- Submissions

Full Text

Aspects in Mining & Mineral Science

Numerical Simulation of Induction Heating of Well Casing

Ramil Sharafutdinov, Ruslan Akchurin, Filyus Davletshin and Ayrat Ramazanov*

Bashkir State University, Russia

*Corresponding author: Ayrat Ramazanov, Bashkir State University, Zaki Validi 32, Ufa, 450076, Russia

Submission: June 06, 2022;Published: June 21, 2022

ISSN 2578-0255Volume9 Issue3

Abstract

The article considers questions of calculation of the temperature field in the well during induction heating of the casing section. CFD simulation of temperature field formation in Ansys Fluent simulator was performed. Heating in column and flow is calculated for the modeling parameters considered. Recommendations on the application of numerical model in the planning of well research by the method of active thermometry are given.

Keywords:Active thermometry; Heat marker; Induction heating; Natural convection; Casing temperature

Introduction

Active thermometry is one of the most promising methods of geophysical research of active wells. The method is based on the creation of an artificial temperature field in a well due of local heating of a metal casing [1,2]. Monitoring of temperature markers allows to determine low flow rate in a well and diagnose behind-the-casing flow. Up to date, the theoretical basis for the application of induction heating for solving of field problems is not sufficiently developed. The work presents the results of calculation of the temperature field in the well during induction heating of the casing, obtained by numerical simulation in Ansys Fluent.

Mathematical Model of Induction Heating

The geometry of the model, constructed in Ansys Fluent 2021 R1 (ANSYS Academic Research CFD license, agreement with Bashkir State University dated 06/15/2020), is shown in Figure 1a; [1]. The inductor heats the casing, the column transfers heat to the fluid flow and the surrounding rocks. At the input of the model (fluid area) constant temperature T and flow velocity v are set at the output boundary condition on the pressure p is set. At other boundaries, the heat flow is zero (Figure 1b). In the field of inductor, casing and rock the equation of thermal conductivity is solved [3],

where с–specific heat capacity, J/(kg∙K); ρ–density, kg/m3; λ–thermal conductivity, W/(m∙K); T–temperature, K.

For the liquid in the column the Navier-Stokes equations in the Oberbeck - Boussinesq approximation of [4] are solved.

where ρ - liquid density, kg/m3; υ–flow velocity, m/s, p–pressure, Pa; μ–dynamic viscosity, Pa∙s; g - gravitational acceleration, m2/s; T–temperature, K

Figure 1:Model geometry.

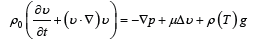

Figure 2:(b) Temperature field in a well during the heating.

Calculation Discussion

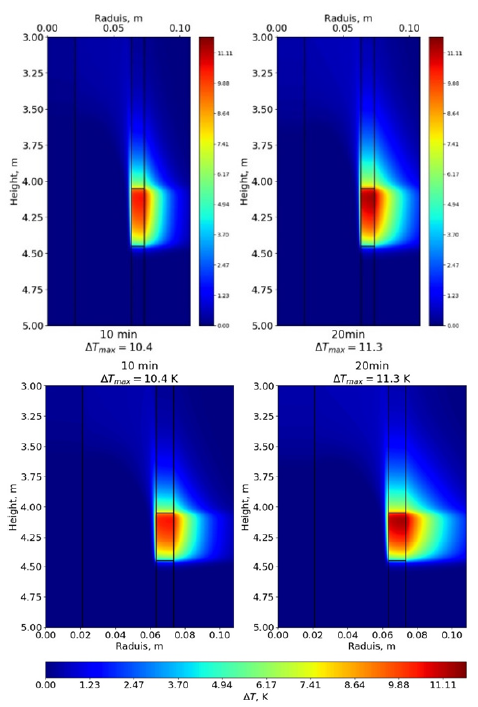

Numerical simulation on the formation of the temperature field during induction heating and after stopping the inductor is performed. Parameters used during modeling are the following: the inner and outer radius of the casing is 63.5 and 73.5mm, respectively, the outer diameter of the inductor is 42mm, the length of the inductor is 0.4m, the power of the inductor is 1000W, the heating duration is 20 minutes, the viscosity of the liquid is 0.5mPa∙s, the thermal conductivity is 0.65W/(m∙K), the specific heat capacity is 4185J/(kg∙K), density 980kg/m3, thermal conductivity of metal 50W/(m∙K), specific heat 500J/(kg∙K), density 8000kg/m3, thermal conductivity of rocks and cement 1.2W/(m∙K), specific heat 1000J/ (kg∙K), density 2500kg/m3, the volume flow rate in a well is 25m3/ day, for convenience, the initial temperature in the model is 0 [5]. Figure 2 shows the mass weighted average temperature in the well during heating and stoppage the inductor. The heating of the liquid during the heating period is about 0.7K, due to natural convection, the maximum temperature shifts 0.4m higher relative to the heating interval. After stoppage of the inductor, thermal anomalies are dispersed: after 5 minutes they are less than 0.2K, after 20 minutes – less than 0.05K.

Figure 3: Mass weighted average temperature in a well during heating (a) and cooling (b); color - heating interval. Here: 1, 2, 3, 4 – temperatures at 5, 10, 15, 20 minutes.

Concluding Remarks

Based on numerical modeling in Ansys Fluent, the formation of a temperature field in a liquid and a casing during induction heating and stoppage of the inductor is considered [6]. For the considered simulation parameters, the maximum heating in the column and the liquid flow was calculated, which was about 10 and 0.7K, respectively. Moreover, the maximum temperature of the liquid is reached above the heating interval due to natural (free) convection. The results of the calculations can be used in the prediction of temperature anomalies, planning of well surveys by the method of active thermometry.

Funding

The work was carried out with the financial support of the Ministry of Science and Higher Education of the Russian Federation on the topic: “Creation of an intelligent integrated technology for the study and interpretation of data from field and geophysical studies of wells...”, Agreement No. 075-11-2021-061 dated June 25, 2021.

References

- https://www.ansys.com/

- Valiullin RA, Sharafutdinov RF, Ramazanov AS (2002) Method of active thermometry of operating wells (options). Patent RU 2194160.

- Valiullin RA, Sharafutdinov RF, Ramazanov AS (2012) Enhancement of well productivity using a technique of high-frequency induction treatment. SPE Heavy Oil Conference Canada, Society of Petroleum Engineers, Paper SPE 157724.

- Loginov VS, Milutin VG (2017) Temperature fields in the well with the flushing fluid circulation turned off. News of higher educational institutions. Oil and Gas 5: 75-80.

- Ferzieger JL, Peric M (1996) Computational methods for fluid dynamics. Springer-Verlag, Heidelberg, Germany.

- Valiullin RA, Sharafutdinov RF, Sorokan VY, et al. (2002) The use of artificial thermal fields in borehole thermometry. Scientific and Technical Bulletin Logger 10: 124-137.

© 2022 Ayrat Ramazanov. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)