- Submissions

Full Text

Aspects in Mining & Mineral Science

A Statistical Comparison of Bond Ball Mill Grindability Work Index Testing Equipment

Tyrel Jacobsen and Corby G Anderson*

Department of Mining Engineering, Kroll Institute for Extractive Metallurgy, USA

*Corresponding author: Corby G Anderson, Department of Mining Engineering, Kroll Institute for Extractive Metallurgy, Colorado School of Mines, Golden, Colorado 80401, USA

Submission: September 27, 2022;Published: October 12, 2022

ISSN 2578-0255Volume10 Issue1

Abstract

Research was performed to make an objective comparison of Bond Ball Mill Grindability Work Index results derived from using two commercial testing apparatus, from BICO and Sepor respectively, each with a different mill shell design. Six tests were carefully performed with both mills using the same aggregate rock sample and with the same method of grindability testing based on Fred Bond’s Ball Mill Grindability Work Index (BWi) testing methods. After the tests were completed, statistical analysis using the Q test, p values, the F test and the student t test were used to confirm and compare the data sets derived from both commercially available testing equipment. The result of this testing indicates that the design of the Sepor ball mill delivers less variable BWi results than the BICO ball mill. As well, the Sepor mill returned a significantly higher and more reproducible mean BWi value of 12.238kWhr/t versus the BICO BWi mean value of 10.786kWhr/t in testing of the same material. It is postulated that the differing shell design on the BICO mill is the root cause of these differences.

Keywords:Grindability; Material; Energy; Bond ball; Crushing

Introduction

The purpose of this research was to statistically evaluate comparative BWi determinations using two different commercial ball mill testing apparatus. These experiments were run based the Bond Ball Mill Grindability Test. The main difference that was being investigated was the impact of using a testing mill with a 4-inchX8-inch hand hole door in the shell versus a mill with the inside completely smooth. The materials, experimental procedure, and all other variables were kept constant in the testing and the results were statistically analyzed and verified.

Background

The crushing and grinding circuit are the most energy intensive process in a mining project. Improvements in predicting the energy required to crush a given material, and therefore the cost of comminution, would help to mitigate cost overruns in mining. The Bond Grindability Work Index Test is an empirical way to predict this energy cost. According to Fred Bond, “the work index is the comminution parameter which expresses the resistance of the material to crushing and grinding” [1-3]. Recently there have been any number of evaluations and comparisons of comminution testing method [4-10]. However, the literature is devoid of any direct comparison of the actual testing apparatus used for Bond Work Index determinations. While the Bond Work Index and procedure have become a world standard for measuring the energy required to grind material and designing grinding circuits, the test is highly empirical and can vary significantly as a result. According to one isolated study, the Bond Work Index measured by three different mills that were side by side varied as low as 4.2% and up to 8.6%. Even variations within the distribution of the ball charge will result in differences between 2.9% and 8 6.9% [11]. Thus, even though there are difficulties in reproducing Bond Work Indices and there is variability in the results, the quantity is one of the better measures of the energy required in a grinding circuit and persists in engineering design.

In 2016 the Sepor mill was evaluated against an older BICO mill with two reference materials, one used by Dr. Husni Usman for his PhD thesis and the other one was a standard reference material from JKTech in Australia and was sent around the world to compare the Bond Grindability Work Indices [12,13]. The Bond Work Test was run in duplicate on each mill for each material. The Bond Work Indices from Dr. Usman’s material were calculated to be, 13.39kWh/ mt and 14.87kWh/mt for the BICO and Sepor mills, respectively. The Bond Work Indices for the Australian material were calculated to be 13.01kWh/mt and 14.71kWh/mt for the BICO and Sepor mills, respectively. A student-t test was calculated for each set of tests with a 95% confidence interval. The data from Dr. Usman’s material suggested that there was no statistical difference between the two mills, but the data from the Australian reference material suggested that there was. The data from the Sepor mill was still slightly lower than the reported reference material value which was 15.39kWh/ mt, but it was much closer than the BICO mill. An economic analysis was conducted, and it was found that the calculated Bond Work Indices resulted in large discrepancies in capital and operating cost. The difference between the values from the BICO and Sepor mills from the Australian material resulted in an estimated $5.1 million dollar difference in power operational costs for a year for 80,000 tonnes feed per day. Given this initial outcome, a more focused follow up effort as detailed in this publication was conducted.

