- Submissions

Full Text

Aspects in Mining & Mineral Science

Effect of Superplasticizer Addition on Injectability of CEM II/B-M Based Cement Grouts

Christodoulou Dimitrios1* and Droudakis Alexandros2

1Department of Environmental Sciences, University of Thessaly, Greece

2Geosynthetic Engineering Specialist, Thrace Nonwovens & Geosynthetics, Greece

*Corresponding author: Christodoulou Dimitrios, Assistant Professor, Department of Environmental Sciences, University of Thessaly, Campus Gaiopolis, Larissa, Greece

Submission: January 28, 2022;Published: February 07, 2022

ISSN 2578-0255Volume8 Issue4

Abstract

The use of very fine cement grouts for injection into fine-to-medium sands has been proposed to circumvent problems associated with the permanence and toxicity of chemical grouts and the inability of ordinary cement grouts to permeate soil formations finer than coarse sand. An experimental investigation was conducted in order to evaluate the penetrability of cement suspensions. Four gradations from CEM II/B-M (according to EN 197-1) type of cement were used having nominal maximum grain sizes of 100μm, 40μm, 20μm and 10μm. The properties of suspensions, with water-to-cement (W/C) ratios of 1:1, 2:1 and 3:1 by weight, were determined in terms of apparent viscosity. Penetrability was evaluated by conducting one-dimensional injections into five different, clean sands using a specially constructed device. Penetrability of cement suspensions increases with increasing cement fineness and water-to-cement (W/C) ratio. In cases of guaranteed injectability of cement suspensions, the use of superplasticizer is not required as it does not affect the result of the injection.

Keywords: Permeation grouting; Suspensions; Microfine cements; Superplasticizer; Sand fraction

Introduction

The safe construction and operation of many technical projects often requires the improvement of the properties and mechanical behavior of the soil formations. The shear behavior of a soil material is of particular interest because it has a direct impact on practical bearing capacity problems [1,2], stability of slopes and embankments [3,4] as well as permanent seismic movements of slopes [5,6]. Permeation grouting is commonly used in geotechnical engineering either to reduce the permeability or improve the mechanical properties of soil and rock [7]. Success in a given grouting operation requires that the grout is capable of being injected into the soil formation and that the desired improvements in the properties of the formations are attained. Grouts are generally categorized as suspension, or particulate grouts, which are prepared with ordinary Portland or other cements, clays, or cement-clay mixtures, and fine sands in some cases, and solution, or chemical grouts which include sodium-silicate formulations, acrylamides, acrylates, lignosulfonates, phenoplasts and aminoplasts as well as other materials that have no particles in suspension. Chemical solutions can be injected in fine sands or coarse silts but are more expensive and some of them pose a health and environmental hazard. Efforts have been made to extend the injectability range of suspension grouts by developing materials with very fine gradations [8-15].

