3 demonstrates comparative data on the effectiveness of polymers for different types of clays (by mineralogical origin). The given dependences (Figure 3) testify to preservation of qualitative laws established for clay rocks concerning degree of their hypostasis under the influence of a filtrate of washing liquids at use of surfactants (organic and inorganic origin); in other words, the mineralogical composition of clays is the starting point of the method of selection of the type and concentration in the drilling fluid of polymeric substances.

Figure 3:Dependence of the degree of swelling of the main types of clays for the conditions of use as a reagentregulator of Carboxymethylcellulose (CMC).

Conclusion

a. On the basis of theoretical and laboratory studies of

mechano-hydraulic processes in the construction of wells in

sedimentary rocks, restrictive measures of drilling technology

are formulated, which are based on the need to slow down or

completely eliminate the swelling caused by increasing the size

of silicate minerals.

b. Laboratory studies have confirmed that in order to

prevent the manifestation of primarily swelling, drilling fluids

must be subjected to chemical treatment with surfactants that

will prevent the penetration of the filtrate of washing liquids

in the interpackage space of clays, in addition, the following

is shown: surface-active substances reduce significantly the

degree of swelling of clays under the action of the filtrate of

washing liquids, and organic surfactants are more suitable for

use in the treatment of washing liquids, because they are much

more effective in reducing the degree of swelling of clays than

inorganic.

c. It is proved that an effective means of preventing

complications during drilling is the correct selection of washing

agents for the composition and properties for each specific

interval and competent prompt adjustment of the washing

mode depending on the properties of drilled rocks.

d. It has been laboratory proven that the use of watersoluble

polymers, most of which combine the properties of

anionic surfactants and polyelectrolytes, significantly reduces

the swelling of clays.

Acknowledgement

The research has been carried out by Dnipro University of Technology (Ukraine). We express gratitude to our colleagues from Department of Oil and Gas Engineering and Drilling who provide us with the required information and helped considerably complete the research.

References

- Ihnatov A, Koroviaka Y, Rastsvietaiev V, Tokar L (2021) Development of the rational bottomhole assemblies of the directed well drilling. Gas Hydrate Technologies: Global Trends, Challenges and Horizons - 2020, E3S Web of Conferences 230.

- Hossain ME, Islam MR (2018) Drilling engineering: problems and solutions. Scrivener publishing, England.

- Ihnatov A (2021) Analyzing mechanics of rock breaking under conditions of hydromechanical drilling. Mining of Mineral Deposits 15(3): 122-129.

- Lopez JC, Lopez JE, Javier F (2017) Drilling and blasting of rocks. CRC Press Taylor & Francis, USA.

- Dareing DW (2019) Oilwell drilling engineering publisher: ASME Press, USA.

- Koroviaka YA, Ihnatov AО, Rastsvietaiev VO (2021) Peculiarities of drilling works during engineering investigations and preparation of the territory. Instrumental materials science - Tooling materials science 24: 102-113.

- Ihnatov AO, Koroviaka YA, Pinka J (2021) Geological and mining-engineering peculiarities of implementation of hydromechanical drilling principles. Scientific Bulletin of National Hirnichoho University, Ukraine, 1: 11-18.

- Pavlychenko AV, Ihnatov AO, Koroviaka YA, Ratov BT, Zakenov ST (2022) Problematics of the issues concerning development of energy-saving and environmentally efficient technologies of well construction. ICSF-2022. IOP Conf. Series: Earth and Environmental Science 1049: 012031.

- Pavlychenko AV, Koroviaka YА, Ihnatov AО, Davydenko AN (2021) Hydro-gas dynamic processes during the construction and operation of wells: monograph. Dnipro: Dnipro University of Technology, Ukraine.

- Azar JJ, Robello SG (2007) Drilling Engineering. PennWell Books.

- Hupalo OP, Tushnytskyi OP (2010) Organic chemistry. Kyiv: Znannia, Ukraine.

- Sharma KK, Sharma LK (2016) Physical Chemistry. Vikas Publishing, India.

© 2022 Yevhenii Koroviaka. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)