Testing Procedure

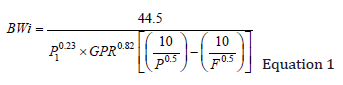

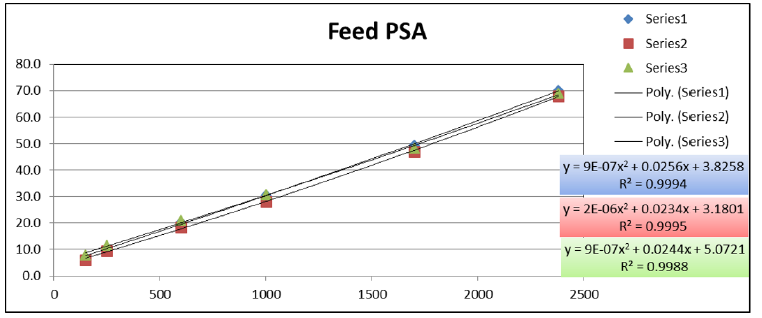

Since this work was a continuation and an objective statistical verification of previous work done by students at the School of Mines in their Senior Design course work, the same conditions that they used were replicated as closely as possible [12]. First, material was collected and crushed to 100% passing-6 Tyler mesh. This material was blended and split using a jones type riffle splitter to obtain all samples used throughout the testing. A compaction test was executed to determine the feed volume by obtaining sample and using it to fill a 1000ml graduated cylinder. This was compacted as it was filled until it reached the 700-cc mark. This volume’s mass was used to calculate the mass of undersize for a 250% circulating load. Then a size analysis was done on three samples of approx. 400g. This size analysis was used to find the 80% passing size of the feed. This is one of inputs for the BWi equation which is shown in Equation 1. The grindability testing occurred next. The correct mass of sample was placed in the mill with the ball charge and first run was 100 revolutions. The ground sample was then ro-tapped to the plus and minus fractions, both of which were weighed. The undersize was segregated and the oversize had new feed added to it until it was the same as the first sample. This new feed was added to the mill and run the calculated number of revolutions and then screened and weighed. The tests were run until there was a closure of the gbp value determination that was indicated by a reverse trend. The reversal was to be within 3% to be considered valid, with at least 5 cycles run. The grams of product per revolution is calculated and plugged into Equation 1. An equal mass composite was made of the undersize product of the final 3 runs of each test. These were wet screened at 400 micron and then the oversize was dried and screened to get a distribution for the 80% passing size of the product which is plugged into Equation 1.

Results and Discussion

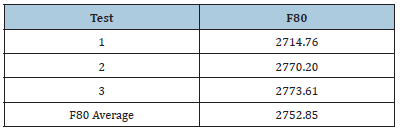

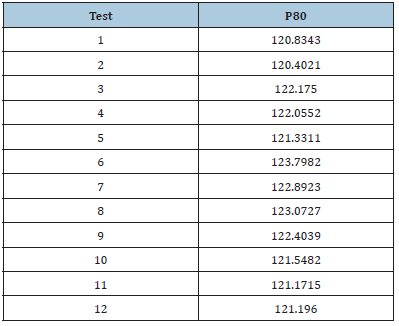

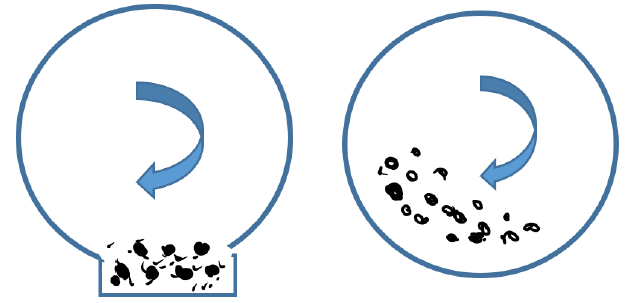

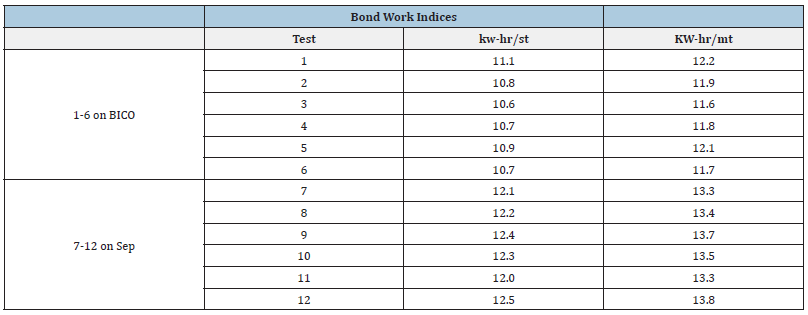

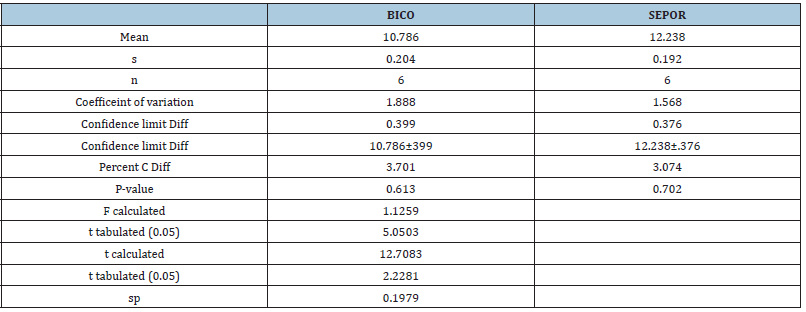

A P-value test was run on the Particle Size Analysis (PSA) of the feed and a value greater than 0.05 was found indicating that a standard polynomial regression analysis was acceptable to use to fit the data and determine the 80% passing size, F80, for the feed. This analysis can be found in Table1 and Figure 1. Three tests were run, the results were highly consistent, and the average value was used for the F80. There were 12 Bond Work Index tests run in total. Six tests were performed on a BICO model ball mill (which has a noted hand hole door area) and six on a Sepor model ball mill which has a completely smooth inside chamber. A diagram is shown in Figure 2 highlights these differences. Tests 1-6 were performed using the BICO BWi mill and tests 7-12 were performed using the Sepor BWi mill. The results of the product particle size P80 analysis derived from each test can be found in Table 2. This information, along with the grams per revolution (gbp) from each test was input into BWi Equation 1. The results can be seen in Table 3 with the statistical analysis summary in Table 4.