Materials and Procedures

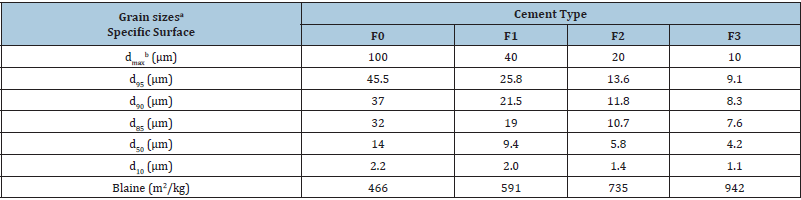

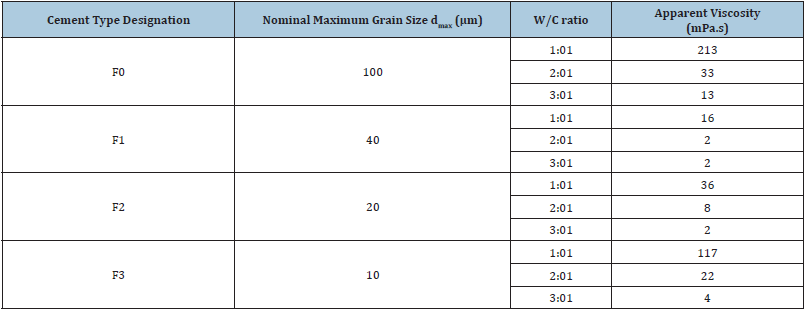

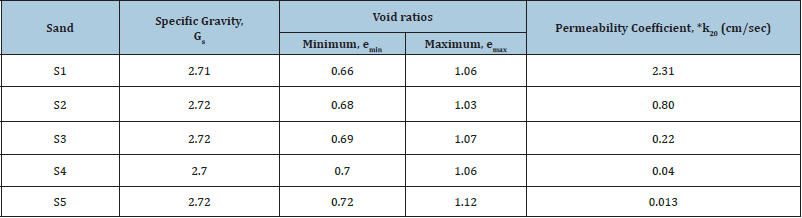

For the purposes of this investigation, a cement of type CEM II/B-M, according to EN 197-1, was used. The ordinary cement (designated as F0) was pulverized in order to produce three additional cements with nominal maximum grain sizes of 40μm, 20μm and 10μm, which are designated as F1, F2 and F3, respectively. Characteristic grain sizes and Blaine specific surface values for all cements are presented in Table 1. All suspensions were prepared using potable water. The water-to-cement (W/C) ratio of all suspensions used, was equal to 1:1, 2:1 and 3:1 by weight. A superplasticizer at a dosage of 1.4% by weight of dry cement, was used to improve the suspension properties of the microfine cements. This fixed superplasticizer dosage was determined following a laboratory evaluation of the effect of various dosages on the apparent viscosity and the rheological characteristics of the pulverized cement suspensions [9]. Presented in (Table 2) are the apparent viscosity values of ordinary cement suspensions without superplasticizer and microfine cement suspensions with superplasticizer, obtained at t=30min after preparation and at viscometer rotation speed equal to 60rpm. The grouted soils were clean, uniform sands with angular grains. Five different sand gradations were used with grain sizes limited between sieve sizes (ASTM E11) Nos. 5 and 10, 10 and 14, 14 and 25, 25 and 50, and 50 and 100, and designated as S1, S2, S3, S4 and S5, respectively. The sands were grouted in dense condition (mean value of relative density, Dr, 98±1%) and were dry prior to grouting. The values of other properties of sands are presented in Table 2.

Table 1: Cements gradations. ad95, d90, d85, d50, and d10 correspond to the particle diameter at which 95%, 90%, 85%, 50%, and 10% of the weight of the specimen is finer, respectively b Nominal maximum cement grain size.

Table 2: Apparent viscosity of cement suspensions.

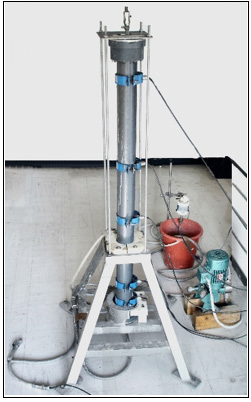

The special apparatus shown in Figure 1 was used for injecting sand columns with cement suspensions. It allows for adequate laboratory simulation of the injection process and investigation of the influence of the distance from injection point on the properties of grouted sand. The grouting column was made of thick PVC tube with an internal diameter of 7.5cm and a height of 144cm and was formed by placing at each end a 5cm thick gravel layer, between two screens of suitable aperture, and filling the remaining length (134cm) with dry sand in a dense or loose condition (Table 3). The sand was saturated, when required by the testing program, by upward flow of water pumped from the grout tank. Injection was stopped when either the volume of the injected grout was equal to two void volumes of the sand in the column or when the injection pressure became equal to 700kPa. The grout pressure was continuously recorded during the injections, by installing one pressure sensor at the inflow pipe of the grouting column and six pressure sensors on the grouting column, at distances from the injection point equal to 4cm, 14cm, 34cm, 54cm, 83cm and 123cm, respectively. The pressure sensors (PWF-PA pressure transducers of Tokyo Sokki Kenkyujo) were placed in cyclical openings on the grouting columns using specially designed clamps and were connected to an automatic data acquisition system.

Table 3: Sand properties. *Sands in dense condition.

Figure 1: Laboratory equipment for penetrability evaluation [8-14].

Experimental Results and Discussion

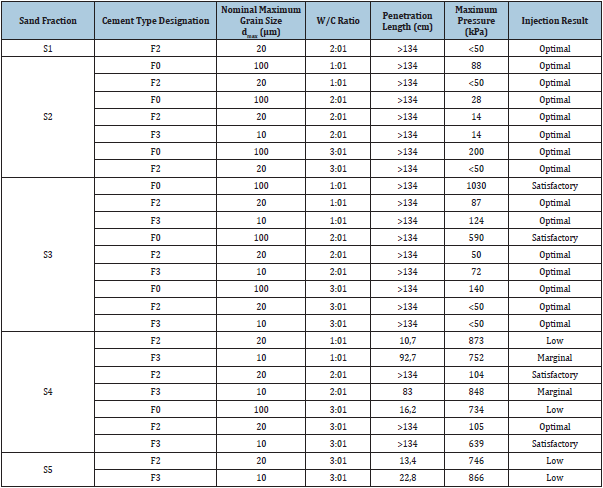

The grout ability of a suspension grout can be evaluated in terms of: (a) the ability of the grout to enter into the voids of a given soil and (b) the permeation distance that can be achieved under a predetermined maximum injection pressure. The terms “injectability” and “penetrability”, respectively, were selected to describe these two conditions or criteria. Thus, the penetrability of cement grouts was the objective of the investigation reported herein. All factors relating to penetrability were evaluated experimentally by grouting sand columns with the apparatus shown in Figure 1 and the results obtained, are presented in Table 4. Penetrability was considered “optimal” when the entire amount of suspension penetrates the sand column with low impregnation pressure, “satisfactory” when all or almost the entire amount of suspension penetrates the sand column with increasing impregnation pressure, “marginal” when penetration length is greater than 60cm with maximum impregnation pressure and “low” when penetration length is less than 60cm with maximum impregnation pressure.

Table 4: Experimental results.

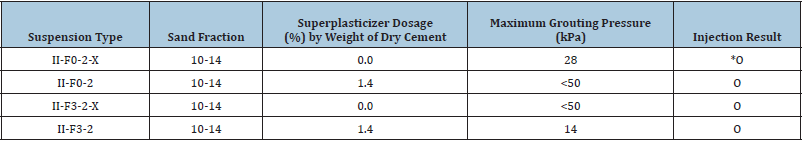

The effect of superplasticizer addition on cement suspensions penetrability was investigated by examining dry columns of the sand fraction S2 (Nos. 10-14), impregnated with suspensions of finegrained (II-F3-2) and common (II-F0-2) cement type CEM II/B-M containing superplasticizer. To perform the required comparisons, the impregnations were repeated using the same materials (sand and cement) but the suspensions did not contain a superplasticizer (suspensions II-F3-2-X and II-F0-2-X, respectively). This test was not large-scale, as it is common practice in field applications to use superplasticizers to improve the rheological behavior of finegrained cement suspensions. On the other hand, for the same reason it is not necessary to add such materials to common cement suspensions. Table 5 presents the data of impregnations performed in order to evaluate the effect of superplasticizer addition on the injectability of cement suspensions. Regarding injections of finegrained cement suspensions (II-F3-2 and II-F3-2-X) in S2 (Nos. 10- 14 sand columns, it was observed that the columns were completely impregnated with low maximum impregnation pressures (<50kPa) and the volume of suspension compressed was twice the volume of voids in the soil column. The only difference found is the waterto- cement ratio of the suspension after it exits the sand column. Note that the initial water-to-cement (W/C) ratio of the suspension was 2:1. Collection of the suspension from the outlet column for the suspension without the addition of superplasticizer (II-F3-2-X) yielded water-to-cement ratio values ranging from 1.65:1 to 1.77:1. Correspondingly, the values of water-to-cement ratio at the outlet of the suspension column with the addition of superplasticizer (II-F3-2) showed a range from 1.74:1 to 1.82:1 approaching the initial water-to-cement ratio of the suspension prepared. From the impregnations in S1 sand columns (Nos. 10-14) with common cement suspensions of type CEM II/B-M (II-F0-2-X and II-F0-2), it emerged that the use of superplasticizer did not affect their penetrability, as complete impregnation was observed and low values of the maximum impregnation pressure. Collection of the suspension from the outlet column for the suspension without the addition of superplasticizer (II-F0-2-X) yielded water-to-cement ratio values ranging from 2.07:1 to 2.11:1. Correspondingly, the values of water-to-cement ratio at the outlet of the suspension column with the addition of superplasticizer (II-F0-2) ranged from 1.97:1 to 2:1. From the above investigation it was found that in cases of guaranteed injectability of cement suspensions, the use of superplasticizer is not required as it does not affect the result of the injection.