Table 1:Feed particle size analysis in Microns.

Table 2:Product particle size analysis in Microns.

Figure 1:Feed Particle Size Analysis (PSA) in Microns.

Figure 2:Feed Particle Size Analysis (PSA) in Microns.

Table 3:Bond work index comparative testing apparatus determinations.

Table 4:Statistical analysis and comparison of different BWi testing apparatus.

Conclusion

From the analysis of the student t test, it can be concluded that there is a distinct objectively and statistically confirmed difference between the two-ball mill grindability testing apparatus. In addition, the BWi mean value generated by the Sepor mill is distinctly higher and more consistent than that generated with the BICO mill. This is consistent with the more extensive underlying comparative testing previously conducted in 2016. Then, the derived Sepor BWi value was also consistently and significantly higher than that derived with the BICO apparatus even when evaluated on standard BWi reference materials supplied from JKTEch in Australia. Statistically, the Sepor mill has a smaller coefficient of variation, a smaller confidence limit diff and a higher P-value. Based on these factors, the statistical review of the data seems to indicate that the Sepor ball mill returns a BWi with better reproducibility and repeatability. This is due to the difference in the way that the grinding media and sample are interacting during revolutions. When the BICO apparatus revolves there is an audible lull while the materials settle into the hand hole, and it can be inferred that during this lull there is a change in the way that the grinding media and sample are interacting. The Sepor mill is smooth and does not have the prominent hand hole in its shell design. The settling difference described here has previously been illustrated in Figure 2. This BICO apparatus settling ends when the material is dumped back into the cylinder due to the rotation. This irregularity, in an otherwise regular process, is the main contributor to a larger variation noted in the BWi as determined by the BICO ball mill.

Acknowledgement

The authors thank Elliott Britvic, Hannah Steadman and Nathanael Williams for the extensive applied laboratory testing underlying this final definitive comparative statistical analysis. Also, thank you to Bruce Yoshioka of Colorado School of Mines for his gracious laboratory assistance. Finally, thank you to Sepor for providing the use of their equipment.

References

- Bond FC (1949) Standard grindability test tabulated. Trans Am Inst Min Eng 183: 313.

- Bond FC (1952) A novel process for the study of breakage energy versus particle size. Transactions of the American Institute of Mining, Metallurgical, and Petroleum Engineers 193: 484-494.

- Bond FC (1961) Crushing and grinding calculations, Part I-II. Br Chem Eng 6: 378-385.

- Angove JE, Dunne RC (1997) A review of standard physical ore property determinations. Proceedings of World Gold 97 Conference, Singapore, pp. 139-144.

- Barratt DJ, Allan MJ (1986) Testing for autogenous and semi autogenous grinding: A designer's point of view. Minerals and Metallurgical Processing, Society of Mining Engineers, pp. 65-74.

- Becerra M, Amelunxen P (2012) A comparative analysis of grinding circuit design methodologies. In: Doll A, Kracht W, Kuyvenhoven R (Eds.), Proceedings of the 9th International Conference on Mineral Processing Santiago, Chile, pp. 468-476.

- Doll AG, Amelunxen P (2013) Power-based grinding models. Short course presented at the 10th International Conference on Mineral Processing, Santiago, Chile.

- Doll AG, Barratt DJ (2009) Case studies on the effect of sample dimensions on comminution test work results. In: Amelunxen P, Kracht W Kuyvenhoven R (Eds.), Proceedings of the VI International Mineral Processing Seminar Santiago, Chile, pp. 99-110.

- Doll AG (2016) A public database of tumbling mill grindability measurements and their relationships. Procemin 12th International Processing Conference, Santiago, Chile.

- Todorovic D, Trumic M, Ljubisa A, Milosevic V, Trumic M (2017) A quick method for bond work index approximate value determination. Physicochem Probl Miner Process 53(1): 321-332.

- Kaya E, Fletcher PC, Thompson P (2002) Reproducibility of bond work index with different standard ball mills. In: Dodge P, Safford AZ (Eds.), Dawson Metallurgical Lab, Inc Salt Lake City, USA.

- Britvic E, Steadman H, Williams N (2016) A comparison of bond work indices from Sepor and BICO mills. Kroll Institute for Extractive Metallurgy Senior Design Final Report, Colorado School of Mines, USA.

- Usman H (2015) Measuring the efficiency of the tumbling mill as a function of lifter configurations and operating parameters. Ph D dissertation, Dept Mining Eng Colorado School of Mines, Golden, CO, USA.

© 2022 Corby G Anderson. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)