Table 5: Results of impregnations on long sand columns to investigate the effect of superplasticizer addition on the suspensions injectability. *O: Optimal Penetration.

References

- Lokkas P, Papadimitriou E, Alamanis N, Papageorgiou G, Christodoulou D, et al. (2021) Significant foundation techniques for education: A critical analysis. WSEAS Transactions on Advances in Engineering Education 18: 7-26.

- Lokkas P, Chouliaras I, Chrisanidis T, Christodoulou D, Papadimitriou E, et al. (2021) Historical background and evolution of soil mechanics. WSEAS Transactions on Advances in Engineering Education 18: 96-113.

- Alamanis N (2017) Failure of slopes and embankments under static and seismic loading. American Scientific Research Journal for Engineering, Technology and Sciences (ASRJETS) 35(1): 95-126.

- Alamanis N, Zografos C, Papageorgiou G, Xafoulis N, Chouliaras I (2020) Risk of retaining systems for deep excavations in urban road infrastructure with respect to work staff perception. International Journal of Scientific & Technology Research 9(2): 4168-4175.

- Alamanis N, Dakoulas P (2019) Simulation of random soil properties by the local average subdivision method and engineering applications. Energy Systems 12: 841-861.

- Alamanis N, Dakoulas P (2021) Effect of spatial variability of soil properties on permanent seismic displacements of slopes with uniform load. 14th Baltic Sea Geotechnical Conference, Helsinki, Finland.

- Zebovitz S, Krizek R, Atmatzidis D (1989) Injection of fine sands with very fine cement grout. Journal of Geotechnical Engineering 115: 1717-1733.

- Christodoulou DN, Droudakis AI, Pantazopoulos IA, Markou IN, Atmatzidis DK (2009) Groutability and effectiveness of microfine cement grouts. Proceedings, 17th International Conference on Soil Mechanics and Geotechnical Engineering. In: Hamza et al. (Edt.), The Academia and Practice of Geotechnical Engineering. IOS Press, Alexandria, Egypt, pp. 2232-2235.

- Pantazopoulos IA, Markou IN, Christodoulou DN, Droudakis AI, Atmatzidis DK, et al. (2012) Development of microfine cement grouts by pulverizing ordinary cements. Cement and Concrete Composites 34(5): 593-603.

- Markou IN, Christodoulou DN, Petala ES, Atmatzidis DK (2018) Injectability of microfine cement grouts into limestone sands with different gradations: Experimental investigation and prediction. Geotechnical and Geological Engineering Journal 36(2): 959-981.

- Markou IN, Christodoulou DN, Papadopoulos BK (2015) Penetrability of microfine cement grouts: experimental investigation and fuzzy regression modeling. Canadian Geotechnical Journal 52(7): 868-882.

- Christodoulou D, Lokkas P, Markou I, Droudakis A, Chouliaras I, et al. (2021) Principles and developments in soil grouting: A historical review. WSEAS Transactions on Advances in Engineering Education 18(18): 175-191.

- Christodoulou D, Lokkas P, Droudakis A, Spiliotis X, Kasiteropoulou D, et al. (2021) The development of practice in permeation grouting by using fine-grained cement suspensions. Asian Journal of Engineering and Technology 9(6): 92-101.

- Markou IN, Kakavias CK, Christodoulou DN, Toumpanou I, Atmatzidis DK (2020) Prediction of cement suspension groutability based on sand hydraulic conductivity. Soils and Foundations 60(4): 825-839.

- Santagata MC, Santagata E (2003) Experimental investigation of factors affecting the injectability of microcement grouts. Proceedings, 3rd International Conference on Grouting and Ground Treatment. In: Johnsen FL, Bruce AD, Byle JM (Eds.), Geotechnical Special Publication, New Orleans, ASCE, New York, USA, 120(2): 1221-1234.

© 2022 Christodoulou Dimitrios. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)